Patents

Literature

53results about How to "Auto release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rolling curtain

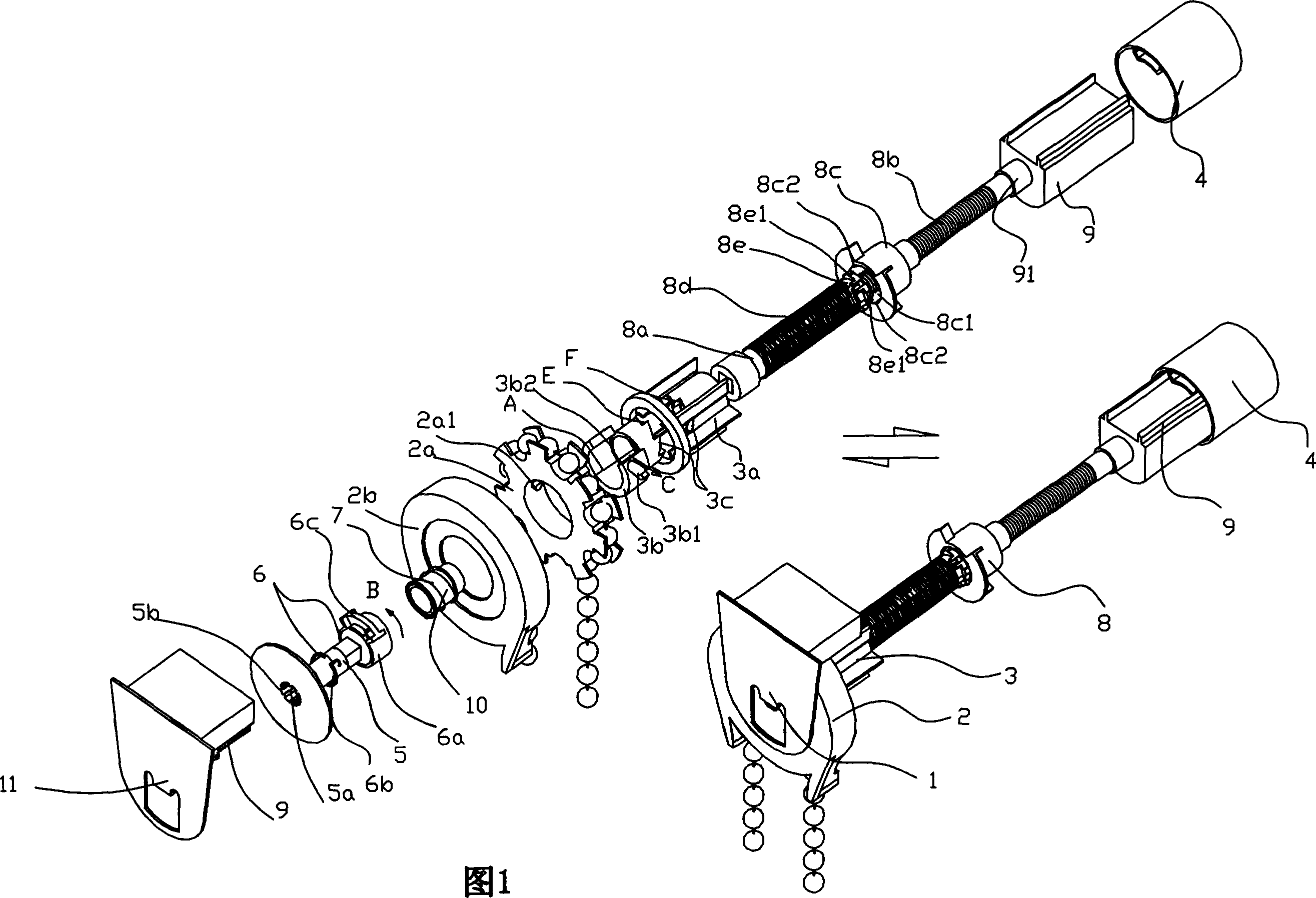

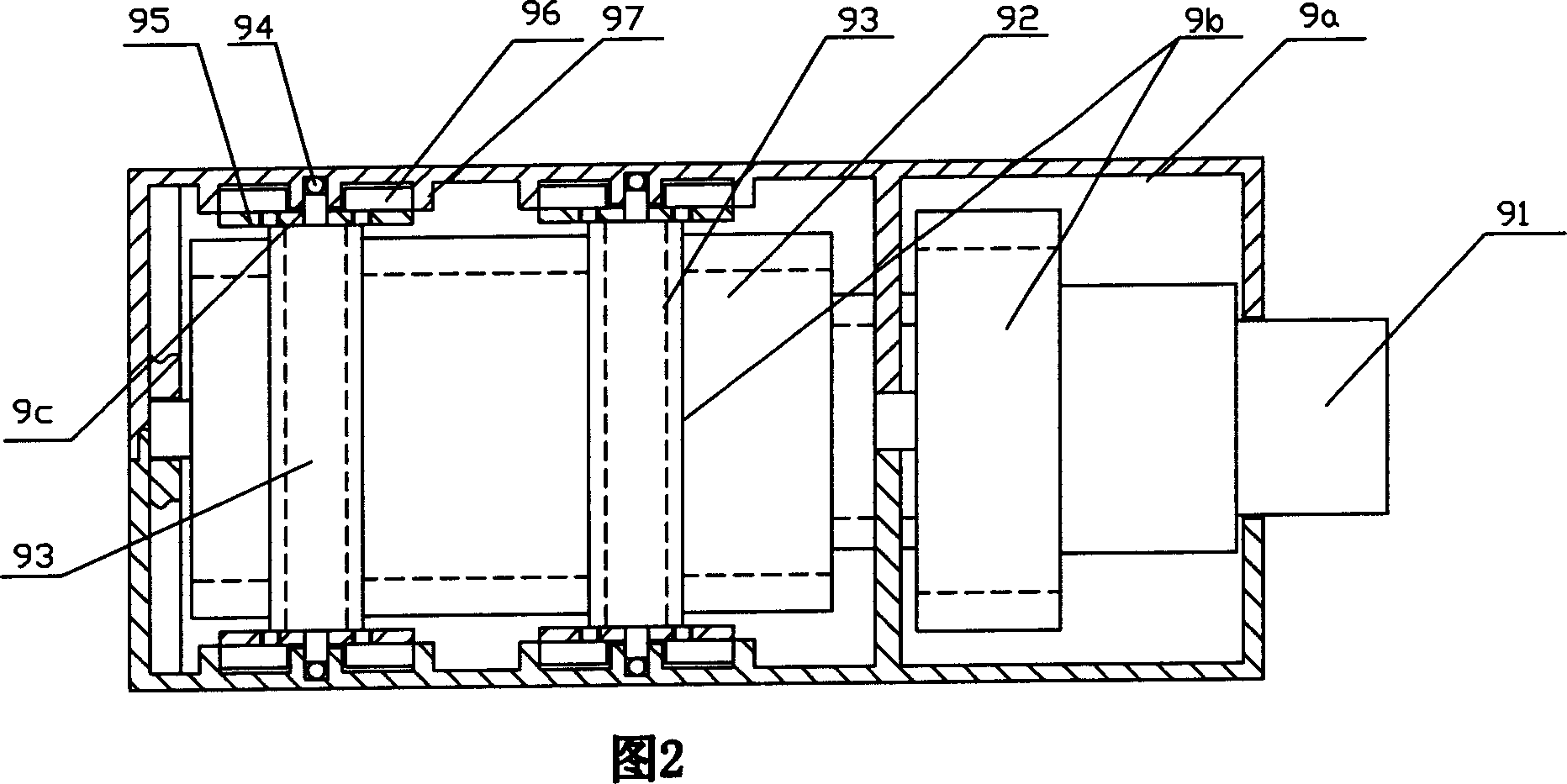

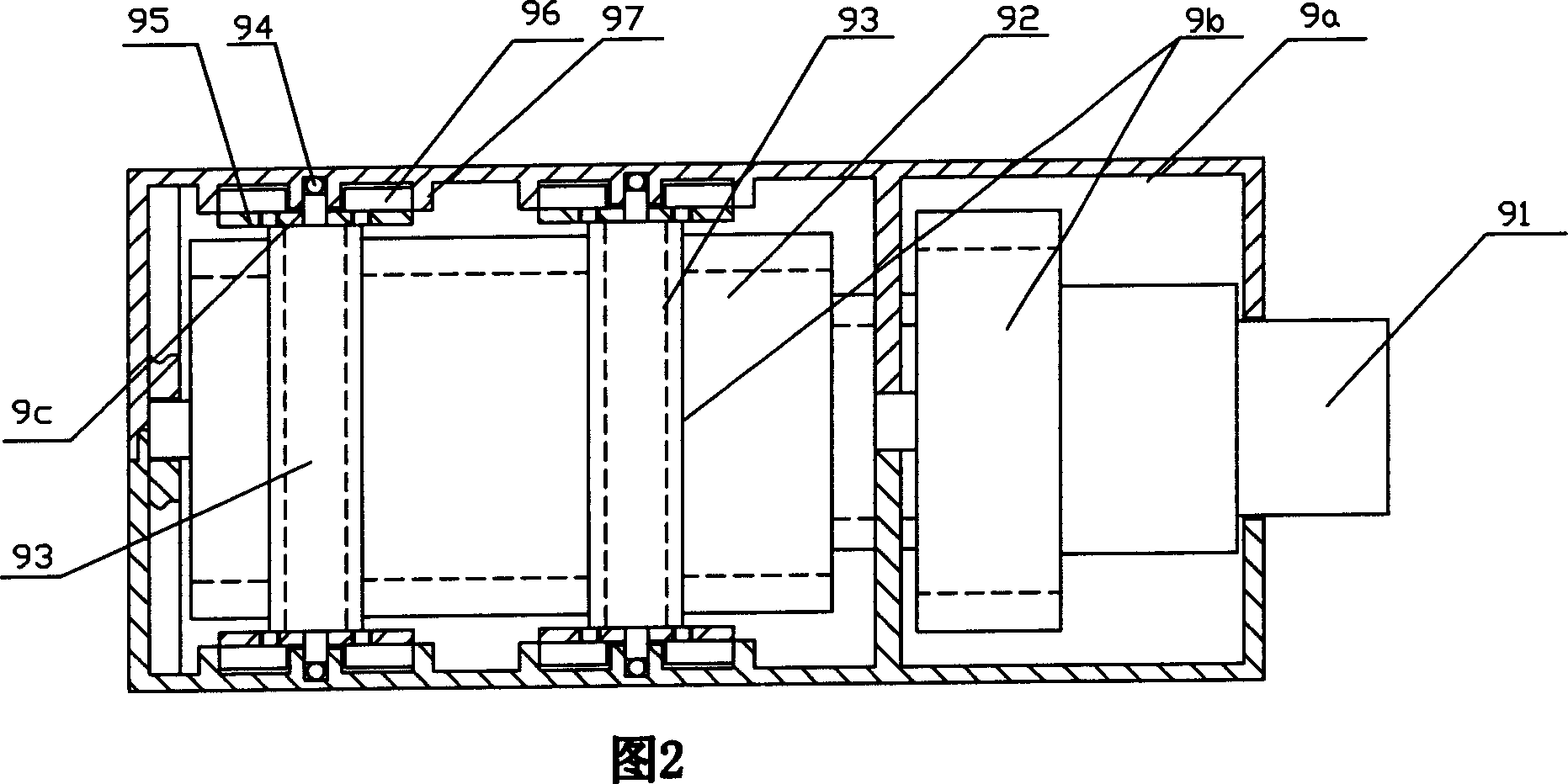

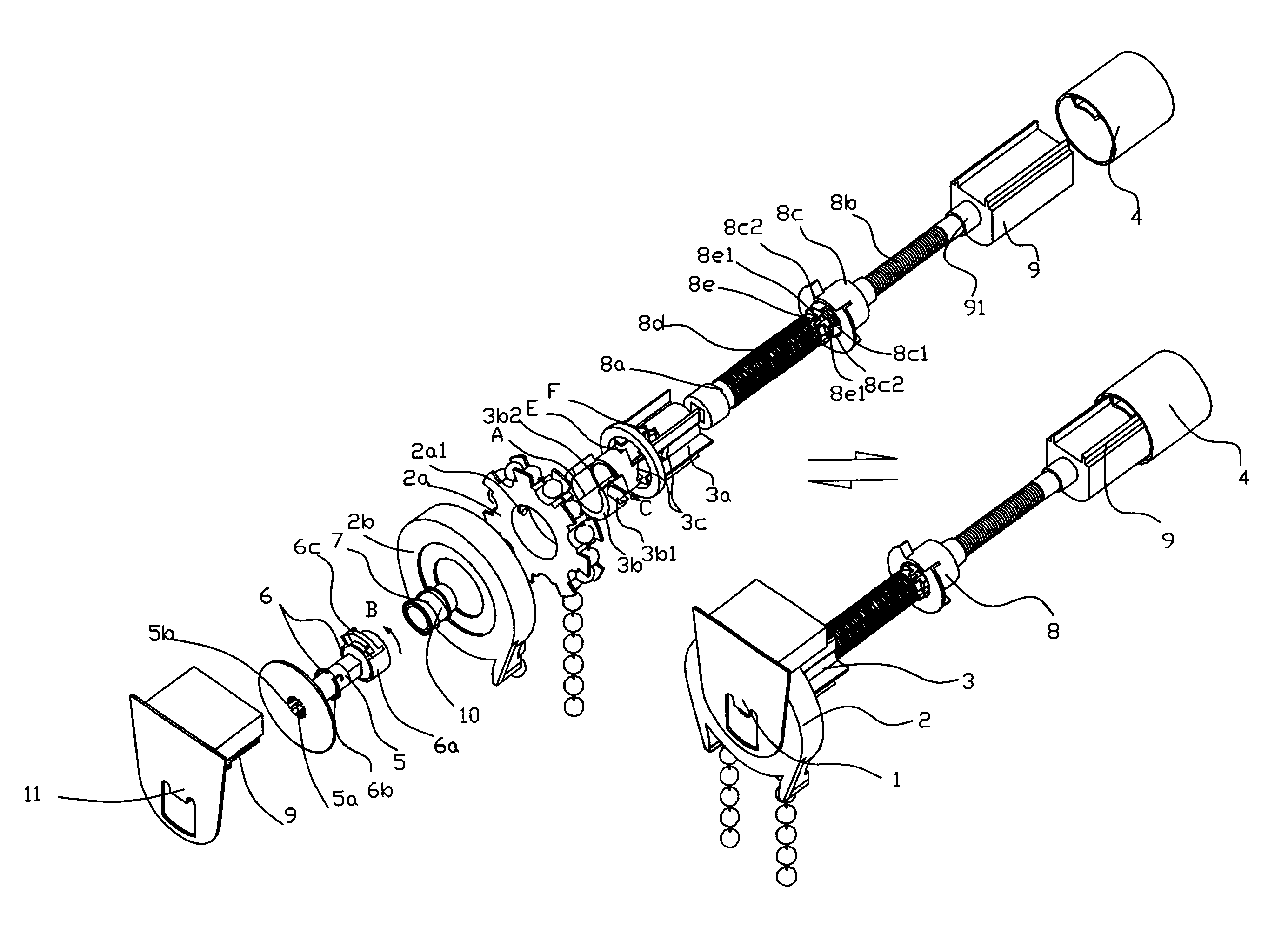

InactiveCN101021139AAuto releaseAutomatically put downLight protection screensMechanical engineering

The present invention relates to a roller blind. It is characterized by that it is made up by using turning device set on the machine frame, engagement and disengagement device connected together with said turning device and blind fabric spool connected together with engagement and disengagement device.

Owner:朱晓荧

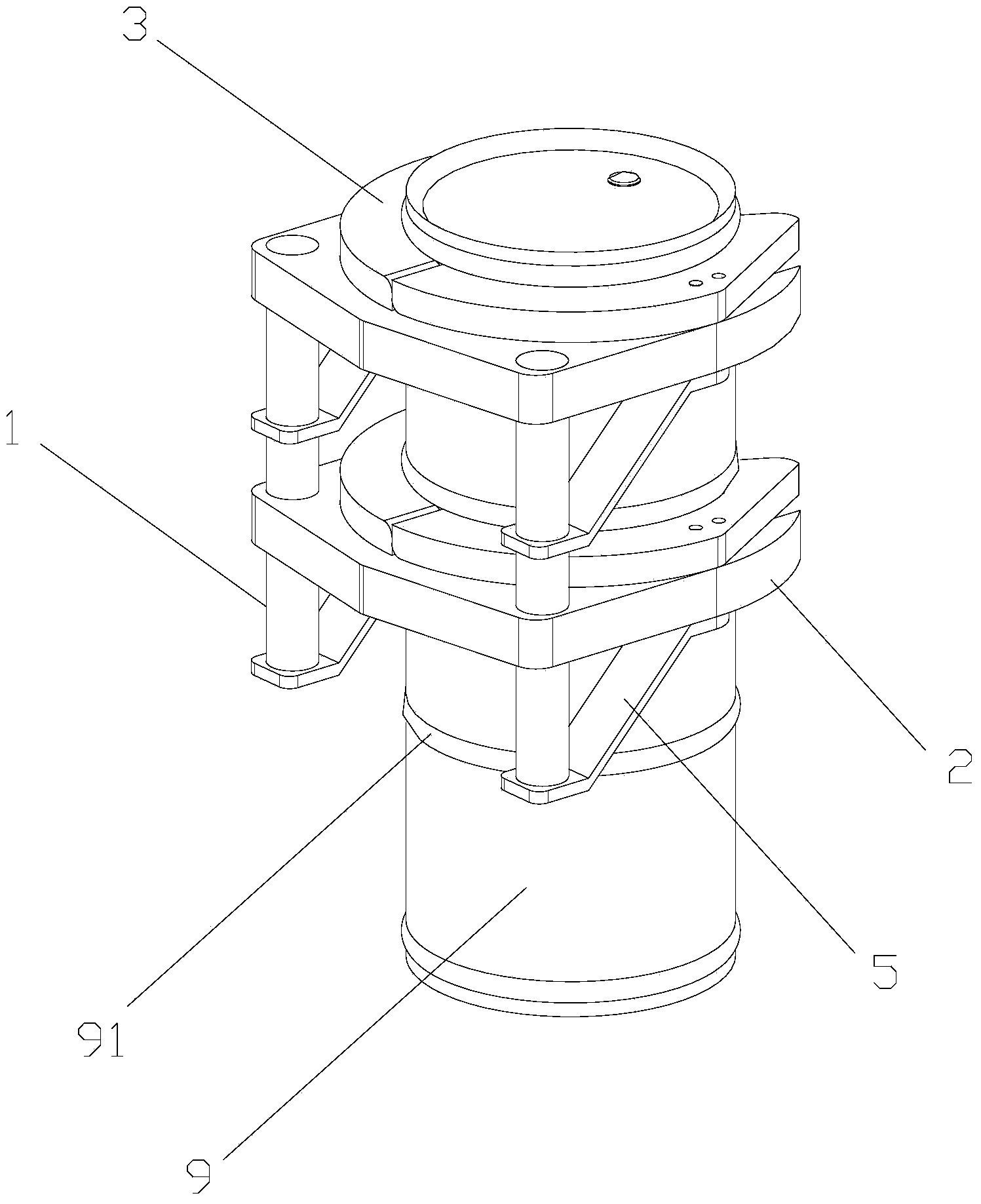

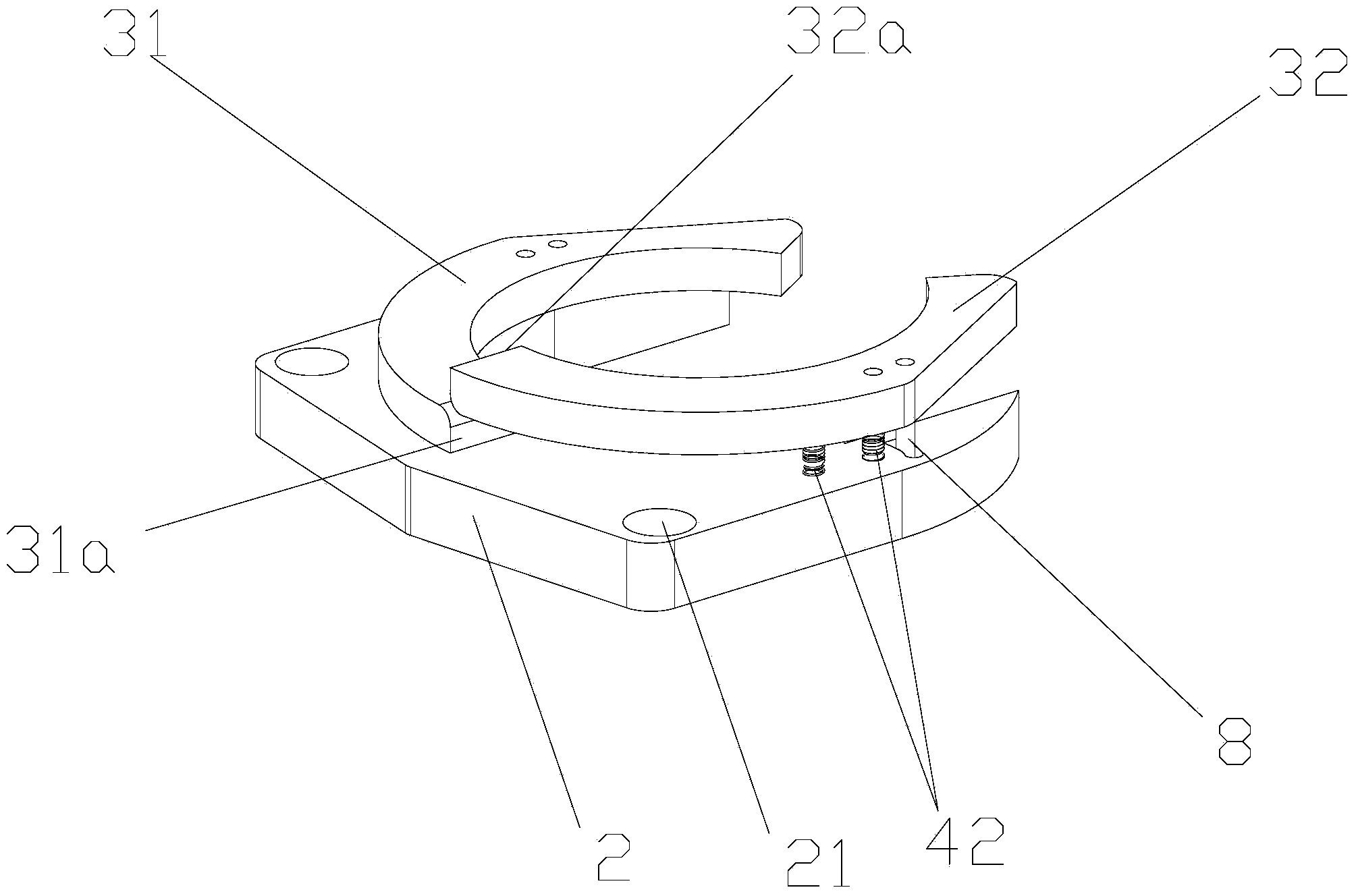

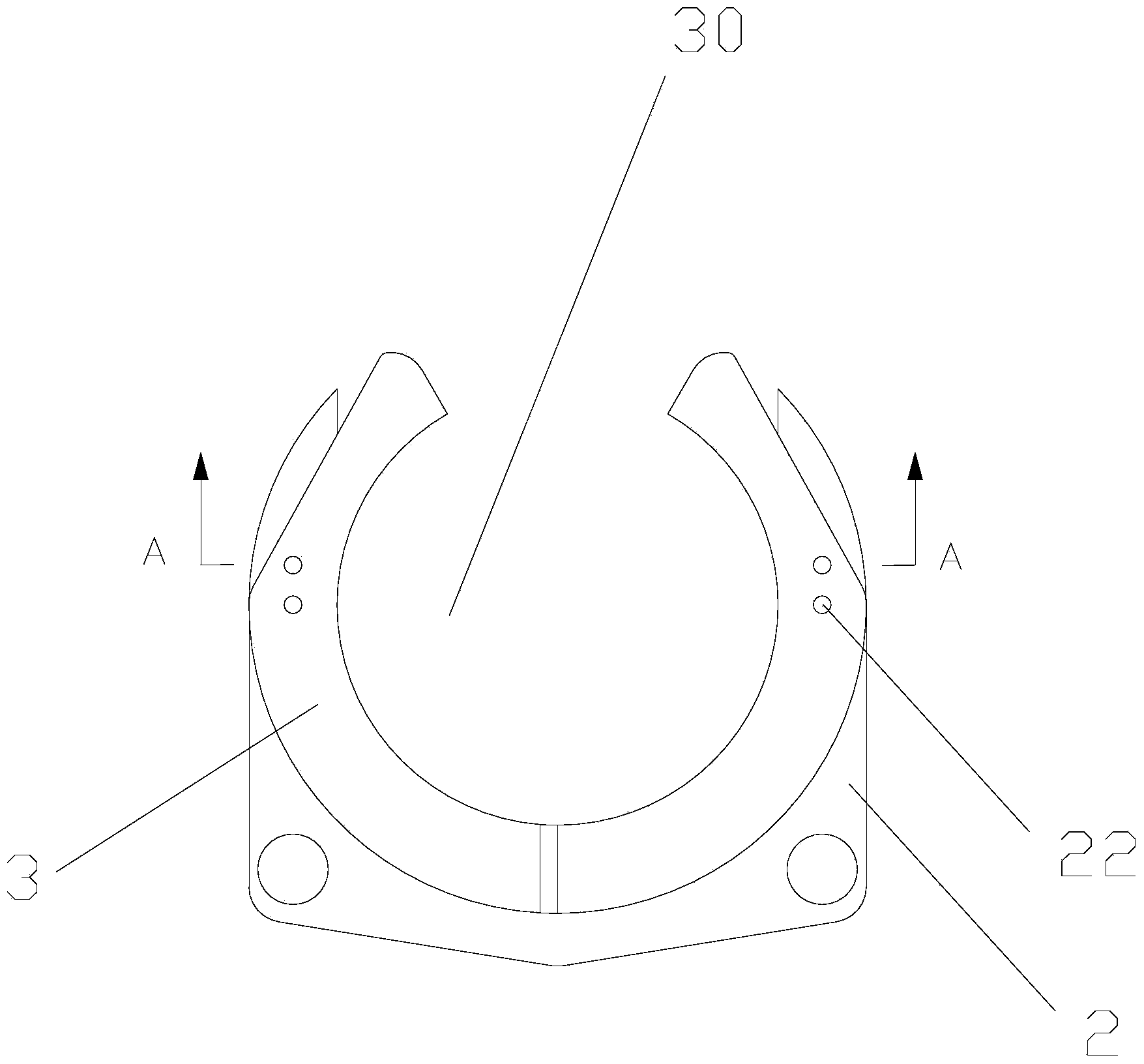

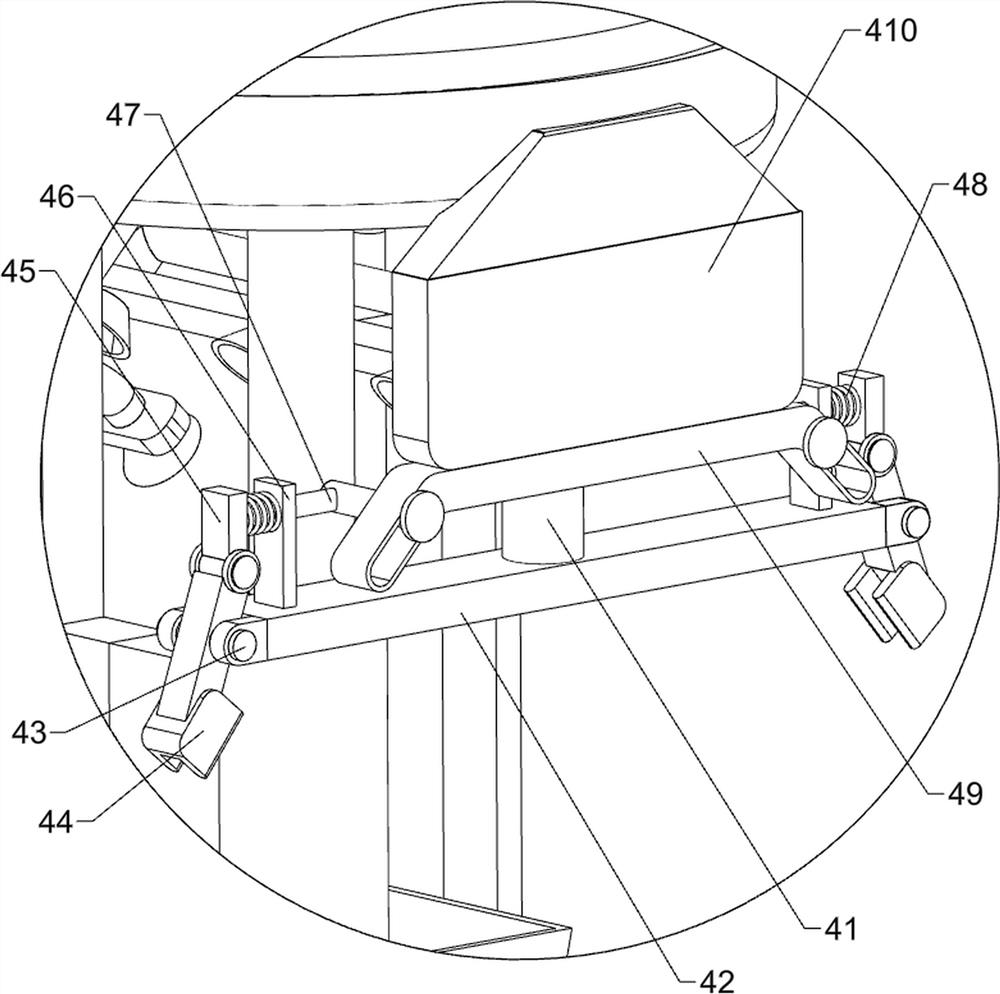

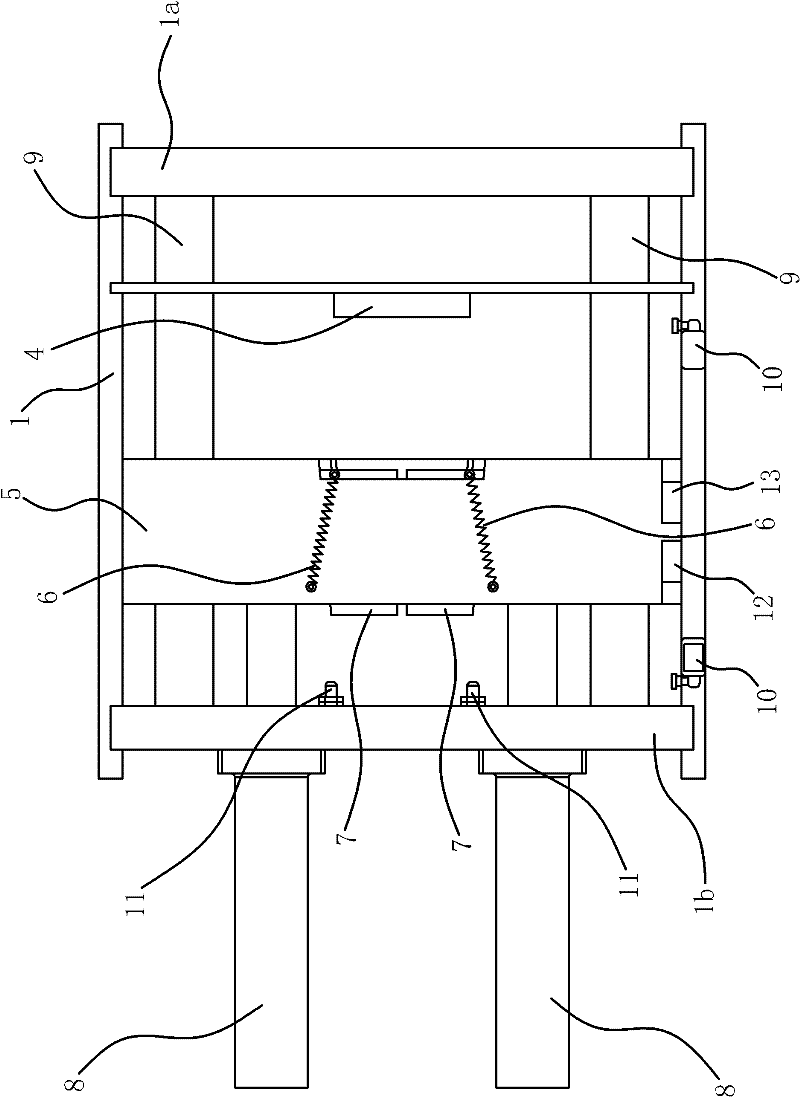

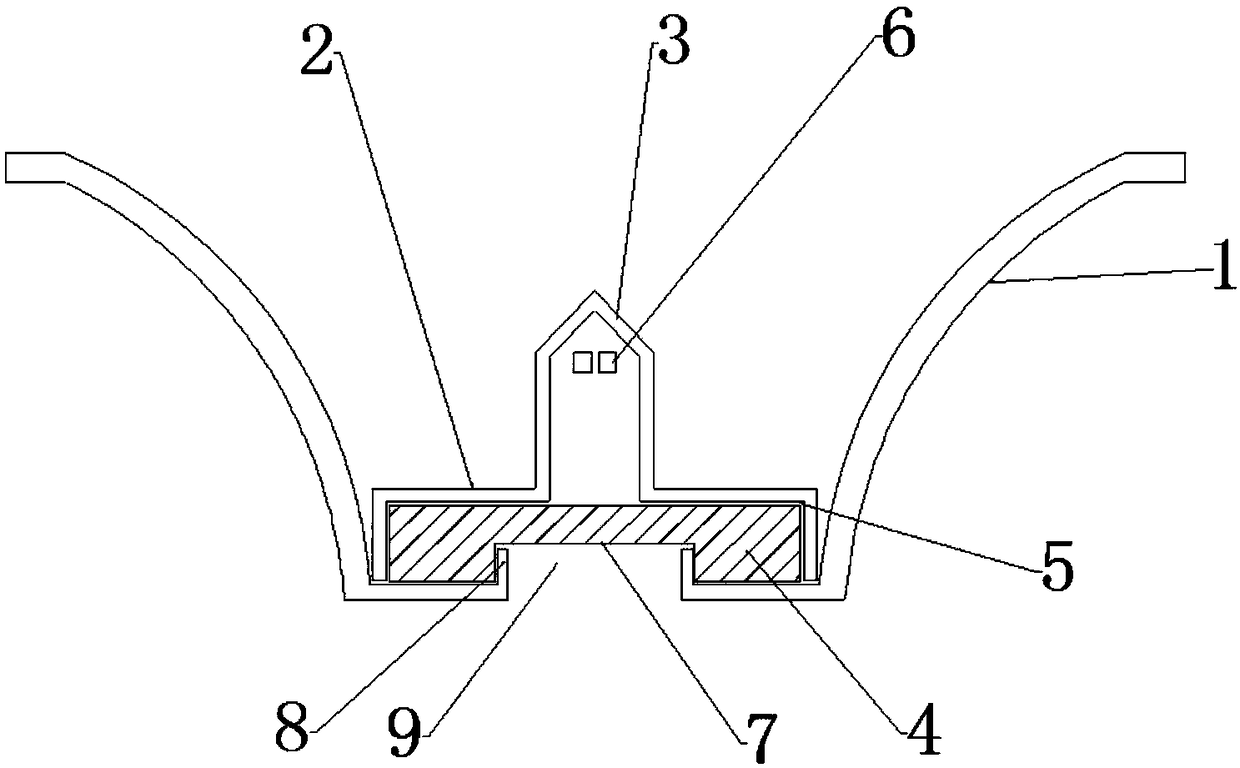

Clamping device for carrying barrel body

The invention discloses a clamping device for carrying a barrel body. The clamping device comprises at least two supporting pillars which are arranged in parallel and at least one group of clamping mechanisms which is fixed on the supporting pillars, wherein the clamping mechanisms comprise clamping plates and clamping claws which are connected to the clamping plates, are provided with arc-shaped openings which are matched with the outer surface shape of the barrel body and are used for clamping the outer wall of the barrel body; the clamping plates are provided with gaps which are used for the barrel body to enter and fixed holes which are used for fixedly connecting the clamping plates with the supporting pillars; the clamping claws comprise clamping claws I and clamping claws II which can be relatively clamped or loosened with each other; the clamping claws I and the clamping claws II are respectively hinged to the clamping plates; elastic reset pieces I which are used for making the clamping claws I, the clamping claws II and the clamping plates outwards open are arranged among the clamping claws I, the clamping claws II and the clamping plates; elastic reset pieces II which are used for making the clamping claws II and the clamping plates upwards move are arranged between the clamping claws II and the clamping plates. The clamping device is higher in strength, can be matched with delivery wagons of different types for use, and is suitable for various working sites, and the clamping mechanisms of the clamping device have self-locking functions when carrying is carried out.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

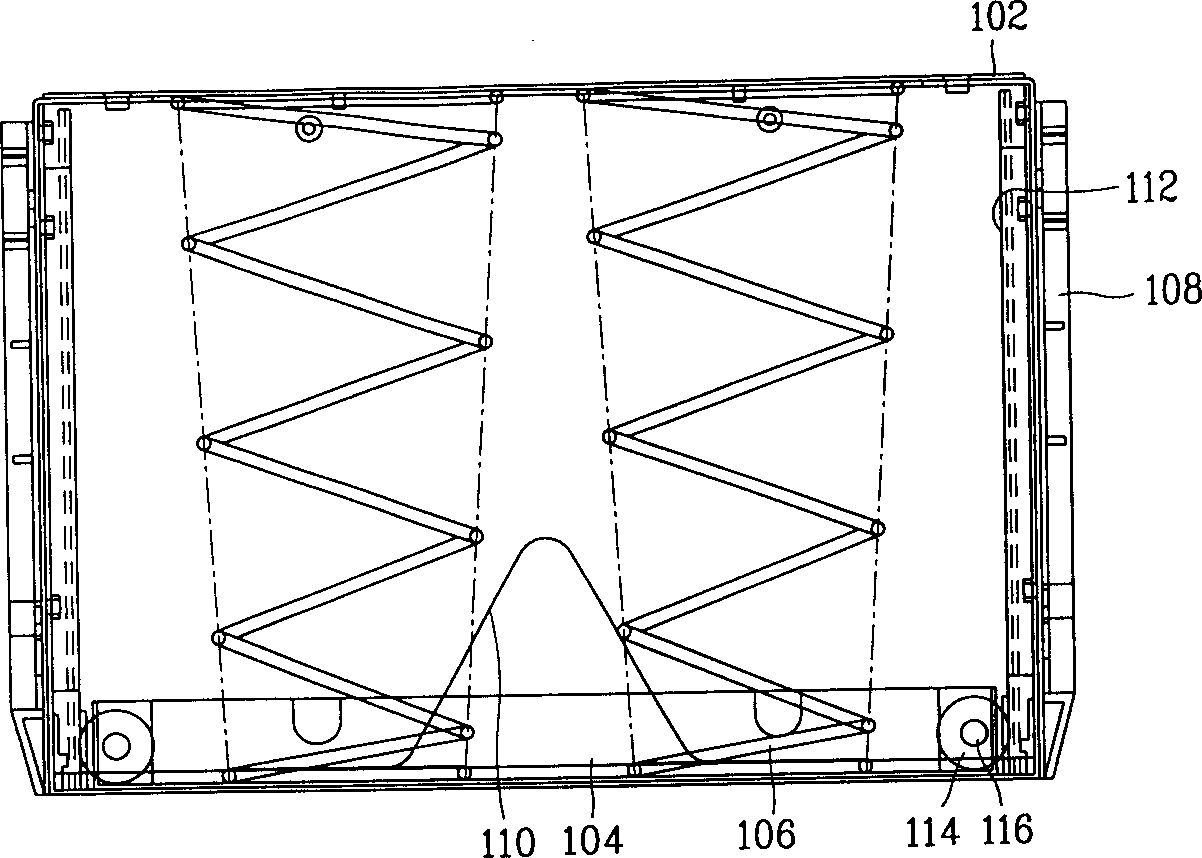

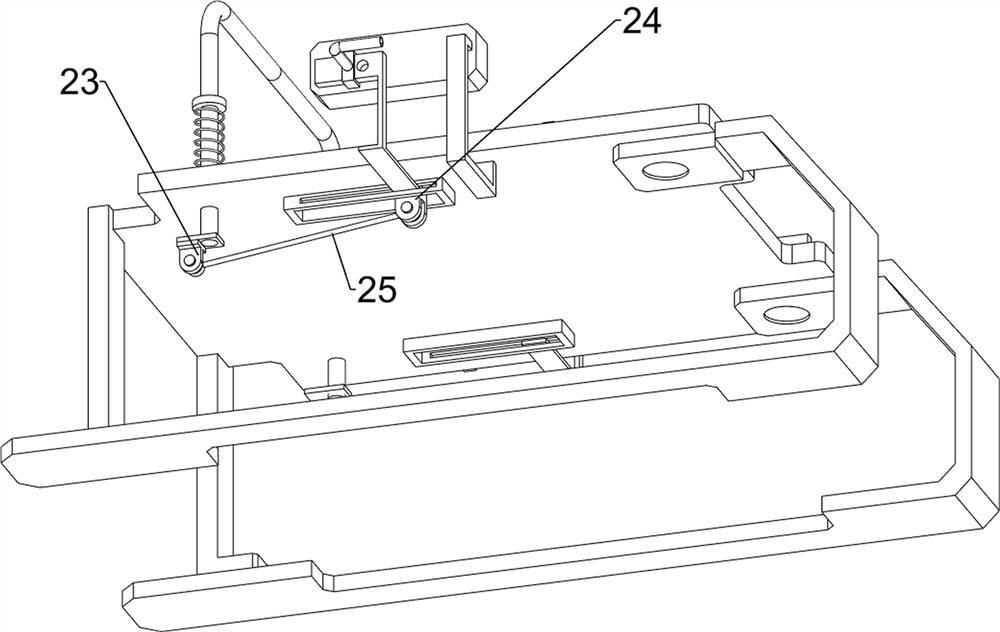

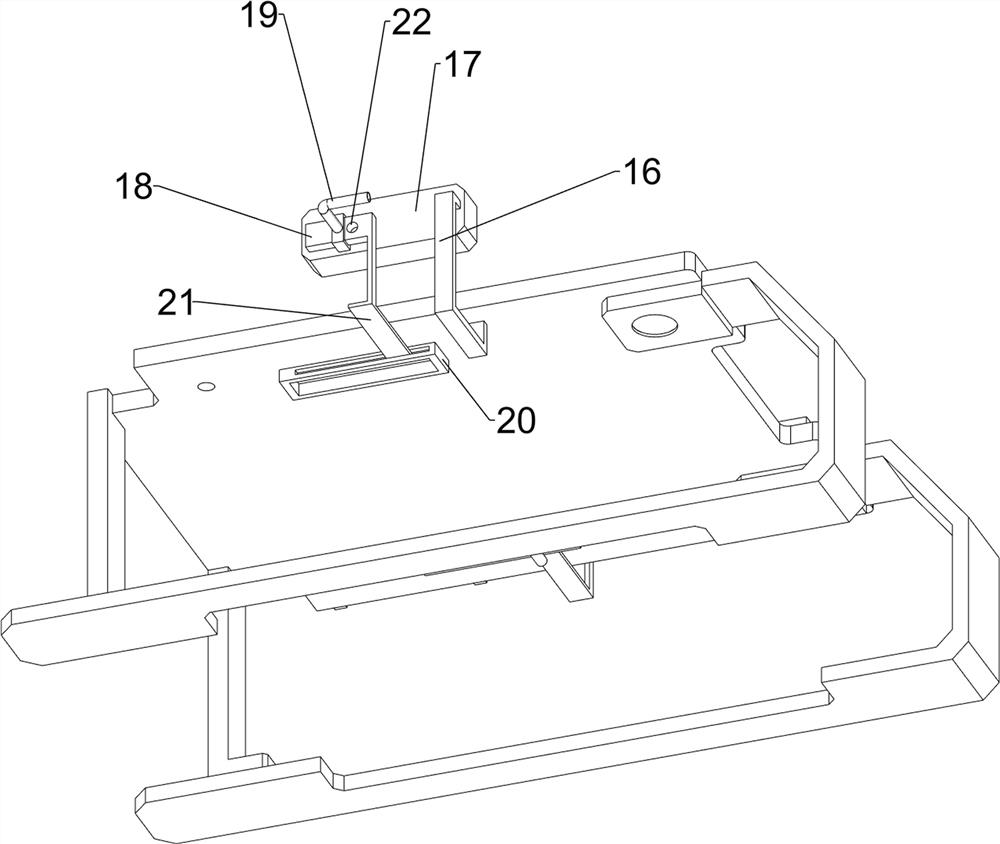

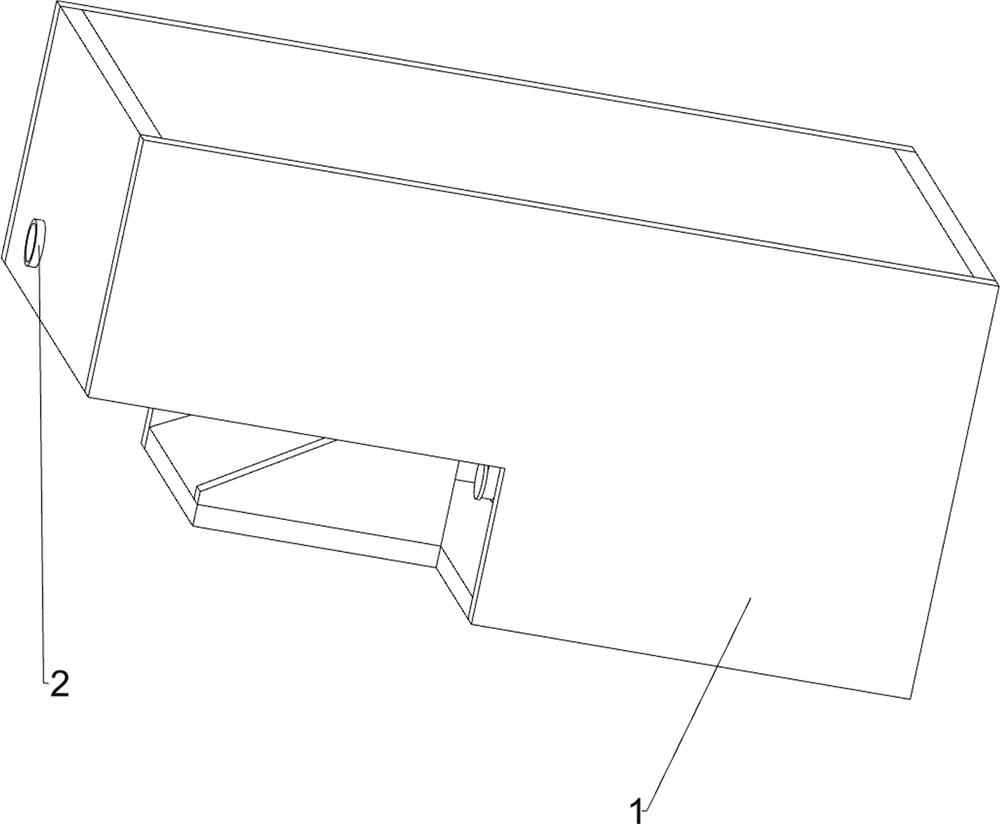

Napkin box for automatic distributor

InactiveCN1350966AEasy to useAuto releaseCoin/currency accepting devicesFlat article dispensingInterior spaceLocking mechanism

A media cassette for an automatic dispenser which can be used easily and solve problems of incorrect operations when a push plate is locked since if the automatic dispenser receives the cassette having a locked push plate, locking is automatically released. The media cassette for an automatic dispenser includes a cassette body having a certain interior space in which media is received, a push plate installed slidably in the cassette body for supporting media, an elastic member positioned between the push plate and the cassette body for urging the push plate, guide members installed between the both sides surfaces of the push plate and the inner sides of the cassette body for guiding the push plate to perform linear movement and a locking mechanism installed between the push plate and the cassette body for locking the push plate and releasing the locking of the push plate in case the media cassette is received in the automatic dispenser.

Owner:ATEC AP CO LTD

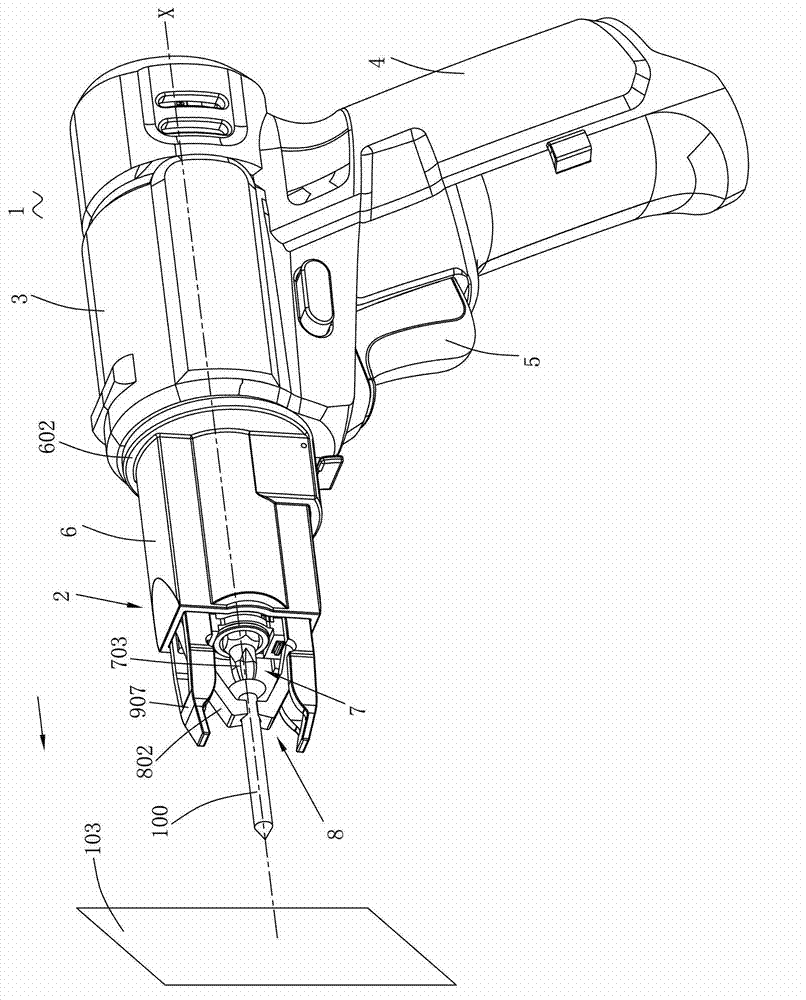

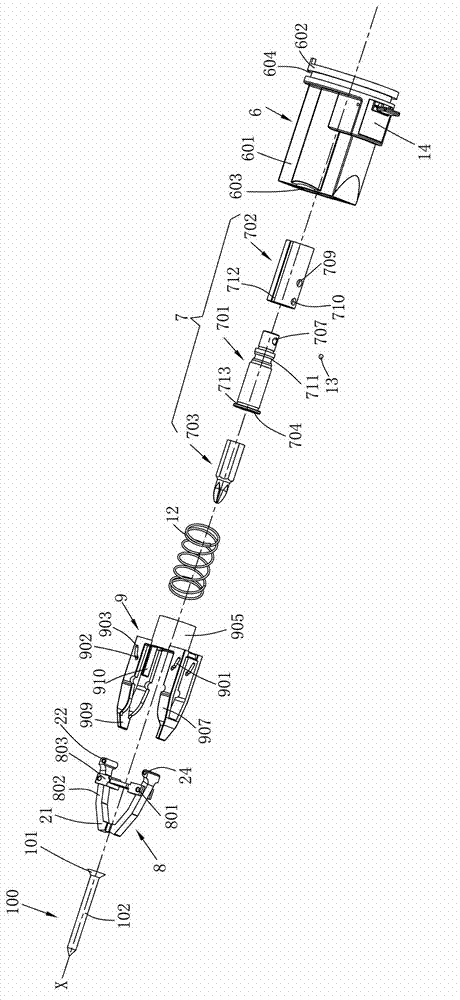

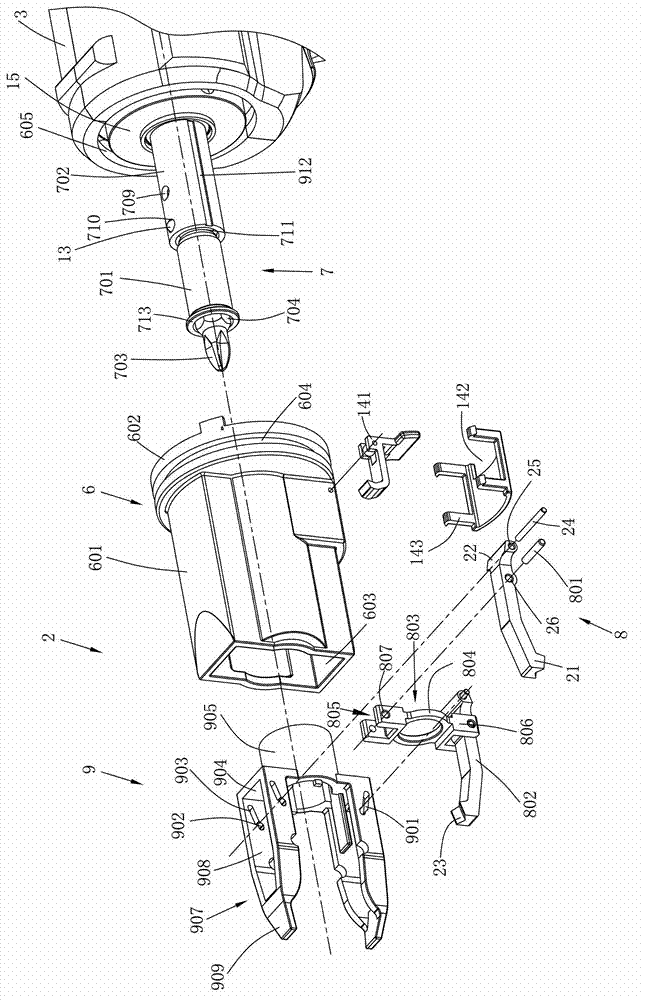

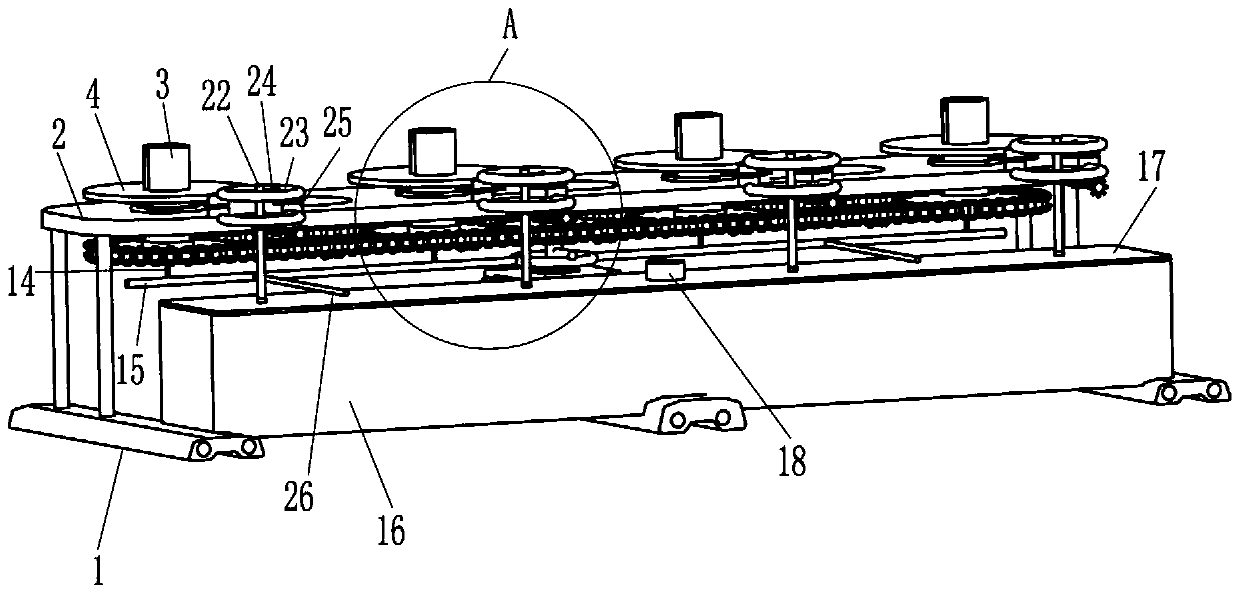

Screw support device and screw tool assembled with screw support device

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Preparing method for slow-release fertilizer based on nutshell biomass carbon

InactiveCN105037015ARealize resource utilizationDoes not affect nutrient release performanceEnergy inputFertilizer mixturesCross linkerFermentation

The invention relates to a preparing method for slow-release fertilizer based on nutshell biomass carbon and belongs to the field of slow-release fertilizer preparation. According to the method, folium cortex eucommiae leaf residues are used as raw materials to form organic fertilizer rich in humic acid through fermentation, then walnut shells are smashed and carbonized into the biomass carbon, rock candy starch is used for being mixed with a cross-linking agent to prepare the biomass carbon into sticky coating liquid, and the sticky coating liquid is dried to obtain the slow-release fertilizer based on the nutshell biomass carbon after being mixed uniformly and pelleted through a pelletizer. As straw is manufactured into the fertilizer, resources are effectively utilized, and the method is environmentally friendly; fertilizer coatings can decomposed in soil automatically, and nutrient release controlling performance of the fertilizer is not influenced after decomposition; the slow-release fertilizer can be released in the soil automatically, and the validity period can reach 15-20 days.

Owner:JIANGSU JINYU ENVIRONMENTAL ENG

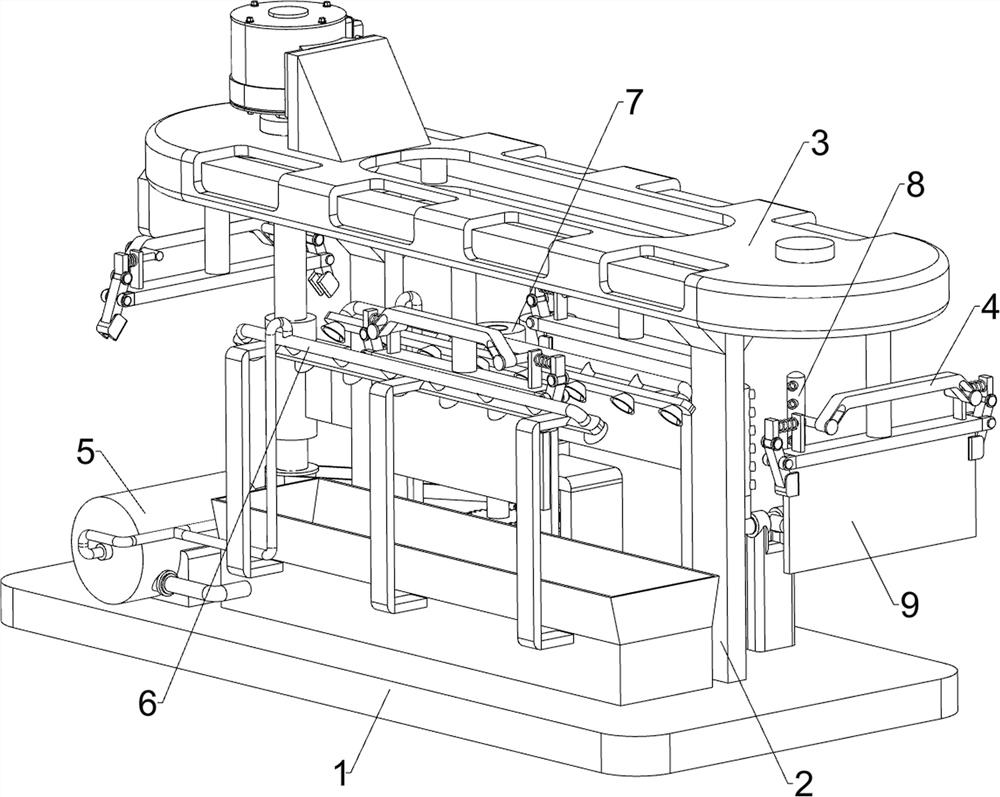

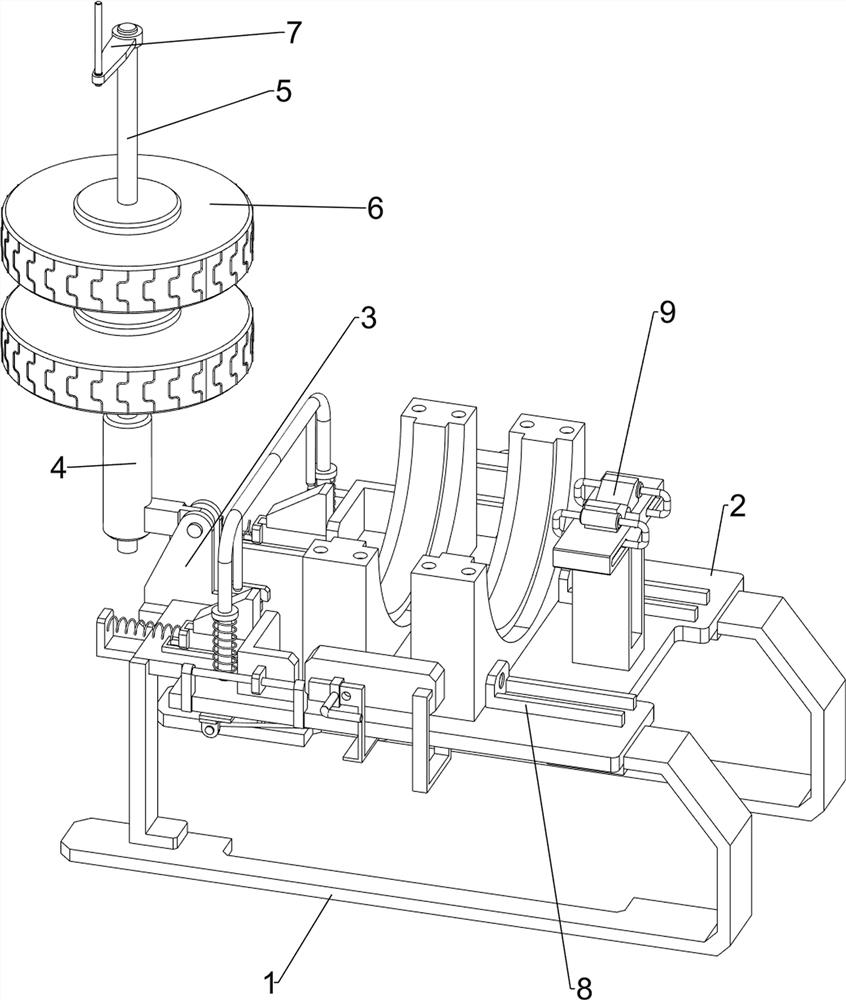

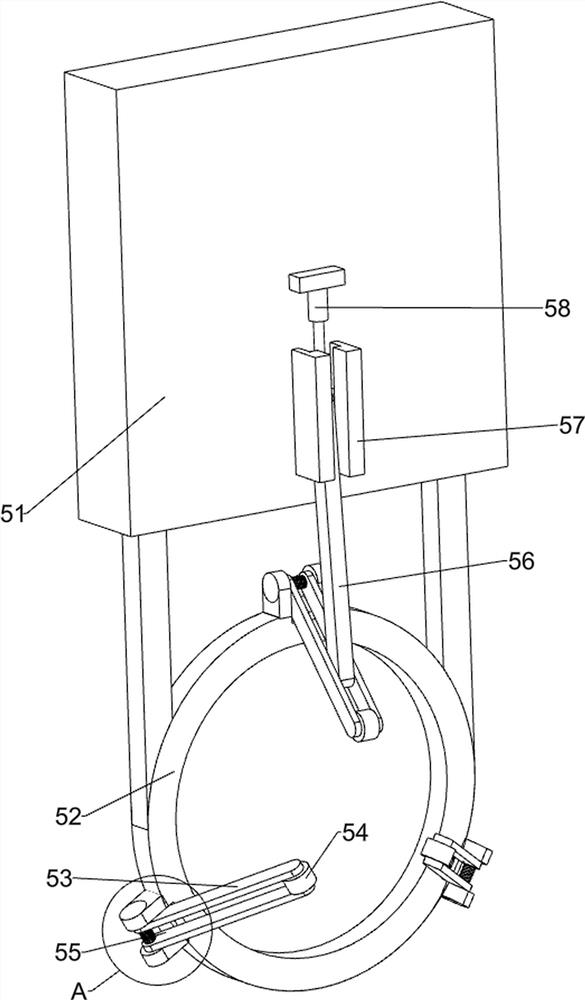

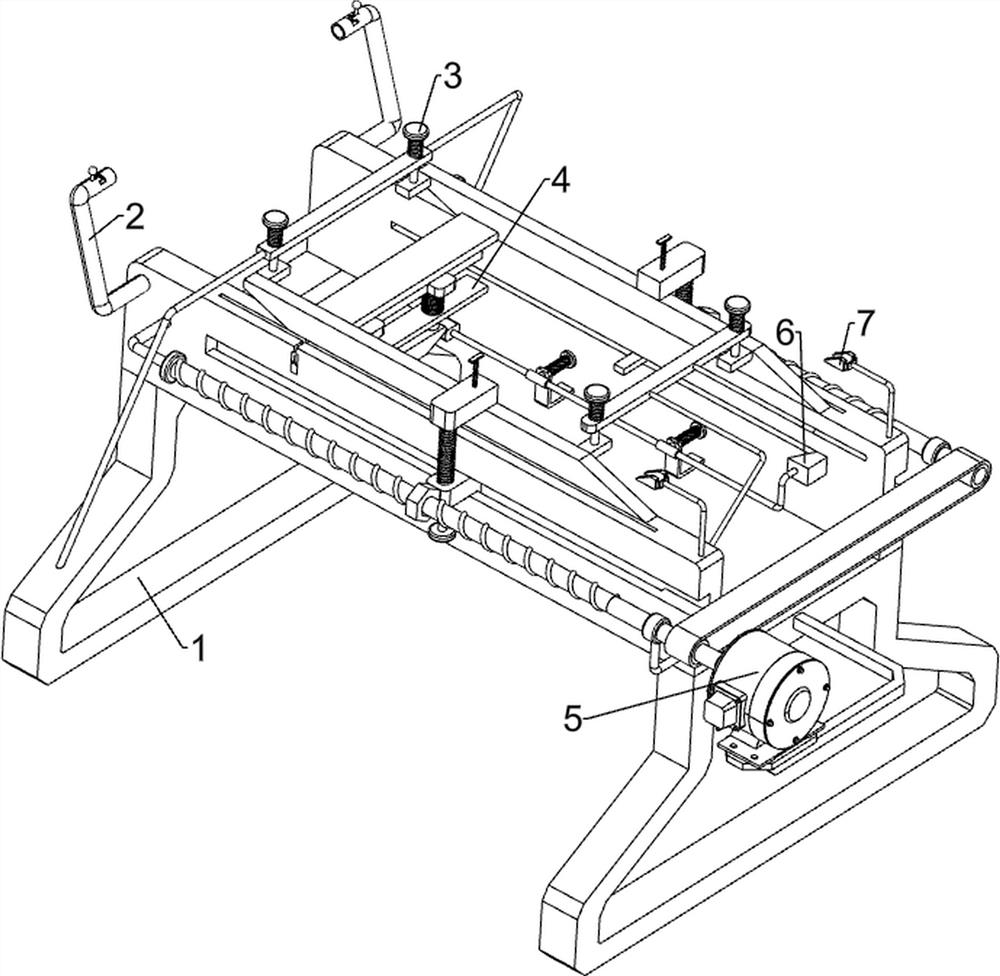

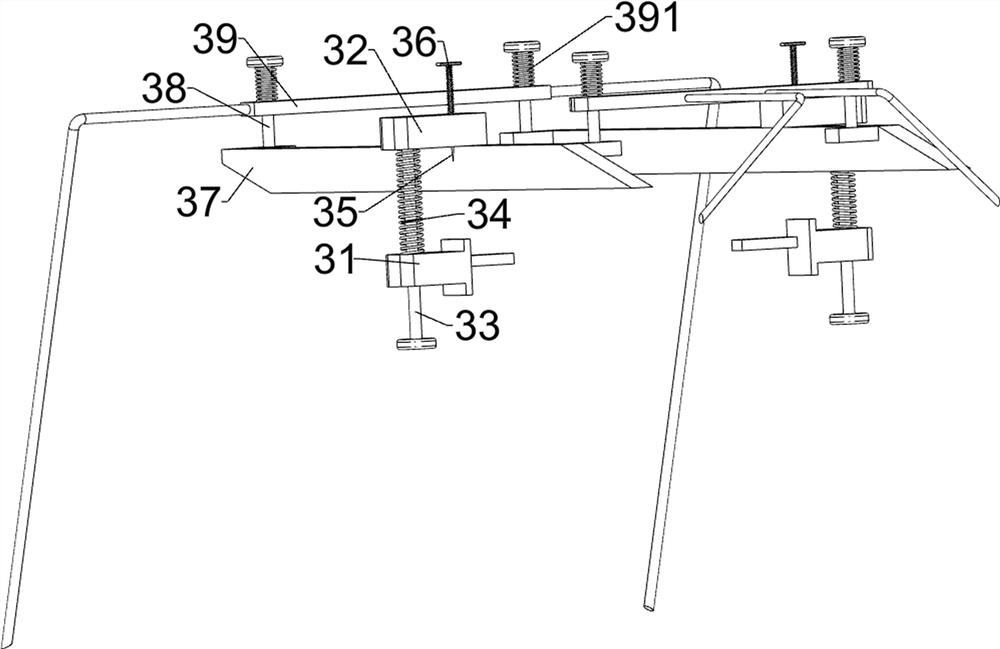

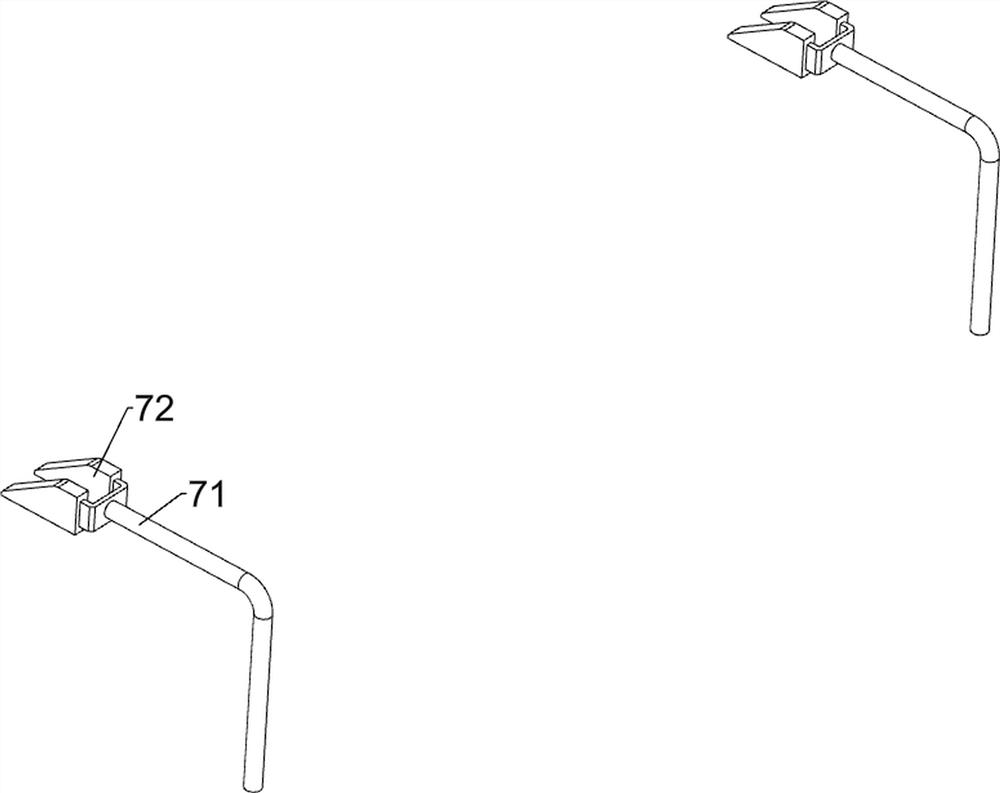

Anti-rust oil smearing device for edges of concrete cutting saw blades

ActiveCN110918362AHigh speedAuto releaseLiquid surface applicatorsCoatingsElectric machineryMining engineering

The invention relates to a smearing device, and particularly relates to an anti-rust oil smearing device for edges of concrete cutting saw blades. The anti-rust oil smearing device for the edges of the concrete cutting saw blades can smear anti-rust oil on the concrete cutting saw blades with different sizes and improve the working efficiency. The anti-rust oil smearing device for the edges of theconcrete cutting saw blades comprises a mounting frame, a mounting plate, a rotating assembly, a fixing assembly, a brushing assembly and the like, wherein the mounting plate is arranged at the top of the mounting frame, the rotating assembly which is powered by a motor to rotate is arranged on the mounting plate, and the fixing assembly which is used for fixing the concrete cutting saw blades ina lifting mode is arranged on the rotating assembly. According to the anti-rust oil smearing device, the anti-rust oil can be brushed on the multiple saw blades only by placing the saw blades on a circular plate through the rotating assembly, so that the speed of brushing the anti-rust oil on the saw blades is increased, and meanwhile, the anti-rust oil can be brushed on the saw blades more safely.

Owner:JIANGXI JIANDE IND

Etching equipment for printed circuit board

PendingCN112188746AAuto releaseClean up quicklyCircuit board tools positioningConductive material chemical/electrolytical removalEngineeringMechanical engineering

The invention relates to etching equipment, in particular to etching equipment for a printed circuit board. According to the etching equipment for the printed circuit board, the circuit board can be etched, etching liquid on the circuit board can be cleaned up, and the cleaning efficiency is high. The etching equipment for the printed circuit board comprises a bottom plate, a supporting frame andan etching device, the moving mechanism is arranged on the supporting frame; the material clamping mechanism is arranged on the moving mechanism; the pressurizing mechanism is arranged on the bottom plate; and a liquid spraying structure is arranged on the pressurizing mechanism. The clamping mechanism can clamp and fix a circuit board needing to be etched, the etched circuit board can be automatically loosened, the circuit board can be moved through the moving mechanism, etching liquid can be sprayed to the circuit board through cooperation of the pressurizing mechanism and the liquid spraying structure, and therefore the circuit board can be etched.

Owner:刘翠

Water drill bit polishing device

ActiveCN111687735ARealize automatic polishingEasy to take by handPolishing machinesGrinding drivesPolishingStructural engineering

The invention relates to a polishing device, in particular to a water drill bit polishing device. According to the water drill bit polishing device, a water drill bit can be automatically fixed, and is polished, and the water drill bit can be automatically replaced. The water drill bit polishing device comprises a polishing base, a polishing mechanism is arranged between the front left side and the right side of the polishing base, a clamping mechanism is arranged between the rear side and the front side of the polishing base, the clamping mechanism is connected with the polishing mechanism, through the polishing mechanism, automatic polishing of the water drill bit can be achieved, after the water drill bit is polished, the polishing head can automatically move upwards to be separated from the water drill bit, through the clamping mechanism, during polishing, the water drill bit is clamped and rotates, after polishing, the clamping mechanism can automatically loosen the water drill bit, through a placing mechanism, manual taking and replacing of the water drill bit can be facilitated, and through an automatic conveying mechanism, automatic replacing of the water drill bit can be achieved.

Owner:永州金科地质装备有限公司

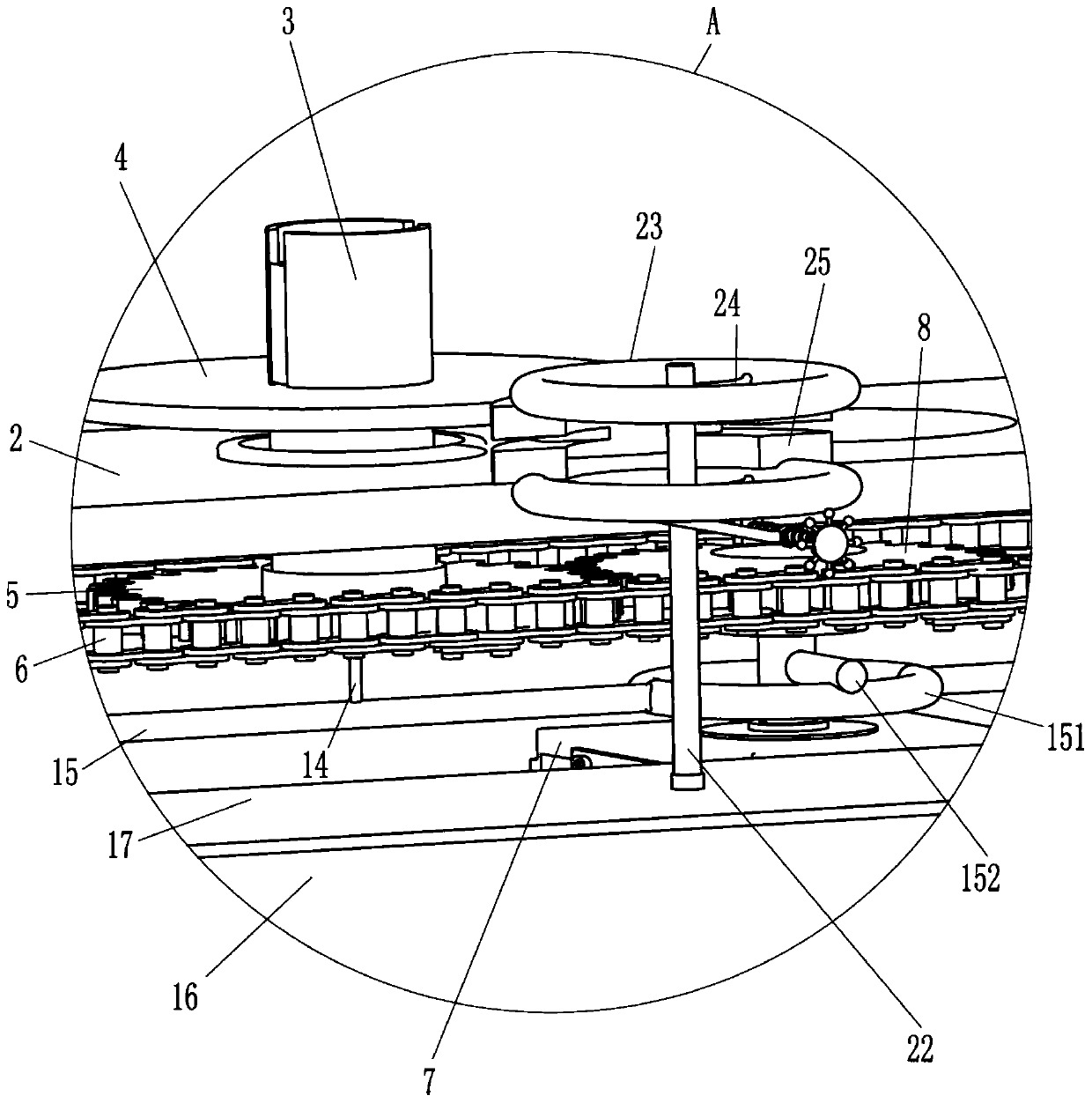

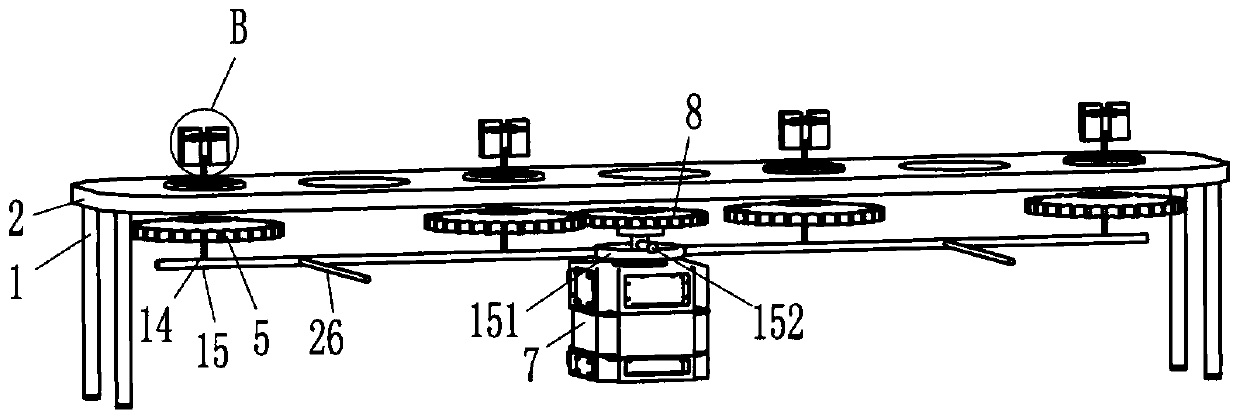

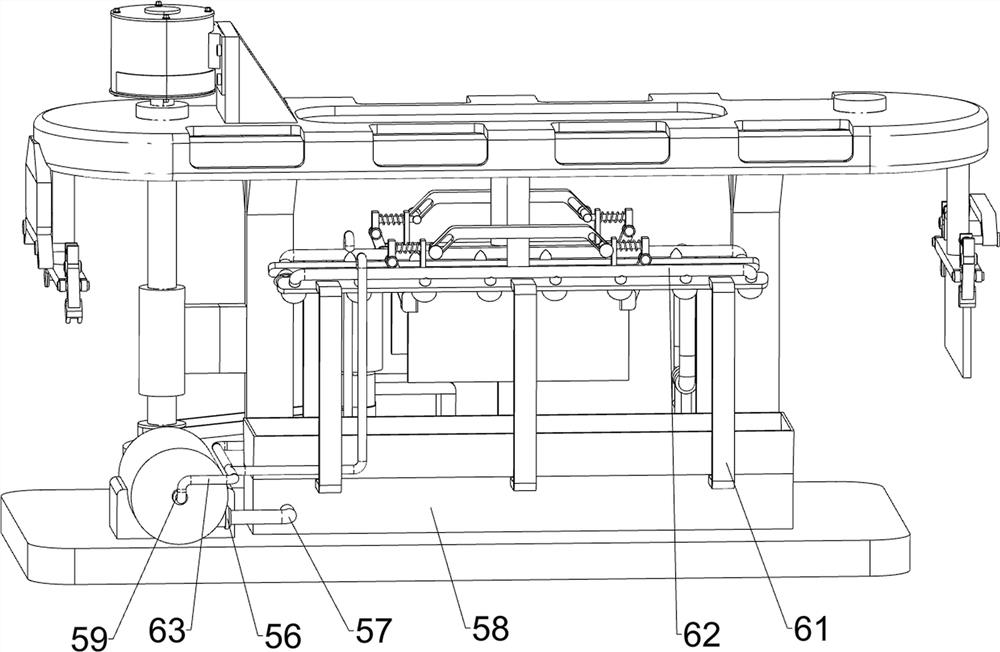

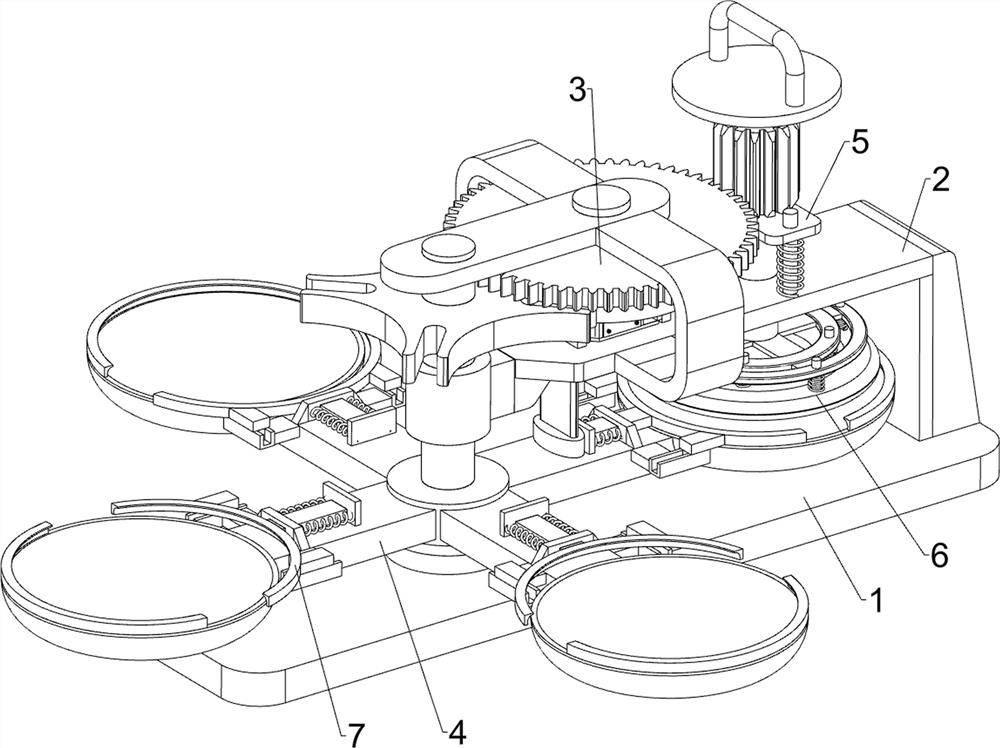

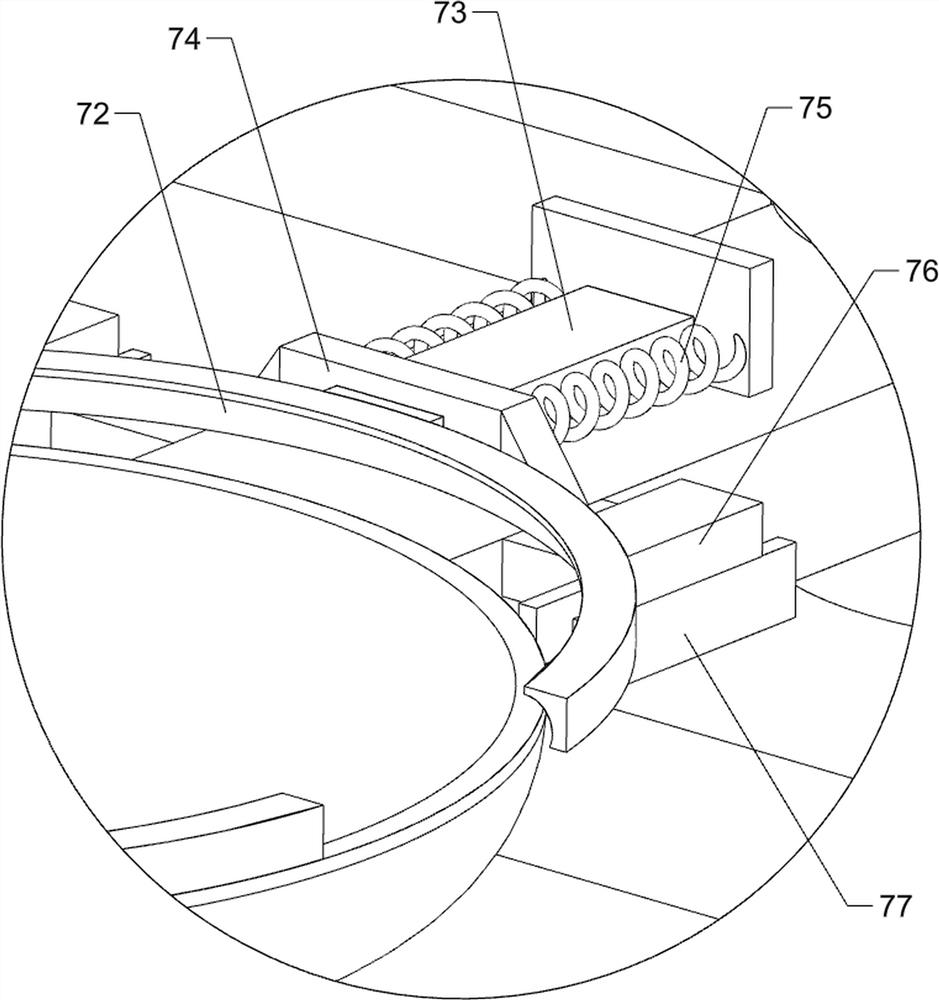

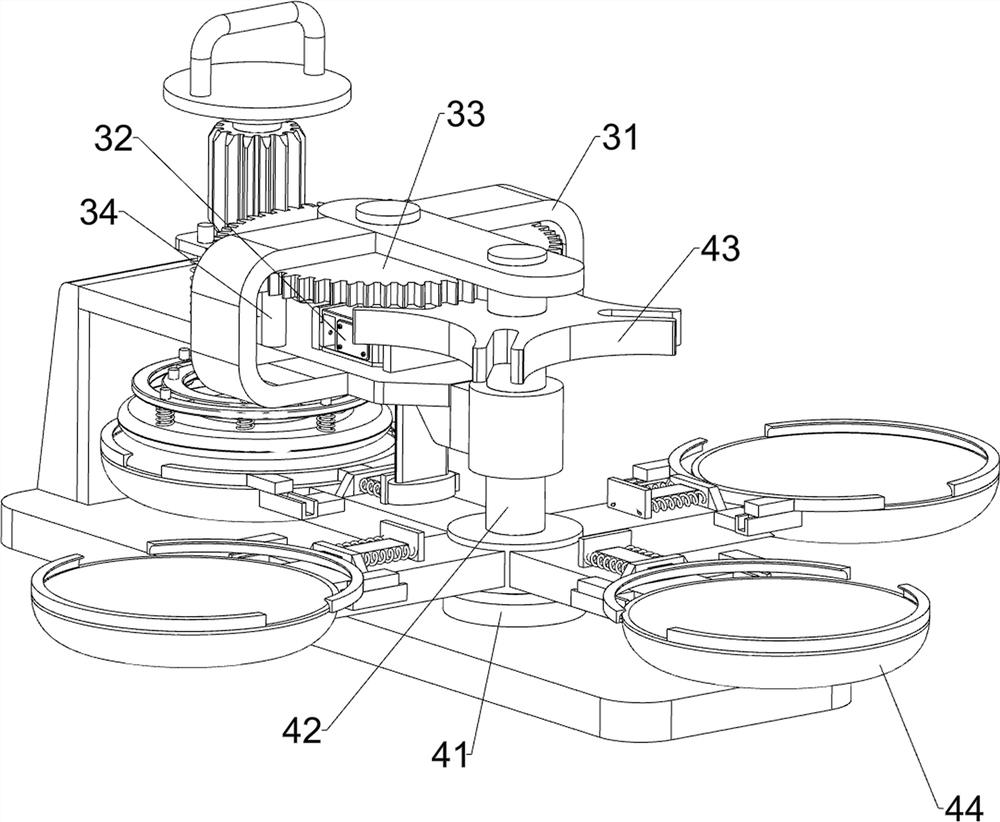

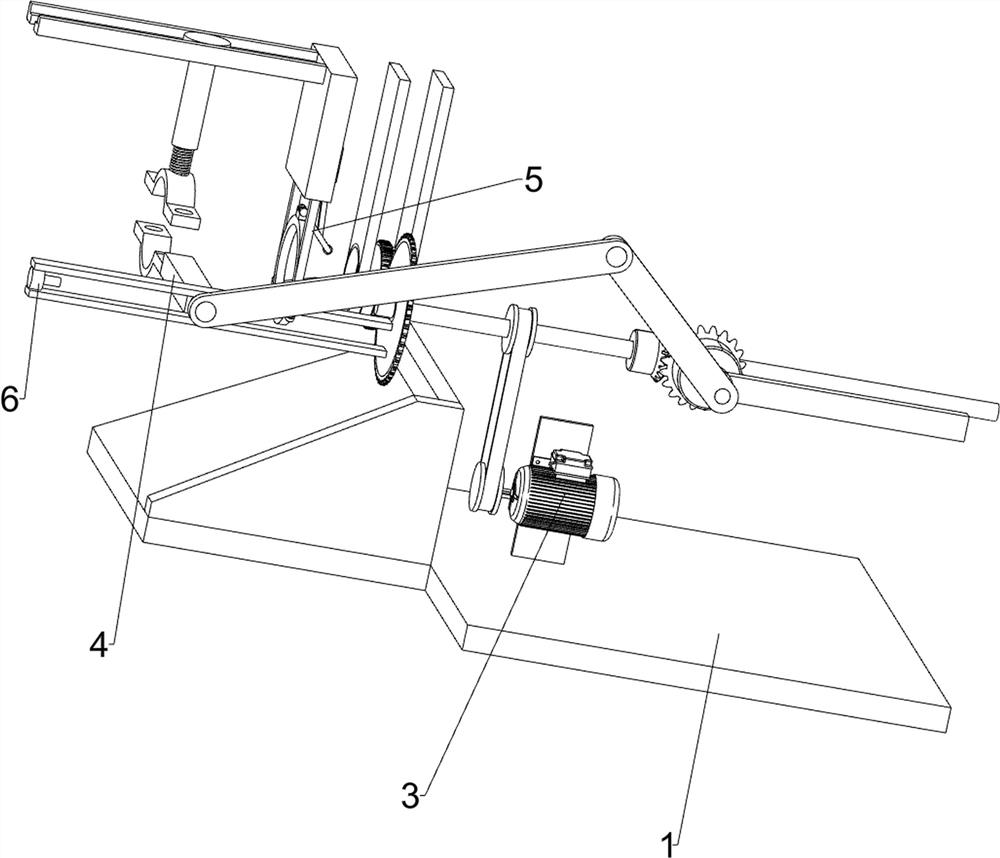

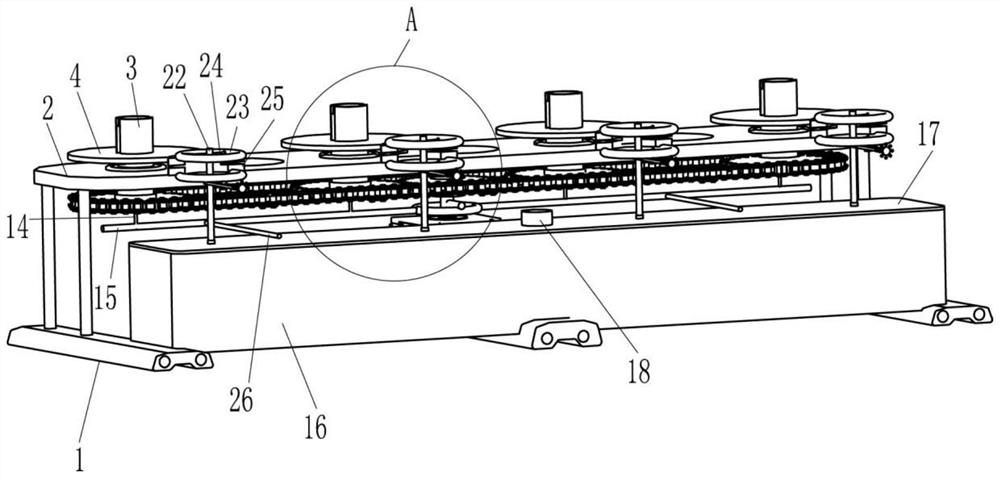

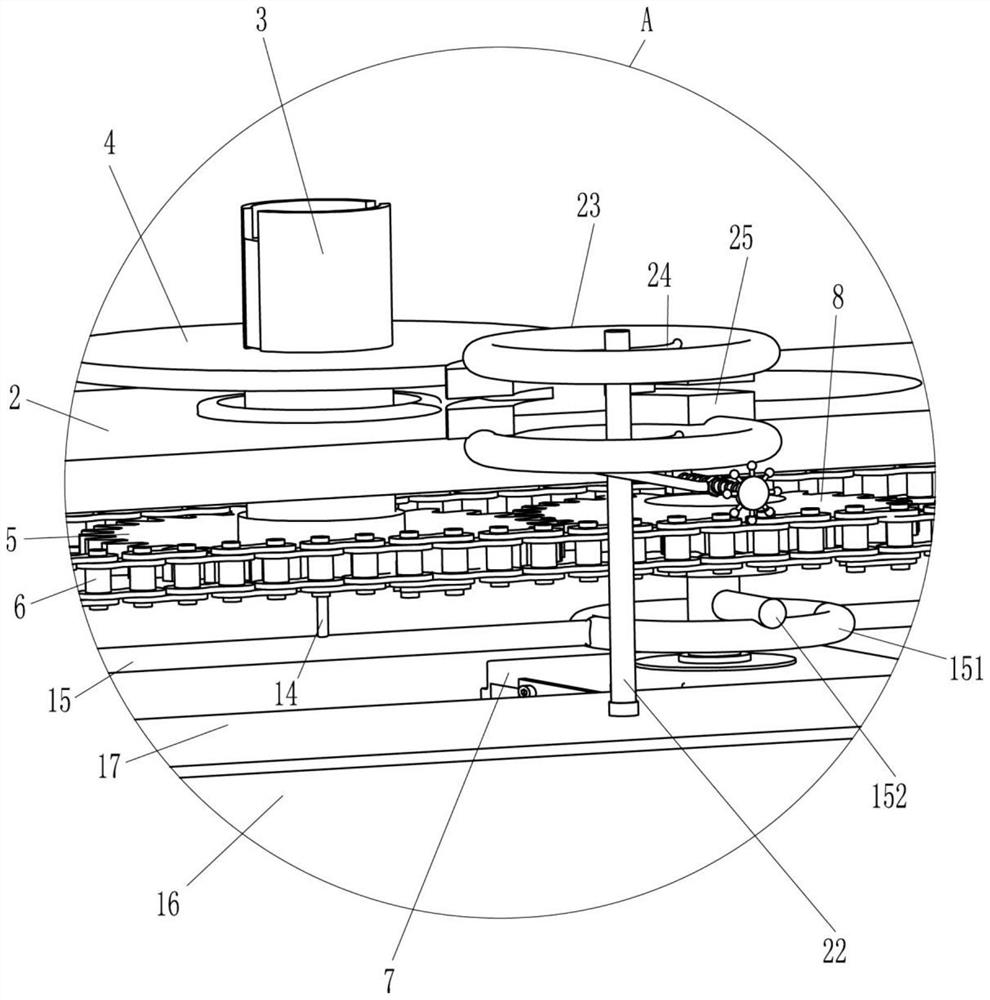

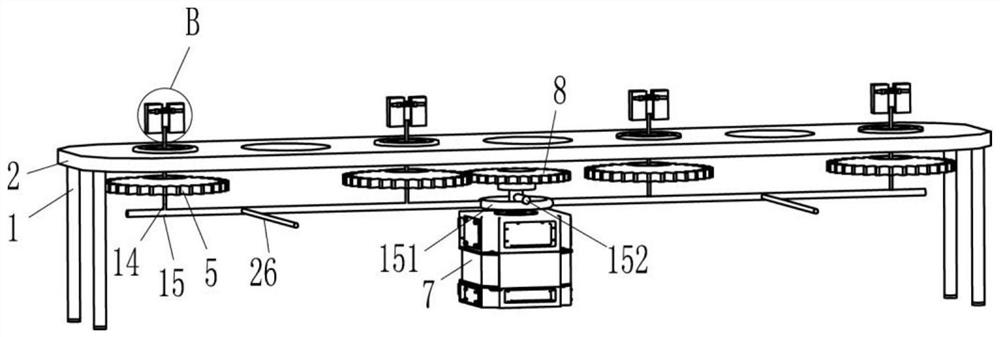

Polishing equipment for stainless steel dinner plate machining

ActiveCN112192421AImprove work efficiencyFast polishingPolishing machinesGrinding drivesPolishingEngineering

The invention relates to internal polishing equipment for machining, in particular to polishing equipment for stainless steel dinner plate machining. The polishing equipment for stainless steel dinnerplate machining is time-saving, labor-saving, high in working efficiency and high in polishing speed. The polishing equipment for stainless steel dinner plate machining provided by the invention comprises a bottom plate, a power mechanism, a rotary rack mechanism and a movable rack mechanism, wherein a mounting frame is connected to one side of the bottom plate; the power mechanism is mounted onthe mounting frame; the rotary rack mechanism is installed on the other side of the bottom plate; the rotary rack mechanism is in transmission connection with the power mechanism; and the movable rackmechanism is mounted on the mounting frame. According to the polishing equipment, power can be provided for the rotary rack mechanism and the movable rack mechanism through the power mechanism; stainless steel dinner plates can be conveyed to the polishing mechanism through the rotary rack mechanism; the polishing mechanism can be driven to work through the movable rack mechanism; and the polishing mechanism works to polish the interior of the stainless steel dinner plates in an omnibearing mode.

Owner:揭阳市庆展不锈钢有限公司

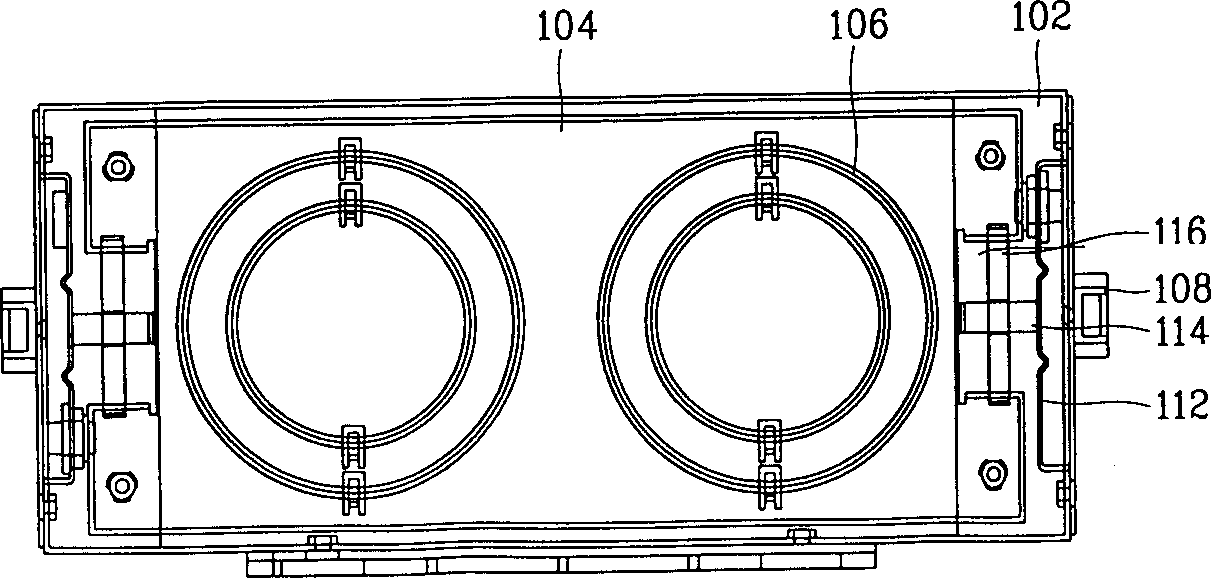

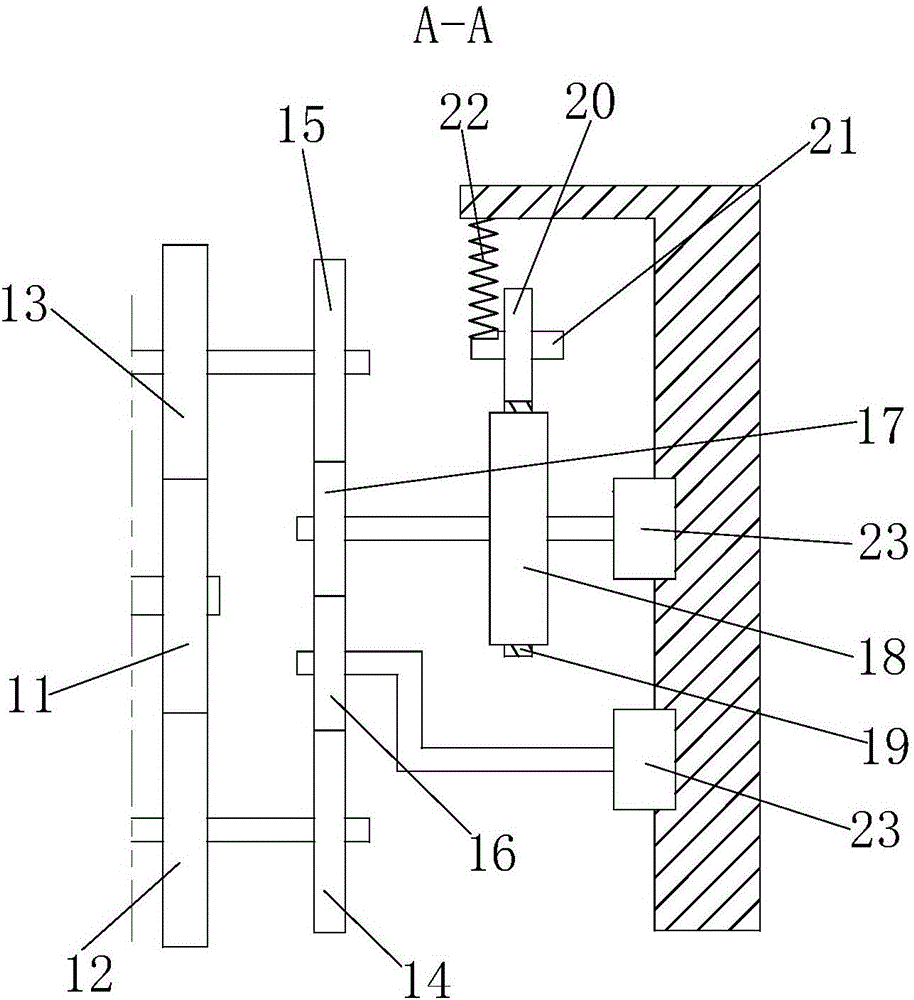

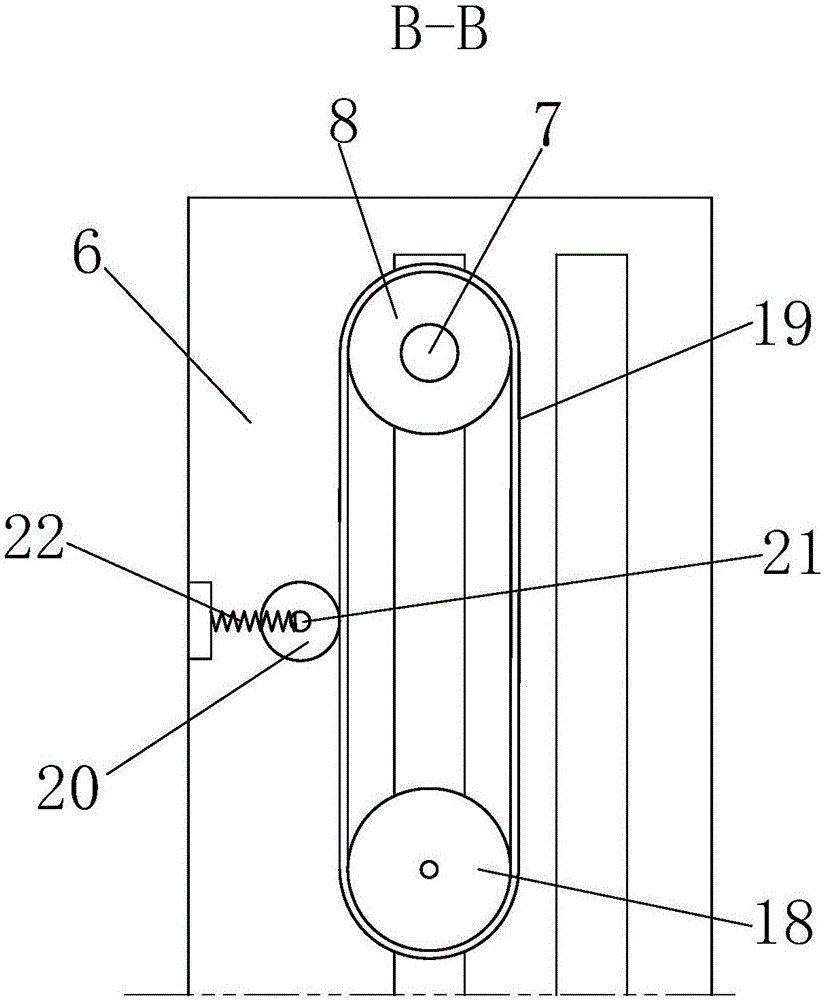

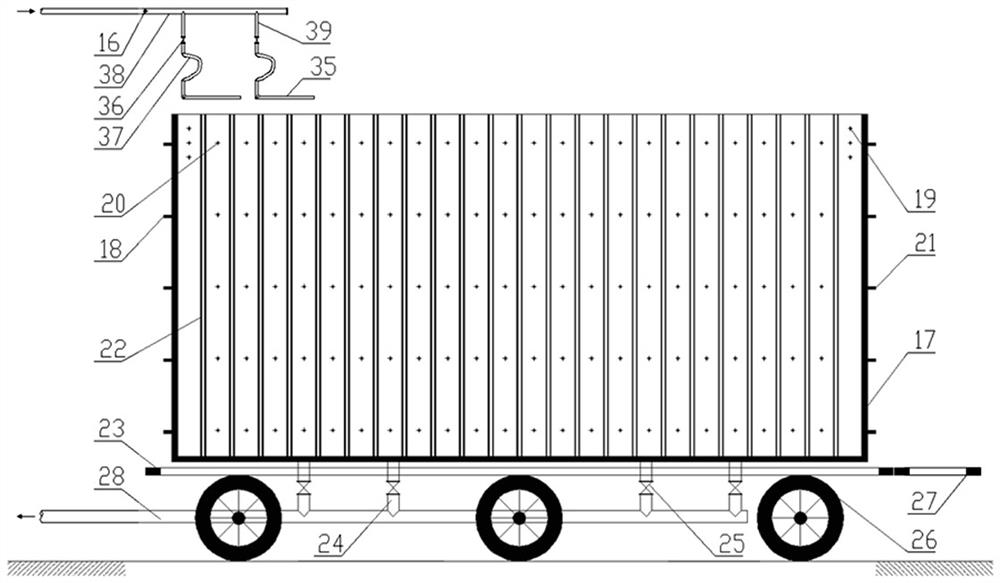

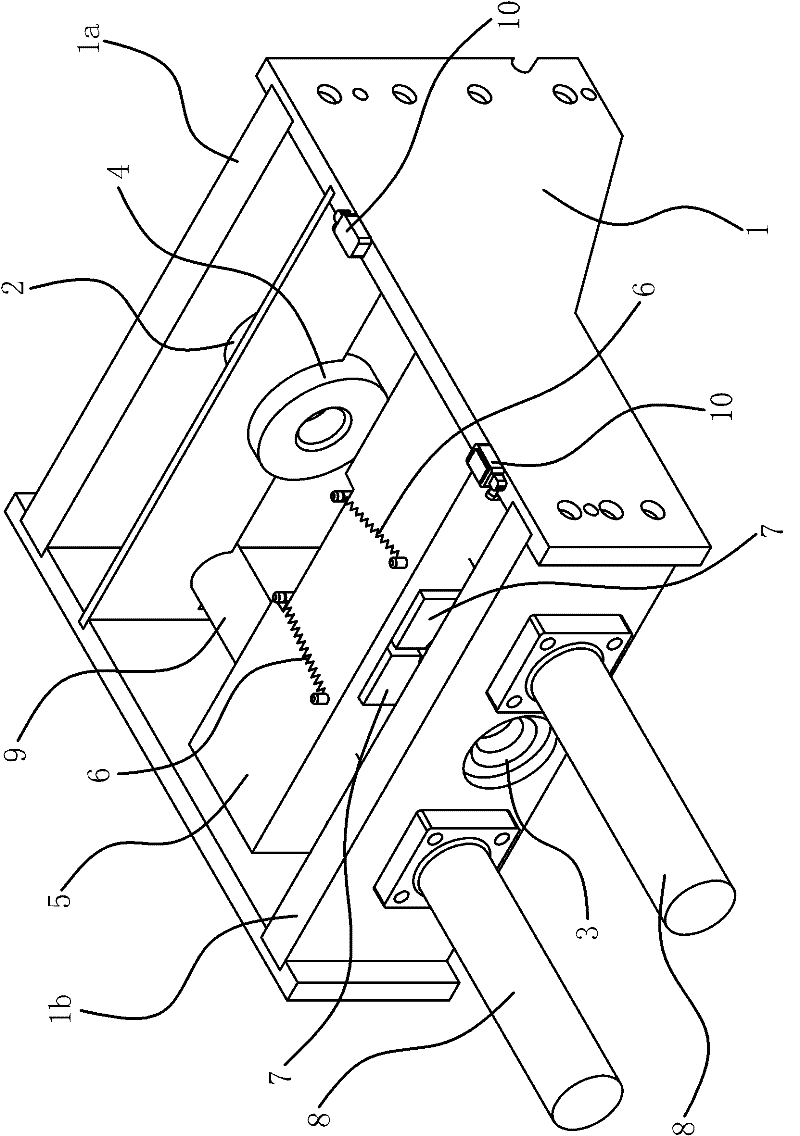

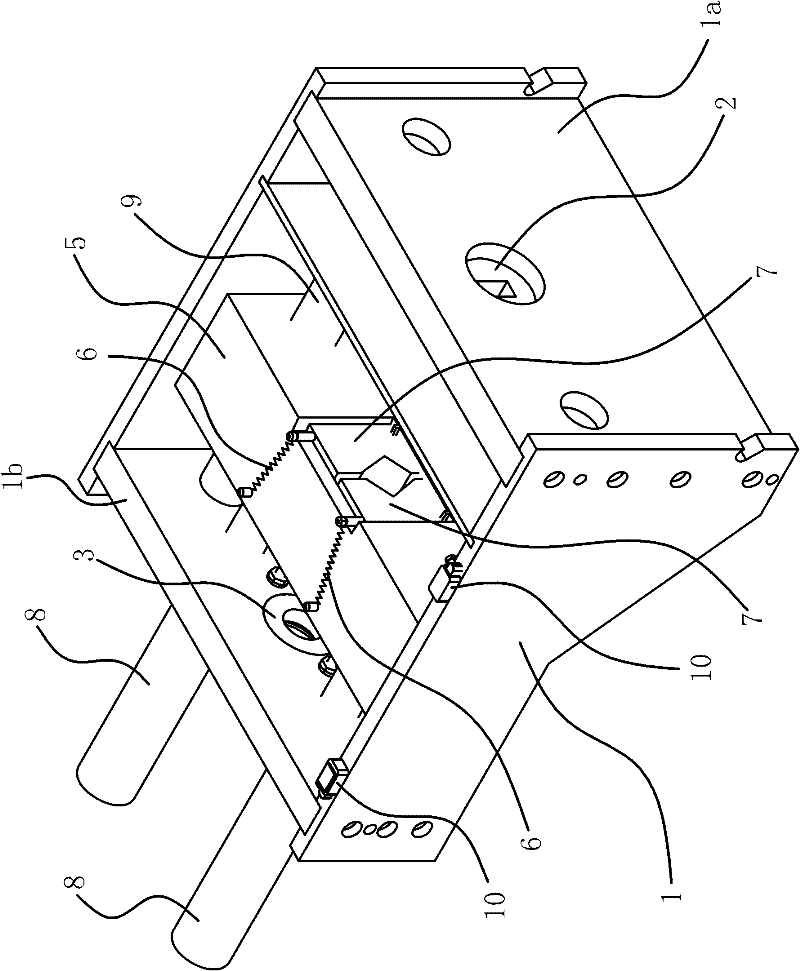

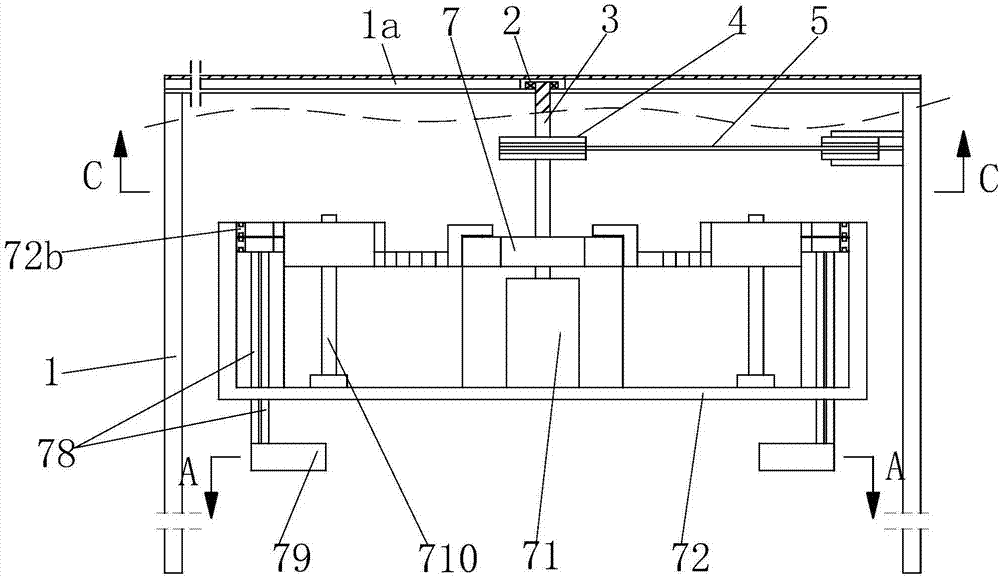

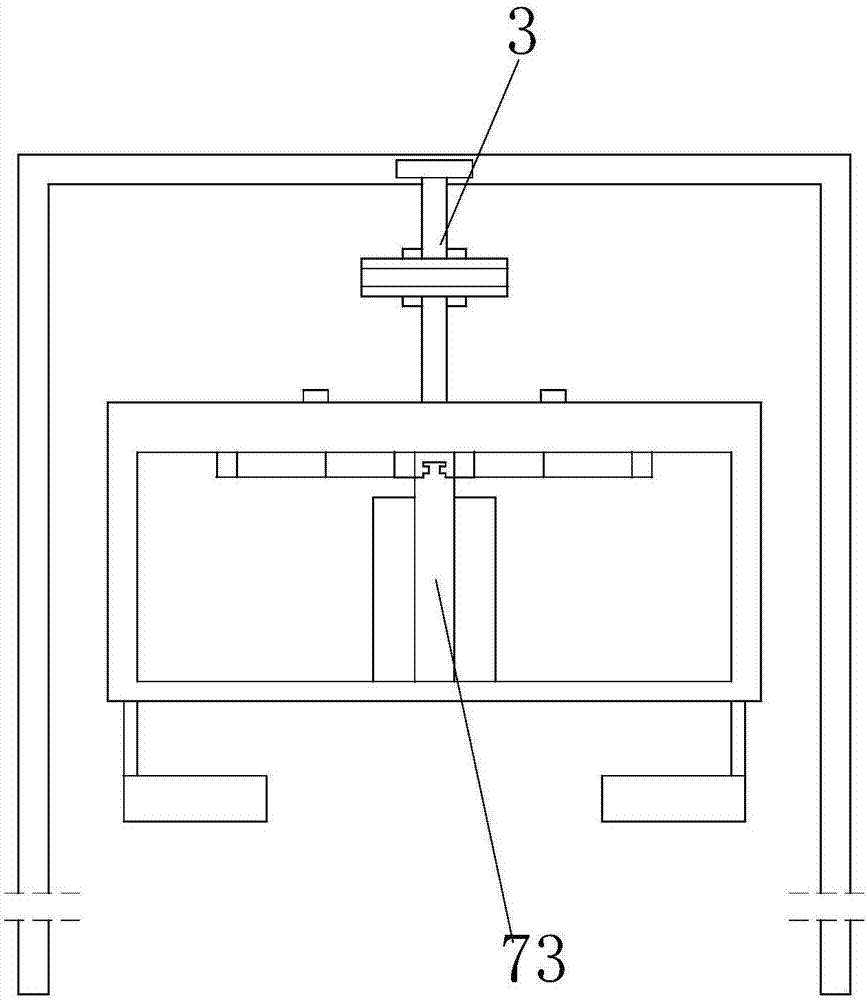

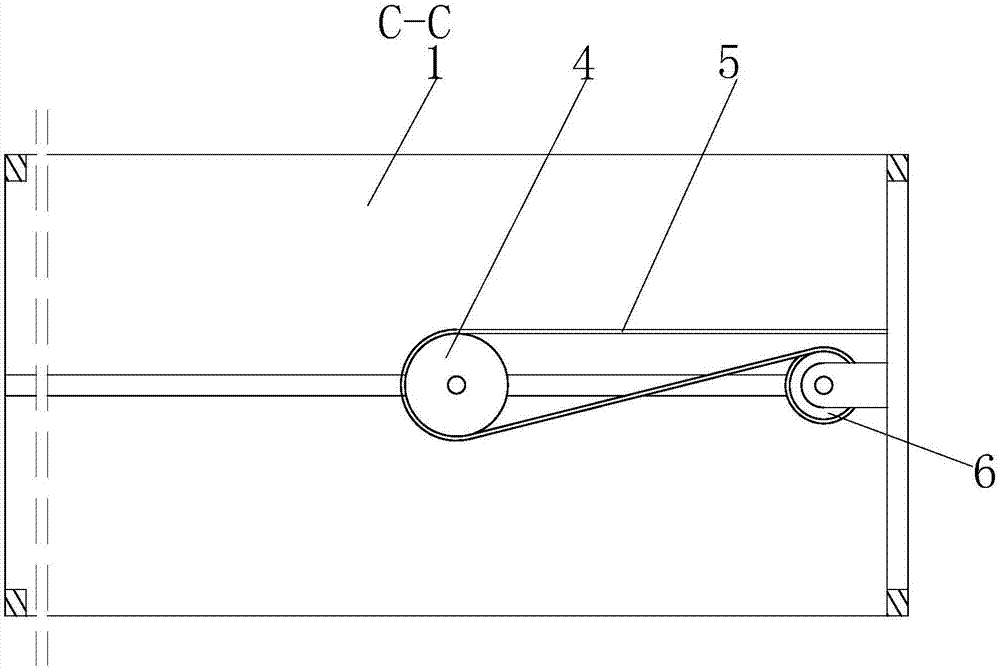

Carrying device used for carrying bars away from quenching bath

The invention relates to a carrying device used for carrying bars away from a quenching bath. The carrying device comprises a main body frame. A spindle is mounted on the upper portion of the main body frame and connected with a motor. A first pulley and a second pulley are mounted on the spindle in sequence. A mooring rope is mounted on the second pulley. A main lifting frame is tied to the lower end of the mooring rope. A ball screw is mounted on the lower portion of the main lifting frame and connected with the motor. A smooth rod is fixedly mounted on the upper portion of the main lifting frame. Two leg frames are slidably mounted on the smooth rod. A clamping opening is formed in the lower end of each leg frame. The carrying device is ingenious in structure and can automatically clamp and release the bars while driving the bars to do lifting movement through belt transmission and incomplete gear steering functions under the conditions of motor drive and belt tensioning due to spring extrusion, and the effect of carrying the bars away from the quenching bath through convenient and rapid operation and control mode is achieved.

Owner:安徽旭虹机械设备有限公司

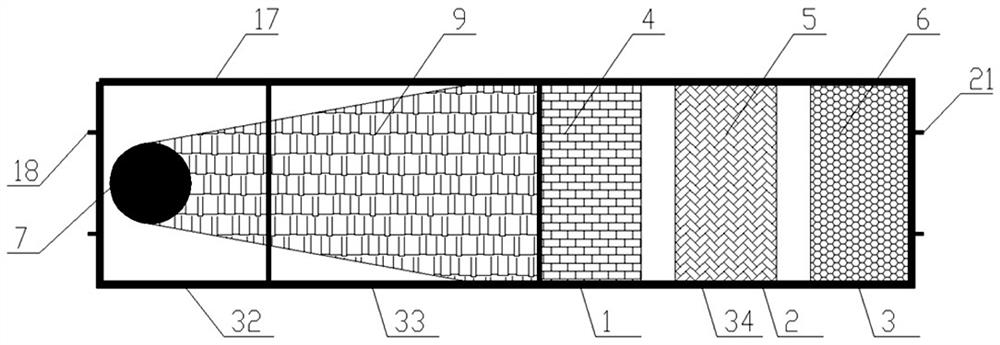

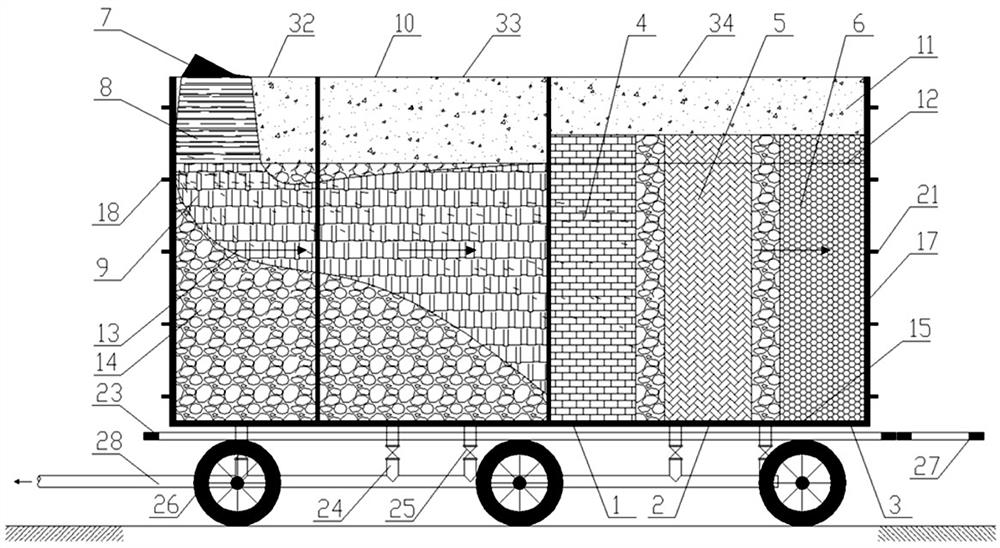

Simulated remediation system and method for underground water containing 1, 2-dichloroethane

InactiveCN111960603AOptimize repair processHighly toxicWater/sewage treatment by irradiationWater contaminantsPersulfateAquifer

The invention provides a simulated remediation system and a method for underground water containing 1, 2-dichloroethane. According to the system, a rectangular tank-type shell with an opening in the top is sequentially divided into a pollution source section, a pollutant migration and transformation section and a pollutant remediation section from left to right; the sample space layers of the pollution source section and the pollutant migration and transformation section are soil sample filling layers; the sample space layer of the pollutant remediation section is sequentially provided with apyrite filling layer, an oxide filling layer and a tourmaline filling layer from left to right. Pyrite is adopted to catalyze persulfate; the natural material tourmaline is introduced into the Fenton-like reaction, so that the pH value and redox potential of the aquifer are optimized, the remediation environment of persulfate in underground water on 1, 2-dichloroethane is integrally improved, andthe effectiveness and practicability of an in-situ chemical oxidation system in remediation of degradation-resistant organic polluted underground water are obviously improved.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

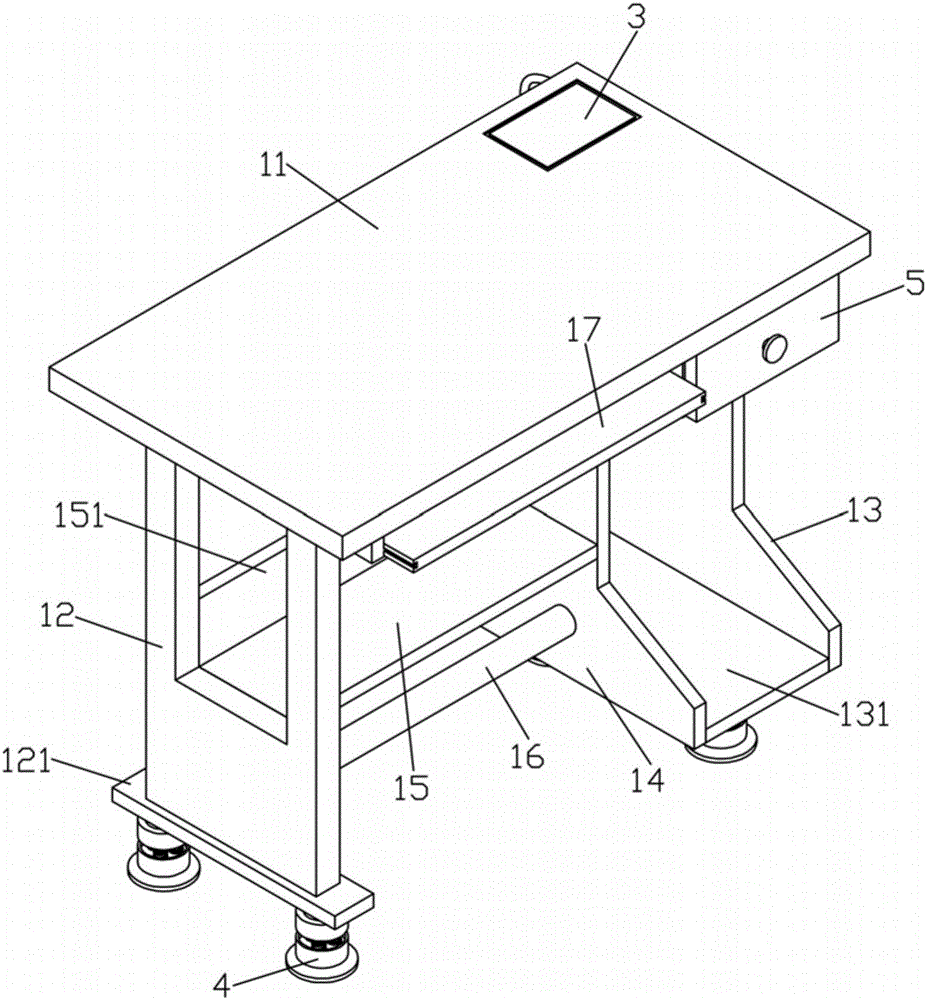

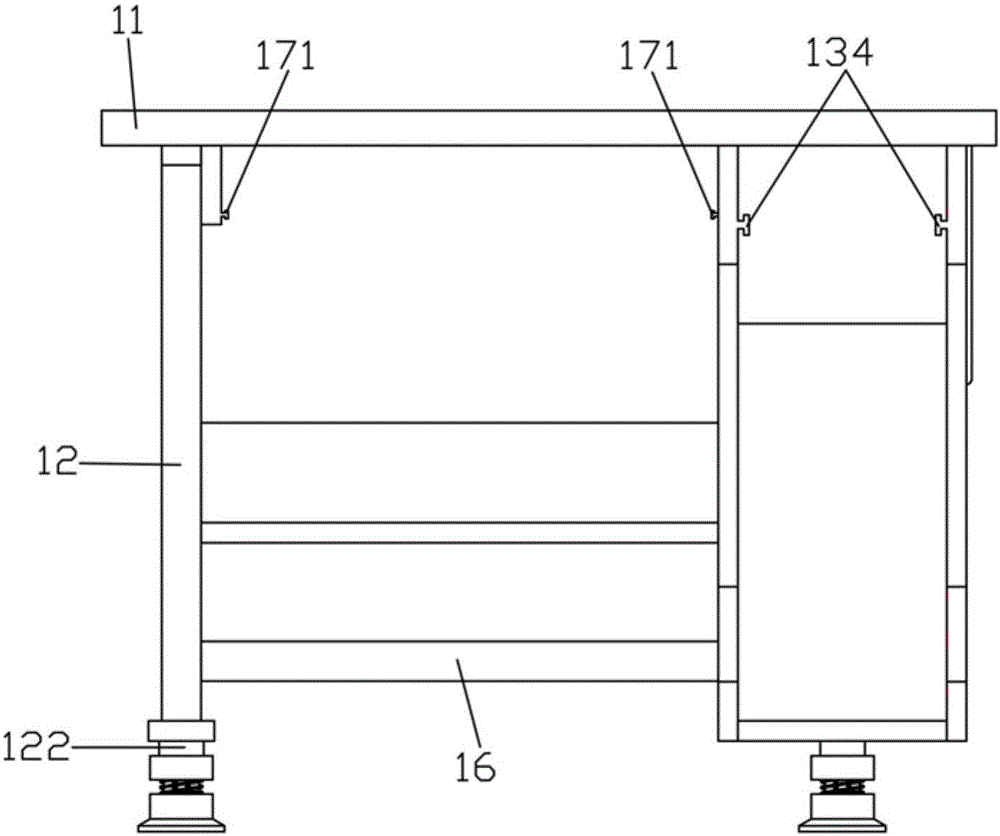

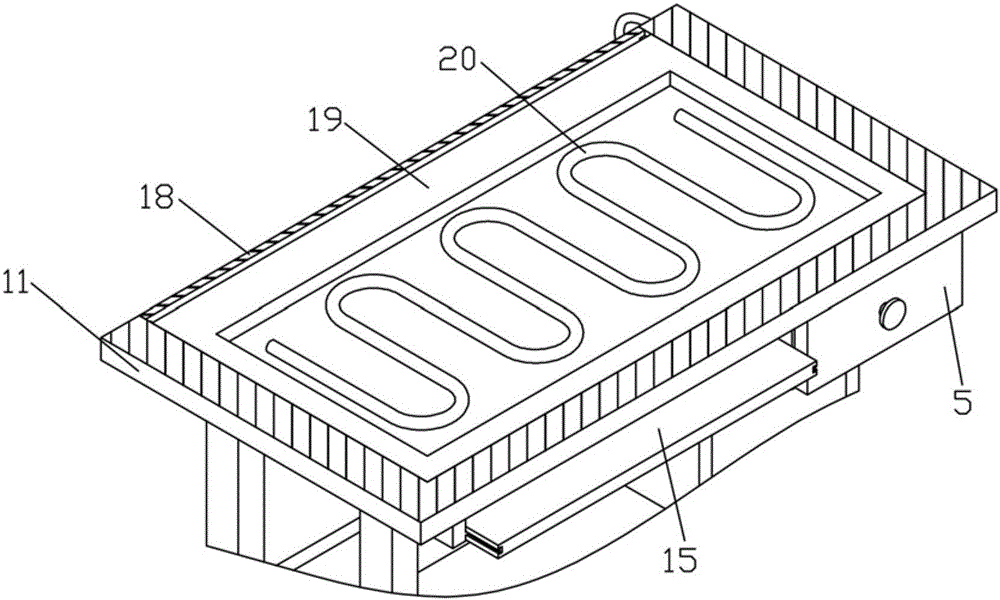

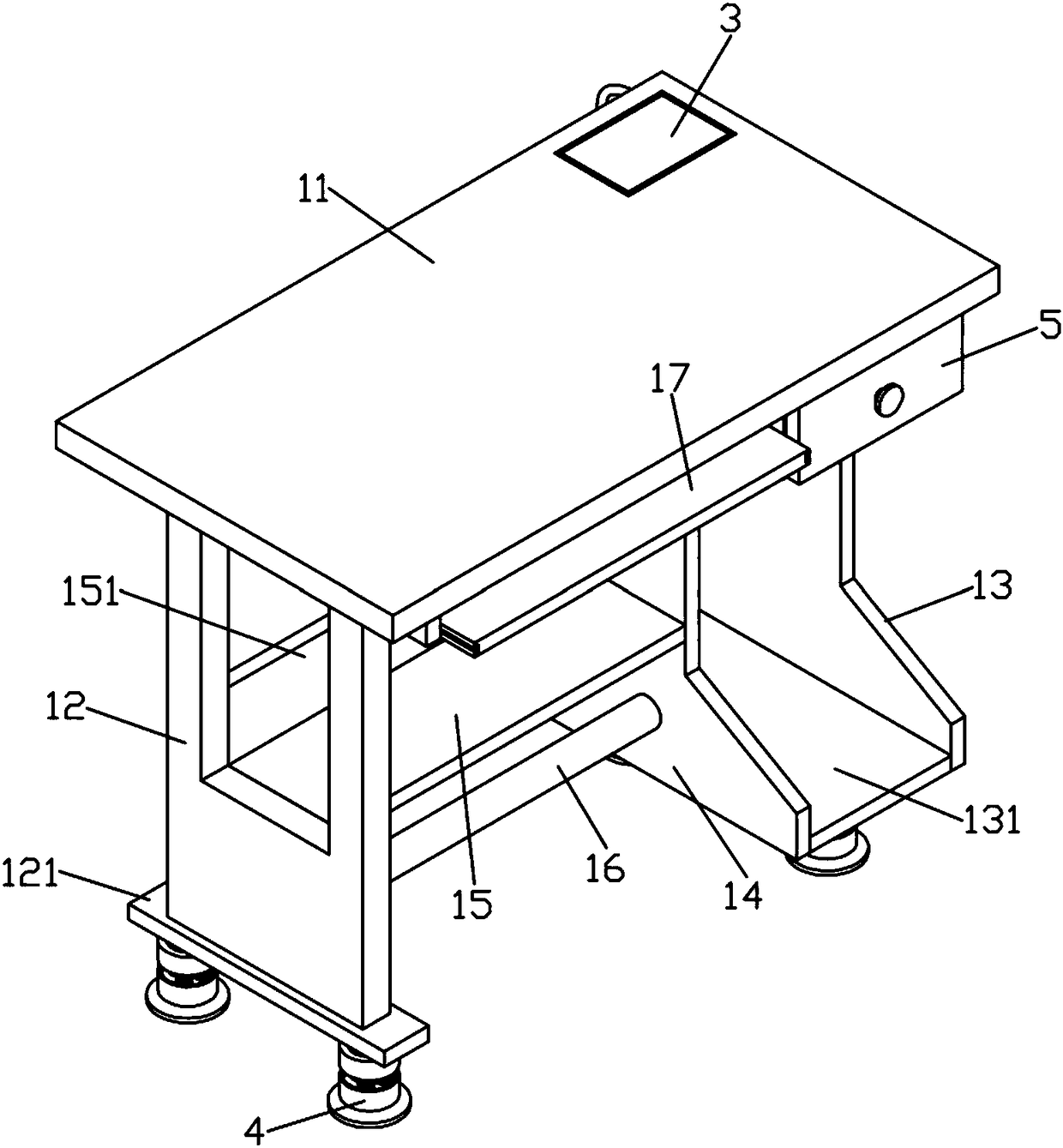

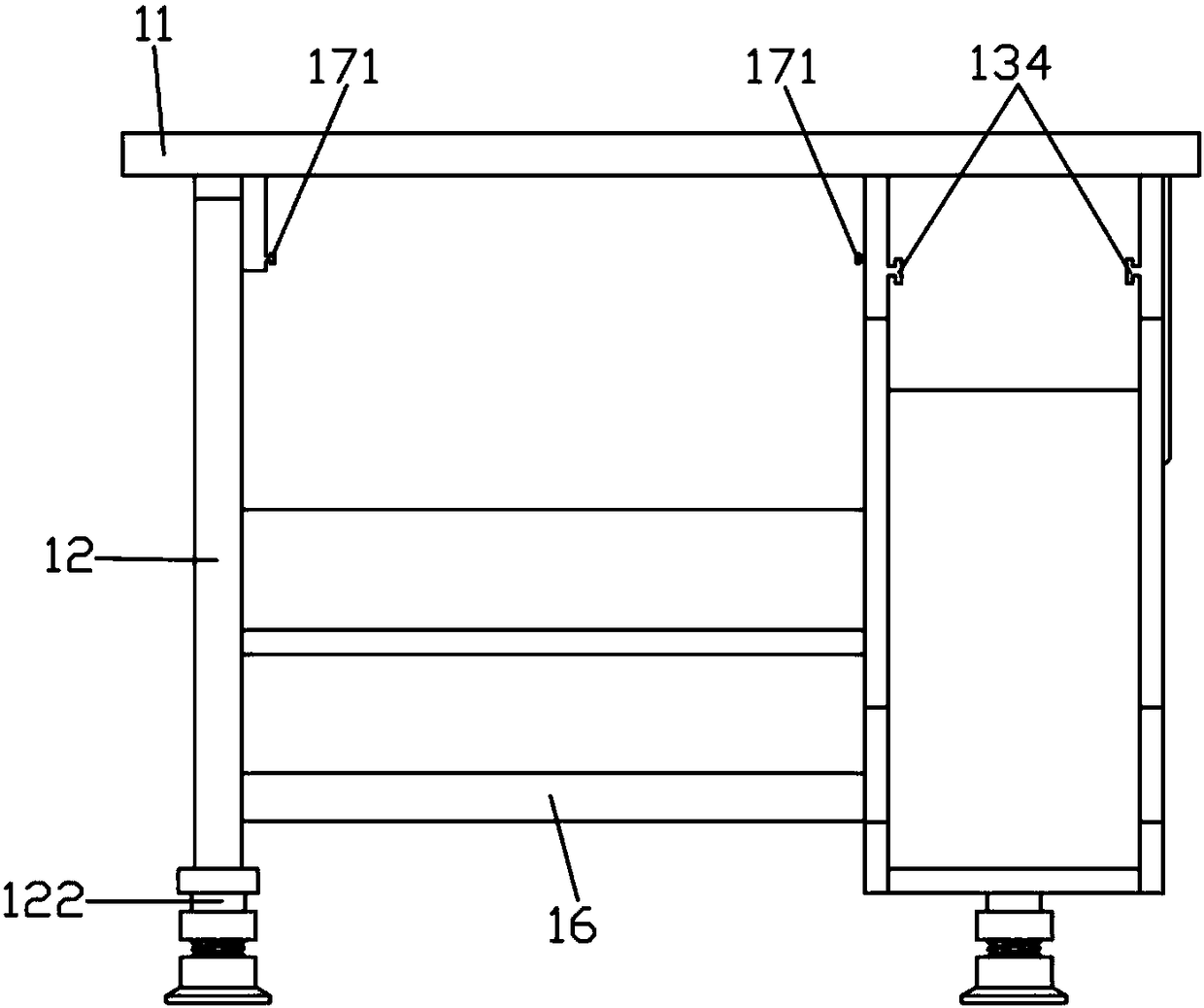

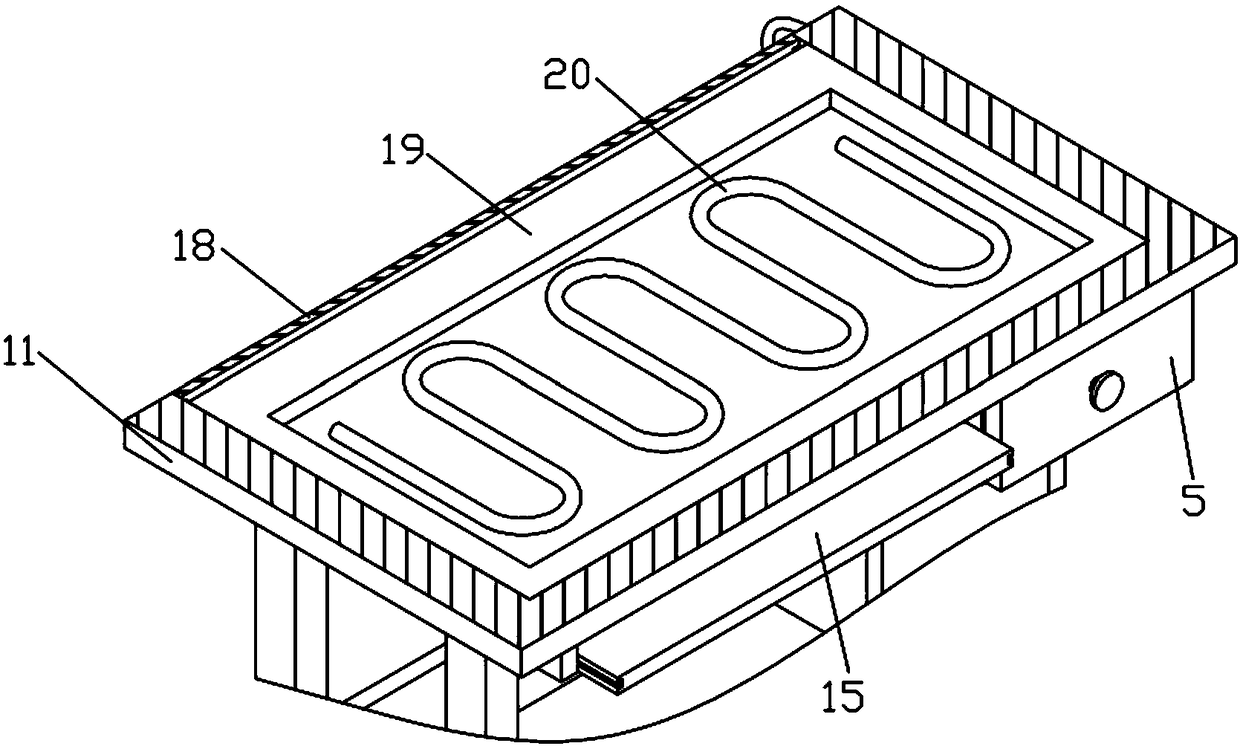

Smart heating desk

The invention discloses a smart heating desk. The smart heating desk comprises a desk main body and a desk panel which is fixedly arranged on the desk main body, wherein a control panel is arranged on the desk panel; buffer supporting legs are arranged at four corners of the bottom of the desk main body; the desk panel is of a hollow platy structure; a heating device is arranged inside the desk panel and is electrically connected with the control panel; a file supporting frame is arranged at the lower part of the desk panel; the file supporting frame is arranged at the lower part of the desk panel through supporting frame sliding rails arranged on the desk main body in a sliding manner; a drawer with an electronic lock is also arranged at the right side of the file supporting frame; the electronic lock of the drawer is a fingerprint electronic lock. The smart heating desk is provided with the heating device which can automatically release the heat and provides a proper study temperature for students concentrating on writing and reading; in addition, the heating device is intelligently controlled. The smart heating desk is simple in structure and is easy to mount and produce.

Owner:赣州市国鼎家具有限公司

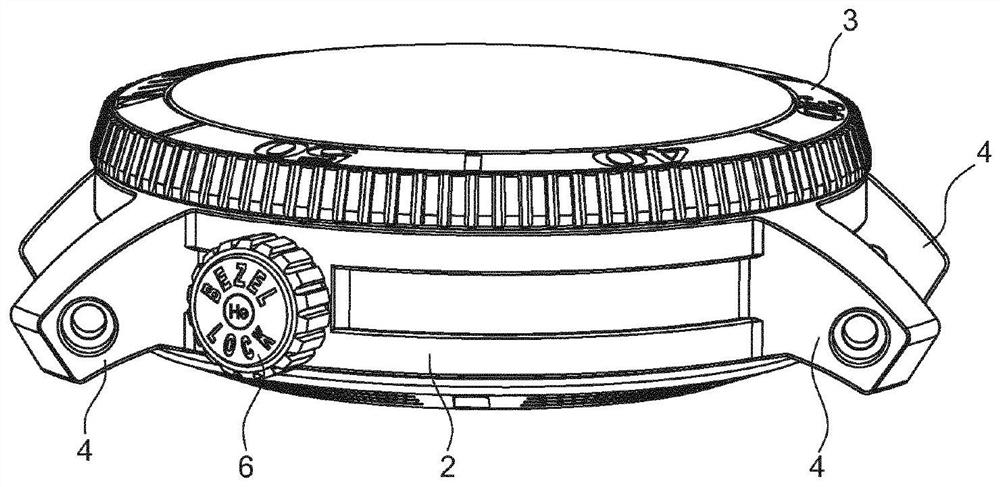

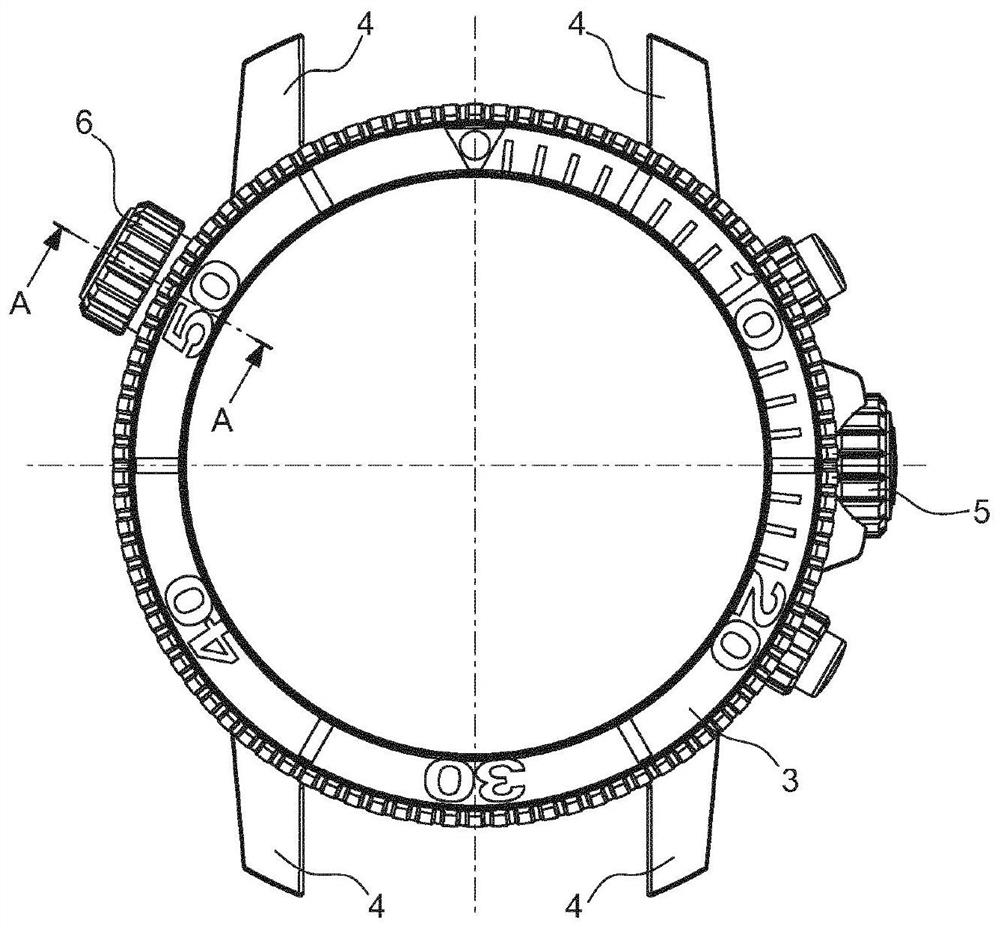

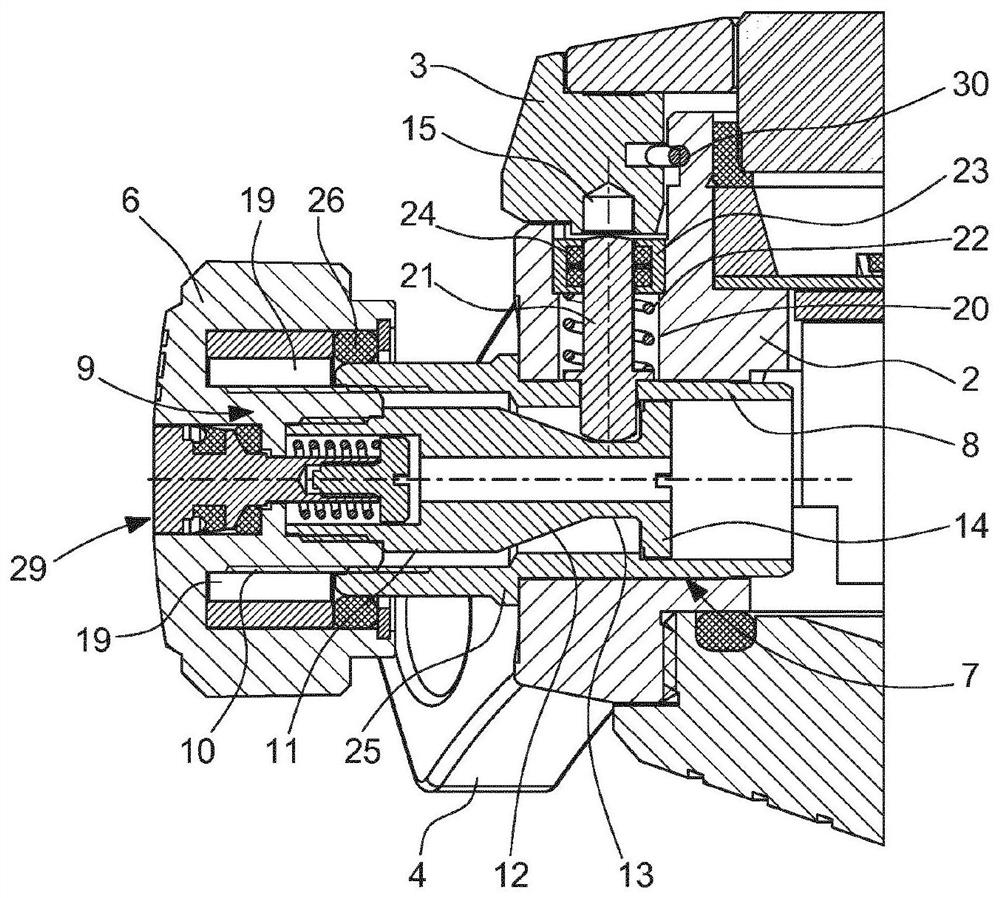

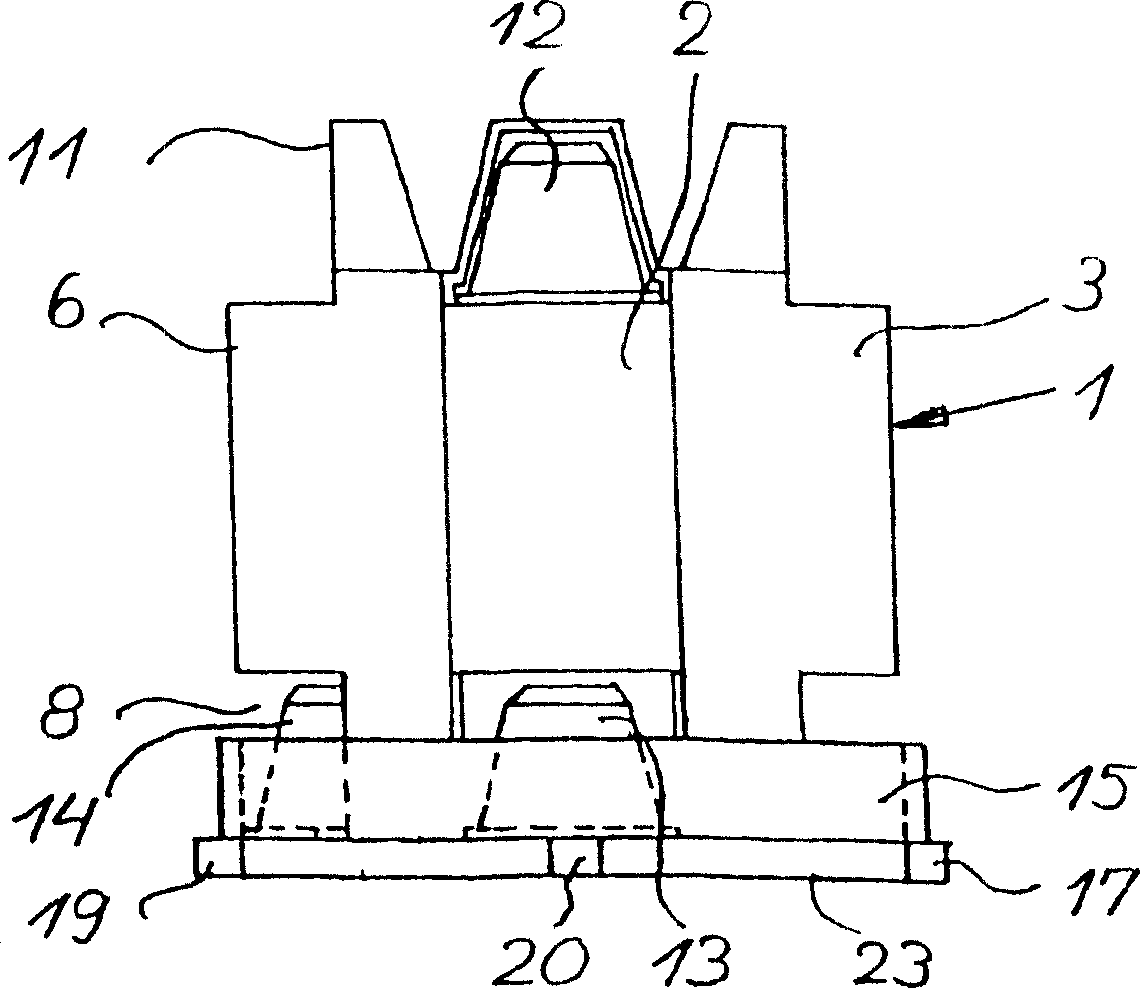

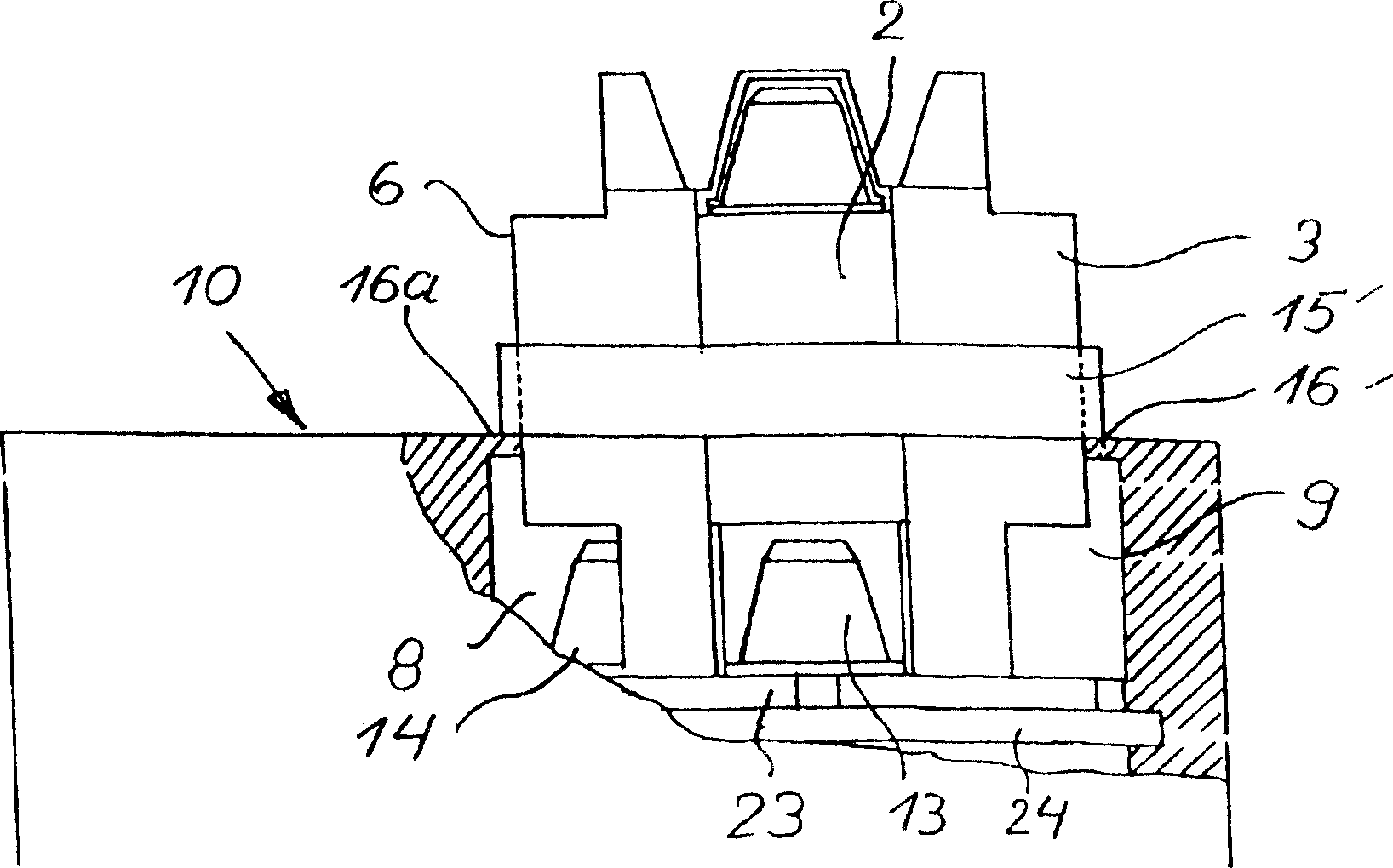

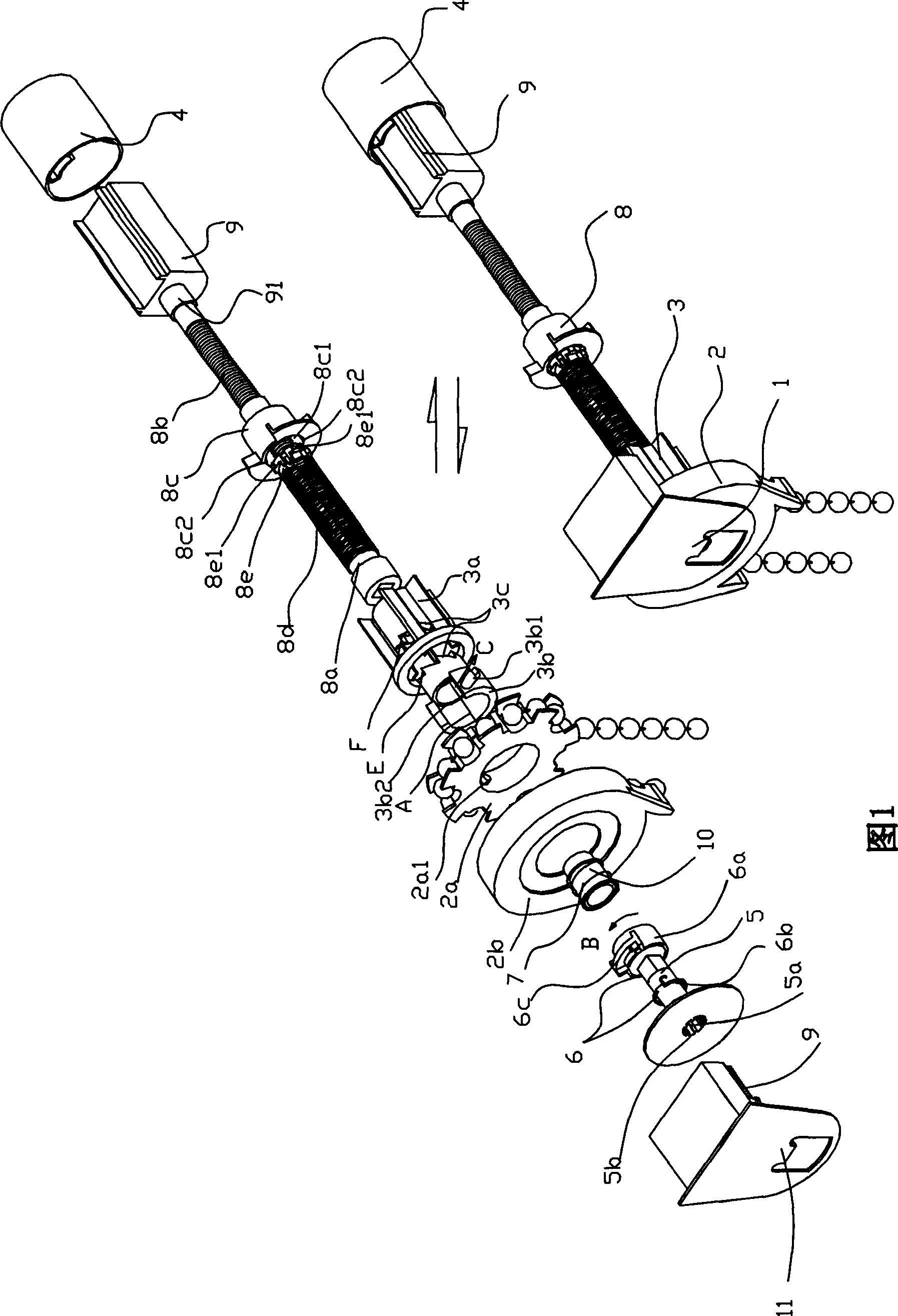

Watch equipped with rotating bezel including bezel locking system with integrated helium valve

The invention relates to a watch the watch case of which comprises a middle (2) and a rotating bezel (3). The watch case is provided with a bezel locking system. The system comprises a rotary crown (6) which is rigidly attached to a shaft (9), the latter being arranged in a radial hole (7) in the middle. By rotating the crown (6), the user can screw or unscrew the shaft with respect to the hole. The shaft comprises a frustoconical section (12) which interacts with a pin (21) mounted perpendicularly to the shaft, and biased towards the shaft by a spring (22). By screwing the shaft (9) into thehole (7), the frustoconical section pushes the pin into a receiving space (15) provided on the inner surface of the bezel (3), which locks the bezel. The unscrewing of the shaft (9) automatically disengages the pin (21) outside of the receiving space, by virtue of a return force exerted by the spring (22). According to a preferred embodiment, the crown incorporates a helium valve mechanism.

Owner:TISSOT SA

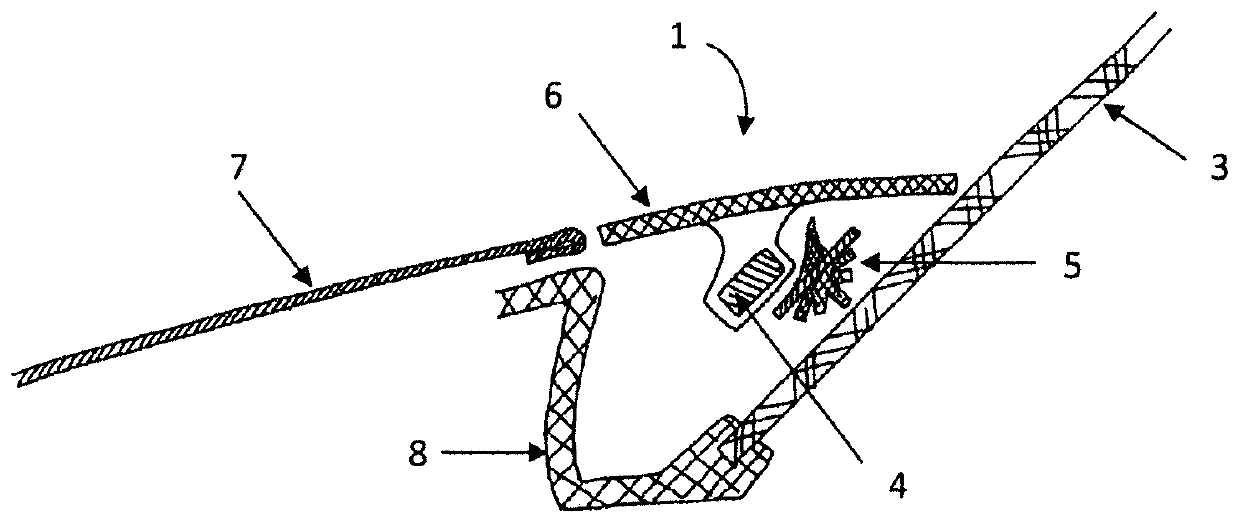

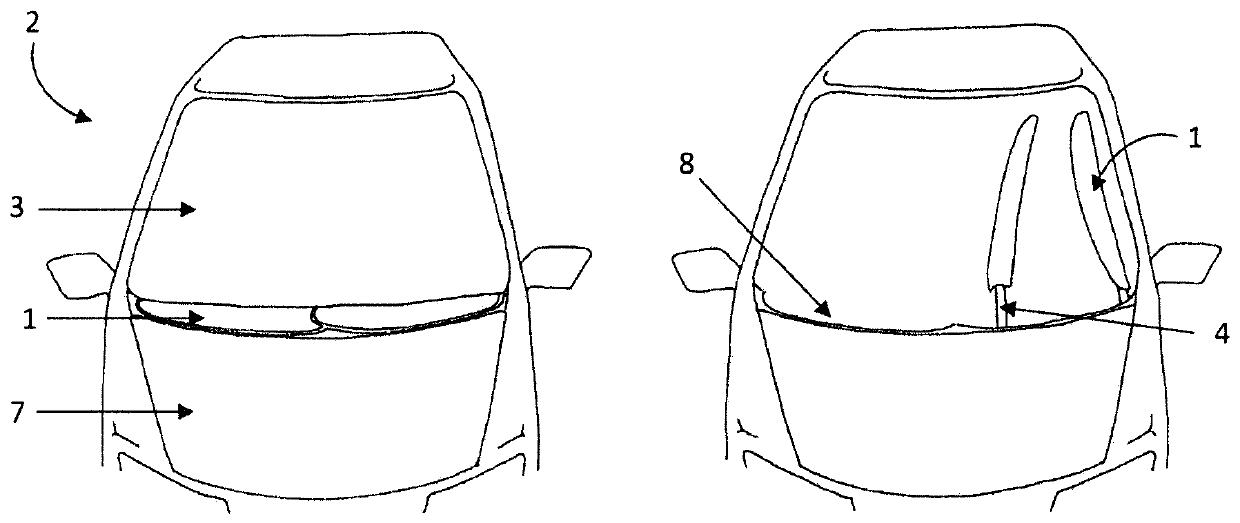

Windscreen wiper and vehicle with windscreen wiper

The invention relates to a windscreen wiper with a wiper arm and a wiper blade, and a cover attached to the wiper arm, into which at least one nozzle for windscreen washer fluid is built. The supply system for the windscreen washer fluid can also be built into the cover. Furthermore, the cover is designed such that the wiper blade, the wiper arm and the cover can be detached from each other. The cover closes the gap between the bonnet and the windscreen in the idle state and can be made compact for the operating state by means of a mechanism.

Owner:A RAYMOND & CO

Rotary polishing device for inner wall of bearing bush

ActiveCN113263369AAvoid shakingAuto releaseRevolution surface grinding machinesGrinding drivesPolishingEngineering

The invention relates to a polishing device, in particular to a rotary polishing device for an inner wall of a bearing bush. According to the rotary polishing device for the inner wall of the bearing bush, fixing and rapid polishing can be conducted, chippings generated during polishing can be cleared, and collection is convenient. The rotary polishing device for the inner wall of the bearing bush comprises a bottom plate and a first bearing block, wherein a supporting plate is arranged on the bottom plate, and the first bearing block is arranged on the supporting plate. After the bearing bush is placed on the supporting plate, a rotating shaft sleeve rotates downwards on the first bearing block by rotating, the rotating shaft sleeve rotates downwards and drives a straight rotating shaft to rotate downwards, a placing mechanism moves rightwards to fix the bearing bush, the straight rotating shaft rotates downwards to extrude a locking mechanism to move away from the straight rotating shaft, the straight rotating shaft is locked through resetting of the locking mechanism, and then a handle is rotated to drive the straight rotating shaft to rotate on the rotating shaft sleeve, the straight rotating shaft rotates to drive a millstone to rotate, and the millstone rotates to polish the inner wall of the bearing bush.

Owner:江苏益达管件股份有限公司

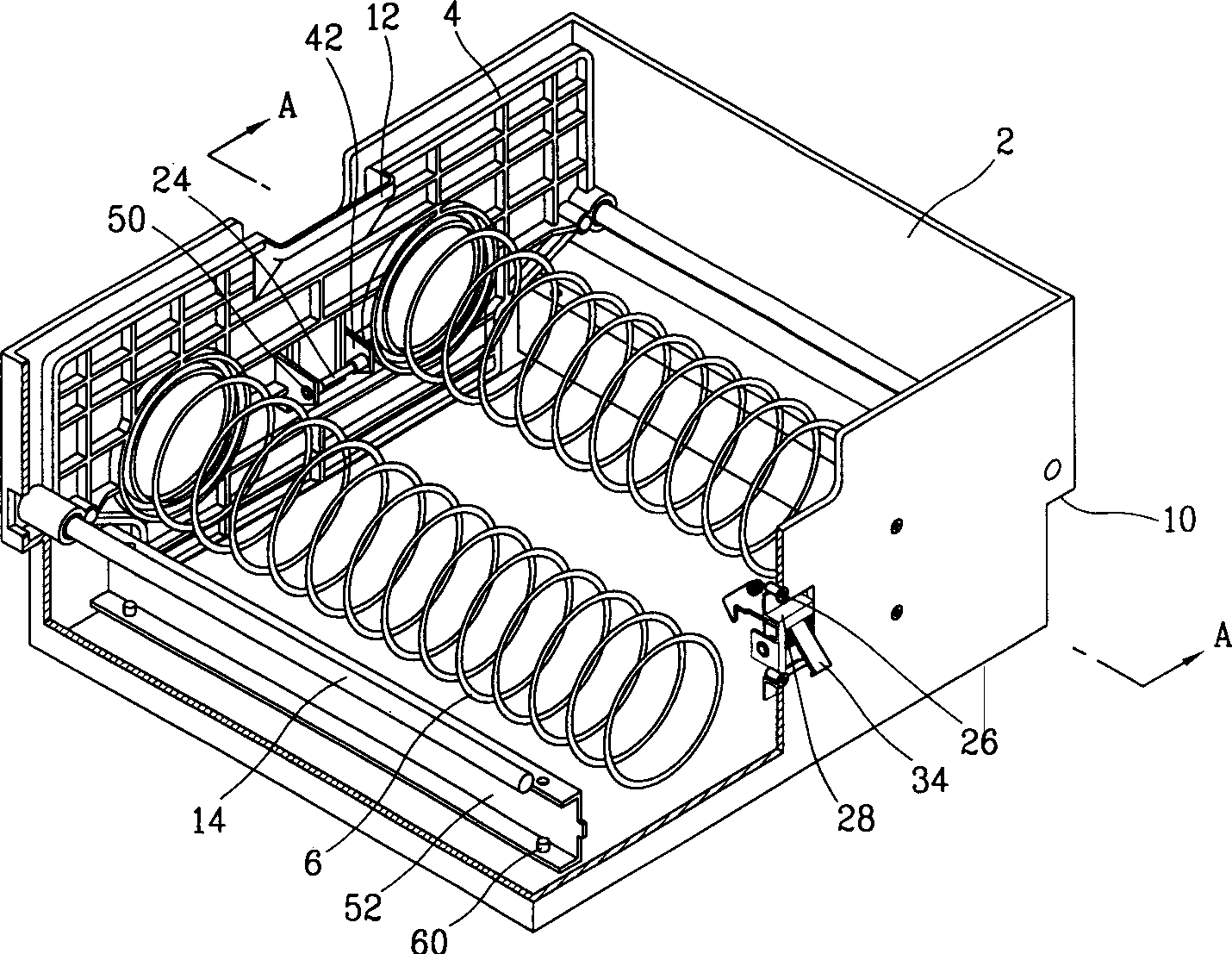

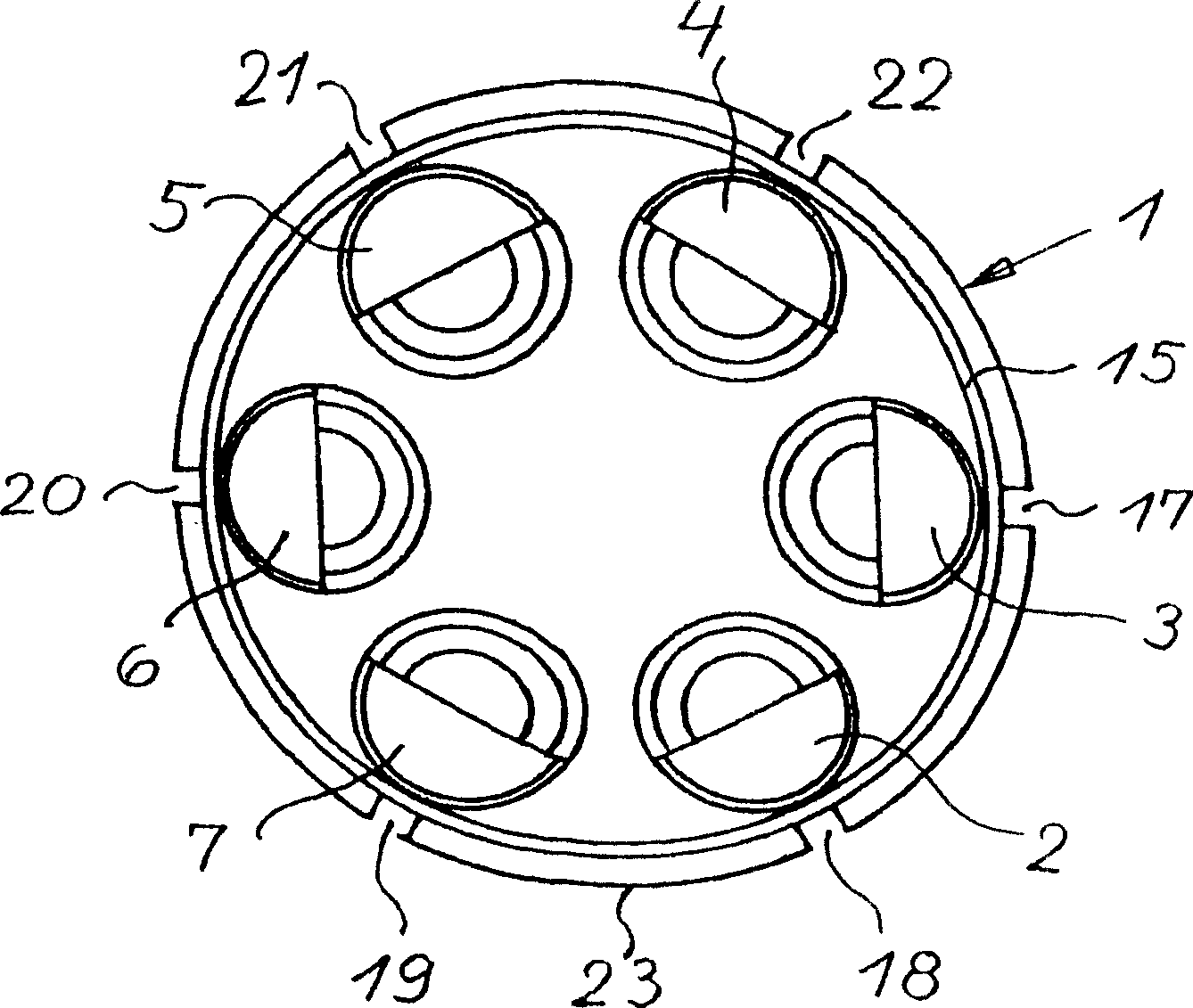

Container packet with holding device especially for steam pressure coffee boiler

Capsule magazine unit having a holding device for capsule magazine unit, into which the capsule magazine unit (1) can be releasably inserted, in particular of an espresso machine, the capsule magazine unit (1) comprising at least one essentially vertical capsule magazine tube (2 to 7) which is suitable for holding coffee capsules (12 to 14) stacked one above another and has a lateral capsule removal opening (8) at the bottom, characterized by a locking ring (15) which is arranged around the capsule magazine unit (1) and can be displaced essentially vertically with respect to the capsule magazine unit (1), and by at least one locking-ring lifting element (16, 16a) on the holding device (9) for the capsule magazine unit, the said lifting element being suitable for acting on the locking ring (15).

Owner:NESTEC SA

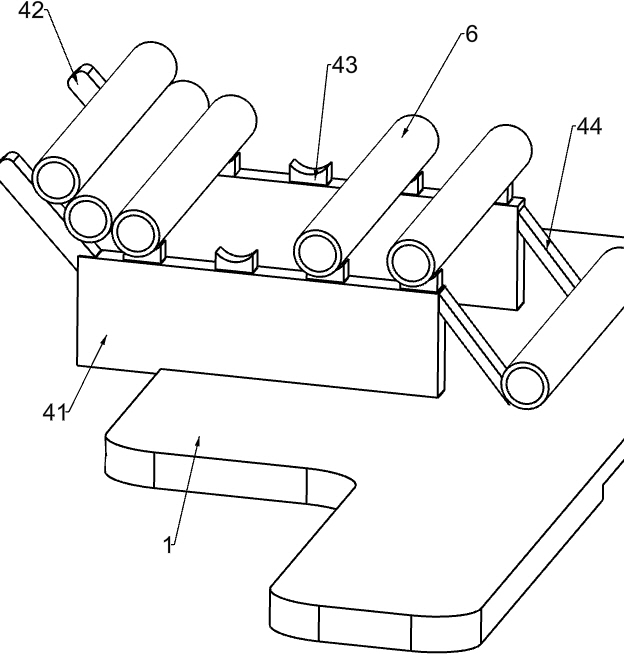

Rotary peeling device for lower part of mulberry fork

ActiveCN112248168AAuto releasePeeled safeFeeding devicesTree debarkingElectric machineryElectric machine

The invention relates to a peeling device, in particular to a rotary peeling device for a lower part of a mulberry fork. The invention provides a rotary peeling device for a lower part of a mulberry fork, which can peel the mulberry fork safely and cannot damage materials. The rotary peeling device for the lower part of the mulberry fork comprises a mounting box body, a feeding pipe, a peeling assembly and a pulling assembly, wherein the feeding pipe is mounted on the mounting box body; the peeling assembly is mounted in the mounting box body; and the pulling assembly is mounted in the mounting box body. According to the rotary peeling device, the mulberry fork is automatically pulled in through the pulling assembly and then peeled through the peeling assembly, so that the effect of automatically peeling the mulberry fork is achieved, and peeling of the mulberry fork is very safe; a gear motor can be automatically controlled to work through a first button, so that the device is more convenient to use; and the mulberry fork can be automatically loosened through a second button, and meanwhile, through rotating scrapers, the situation that the mulberry fork is damaged is avoided whenthe mulberry fork is peeled, so that the manufacturing success rate of the mulberry fork is increased.

Owner:临沂临港国有资产运营集团有限公司

Rolling curtain

InactiveCN101021139BAuto releaseAutomatically put downLight protection screensEngineeringMechanical engineering

The present invention relates to a roller blind. It is characterized by that it is made up by using turning device set on the machine frame, engagement and disengagement device connected together with said turning device and blind fabric spool connected together with engagement and disengagement device.

Owner:朱晓荧

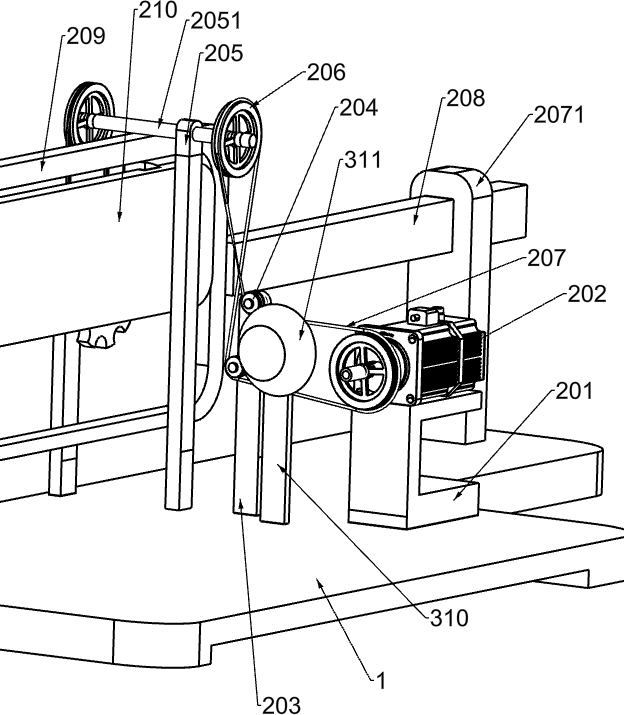

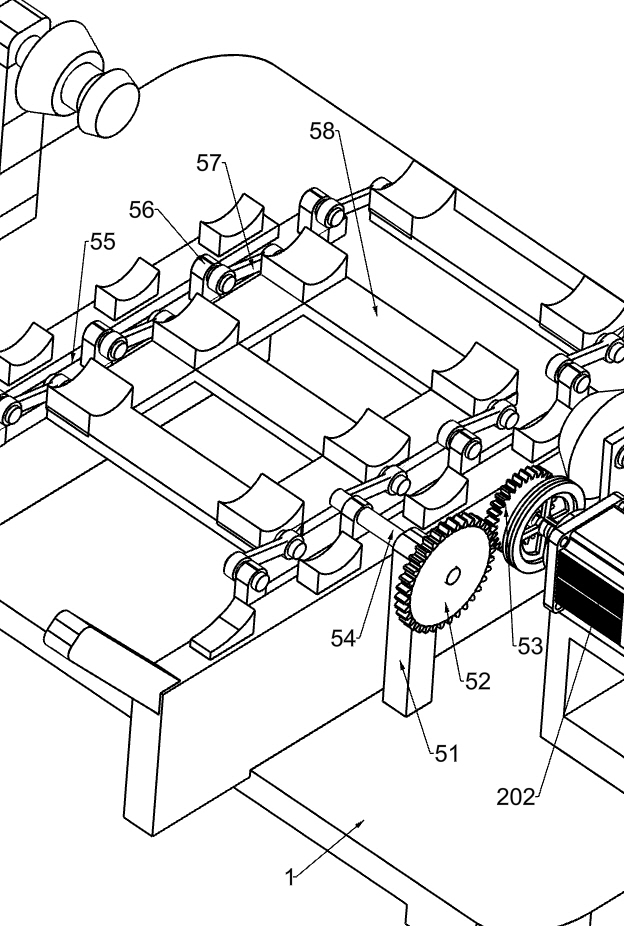

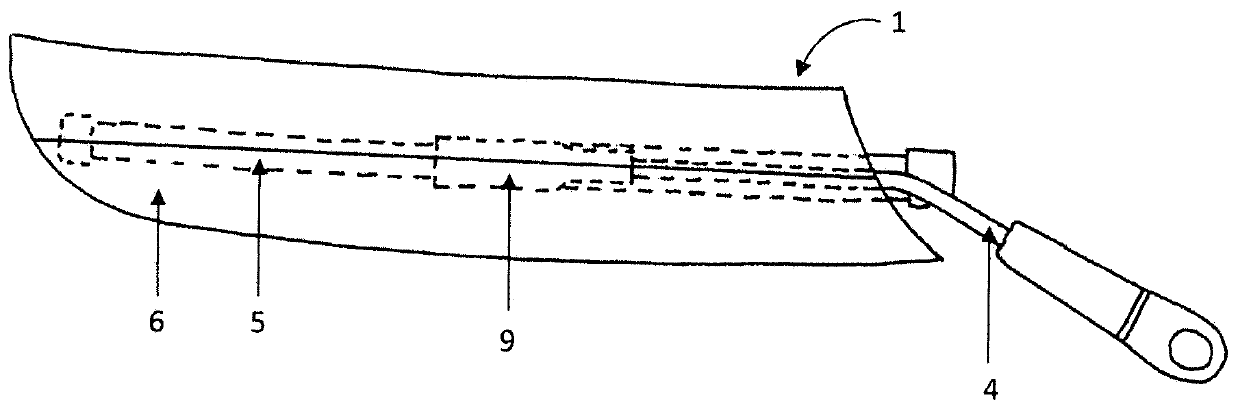

Metal-bar peeler

ActiveCN101912999BIncrease profitIncreased efficiency in the production of metal rodsMetal working apparatusPositioning apparatusEngineeringPower component

The invention provides a metal-bar peeler, belonging to the machine tool technical field. The metal-bar peeler solves the problem that before a metal bar is processed by the existing metal-bar peeler, the front end of a metal bar blank needs to be subjected to head peeling in advance, and then the metal bar can be processed. The metal-bar peeler comprises a rack, a peeling mould and a traction mechanism, wherein, the peeling mould and the traction mechanism are fixed on the rack; a connecting seat which can move along the rack feeding part is arranged on the rack feeding part; a power component which can drive the connecting seat to move is arranged on the rack; a material clamping mechanism which can clamp and loose a metal bar is arranged on the connecting seat; when the power componentdrives the connecting seat to move towards the peeling mould, the metal bar is clamped by the material clamping mechanism, and the head of the metal bar can penetrate the peeling mould to peel the head of the metal bar. The metal-bar peeler can satisfy workpieces which are not subjected to head peeling process in advance, thus having the advantage of improving the production efficiency of metal bars and the utilization rate of metal bar blanks, and having simple structure and reasonable design.

Owner:TAIZHOU JINGHUA ENVIRONMENTAL PROTECTION EQUIP

An intelligent heating desk

ActiveCN105996472BAuto releaseSuitable learning temperatureSchool benchesFeetElectricityBiochemical engineering

The invention discloses a smart heating desk. The smart heating desk comprises a desk main body and a desk panel which is fixedly arranged on the desk main body, wherein a control panel is arranged on the desk panel; buffer supporting legs are arranged at four corners of the bottom of the desk main body; the desk panel is of a hollow platy structure; a heating device is arranged inside the desk panel and is electrically connected with the control panel; a file supporting frame is arranged at the lower part of the desk panel; the file supporting frame is arranged at the lower part of the desk panel through supporting frame sliding rails arranged on the desk main body in a sliding manner; a drawer with an electronic lock is also arranged at the right side of the file supporting frame; the electronic lock of the drawer is a fingerprint electronic lock. The smart heating desk is provided with the heating device which can automatically release the heat and provides a proper study temperature for students concentrating on writing and reading; in addition, the heating device is intelligently controlled. The smart heating desk is simple in structure and is easy to mount and produce.

Owner:赣州市国鼎家具有限公司

Method for preparing coated sustained-release calcium fertilizer from waste seafood shell

InactiveCN105399523AAuto releaseSave resourcesAnimal corpse fertilisersLayered/coated fertilisersCalcium in biologyFiltration

The invention relates to a method for preparing coated sustained-release calcium fertilizer from a waste seafood shell, which belongs to the field of preparation of sustained-release calcium fertilizer. The method provided by the invention is directed at the problems of soil hardening caused by excessive application of calcium fertilizer and difficulty in absorption of common bio-calcium and comprises the following steps: desalinating the waste seafood shell; then carrying out alkaline hydrolysis and pumping filtration so as to prepare seafood chitosan; preparing a sustained-release coating material from seafood chitosan; and coating treated bio-calcium. The sustained-release calcium fertilizer prepared in the invention can be automatically realized in soil and has an action period of 15 to 30 d; and through preparation of the fertilizer from the waste seafood shell, resources are saved, and greenness and environmental protection are realized.

Owner:CHANGZHOU UNIV

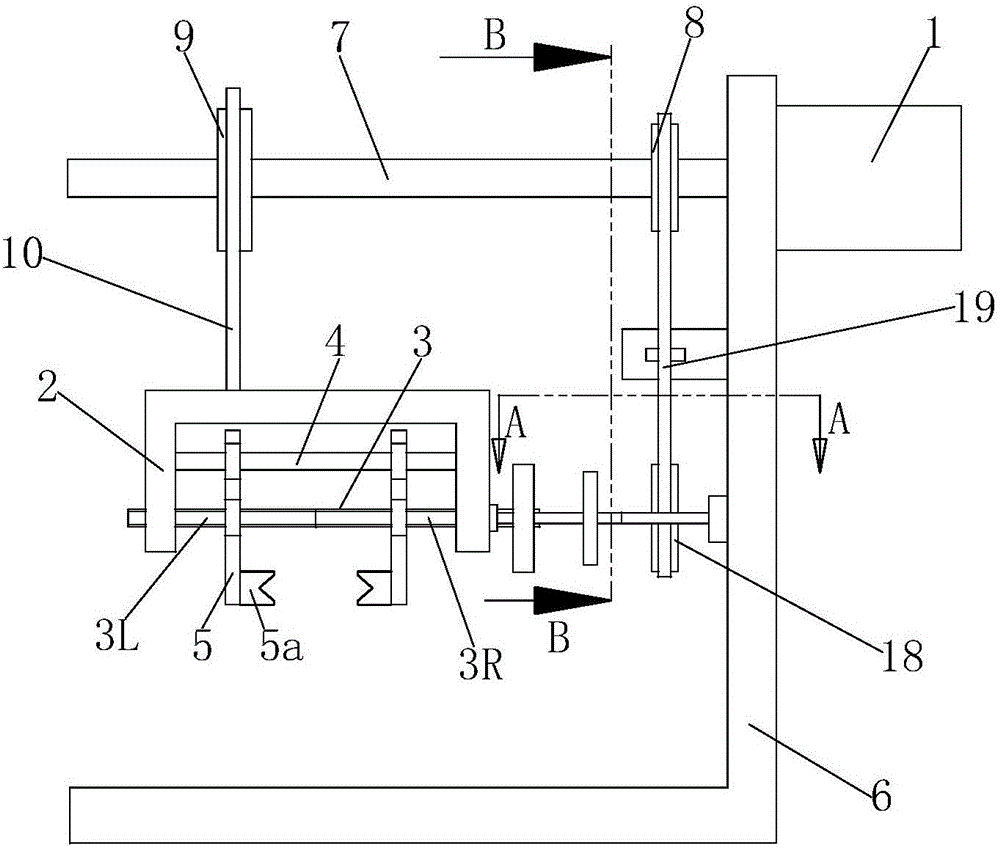

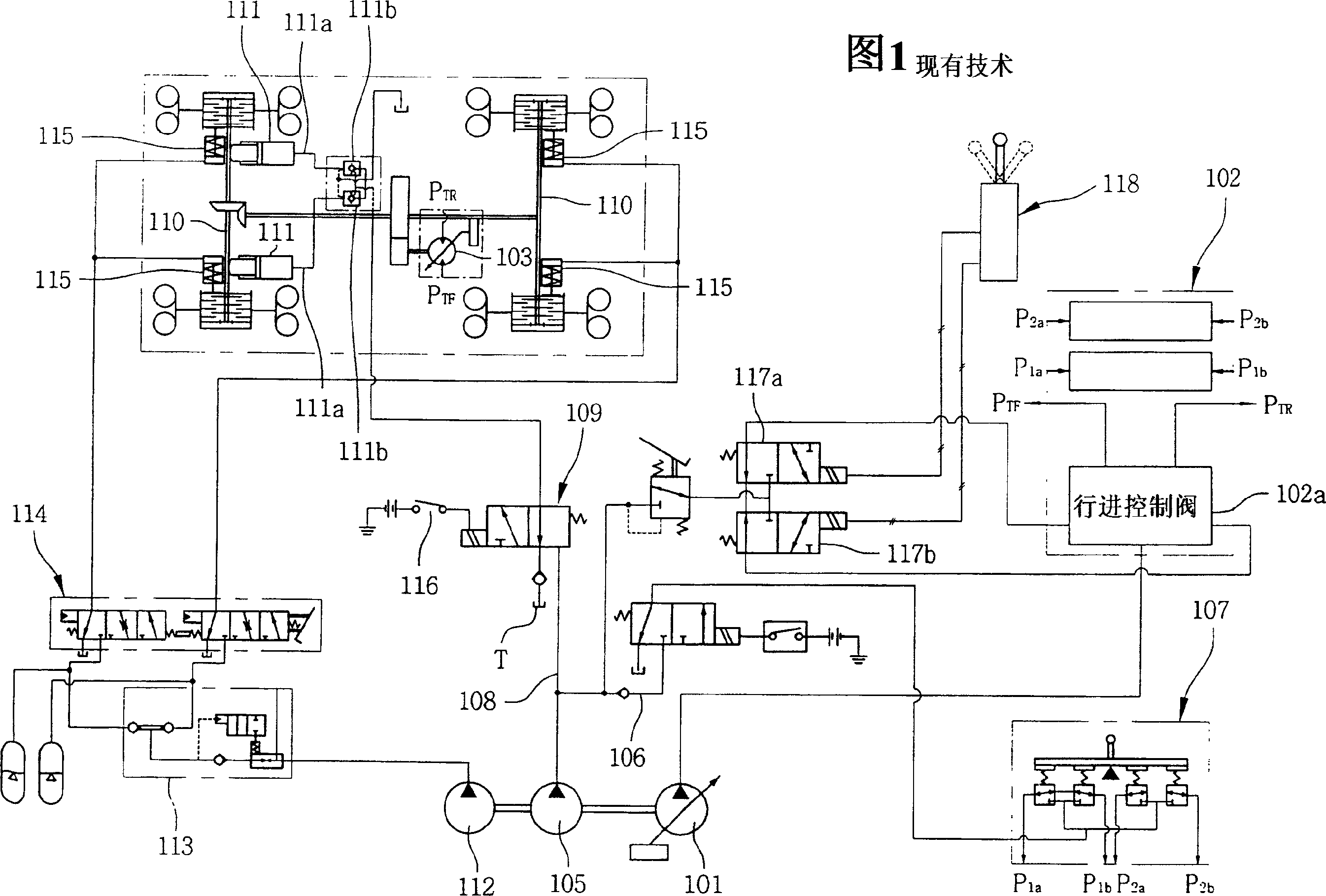

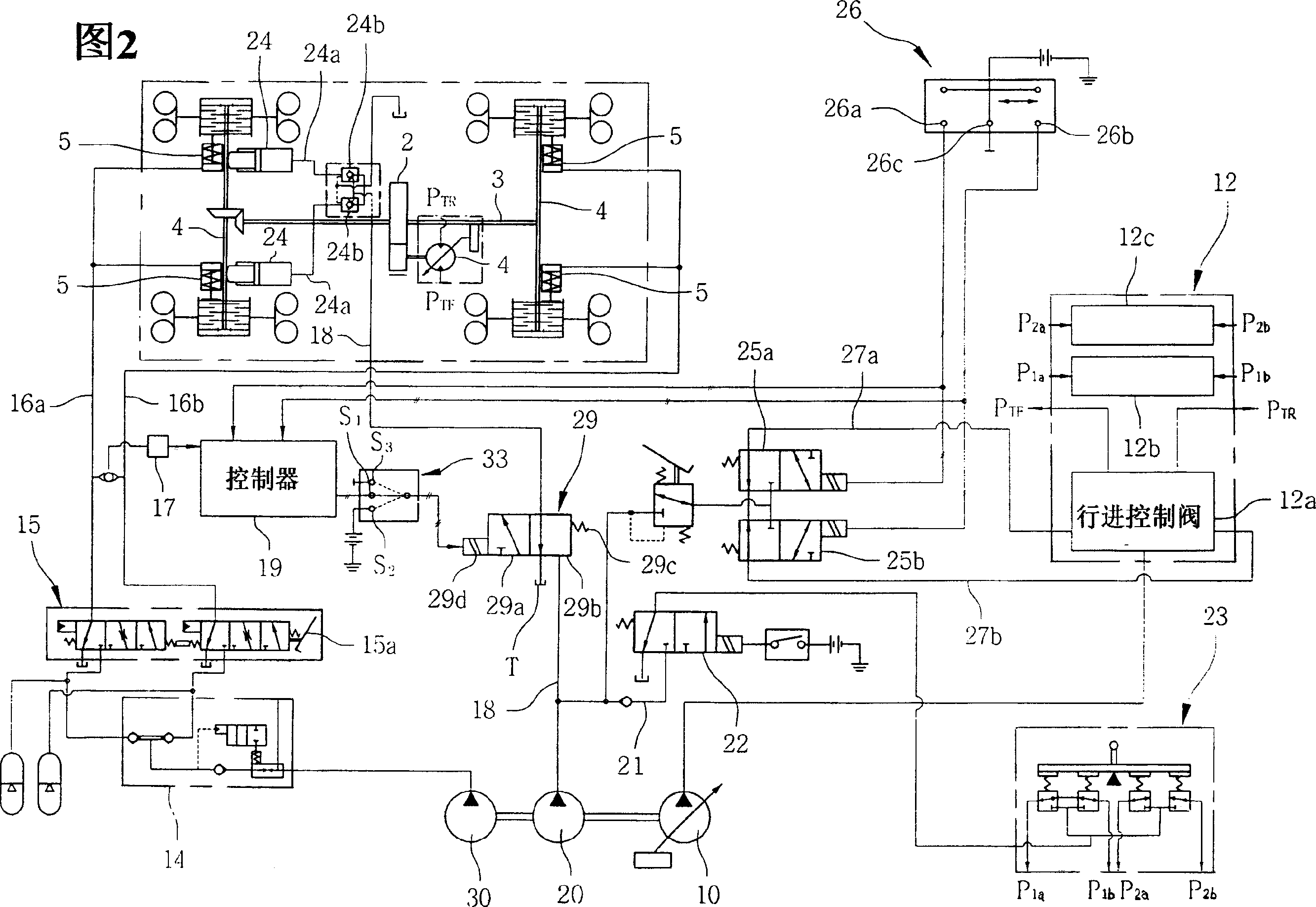

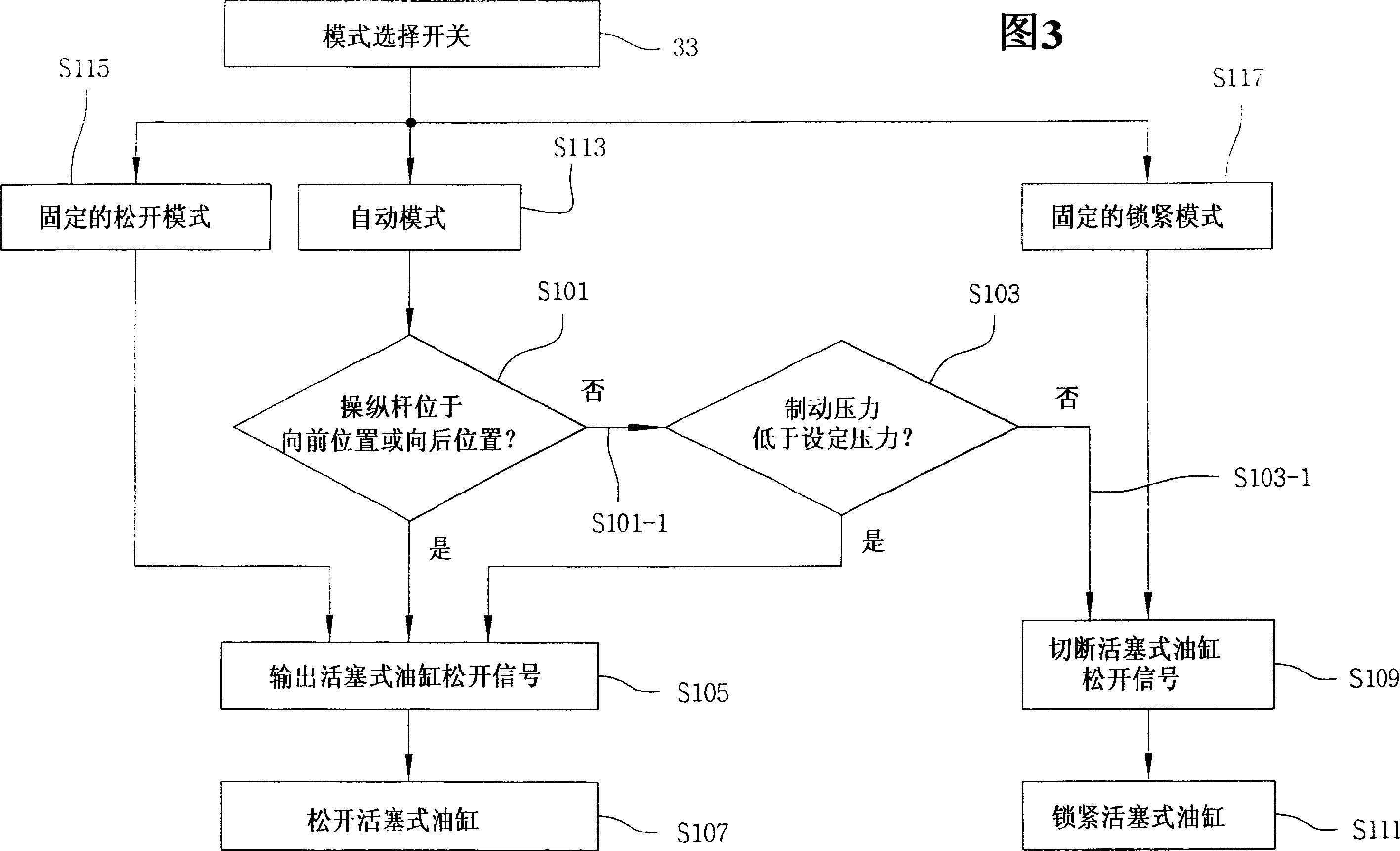

Ram cylinder control system for wheel type excavator

ActiveCN1637211AAutomatic lockingAuto releaseMechanical machines/dredgersServomotorsJoystickControl signal

A piston cylinder control system for a wheeled hydraulic excavator, comprising: an auxiliary hydraulic pump; an auxiliary opening check valve locking the piston cylinder; a piston cylinder control valve adapted to respond to a valve control signal from an original The position is switched to the operating position to allow the hydraulic oil from the auxiliary hydraulic pump to open the check valve so that the hydraulic oil can be discharged from the piston cylinder; the brake pressure sensor is used to detect the hydraulic oil pressure supplied to the brake device; the joystick position detection controller for detecting the position of the joystick to generate one of a forward position signal, a rearward position signal and a neutral signal; and a controller, if a forward position signal or a rearward position signal is received and if the brake pressure If it is not greater than the set pressure, the controller applies the valve control signal to the piston cylinder control valve, if it receives a neutral signal and if the brake pressure exceeds the set pressure, the controller cuts off the application to the piston cylinder control valve valve control signal.

Owner:DOOSAN INFRACORE CO LTD

Treatment device for drinking water prepared from natural minerals

PendingCN108285179AEfficient activationAuto releaseWater/sewage treatment by irradiationTreatment involving filtrationPolyvinyl alcoholNatural mineral

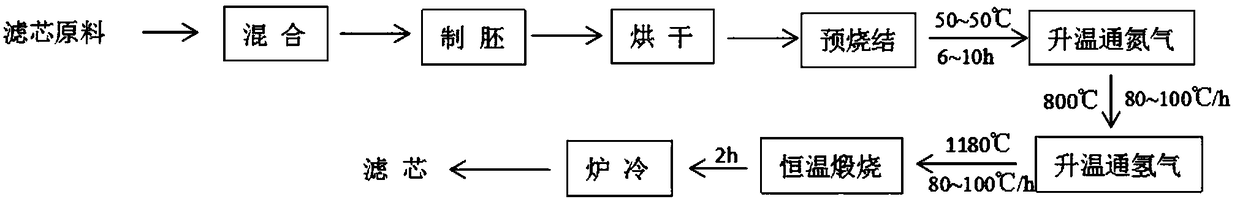

The invention discloses a treatment device for drinking water produced prepared from natural minerals. The treatment device comprises a tray and a filter arranged at the bottom of the inner side of the tray, wherein the filter comprises a water diversion top column and a filter element; the filter element is arranged inside a groove in the water diversion top column. A production method of the treatment device comprises the following steps: firing the tray, firing the water diversion top column and firing the filter element, wherein the filter element is fired from the following raw materialsin parts by weight: 50 parts of tourmaline, 50-100 parts of kaolin, 10-25 parts of zinc oxide, 8-15 parts of polyvinyl butyral, 2-5 parts of polyacrylic acid, 5-15 parts of sodium hydrogen carbonate and 15-35 parts of water. The problems that the existing drinking water device is difficult to clean and short in service life and easily causes secondary pollution are solved; and the drinking water treatment device has the functions of activating water, removing chlorine gas from water and releasing trace elements.

Owner:台州市御津坊家政服务有限公司

A kind of glass fiber cloth quantitative shearing equipment

The invention relates to a shearing device, in particular to a quantitative shearing device for glass fiber cloth. Provided is a quantitative shearing device for glass fiber cloth that can automatically cut, has high work efficiency, and has good cutting quality. A glass fiber cloth quantitative shearing equipment, comprising: a bottom plate; a material clamping component, which is installed on the bottom plate, and the material is clamped by sliding; a pushing component, which is installed on the bottom plate and is pushed by sliding; a cutting component, installed on the On the base plate, the cutting is made by sliding. In the present invention, other components can be installed through the bottom plate, the glass fiber cloth roll that needs to be cut quantitatively can be placed through the clamping component, the glass fiber cloth can be moved for quantitative cutting by pushing the component, the glass fiber cloth can be cut through the cutting component, and the automatic The advancing and retreating component can provide power when cutting the glass fiber cloth quantitatively, and the glass fiber cloth can be automatically cut through the automatic cutting component.

Owner:CHANGZHOU QUNFENG GLASSFIBER

Water-absorption-type temperature lowering particles and preparation method thereof

The invention discloses water-absorption-type temperature lowering particles. The water-absorption-type temperature lowering particles are prepared from, by weight, 20%-80% of polyacrylic acid, 20%-80% of acrylamide and oxyalkylene additives, wherein the weight of the oxyalkylene additives accounts for 2%-5% of the total weight of the polyacrylic acid and the acrylamide. A preparation method of the water-absorption-type temperature lowering particles comprises the following steps of heating stirring, temperature rising stirring, temperature rising reacting and cooling screening. According to the prepared crystal polymers, water absorption is super high and can be more than 1000 times, the crystal polymers can automatically absorb water at room temperature, water cannot be overflowed from the crystal polymers at room temperature even if pressure is exerted, the retainability is super high, and a small quantity of the crystals are absorbed under certain pressure and cannot be broken; the heat conductivity coefficient is improved, heat is automatically absorbed and dissipated, and cool air is automatically released to generate the temperature lowering effect.

Owner:CIXI LINGDONG ELECTRONICS TECH

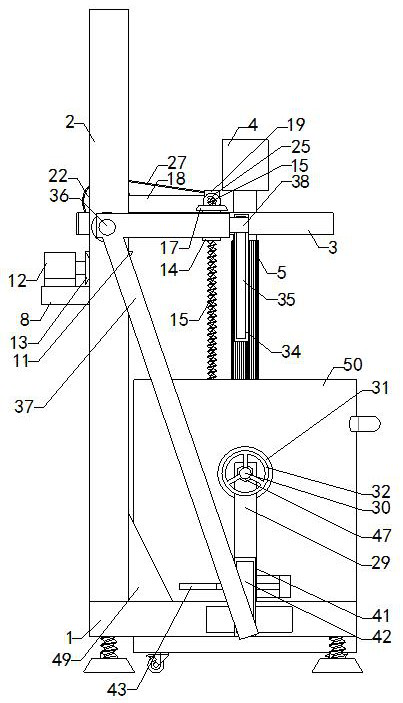

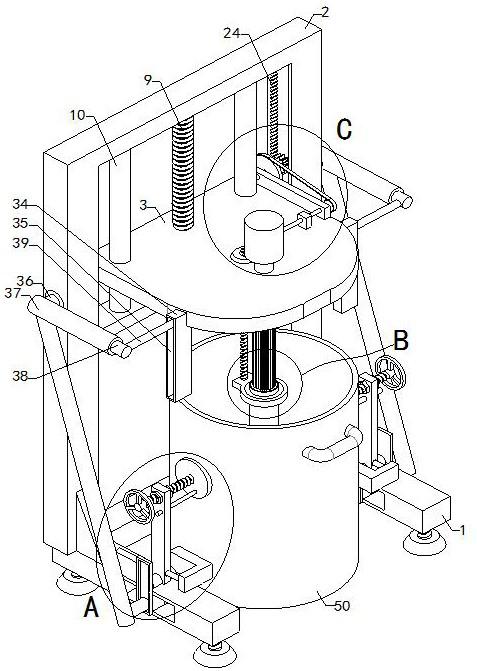

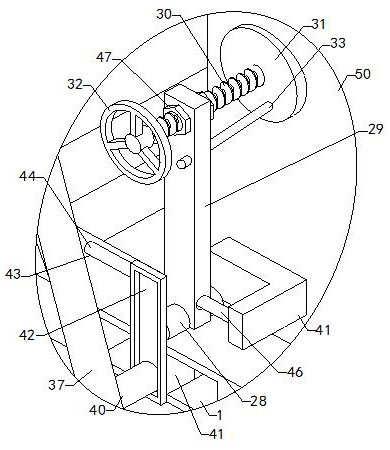

Novel stirring dispersion machine for chemical industry

InactiveCN113578121AAutomatic clampingAuto releaseRotary stirring mixersMixer accessoriesPhysicsChemical industry

The invention relates to the technical field of dispersion machine accessory devices, in particular to a novel stirring dispersion machine for chemical industry, which is simple in structure, the overall height of the device is greatly reduced, a dispersion barrel can be automatically clamped and fixed, the use steps are simplified, the cost is reduced, and the use limitation is reduced. The machine comprises a whole support, wherein the whole support is used for installing a device whole body, comprises a transverse door-shaped first frame body and a door-shaped second frame body which is vertically fixed to the top of the first frame body, and adjusting seats are arranged at the four corners of the bottom of the first frame body; a lifting mechanism which is mounted on the second frame body, wherein a lifting plate is mounted at the output end of the lifting mechanism, a first motor is fixed on the lifting plate, a spline shaft is arranged at the output end of the first motor, a stirring shaft is slidably mounted on the spline shaft, and a dispersing paddle is mounted at the bottom of the stirring shaft; a telescopic mechanism which is used for driving the spline shaft and the stirring shaft to slide relatively; two clamping mechanisms which are slidably mounted on the front side and the rear side of the first frame body and located on the two sides of the dispersion barrel; and a driving mechanism.

Owner:刘莎

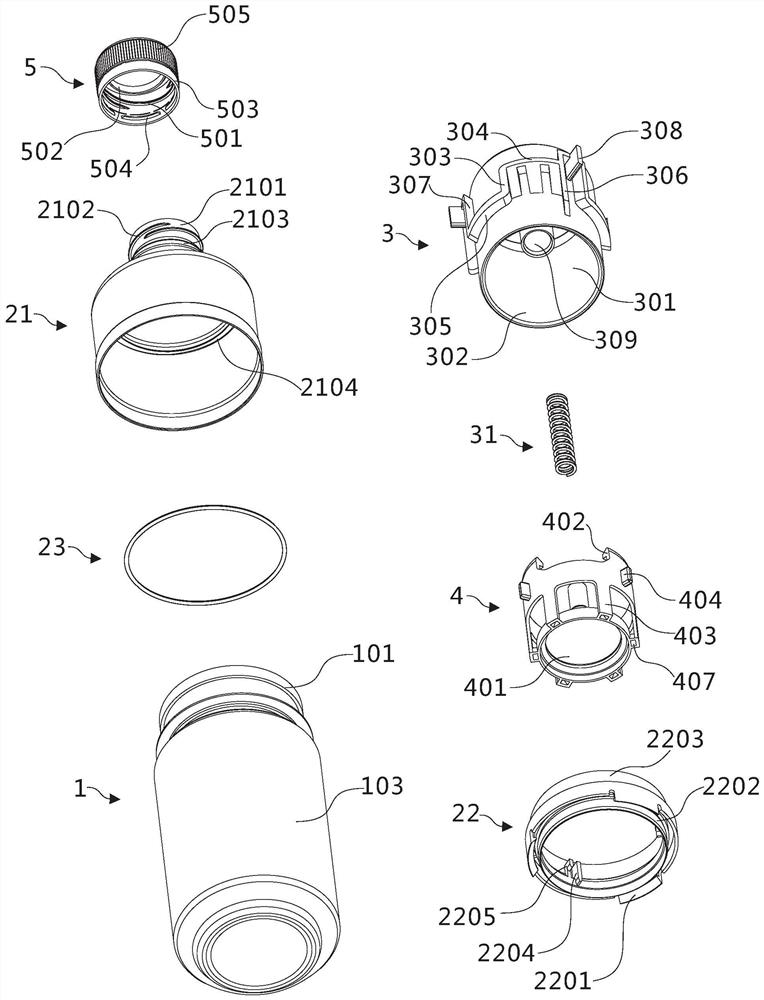

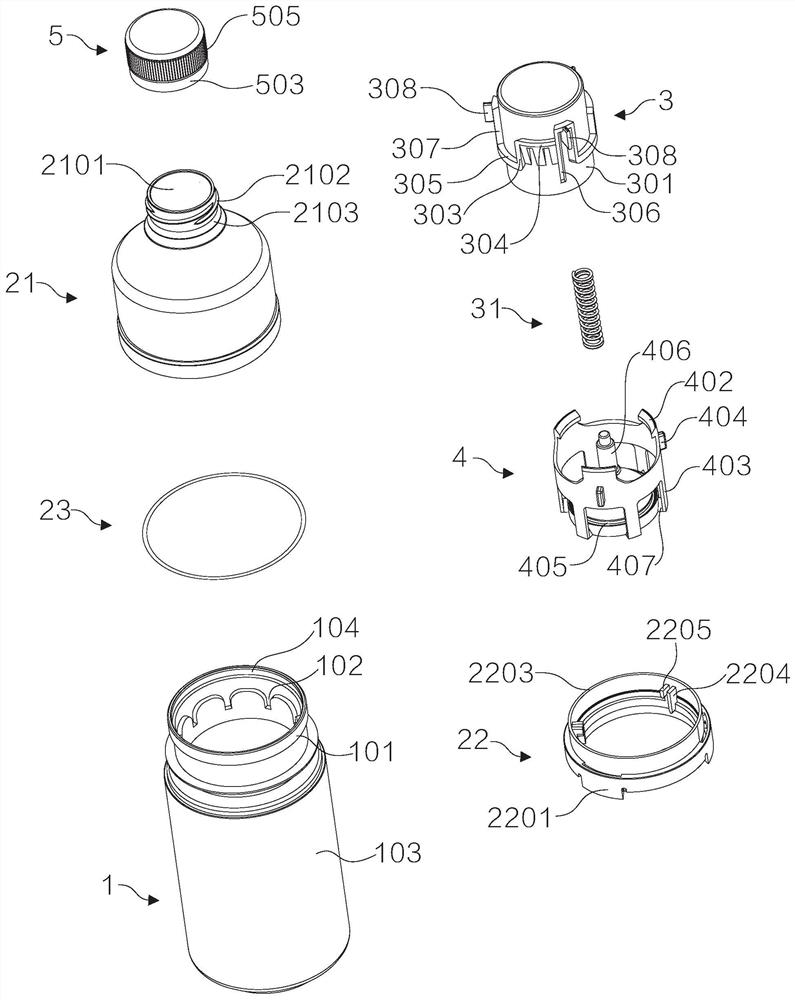

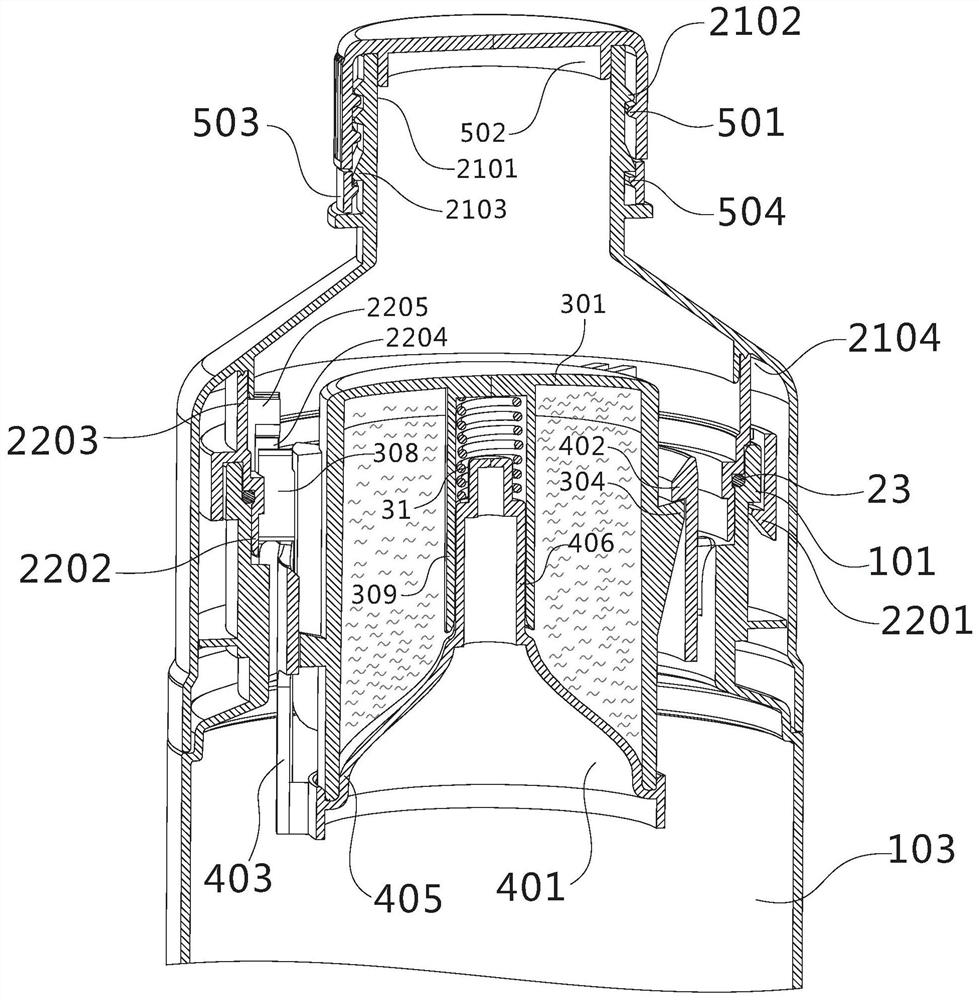

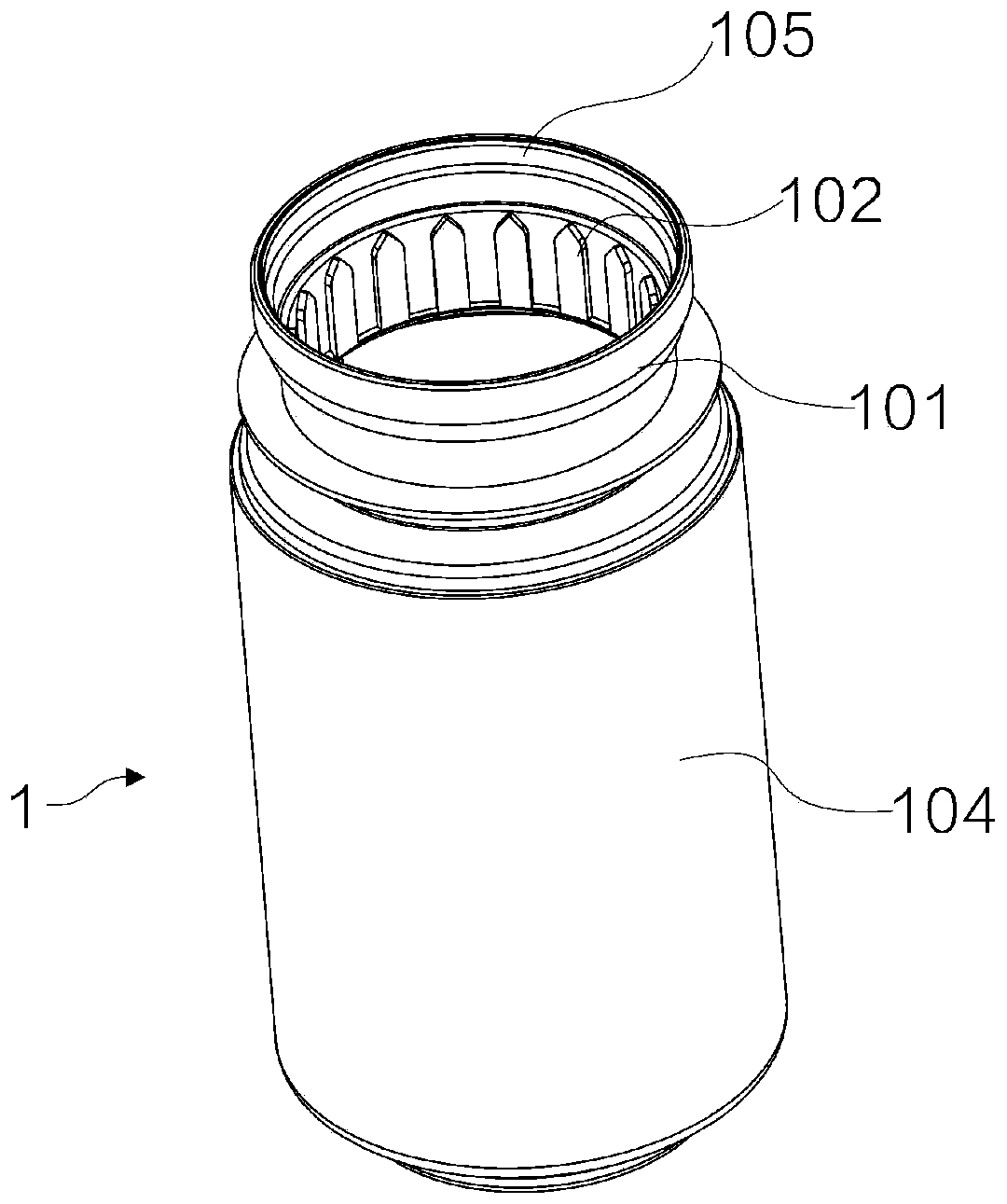

Container sealing device with fixed hanging plug sealing and releasing functions, packaging container and application thereof

PendingCN113371333ATo achieve the role of automatic deploymentEasy to usePackage recyclingClosure with auxillary devicesEngineeringMechanical engineering

The invention discloses a container sealing device arranged on the neck of a container. The device comprises a covering surrounding component, a material cavity component and a hanging plug component, the covering surrounding component and the container can rotate relative to each other, longitudinal displacement occurs between the covering surrounding component and the material cavity component, and the hanging plug component and the neck of the container are relatively fixed; the container sealing device is arranged on a neck structure arranged at the top or the bottom of the container to form a packaging container; and before the packaging container is opened, by rotating the covering surrounding component, longitudinal displacement occurs between the material cavity component and the hanging plug component, then an opening of the material cavity structure is opened, and materials in the material chamber structure can be released into the container, so that the closed storage and release blending functions of the container sealing device are realized. According to the container sealing device, industrial production and material filling are easy, the control experience feeling is good, and the application range is wide. The invention further provides components of the container sealing device, a material storing and releasing device, the packaging container and application thereof.

Owner:福建奥正投资发展有限公司

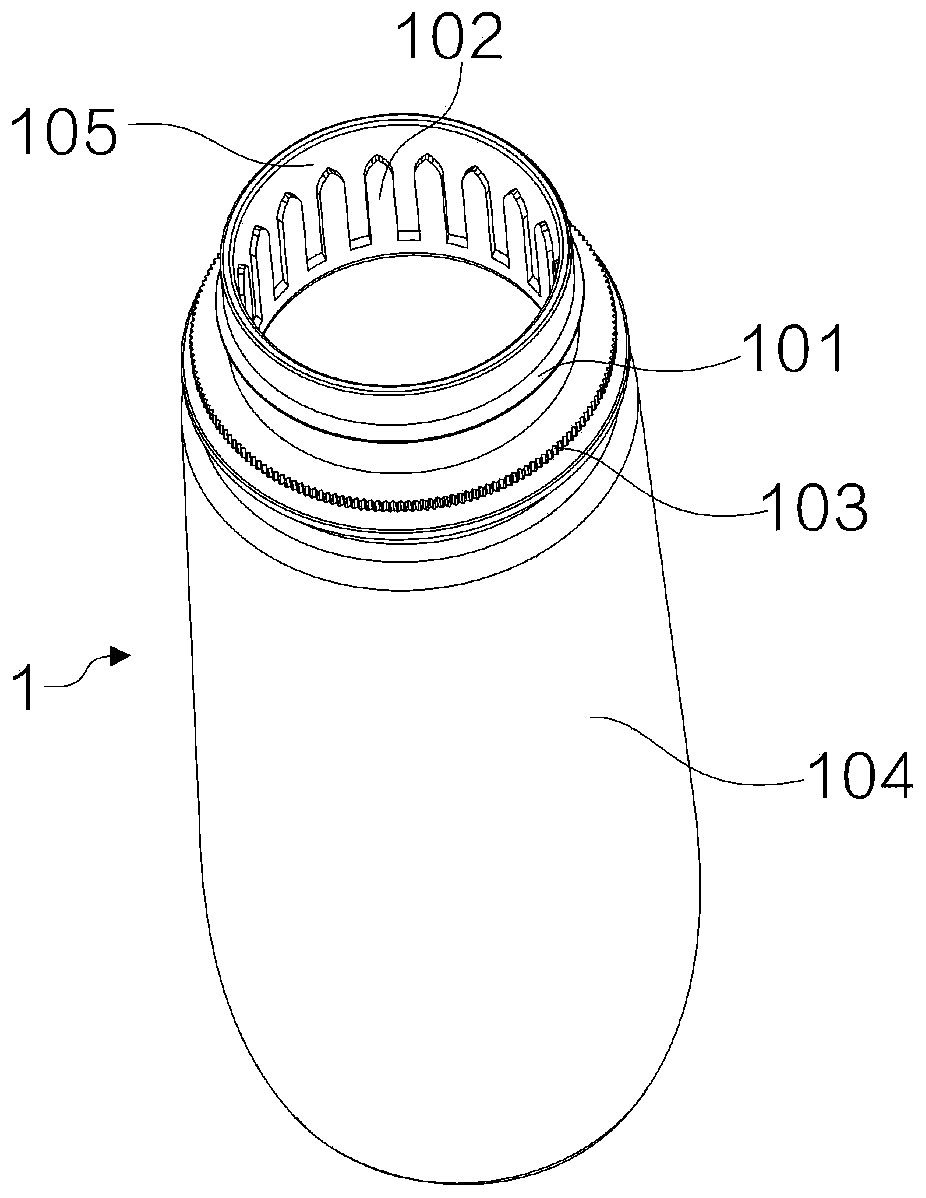

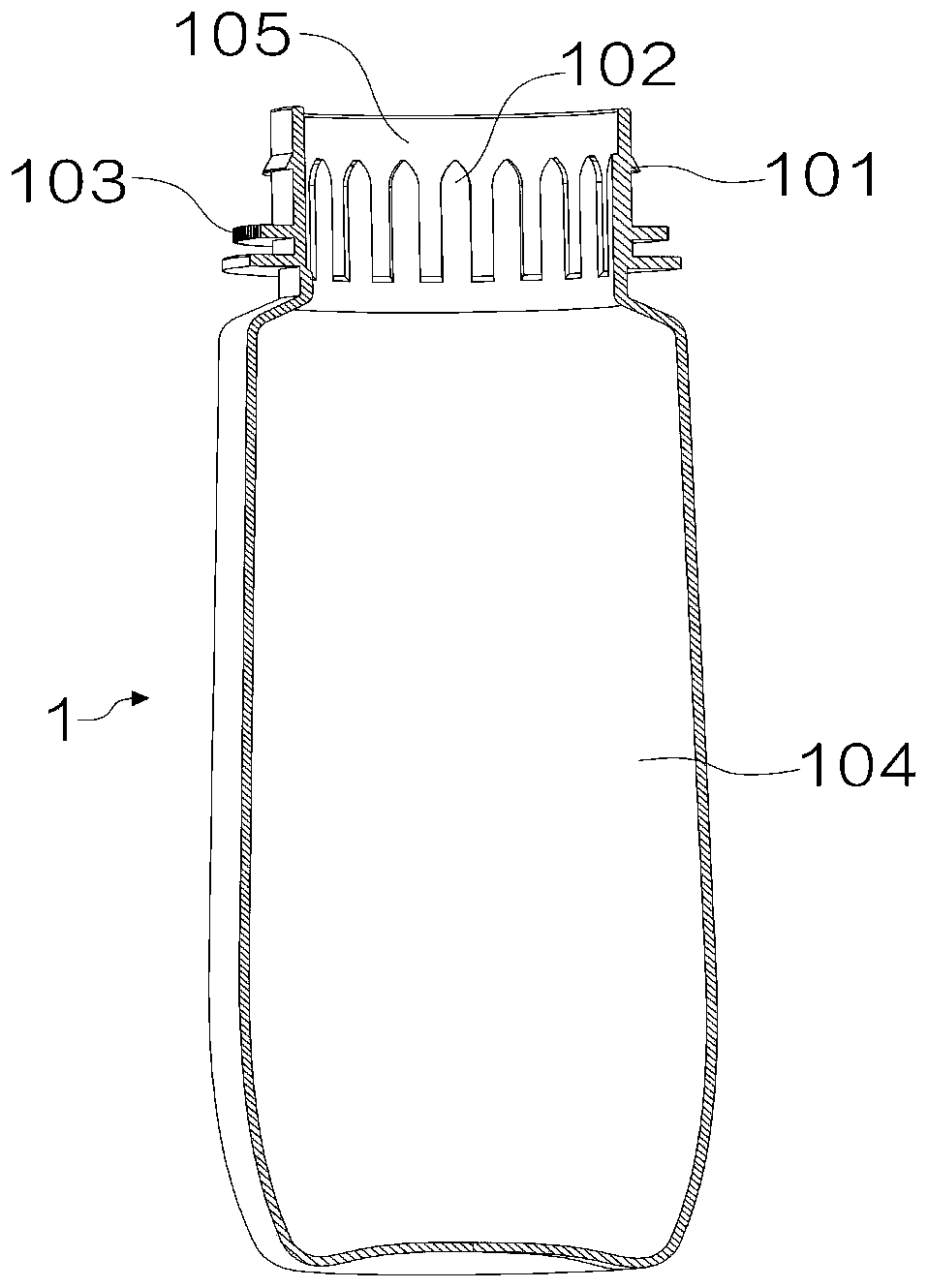

Container and bottle perform thereof as well as application

PendingCN111377103ATo achieve the role of automatic deploymentEasy to useCapsClosure capsBlow moldingBottle

The invention discloses a container. A buckle or threads are arranged on the outer wall of the neck of the container, a convex-concave structure is arranged on the inner wall of the neck of the container, the neck of the container is arranged at the top of the container, or the neck of the container is arranged at the bottom of the container, a opening is formed in the top of the container as well, the container is made of a high polymer material, glass, metal, ceramic, an aluminum-plastic composite material or a paper-plastic composite material, the container can be formed by assembling together individual parts of the neck of the container and a main body chamber of the container. The invention further provides a bottle perform for preparing the container, the bottle perform can be prepared into the container made of the high polymer material through a blow molding process. According to the container and the bottle perform thereof as well as the application, the container can satisfya container sealing device matching with the container, so that the container sealing device has the functions of sealing, storing and releasing materials, and the container sealing device can seal the container provided by the invention to form a packaging container.

Owner:福建奥正投资发展有限公司

Antirust oil smearing device for concrete cutting saw blade edge

The invention relates to a coating device, in particular to a rust-proof oil coating device for the edge of a concrete cutting saw blade. The technical problem to be solved is to provide a rust-proof oil coating device for the edge of the concrete cutting saw blade, which can coat the concrete cutting saw blades of different sizes with anti-rust oil and improve the working efficiency. An anti-rust oil coating device for the edge of a concrete cutting saw blade, including a mounting frame, a mounting plate, a rotating component, a fixing component, a brushing component, etc.; the top of the mounting frame is provided with a mounting plate, and the mounting plate is provided with a power supply through a motor The rotating assembly is rotated, and the rotating assembly is provided with a fixed assembly for fixing the concrete cutting saw blade by means of lifting. By rotating the assembly, the invention only needs to place the saw blade on the circular plate, and then the anti-rust oil can be applied to the plurality of saw blades, which not only speeds up the speed of applying the anti-rust oil to the saw blades, but also increases the speed of applying the anti-rust oil to the saw blades. Anti-rust oil is safer.

Owner:JIANGXI JIANDE IND

Short-distance automatic carrying device for rectangular plates

The invention relates to a short-distance automatic carrying device for rectangular plates. The short-distance automatic carrying device comprises a main lifting plate, the upper end of the main lifting plate is provided with a horizontal slot, the horizontal slot is internally and slidably provided with a movable bearing seat, the movable bearing seat is connected with a main mandrel, the upper portion and the lower portion of the main mandrel are provided with a movable pulley and clamping equipment correspondingly, and the clamping equipment comprises a motor connected with the main mandrel; and the front of the left side of the main lifting plate is provided with a cable in a fixed manner, the rear portion of the left side of the main lifting plate is provided with a fixed pulley in a rotary manner, and the extension portion of the cable extends leftwards to penetrate through the fixed pulley in a surrounding manner and then extends rightwards to be arranged on the fixed pulley in a surrounding manner. The short-distance automatic carrying device is high in automated degree, on the basis of achieving horizontal conveying through match between the movable pulley and the fixed pulley, the rectangular plates can also be grabbed automatically and released automatically after being transported to the destination, and the short-distance automatic carrying device has the effects that control and transport are convenient, and manpower is saved.

Owner:芜湖思科生产力促进中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com