Patents

Literature

46results about How to "Automatic drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

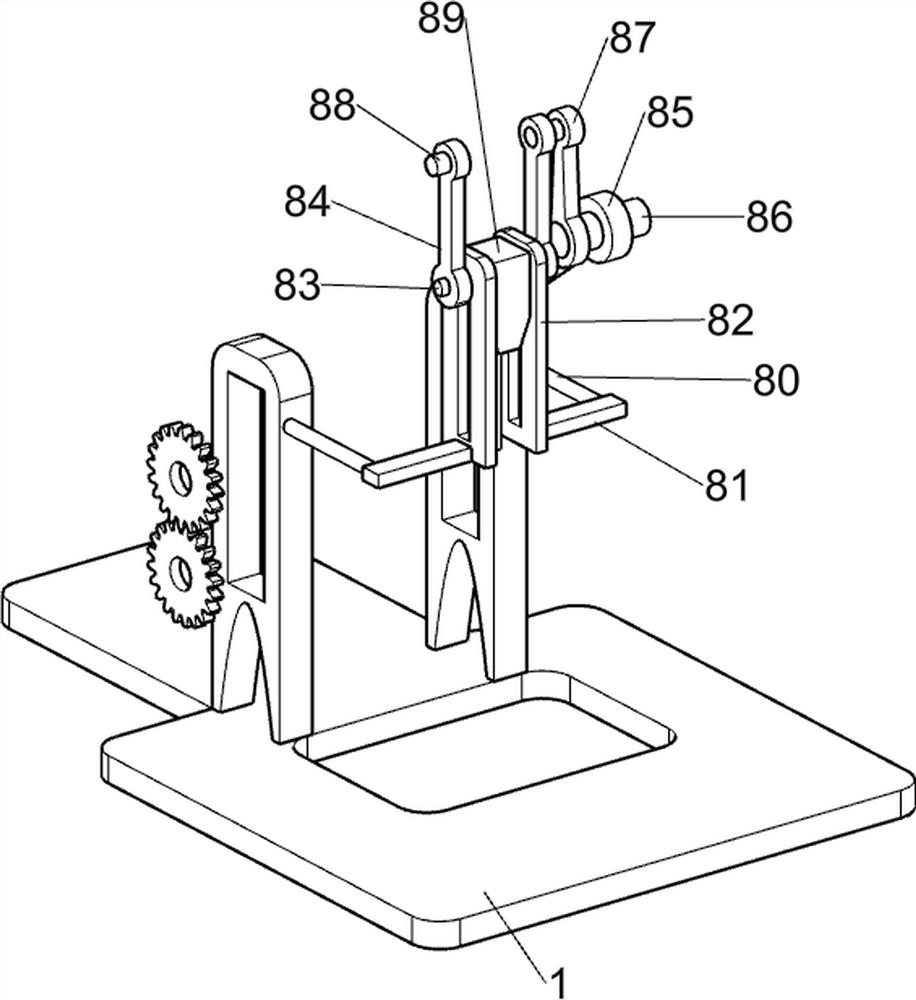

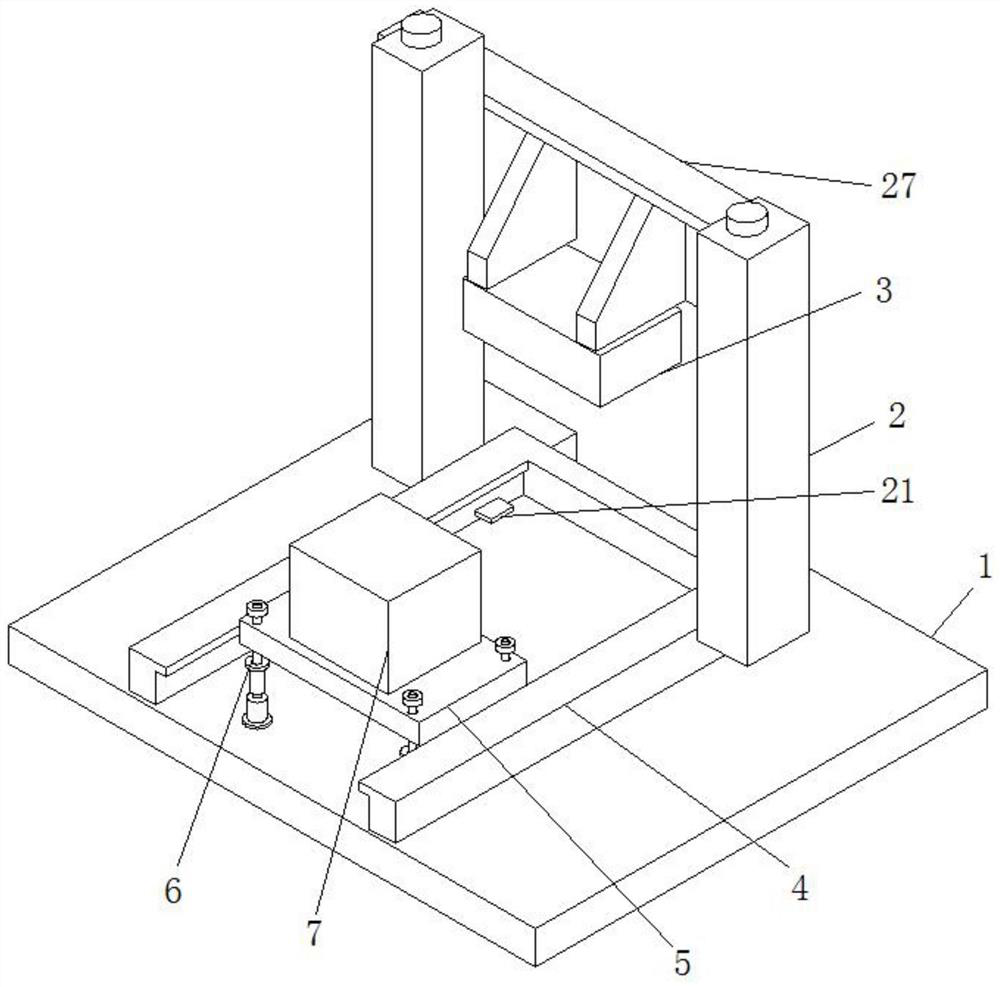

Cardboard printing equipment

The invention relates to printing equipment, in particular to cardboard printing equipment. The cardboard printing equipment provided is good in stamping effect and capable of greatly improving the working efficiency. The cardboard printing equipment comprises a bottom plate, a first bearing seat, and a first rotating shaft. A servo motor is installed on one side of the top of the bottom plate; the first bearing seat is mounted on the side, close to the servo motor, of the top of the bottom plate; and the first rotating shaft is arranged inside the first bearing seat in a rotating mode. According to the cardboard printing equipment, the effects that the stamping effect is good, and the working efficiency can be greatly improved are achieved. A crank is driven by a third rotating shaft to continuously rotate, so that a fifth connecting rod and a pressing block are driven to move downwards, so as to make a stamper move downwards to print a cardboard.

Owner:吴梅娇

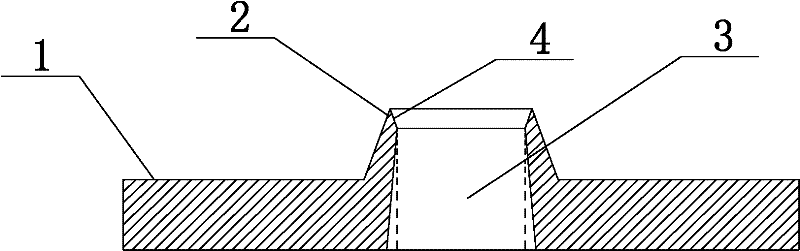

Etching knife die and processing method thereof

ActiveCN102632520AWill not deformDoes not cause deformationMetal working apparatusNumerical controlMilling cutter

The invention discloses an etching knife die comprising a template and one or more knife arranged on the template, wherein a knife edge is arranged on the knife; the cross section of a blanking hole below the knife is trapezoidal; and the lower-end diameter of the blanking hole is greater than the upper-end diameter of the blanking hole. The invention also discloses a processing method of the etching knife die. The method comprises the steps of cutting to form a vertical blanking hole by utilizing a milling cutter through a CNC (Computer Numerical Control) precision carving machine and carrying out turn-by-turn downward expanding cutting from top to bottom on the inner wall of the straight hole by utilizing a dovetail cutter through the CNC precision carving machine to ensure that the cross section of the inner wall of the blanking hole is of a trapezoid which is small in upper part and big in lower part, wherein the included angles of the side edges and the bottom face of the trapezoid are 78-89 DEG. The etching knife die and the processing method thereof, disclosed by the invention, have the advantages that automatic waste discharge can be realized; the blanking piece is avoided being pulled when passing through the blanking hole to ensure that the blanking is smooth, the knife die is not pressed, the deformation and the breakdown of the etching knife die are not created; therefore, the product accuracy can be increased and the service life of the knife die is prolonged.

Owner:陈泳泳

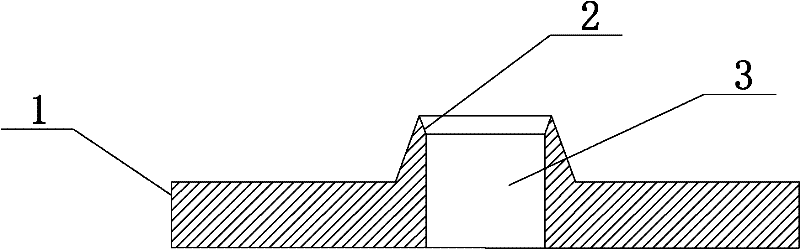

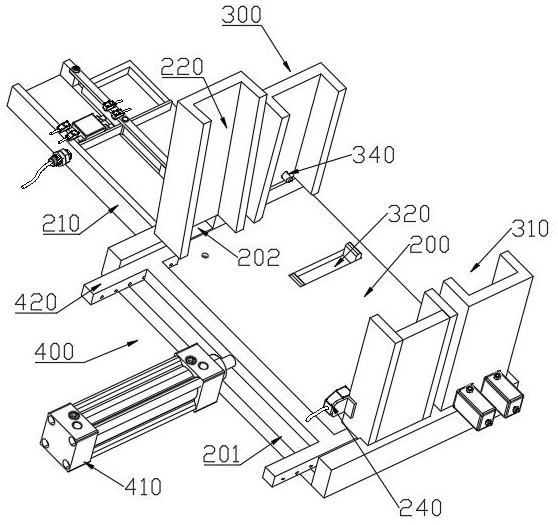

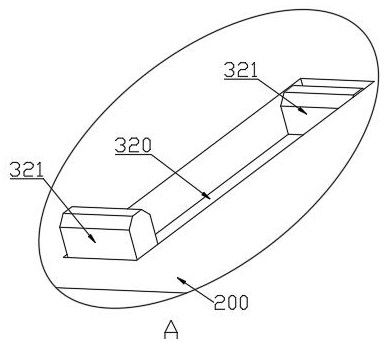

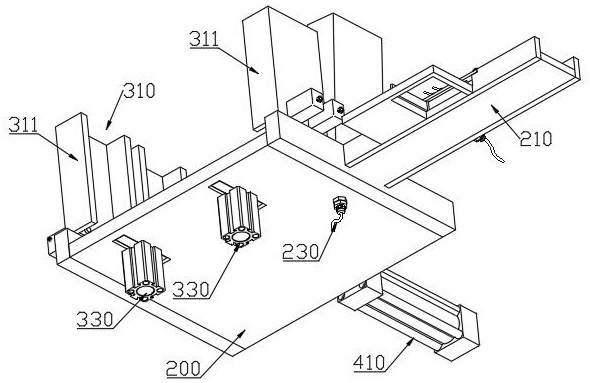

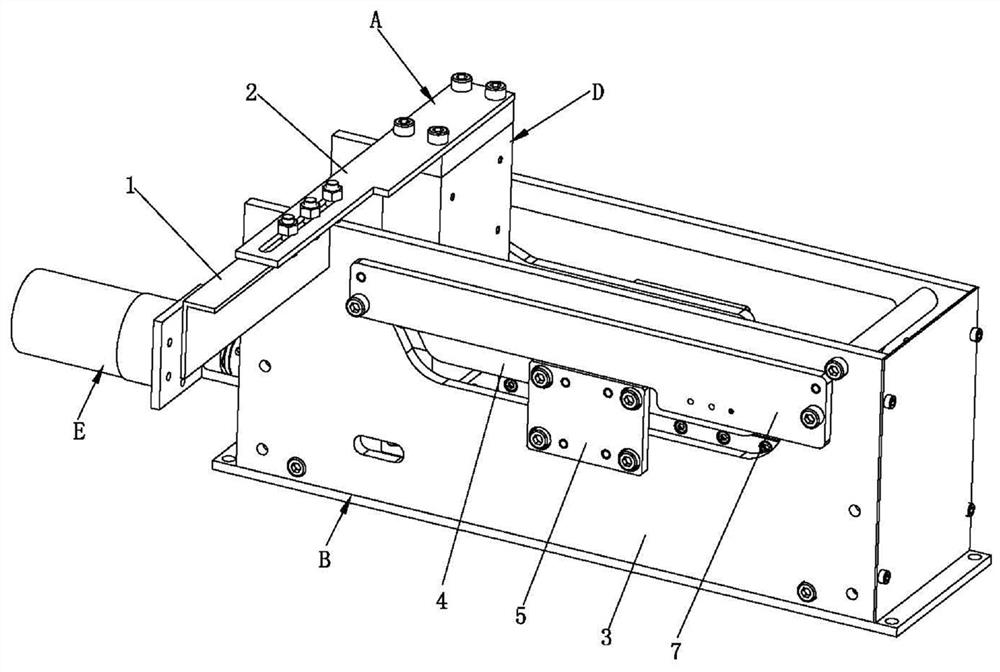

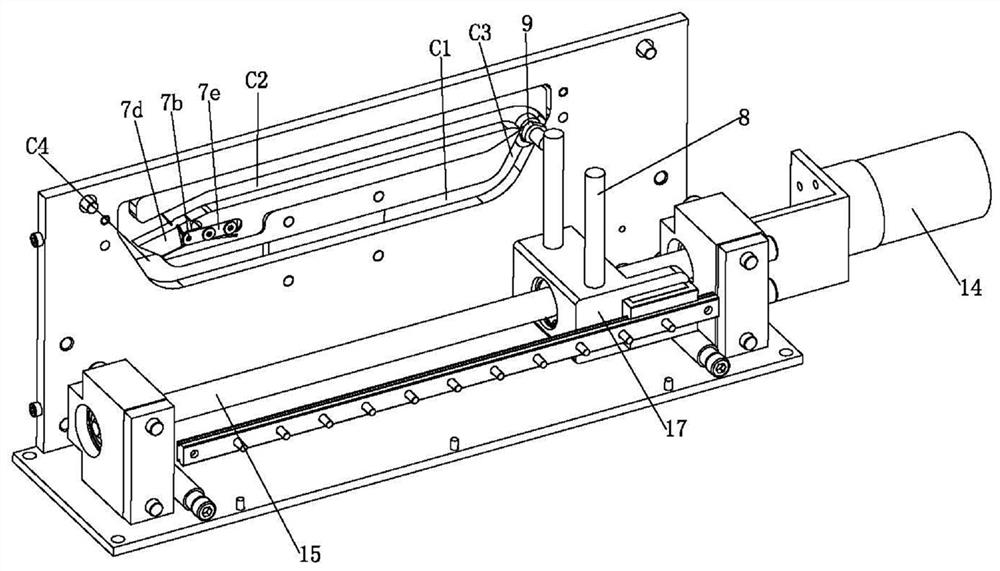

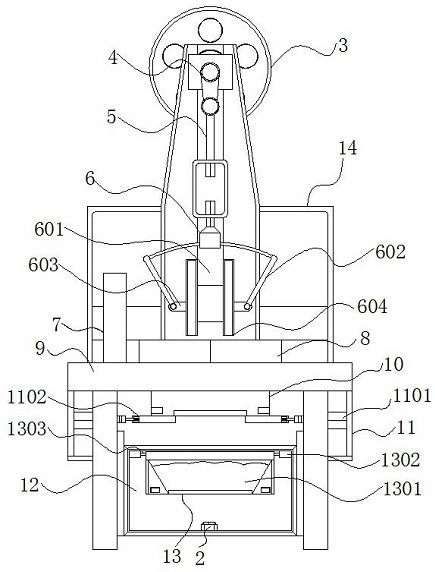

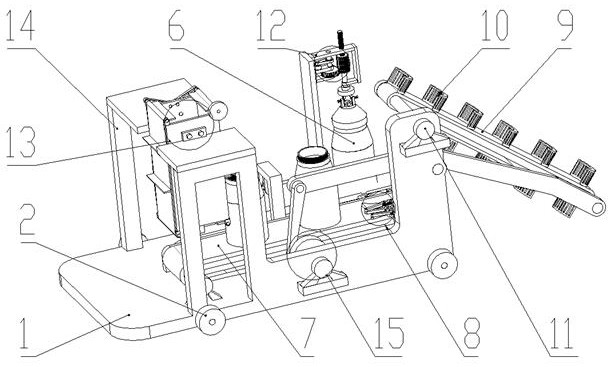

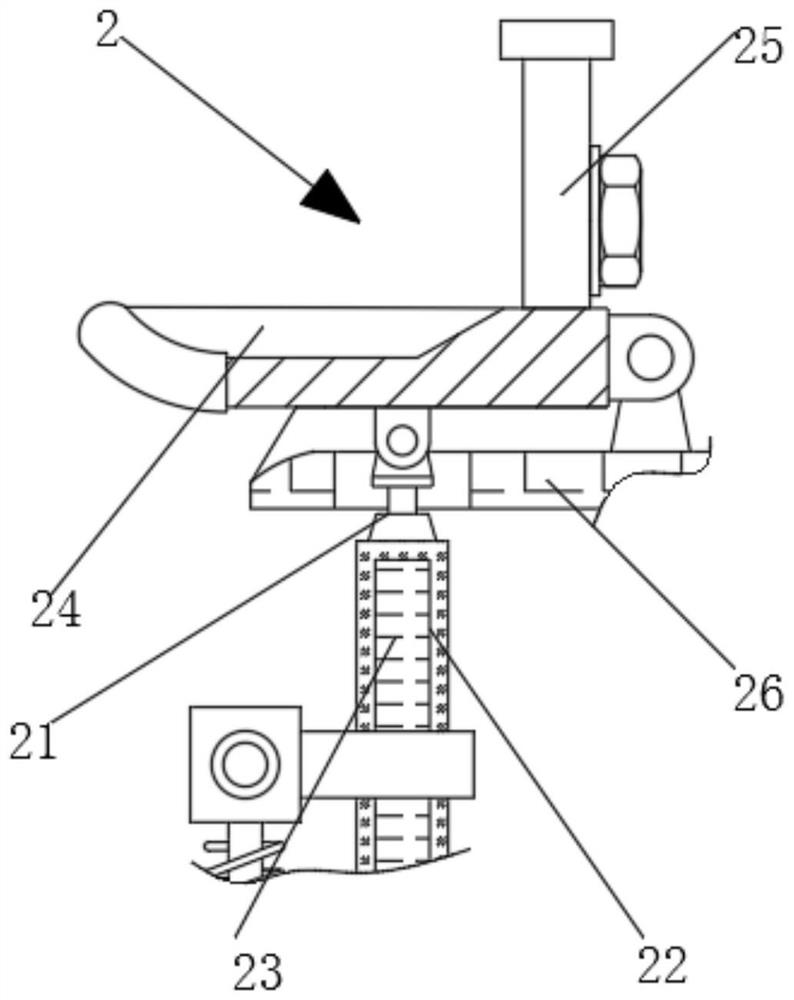

Automatic blanking and feeding device used for polishing workpiece

InactiveCN103522202AEasy to pushAutomatic dropAbrasive machine appurtenancesReciprocating motionSand blasting

The invention discloses an automatic blanking and feeding device used for polishing a workpiece. The automatic blanking and feeding device comprises a main framework and a transfer device arranged on the main framework and is used for transferring a workpiece to be blasted with sand, wherein a sand-blasting machine is arranged on the main framework; a spray gun is arranged in the sand-blasting machine; the spray gun is corresponding to the workpiece to be blasted with the sand, and the workpiece to be blasted with the sand is pressed by a pressing air cylinder on the transfer device; a sand storage box is arranged on the sand-blasting machine below the pressing air cylinder; an output device is arranged at the tail end of the transfer device; the transfer device and the sand-blasting machine are controlled by a controller for automatically feeding, blasting sand and blanking for the workpiece to be blasted with the sand. The device disclosed by the invention can be used for controlling the air cylinder to move back and forth to drive the workpiece to stably enter a sand-blasting zone at a constant speed; meanwhile, a plurality of workpieces are polished, so that the automatic blanking and feeding device is low in manufacturing cost, order in processing and high in efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

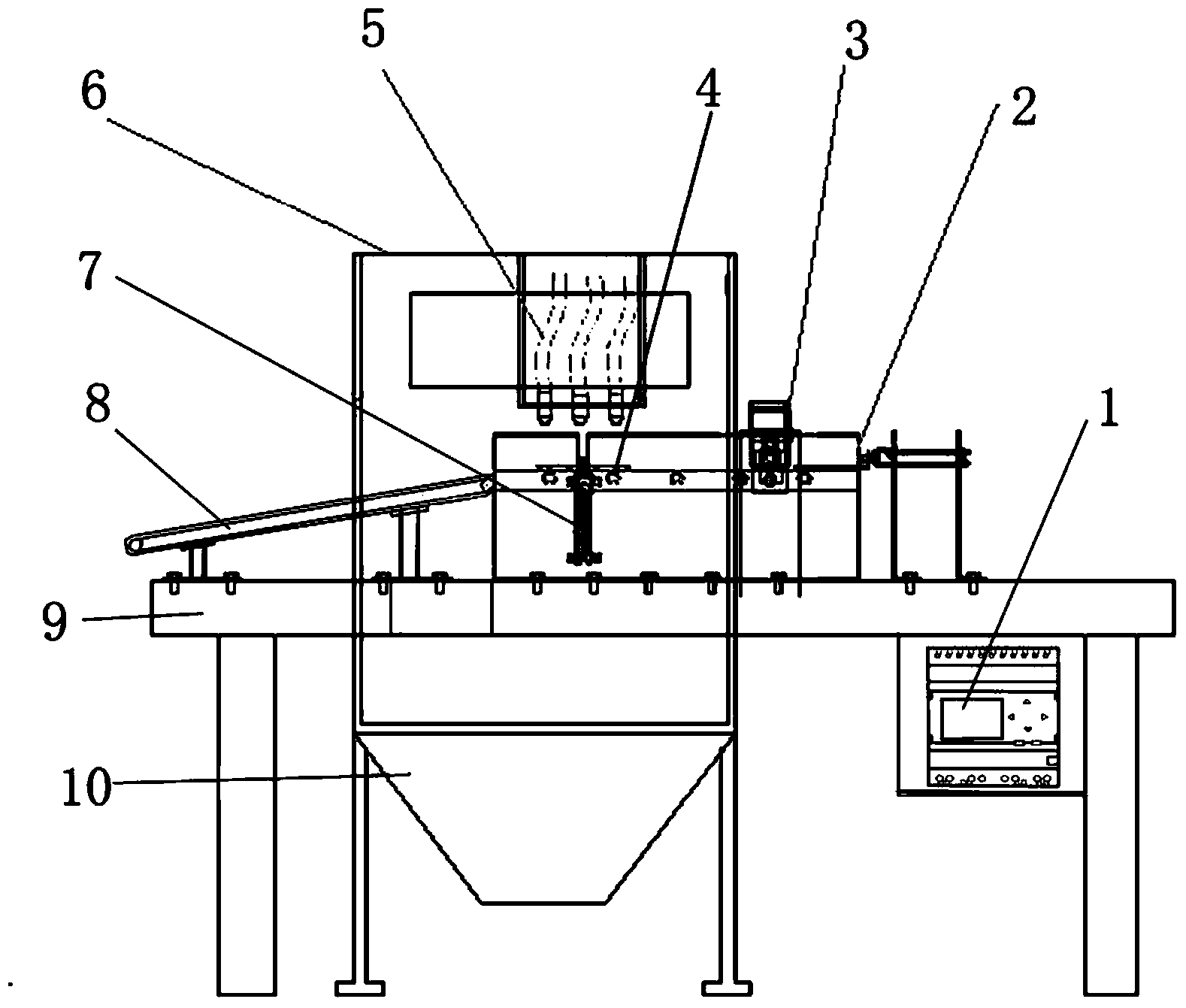

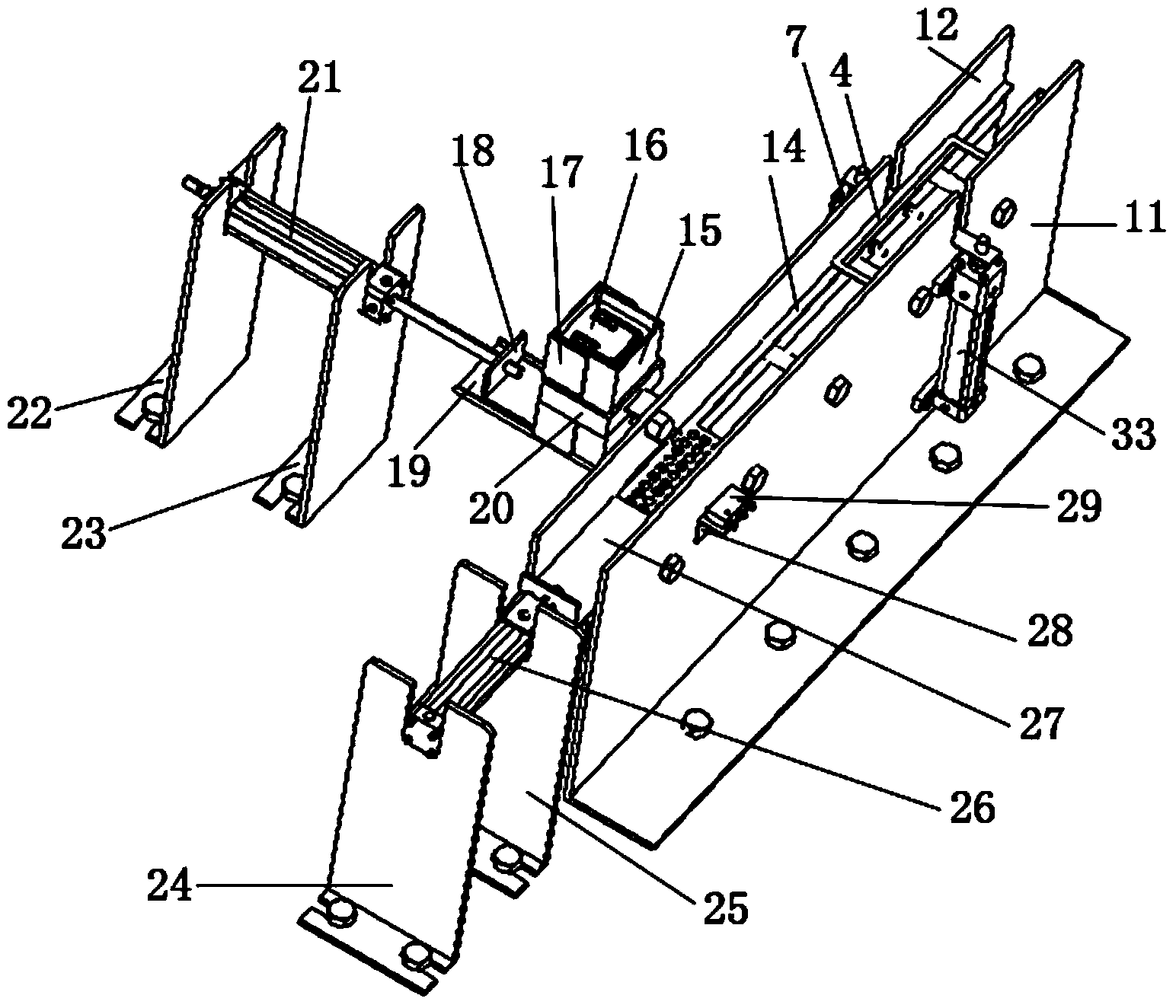

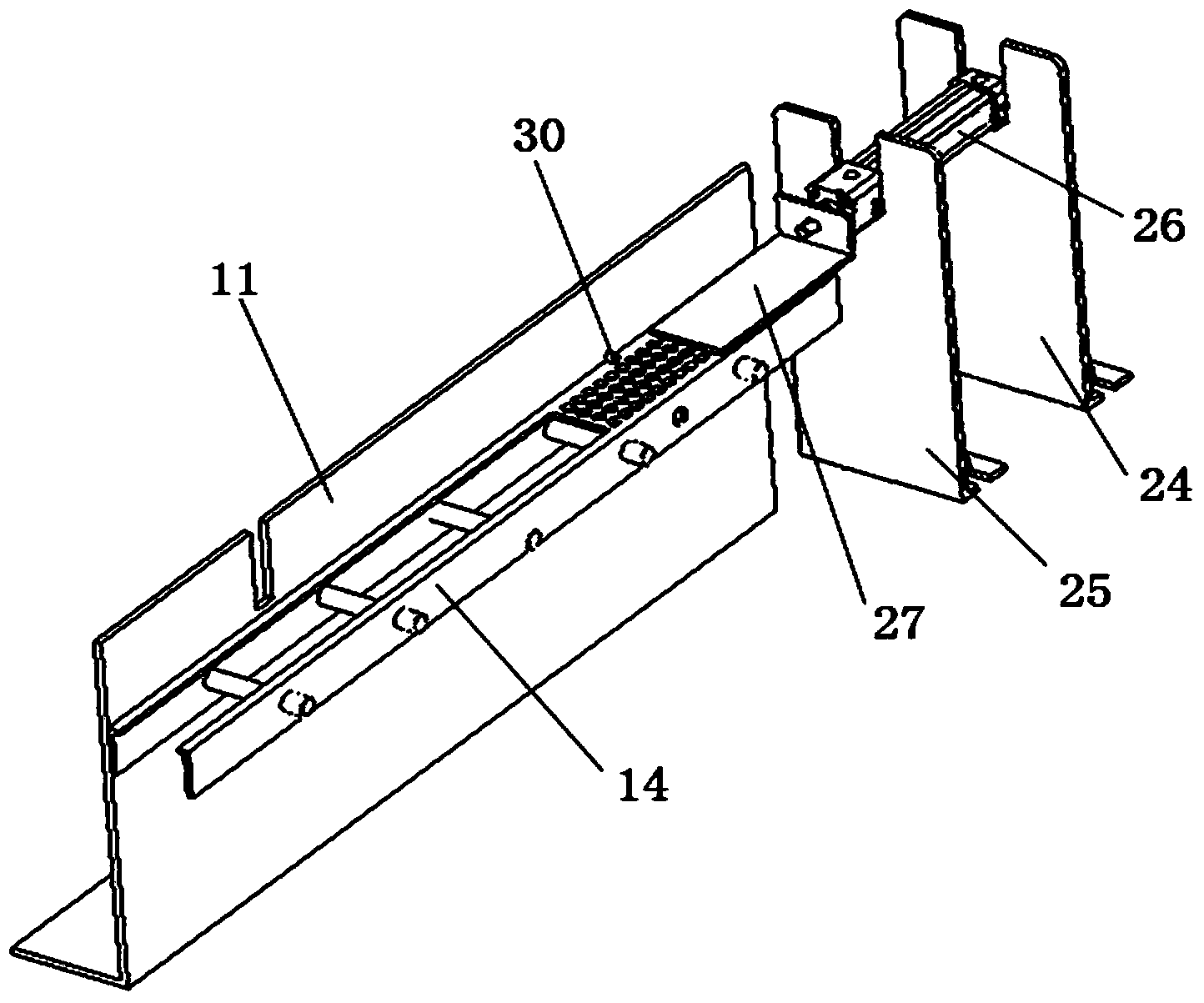

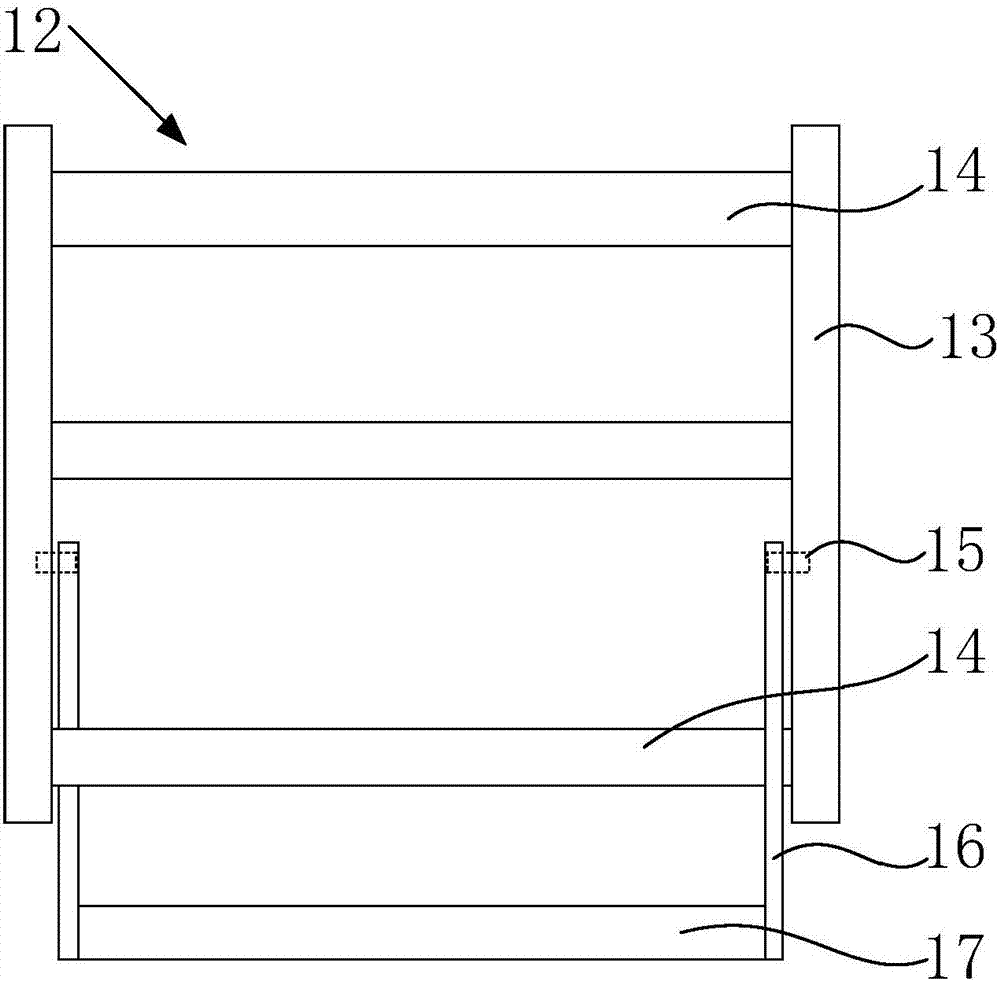

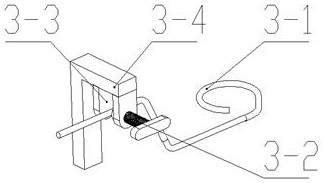

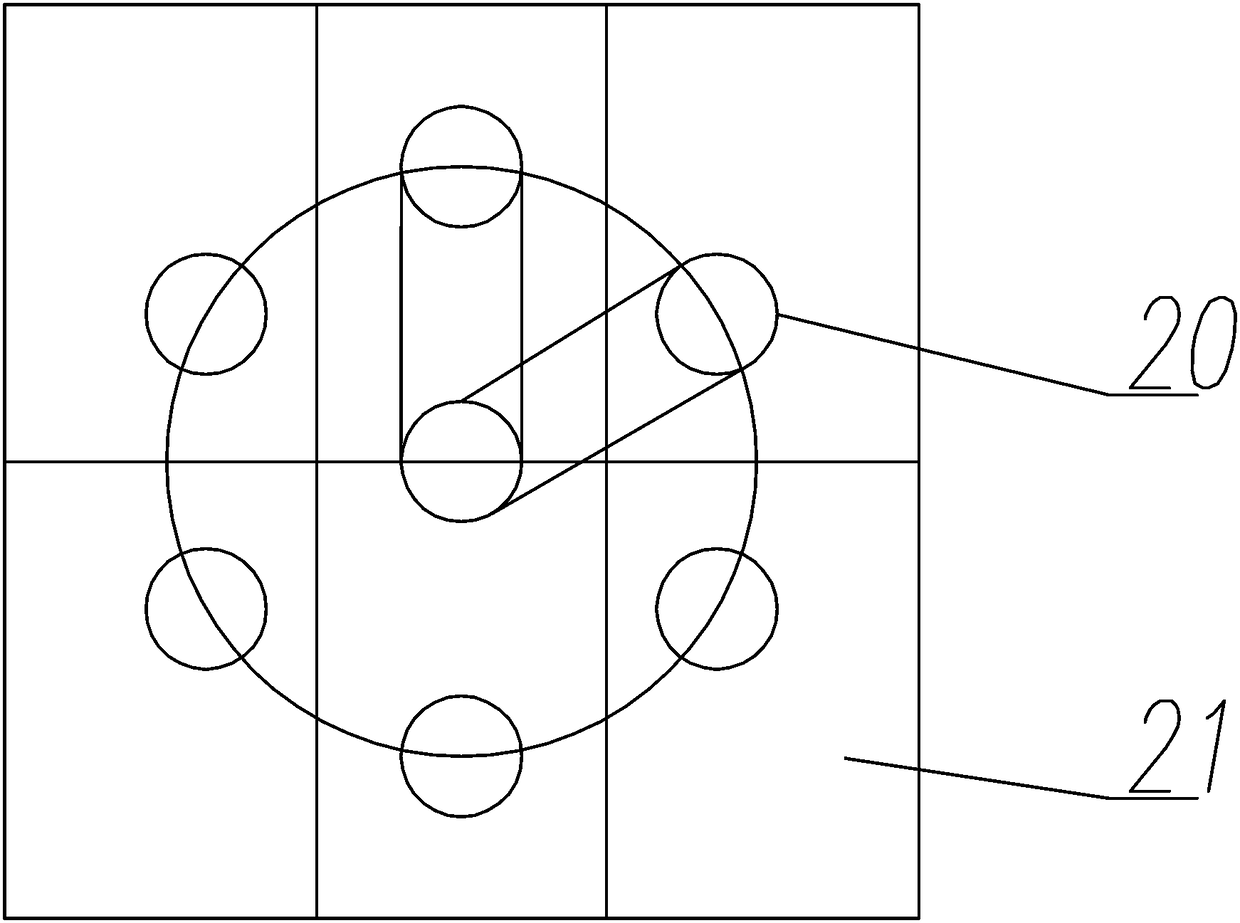

Positioning conveyor

InactiveCN108357859AAttitude unchangedAutomatic dropConveyorsConveyor partsEngineeringProduct processing

The invention belongs to the technical fields of agricultural production planting and agricultural product processing, and particularly relates to a positioning conveyor of a sugarcane seed stem bud calibration system. The positioning conveyor comprises multiple conveying belts which are arranged in the same horizontal plane in parallel at intervals, wherein multiple slots arranged at intervals inthe belt length direction are formed in each conveying belt, width of the slots is larger than diameter of a sugarcane seed stem, the slots in each conveying belt are aligned one by one in the widthdirection of the conveying belt, and clamping mechanisms are arranged in the slots in the two conveying belts on two outermost sides. According to the positioning conveyor, the sugarcane is clamped bythe clamping mechanisms, the sugarcane posture keeps unchanged in the conveying process, besides, a trigger mechanism is arranged at the tail end of each conveying belt, so that when the sugarcane isconveyed to the tail end of the conveying belt, the trigger mechanism can drive the clamping mechanisms to open, and the sugarcane can drop automatically.

Owner:ANQING WANCAO QIANMU AGRI TECH

IC packaged chip discharging device

ActiveCN112978337APrevent fallingHigh degree of automationStacking articlesConveyor partsStructural engineeringMechanical engineering

According to an IC packaged chip discharging device, the section of a storage pipe is rectangular, one end of the storage pipe is provided with an opening, and a through hole is machined in the opening end; a bottom plate is provided with a pipe sliding groove and a feeding groove, the feeding groove communicates with the pipe sliding groove, the communication position is a feeding port of an IC packaged chip, a pipe storage groove is formed above the feeding port, the storage pipe is stacked in the pipe storage groove in a sliding mode, the opening of the storage pipe is aligned to the feeding port during discharging, the bottom plate is provided with a proximity switch corresponding to the through hole, and a gap is formed between the bottom face of the pipe storage groove and the bottom face of the pipe sliding groove; a pipe stacking mechanism comprises a pipe stacking groove and a lifting plate, and a gap is formed between the bottom face of the pipe stacking groove and the bottom face of the pipe sliding groove; the lifting plate penetrates through the bottom of the pipe sliding groove, and supporting rods are arranged on the two side walls of the pipe stacking groove; and a pushing rod is of an H-shaped structure, is connected to a pushing air cylinder and is provided with push rods parallel to each other, and the thickness of the push rods is smaller than that of the storage pipe. The device is high in automation degree and beneficial for improving production efficiency.

Owner:四川明泰微电子科技股份有限公司

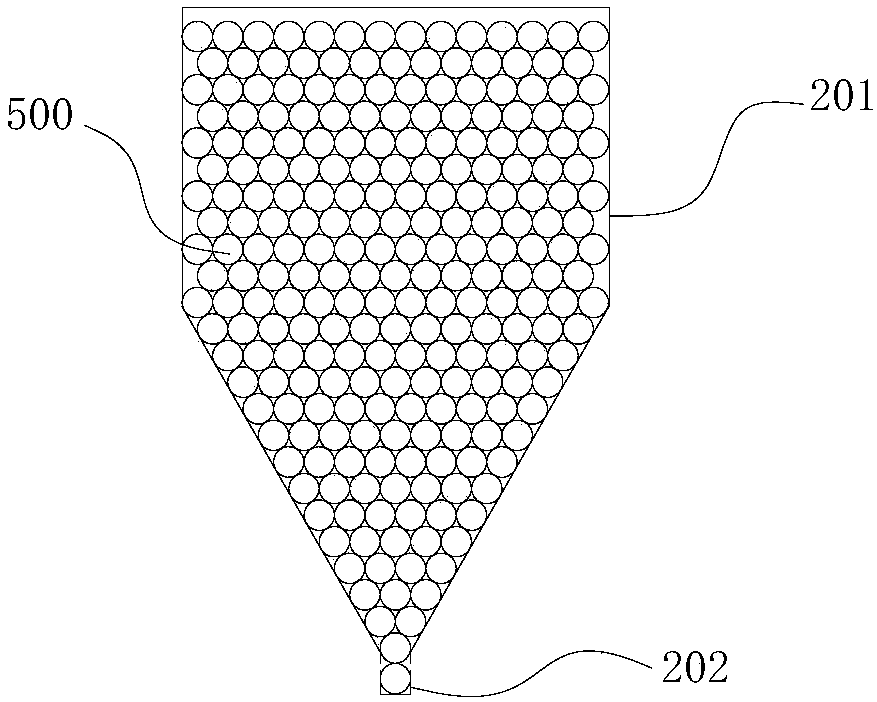

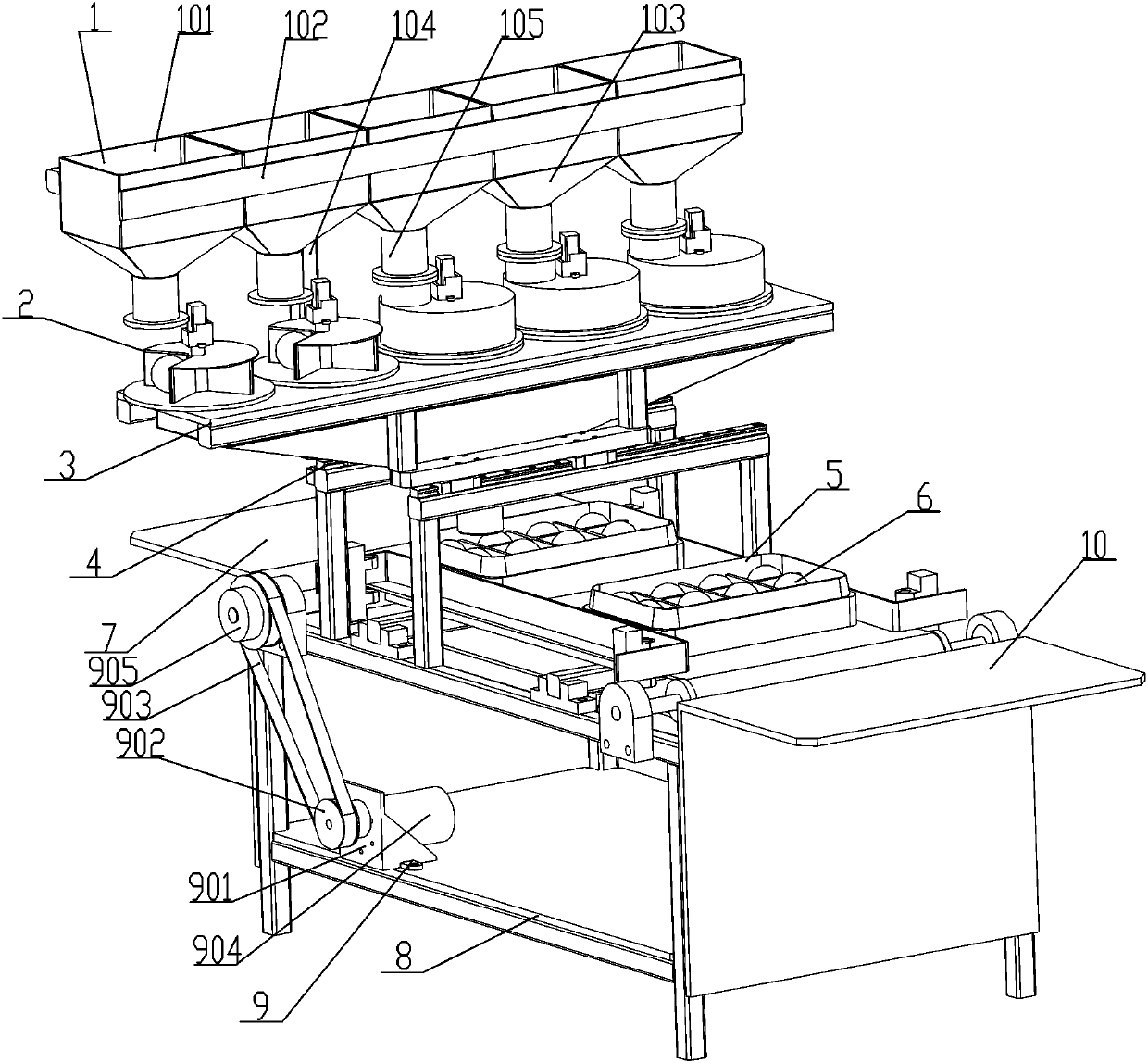

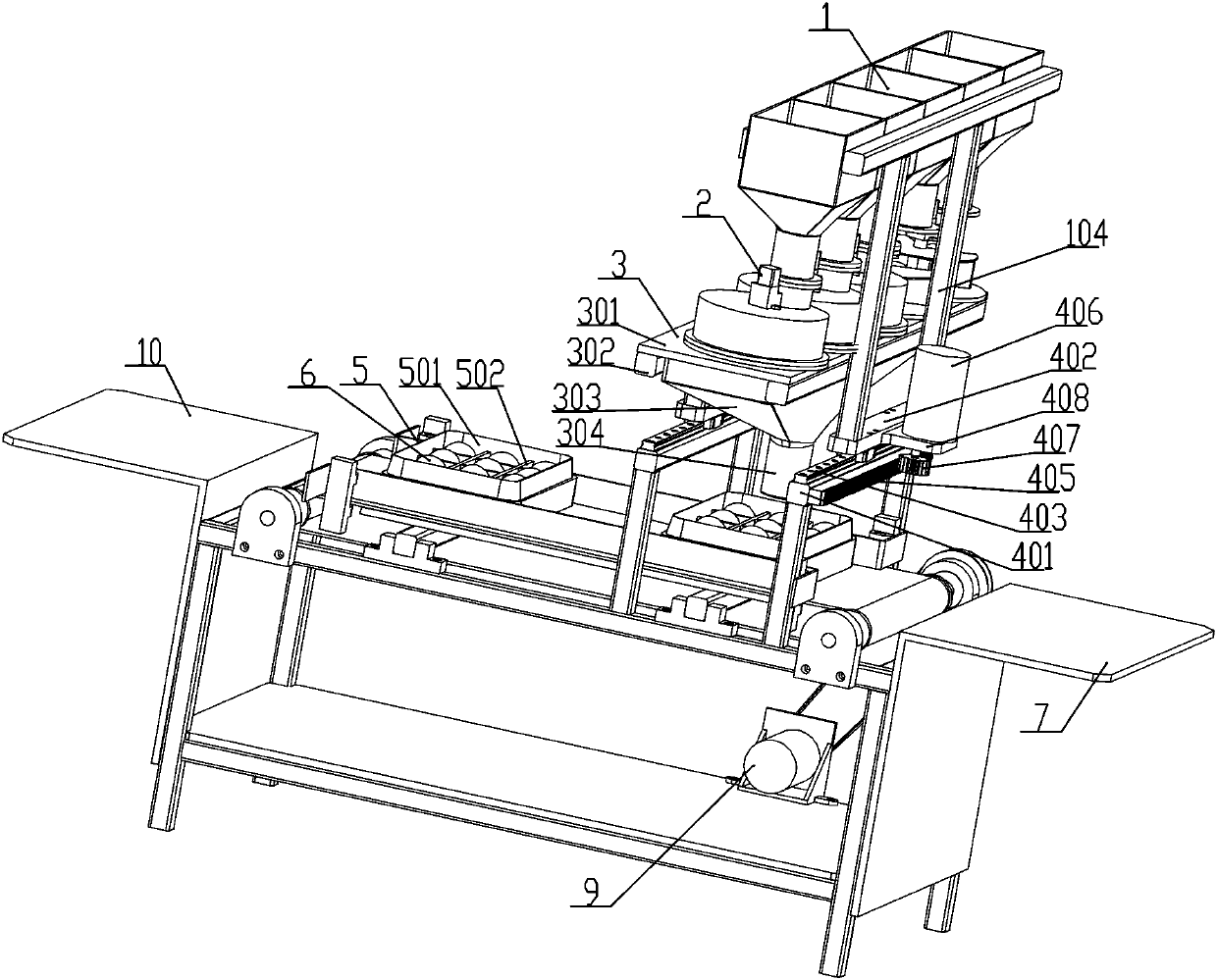

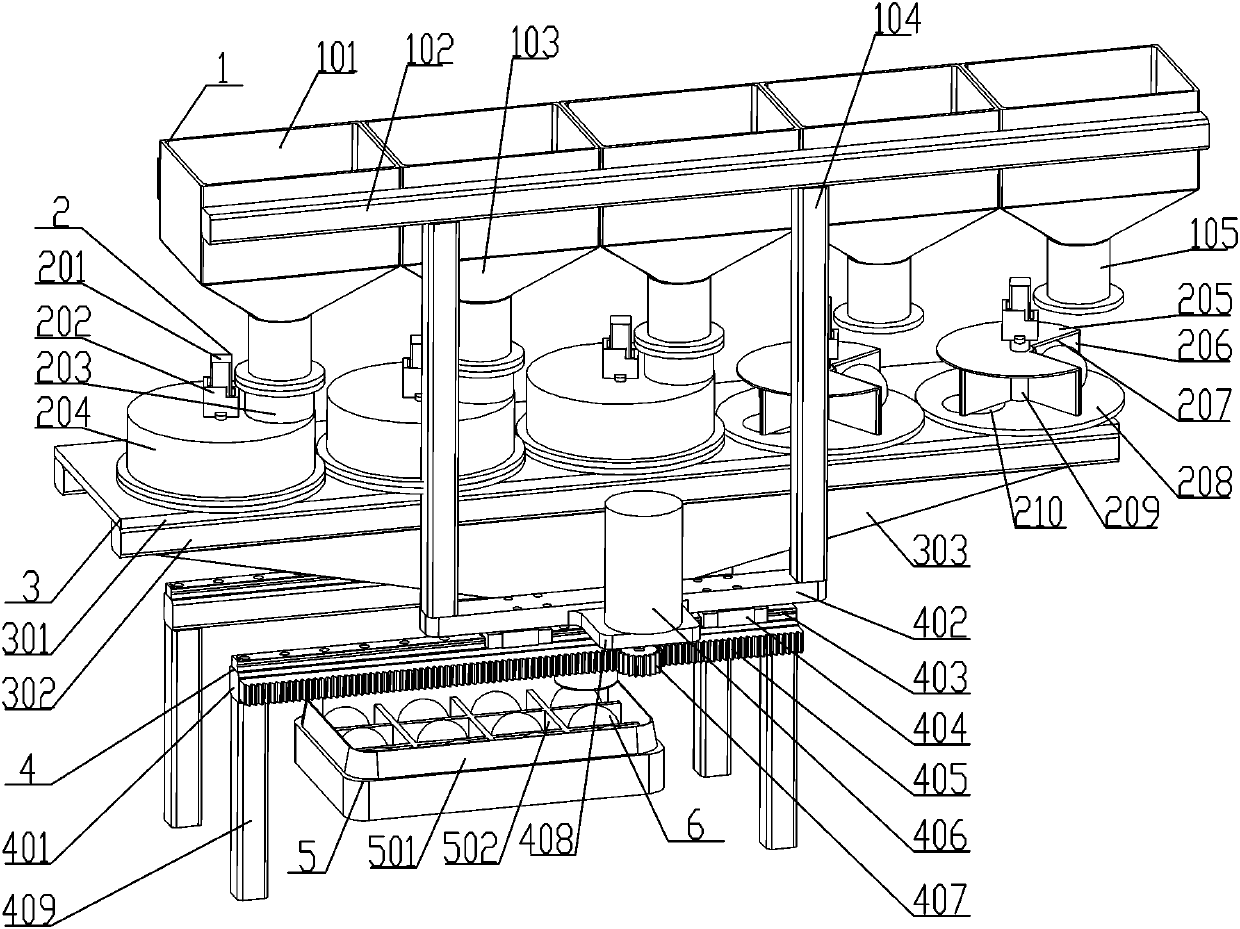

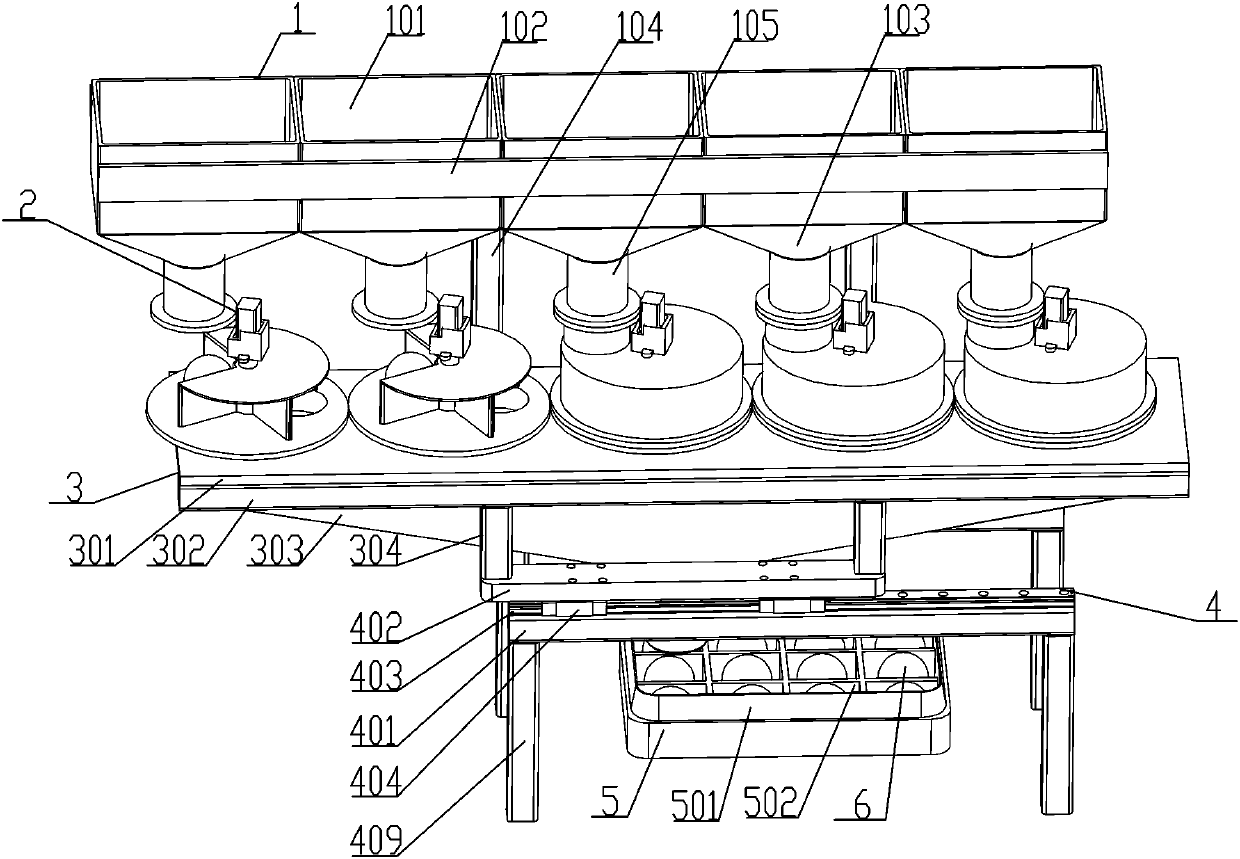

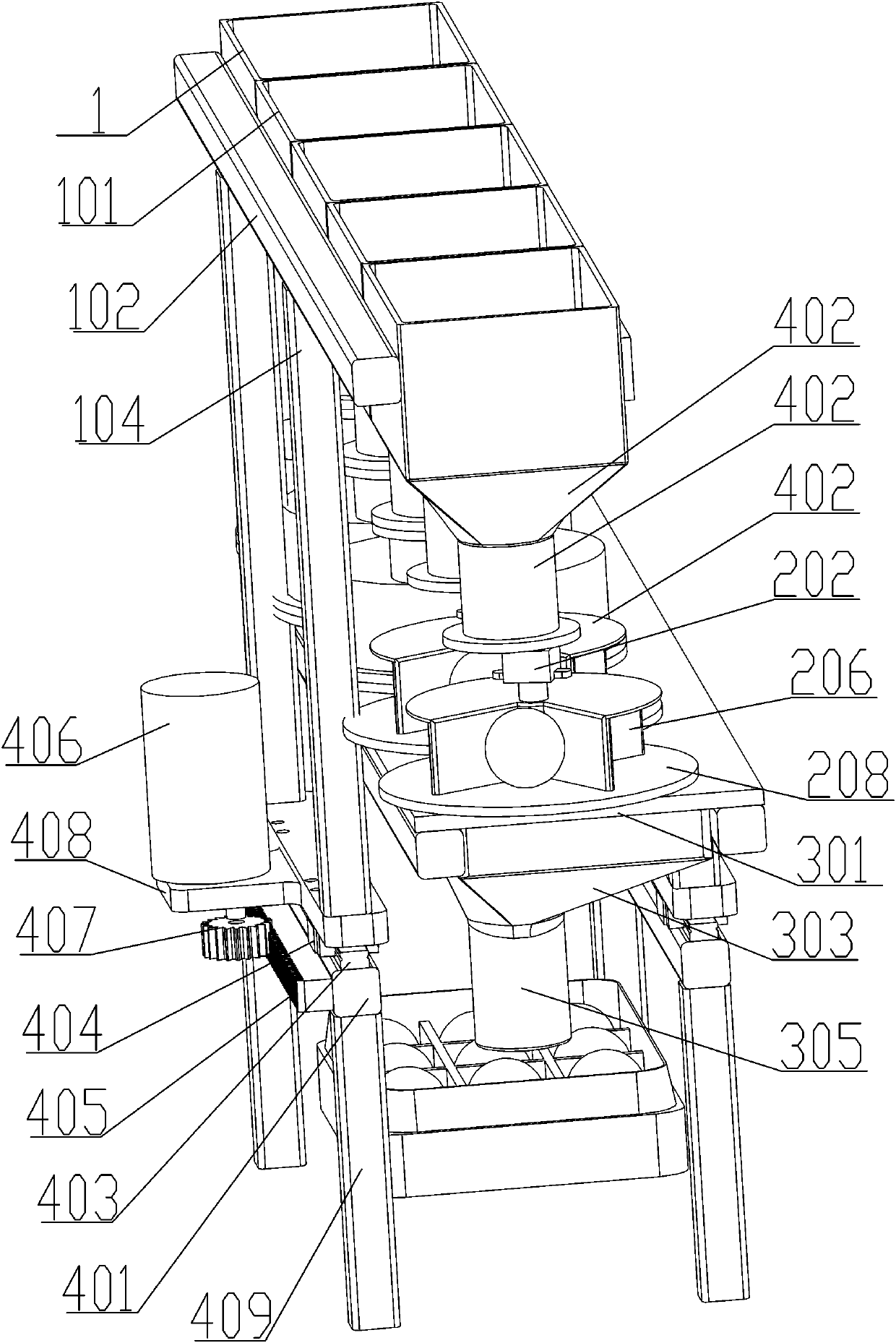

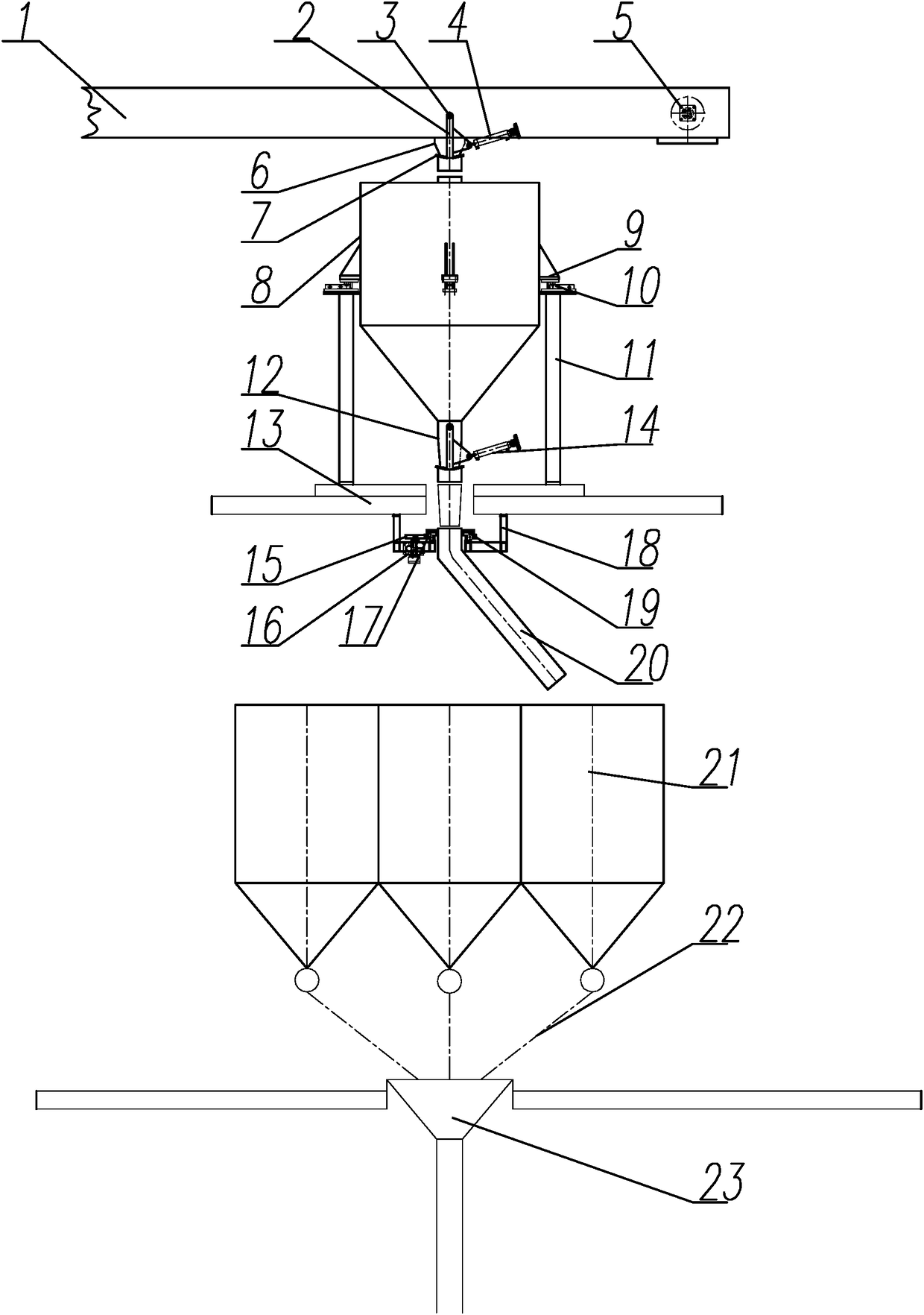

Machine capable of automatically and quantitatively packaging spherical fruits and operation method

InactiveCN107600503ARealize automatic packaging operationsRealize quantitative automatic cuttingPackaging fruits/vegetablesProcess engineeringDistributor

The invention provides a machine capable of automatically and quantitatively packaging spherical fruits and an operation method. The machine comprises a general discharging device for containing the fruits, wherein discharging ports of the general discharging device are provided with distributors for realizing sequential discharging of the fruits correspondingly in a butted mode, and discharging holes of the distributors are provided with a bottom discharging device; the general discharging device, the distributors and the bottom discharging device are all supported on a translation mechanismfor moving the whole device; the translation mechanism is fixedly arranged on a conveyor frame, and a conveyor belt device used for conveying fruit boxes is arranged on the conveyor frame; the bottomdischarging device is arranged right above the conveyor belt device; and the translation direction of the translation mechanism is perpendicular to the conveying direction of the conveyor belt device.The automatic discharging mechanism can ensure that only one object is discharged at each time, so that quantitative packaging is realized, the defects of traditional packaging are overcome, and thepackaging efficiency is guaranteed.

Owner:CHINA THREE GORGES UNIV

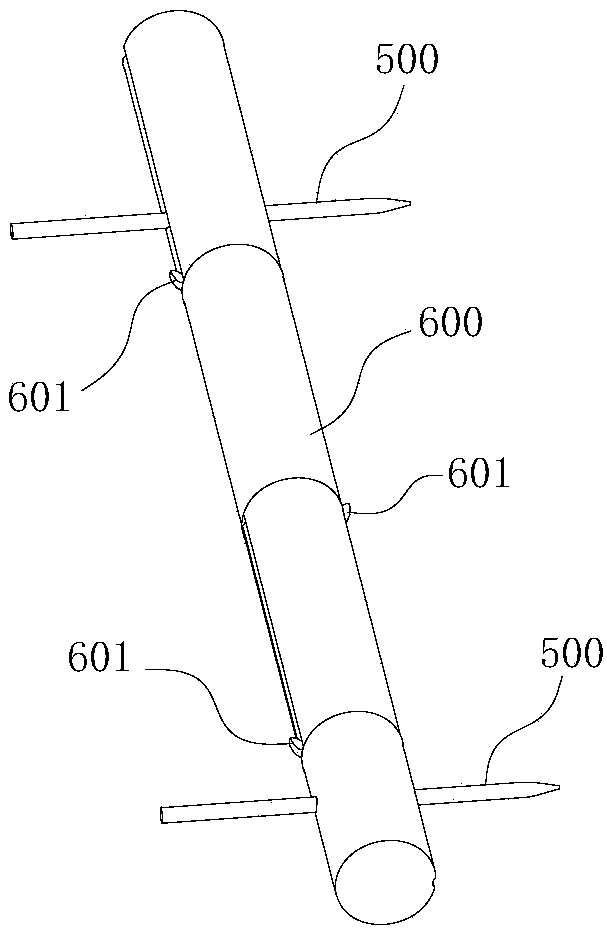

Automatic fruit package discharging mechanism and operation method

InactiveCN107651229ARealize automatic packaging operationsRealize quantitative automatic cuttingIndividual articlesPackaging fruits/vegetablesButt jointDistributor

The invention provides an automatic fruit package discharging mechanism and an operation method. The automatic fruit package discharging mechanism comprises a main discharging device for containing fruits. A discharging port of the main discharging device is provided with a distributor in a butt joint manner, and the fruits are sequentially discharged through the distributor. A bottom dischargingdevice is arranged at a discharging port of the distributor. The main discharging device, the distributor and the bottom discharging device are installed on a horizontal movement mechanism in a supporting manner, and the horizontal movement mechanism is used for moving the whole device. According to the automatic discharging mechanism, it can be guaranteed that only one material can be dischargedevery time, accordingly, quantitative packaging is achieved, the defects of traditional packages are overcome, and the packaging efficiency is guaranteed.

Owner:CHINA THREE GORGES UNIV

Tree fixing device used in garden

InactiveCN106982707AEffectively fixedDoes not affect normal growthCultivating equipmentsNormal growthEngineering

The invention discloses a tree fixing device used in a garden. The device includes a circular ring embedded in soil in advance; the two sides of the circular are vertically and fixedly provided with supporting rods, the upper ends of the supporting rods both pass through the soil and extend to the outside and are fixedly provided with cross rods through fixing bolts, sliding grooves are formed in the surface of the cross rods, one or more first threaded holes are formed in the bottom surface of each sliding groove, a slider is installed in each sliding groove in a sliding mode, second threaded holes are formed in the sliders, the fixing bolts are in threaded connection with the second threaded holes, one end of each fixing bolt extends into the corresponding first threaded hole and is in threaded connection with the first threaded hole, and the surfaces of the sliders are vertically and fixedly provided with straight bars. The device is simple in structure and convenient to use, can effectively fix trees, does not affect the normal growth of the trees, can automatically drop after a long time, and is convenient to use and install next time.

Owner:李勤学

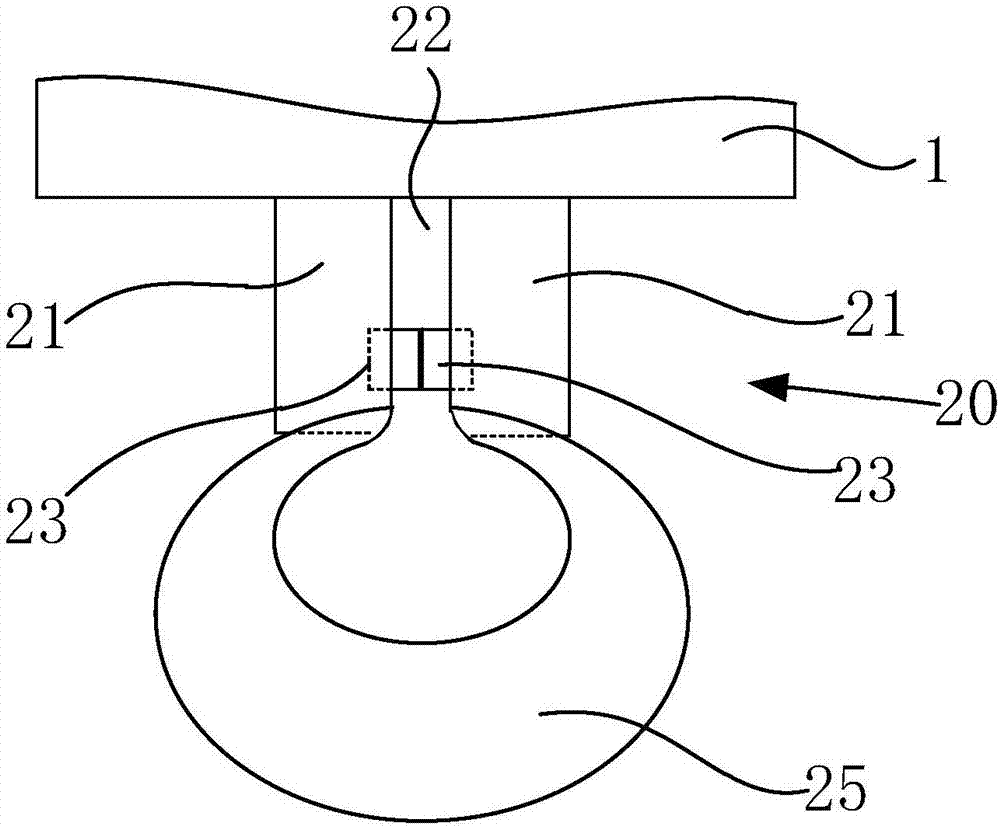

Corrugated pipe cutting machining device

ActiveCN107932579AAutomatic dropExtended service lifeMetal working apparatusRotational axisElectric machinery

The invention relates to a corrugated pipe cutting machining device. The corrugated pipe cutting machining device comprises a motor, a rotary shaft and a round cutter; the bottom end of the rotary shaft is connected with the motor, and the upper end of the rotary shaft is connected with the cutter; a first shaft sleeve located above the cutter and a second shaft sleeve located below the cutter arerotationally connected to the rotary shaft; a plurality of telescopic rods are connected to the first shaft sleeve, the ends, away from the first shaft sleeve, of the telescopic rods are all providedwith fixed barrels, and first springs are connected with the fixed barrels and the first shaft sleeve; second springs are connected to the second shaft sleeve; the rotary shaft is internally providedwith a cavity, and a piston is movably connected into the cavity; a sealing cover is rotationally connected to the top end of the rotary shaft and provided with an opening; the rotary shaft is fixedly connected with a cam and a supporting plate located under the second shaft sleeve, one side of the cam is provided with an air bag, and the air bag and the sealing cover communicate with an air pipe; the outer side of the rotary shaft is rotationally connected with pulleys; and stay cords are connected with the piston and the fixed barrels and penetrate through the opening to be arranged on thepulleys. Through the corrugated pipe cutting machining device, a plurality of corrugated pipes can be cut at the same time.

Owner:SHANDONG WANSHIDA SPECIAL PURPOSE VEHICLE MFG

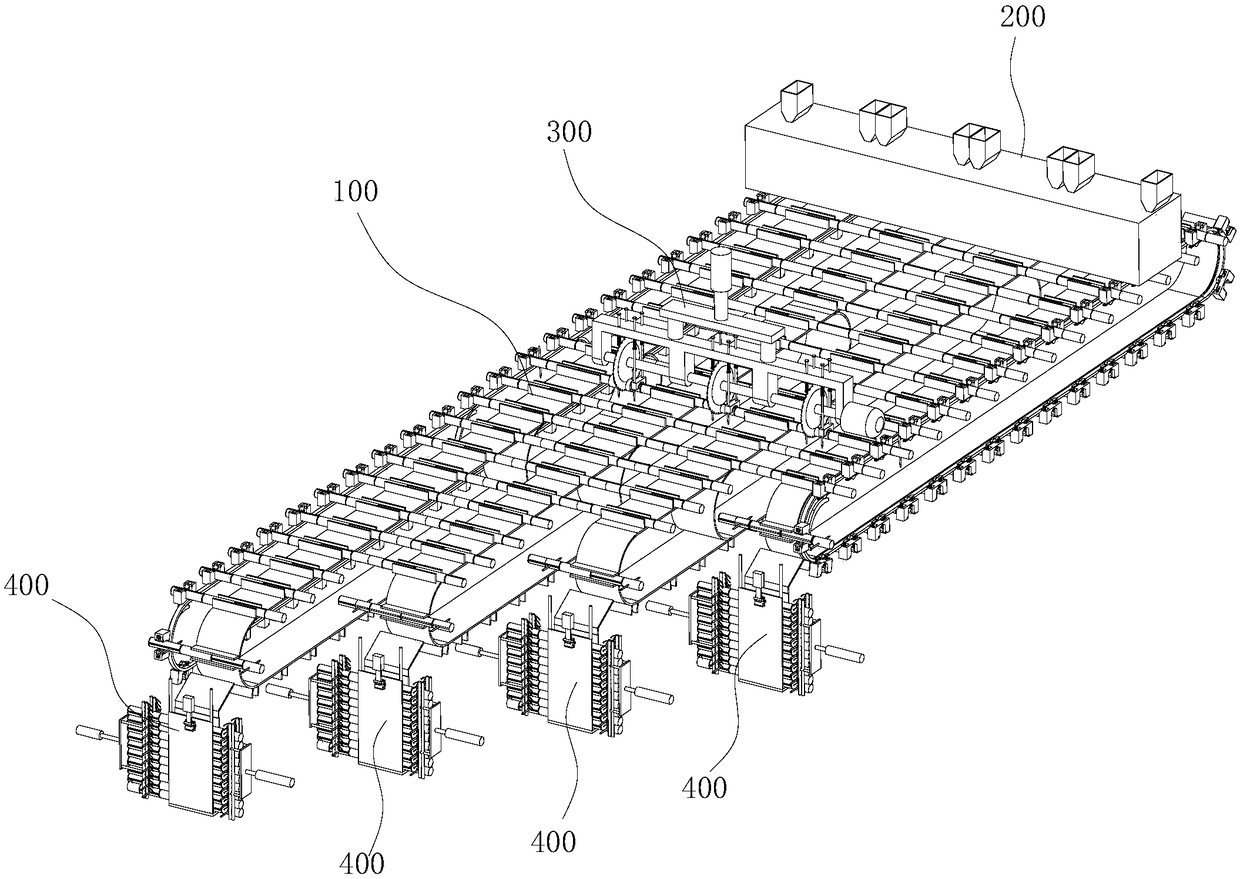

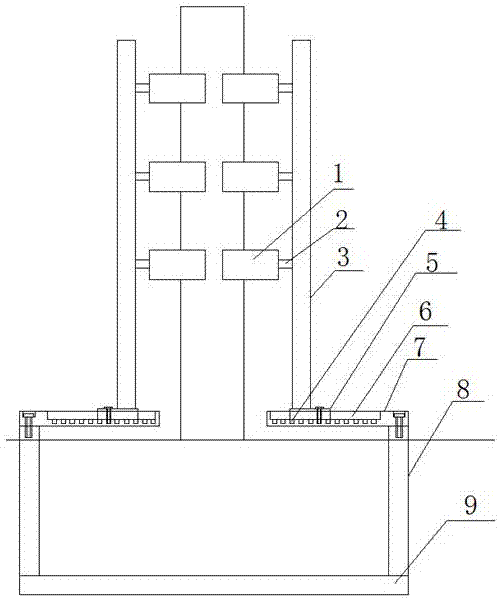

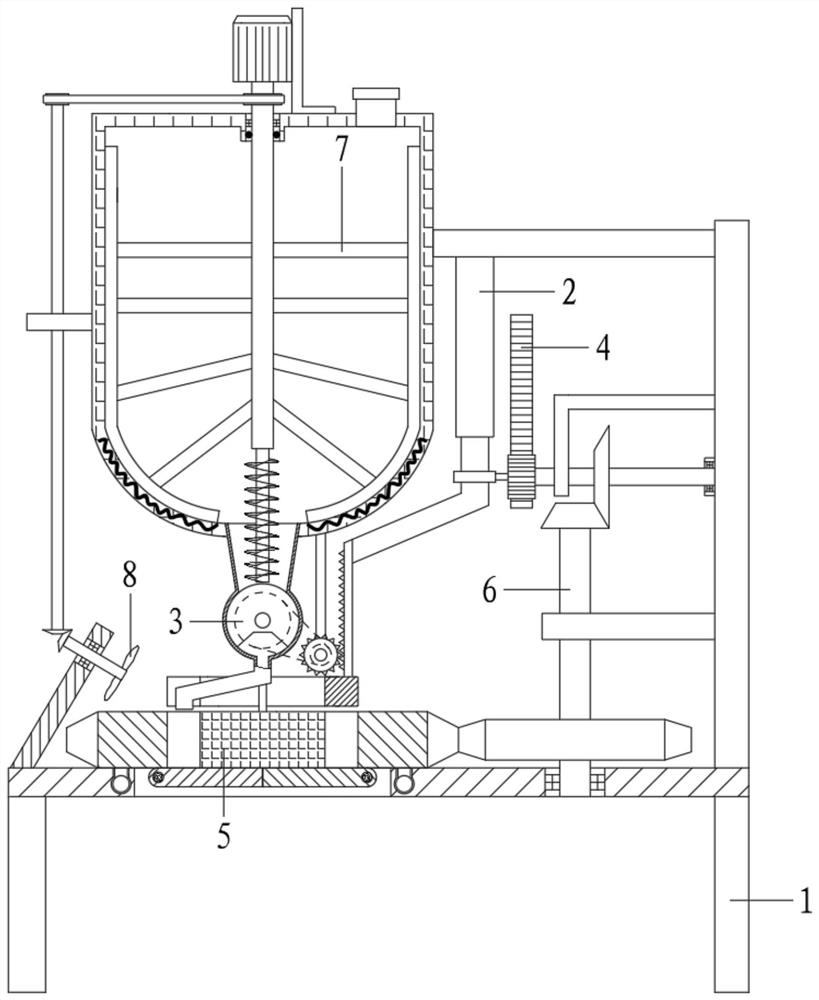

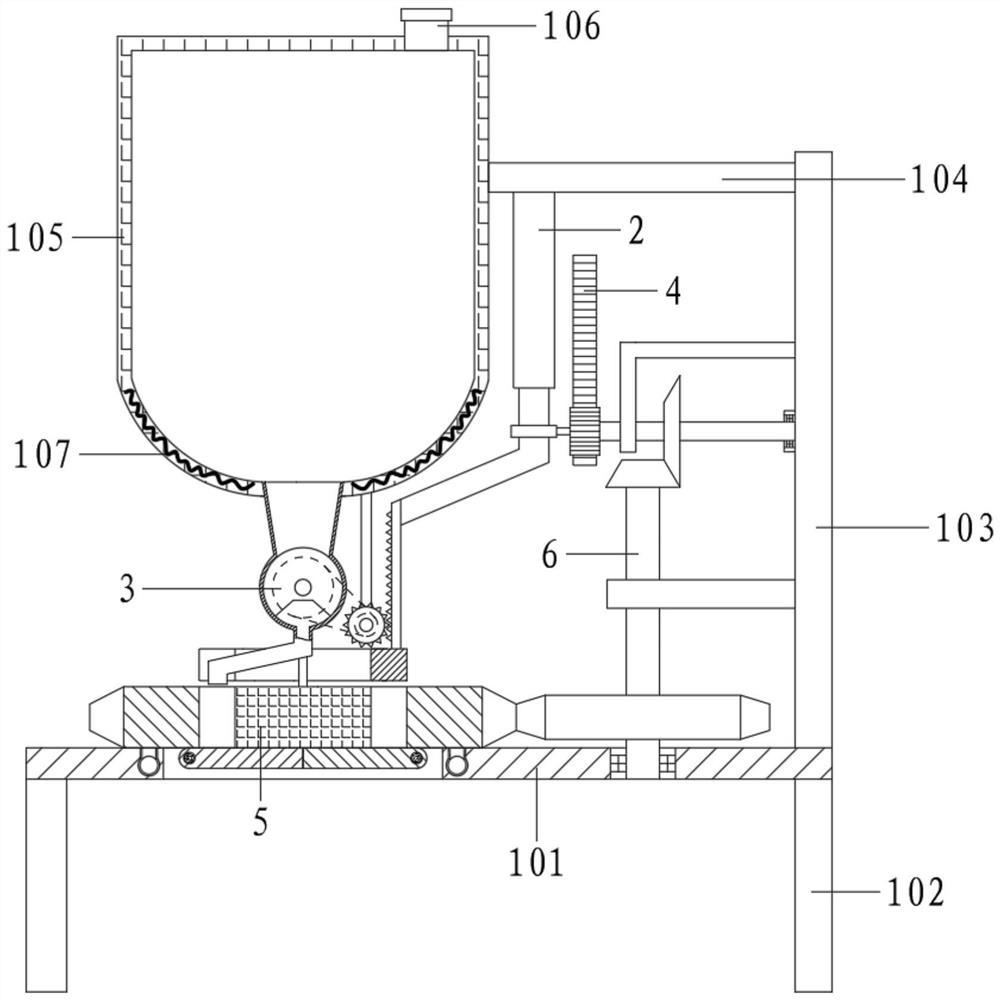

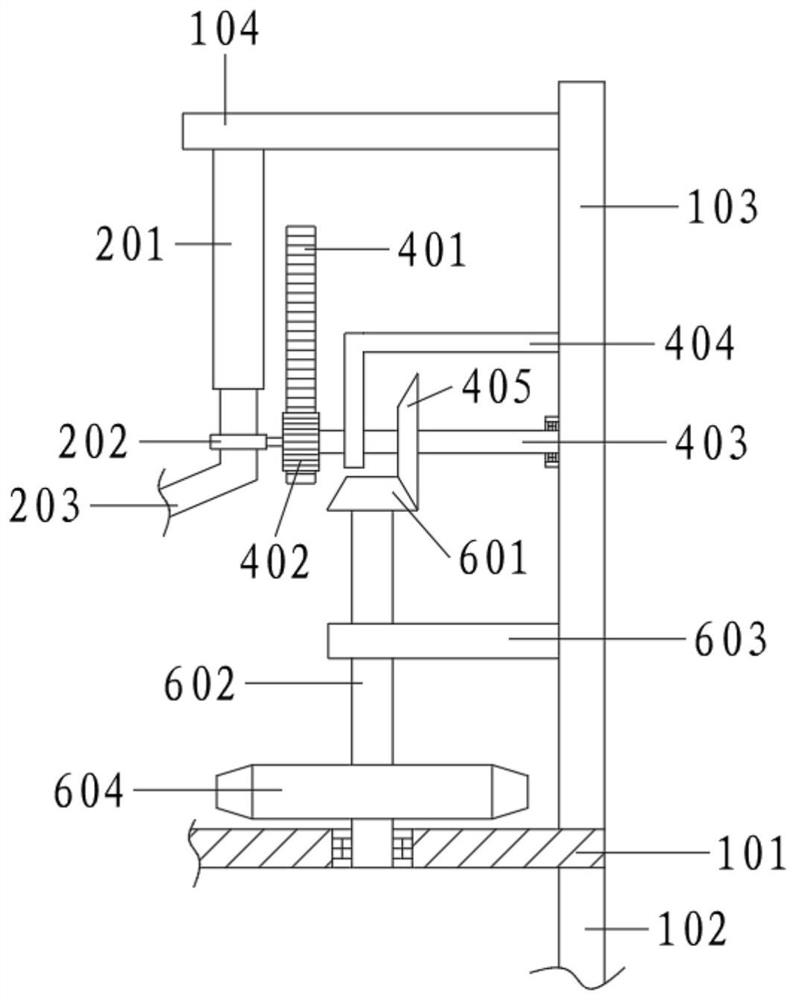

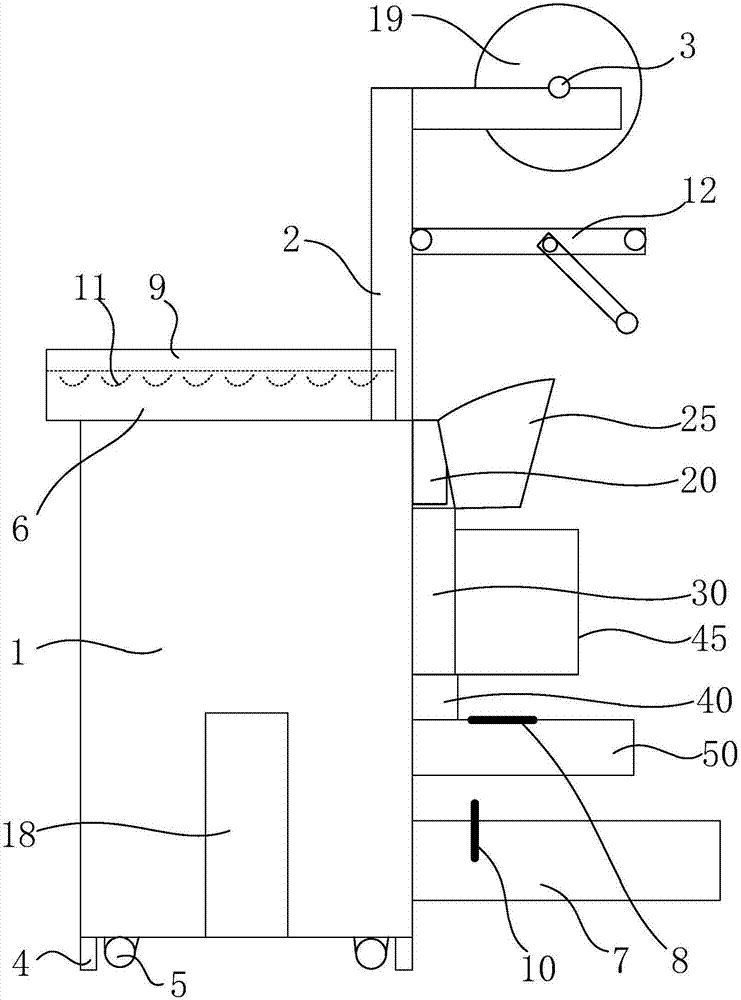

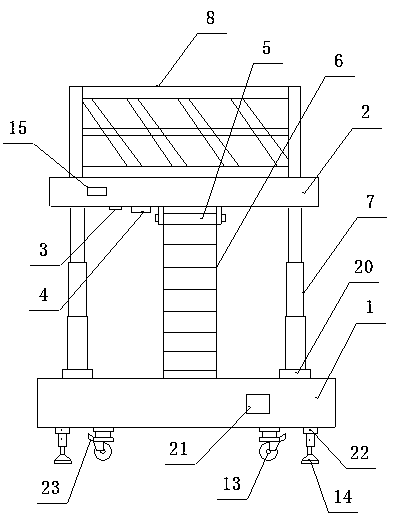

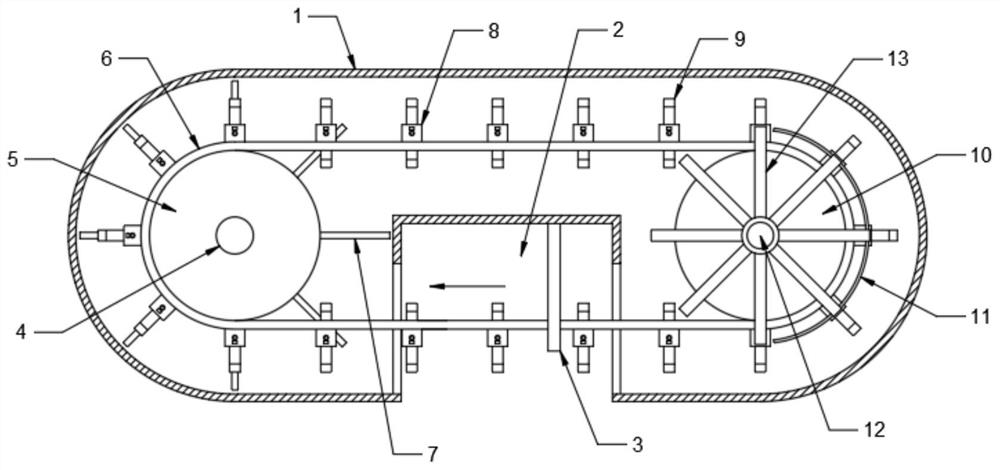

Quantitative and point-fixed multi-station grain automatic unloading device and method

ActiveCN106219260ARealize automatic blanking operationAutomatic dropConveyorsLoading/unloadingAutomatic controlEngineering

The invention discloses a quantitative and point-fixed multi-station grain automatic unloading device and a method. The device comprises an embedded scrapper conveyor; an automatic unloading device is mounted at the bottom of a conveying belt of the embedded scraper conveyor; a cache barrel is mounted at the bottom of the automatic unloading device; support angle steel is fixed at the outer wall periphery of the cache barrel; a static weighing balance is arranged at the bottom of the support angle steel, and is supported and mounted on a stand column; the stand column is supported on a baseplate; an unloading cylinder is mounted at the bottom of the cache barrel; a pneumatic discharge mechanism is mounted on the unloading cylinder; a fixed-point rotary unloading device is mounted rightly below the unloading cylinder; and multiple dipping cylinders are correspondingly arranged below the fixed-point rotary unloading device. The device can realize automatic grain weighing operation, can realize automatic unloading, can realize fixed-point unloading through automatic control in the unloading process, and can perform the feeding operation of multiple dipping boxes in sequence to improve the dipping efficiency.

Owner:HUBEI DAOHUAXIANG WINE IND +1

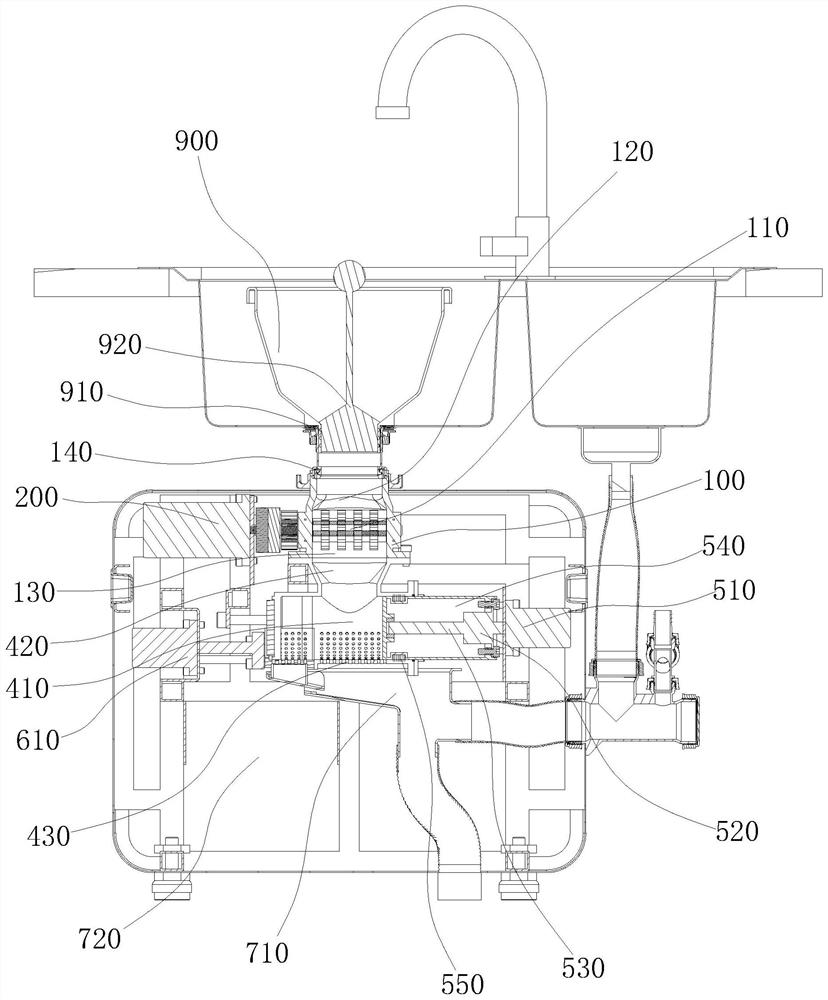

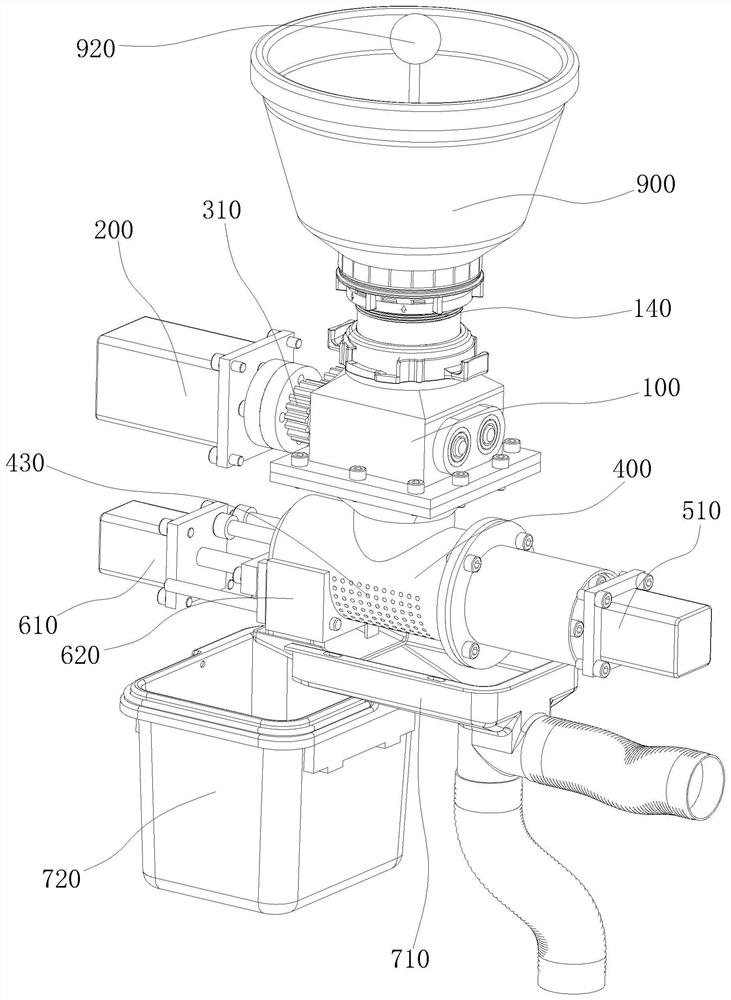

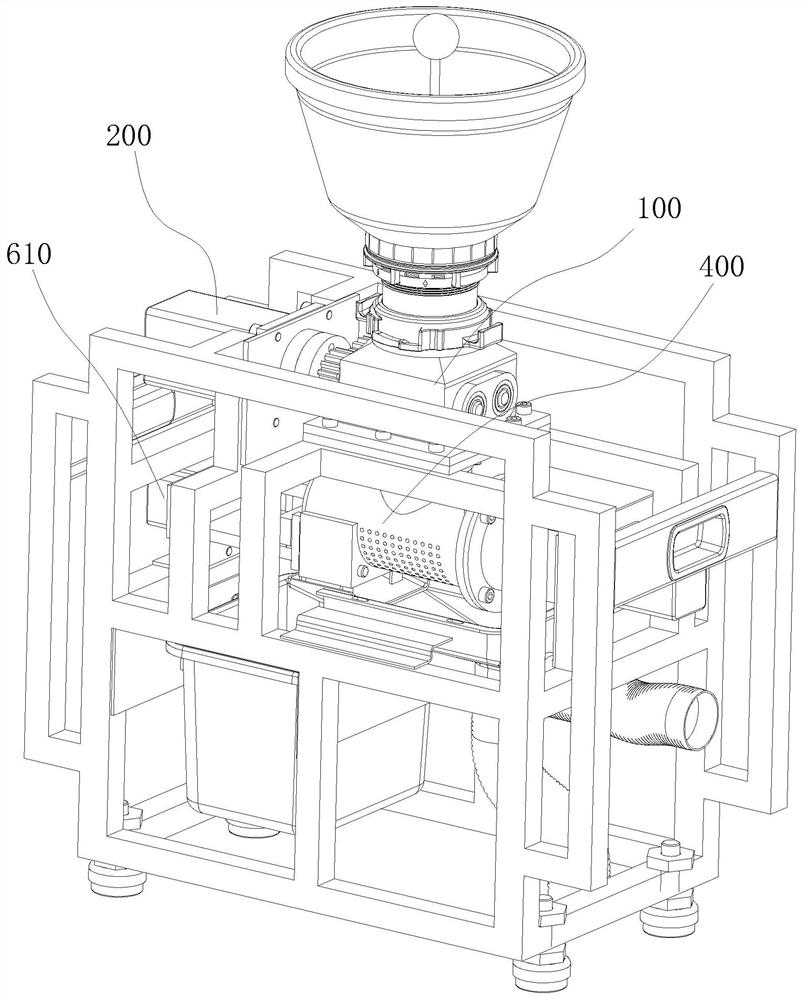

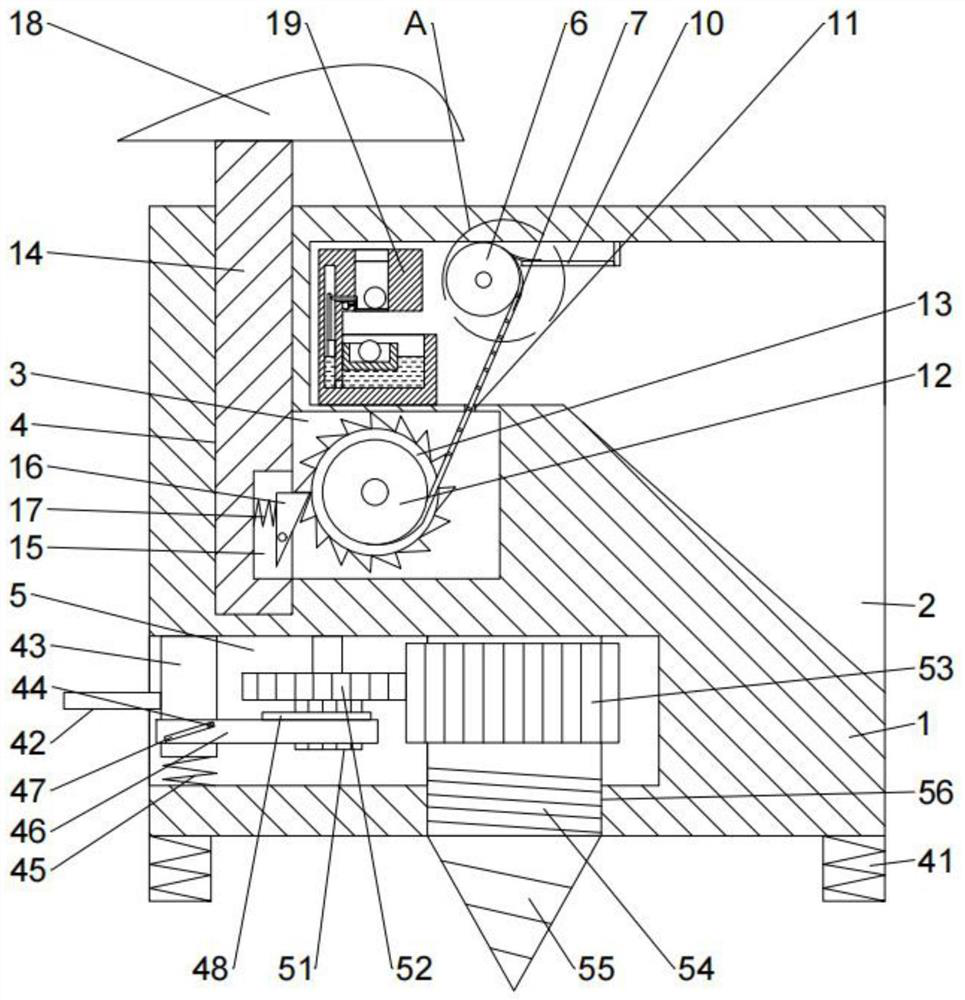

Kitchen garbage disposer

PendingCN113006218AThe overall structure is ingeniousImprove crushing efficiencyDomestic plumbingRefuse DisposalsMechanical engineering

The invention provides a kitchen waste disposer, and belongs to the technical field of kitchen waste crushing and dewatering equipment. The kitchen waste disposer is characterized in that a crushing seat is provided with a crushing cavity, a first feed port and a first discharge port; a crushing assembly comprises a first driving block and a serrated knife block, the serrated knife block is arranged in the crushing cavity, and the first driving block is in linkage connection with the serrated knife block; a dewatering seat is provided with a dewatering cavity, a second feeding hole and a dewatering hole, and the second feeding hole and the dewatering hole both communicate with the dewatering cavity; a dewatering assembly comprises a second driving block and a sliding block, the sliding block is movably arranged in the dewatering cavity, and the second driving block is connected with the sliding block; a water receiving disc is arranged below a dewatering seat, and the dewatering hole faces the water receiving disc; and a collecting box is arranged below the dewatering seat. The kitchen waste disposer has the beneficial effects that the overall structure is ingenious, kitchen garbage can be crushed and dehydrated, then water and residues are discharged respectively, and therefore the purposes of harmlessness and resource circulation of the garbage are achieved.

Owner:NINGBO NEW GUANLIAN MOTOR ELECTRONICS

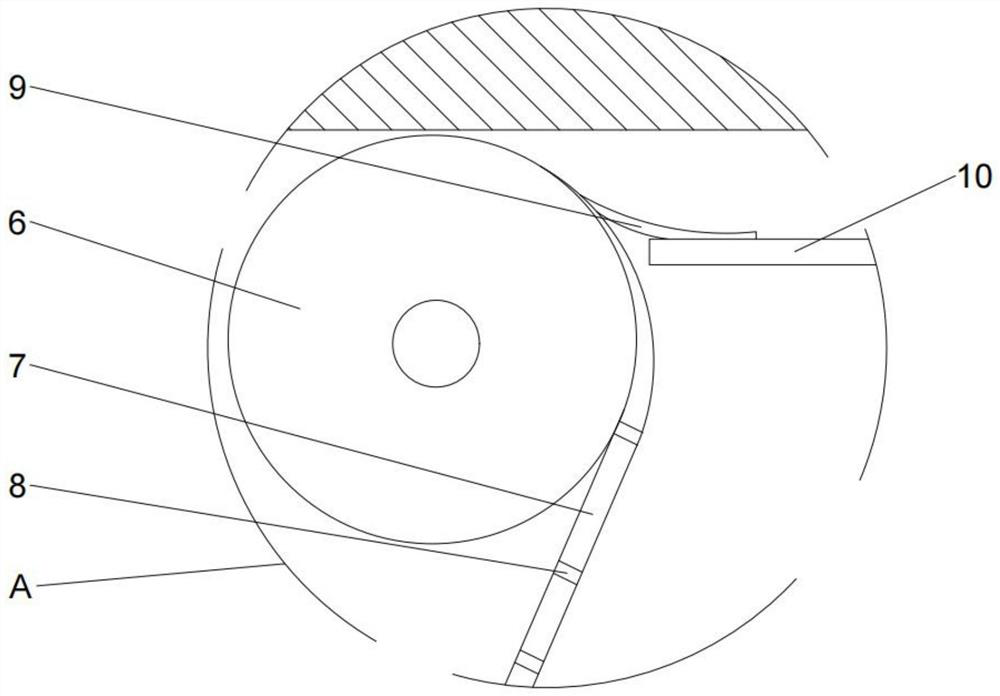

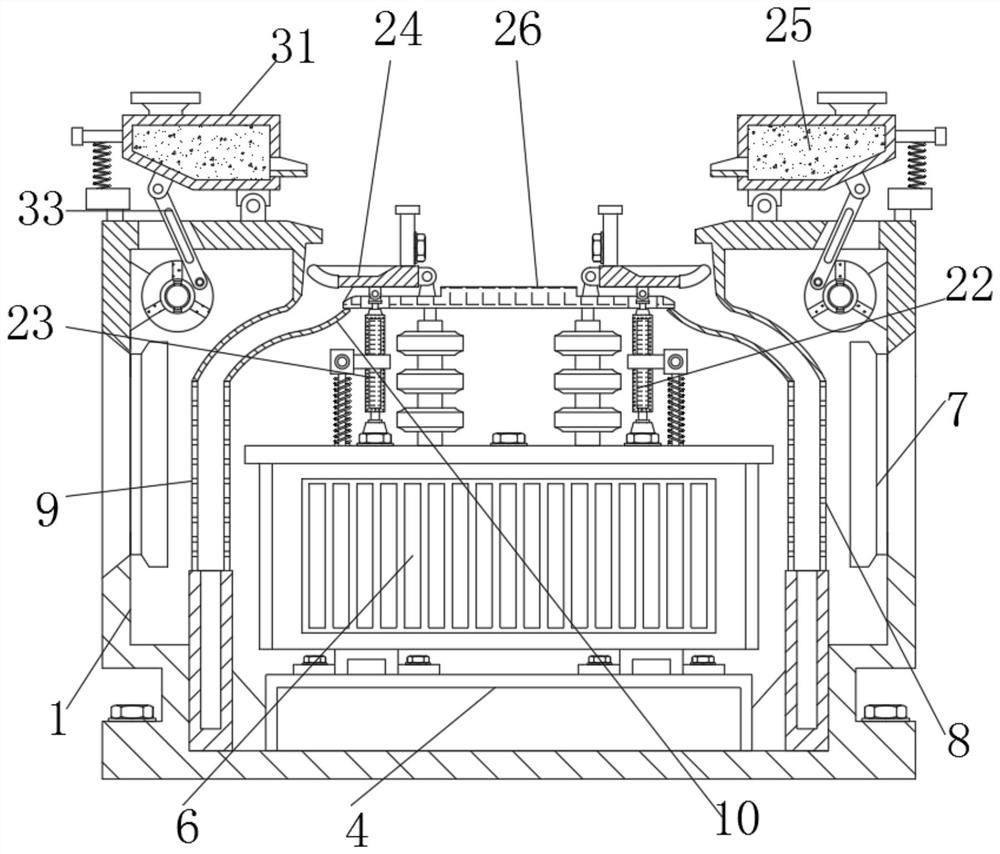

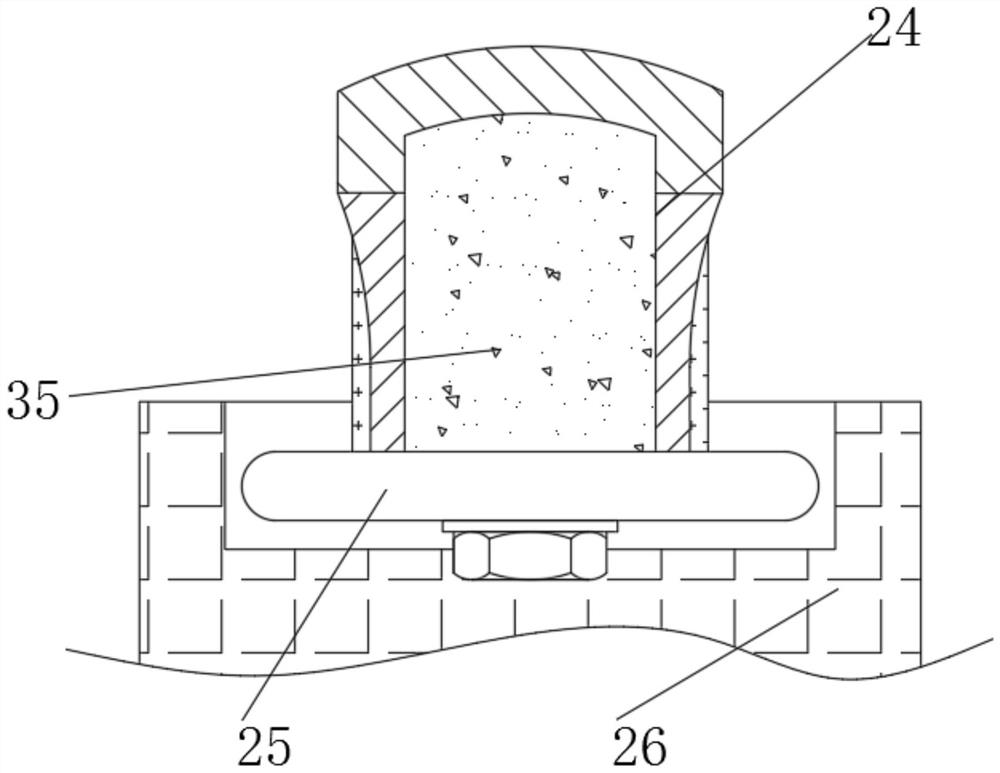

Stamping system for plate heat exchanger sealing gasket production and machining and stamping method thereof

ActiveCN113681798AEasy to operatePouring realizationDomestic articlesPlate heat exchangerEngineering

The invention relates to the technical field of sealing gasket stamping equipment, in particular to a stamping system for plate heat exchanger sealing gasket production and machining and a stamping method thereof. During pouring, an electric control telescopic rod is controlled to contract, namely, a connecting block moves upwards, on one hand, the connecting block is matched with a pouring assembly through a stamping assembly, a groove faces a pouring pipe, molten raw materials in the groove are injected into a pouring cavity from the pouring pipe, and at the moment, a torsional spring enables a blocking door to block the bottom of a pouring grooves, on the other hand, the connecting block drives the rotating assembly through a transmission assembly to enable an outer gear ring to rotate, so that the pouring area is changed, and complete pouring is achieved, during stamping, the electric control telescopic rod is controlled to extend, on the contrary, a first rack and a stamping ring move downwards, the stamping ring stretches into a pouring cavity and extrudes a sealing gasket, a blocking door is extruded by the upper portion to be automatically opened, and therefore the sealing gasket automatically falls off, and a rotating disc reversely deflects to enable the groove to face the material guide pipe again for next casting molding and stamping.

Owner:安徽凌谊密封科技有限公司

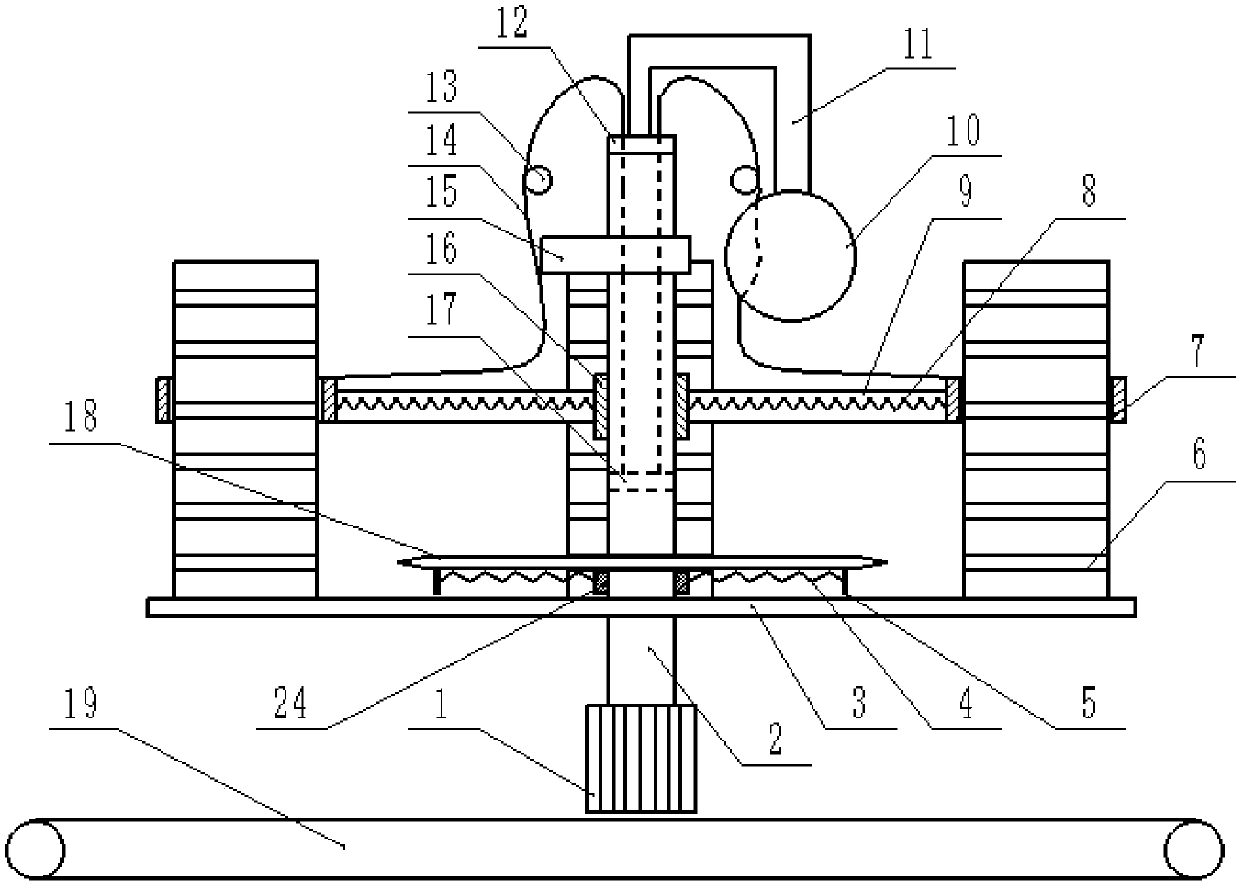

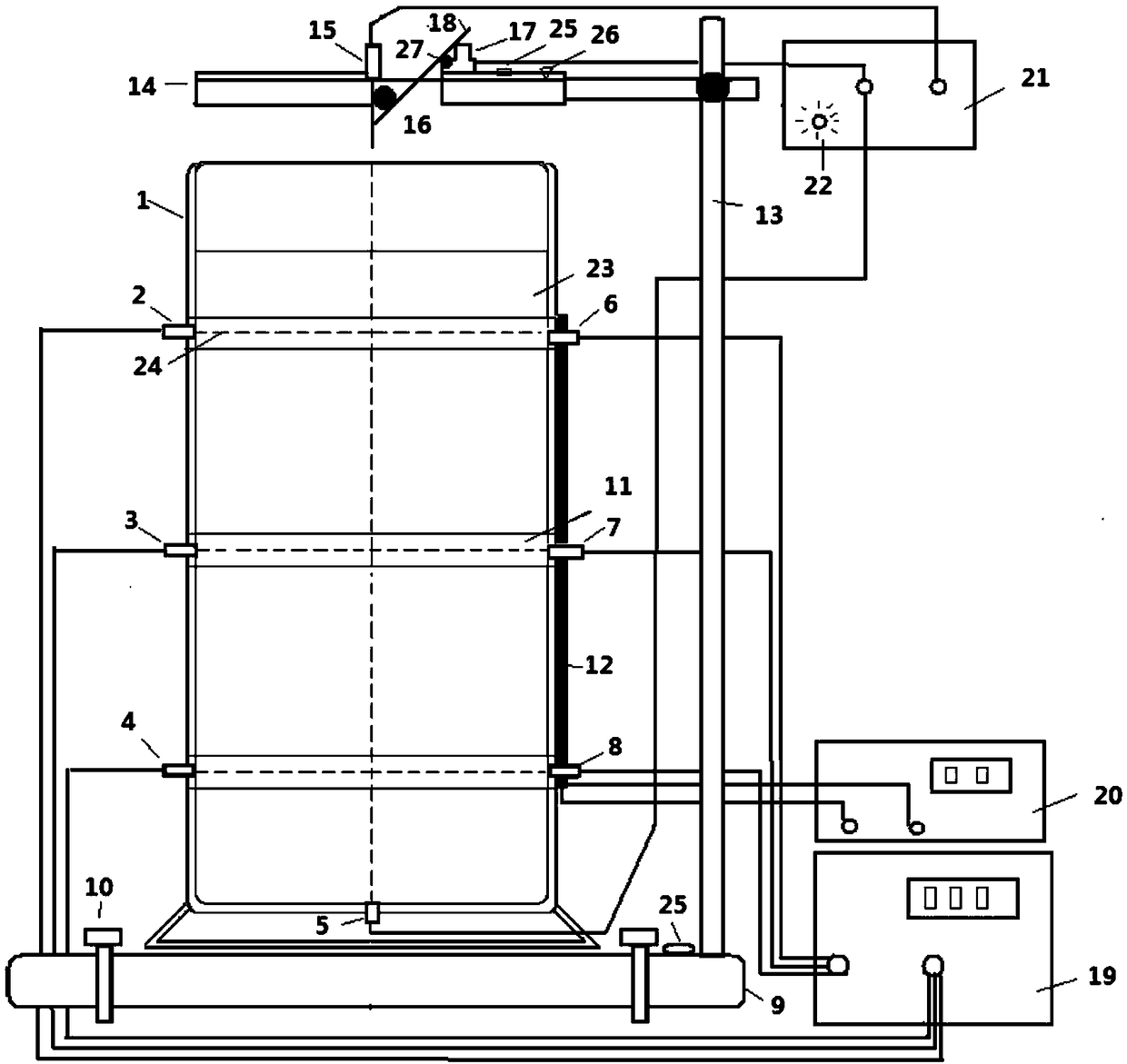

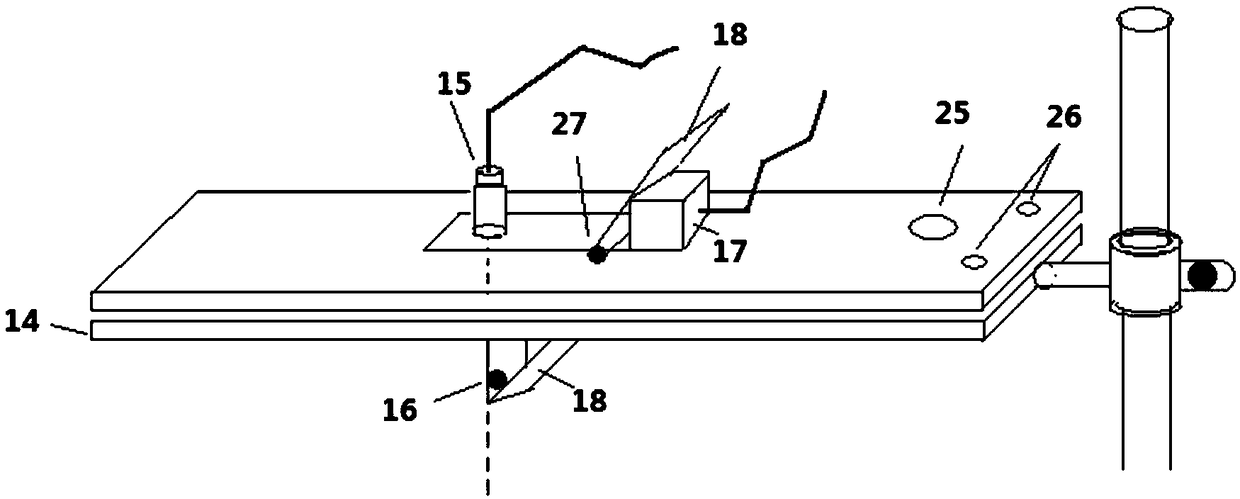

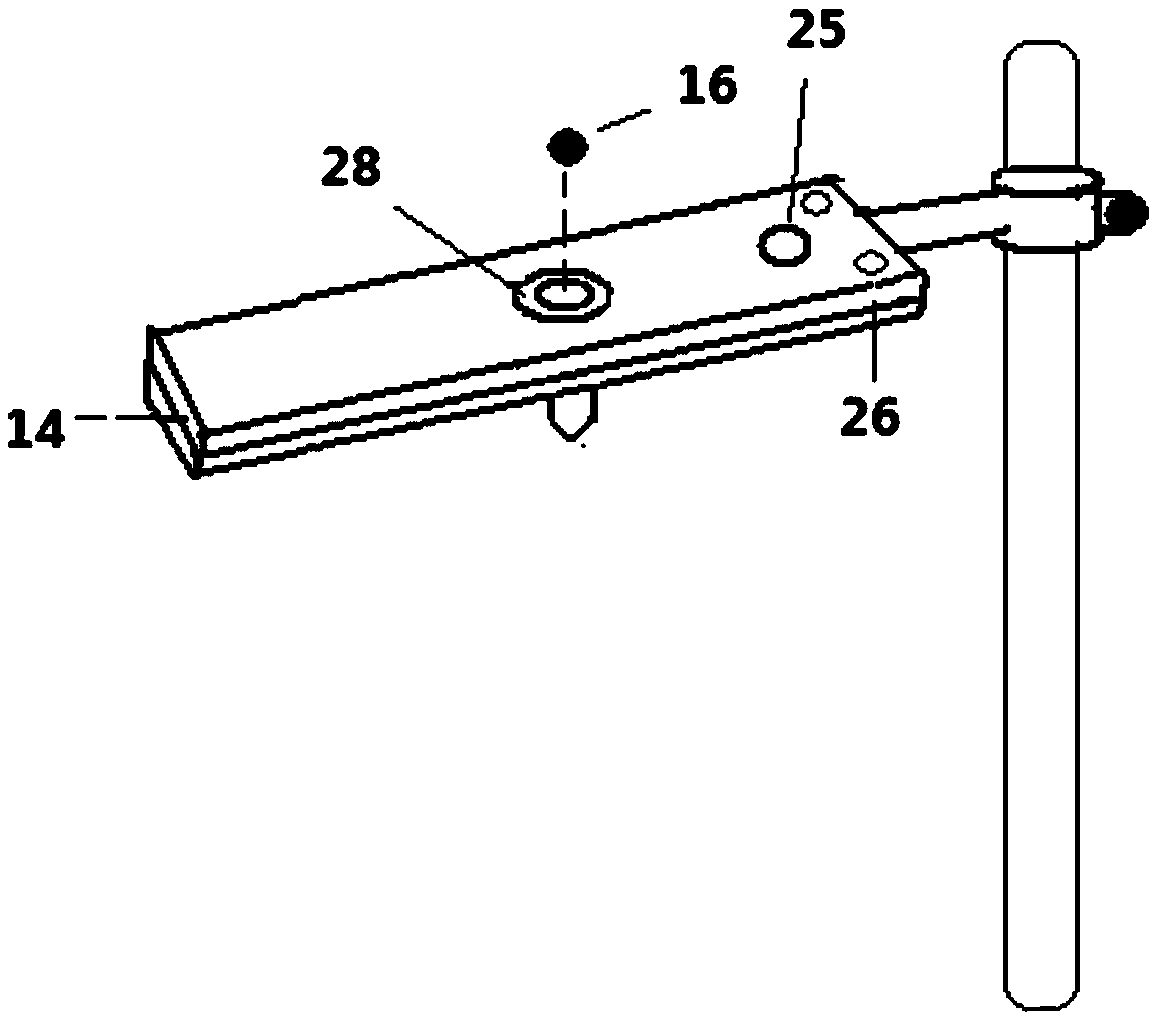

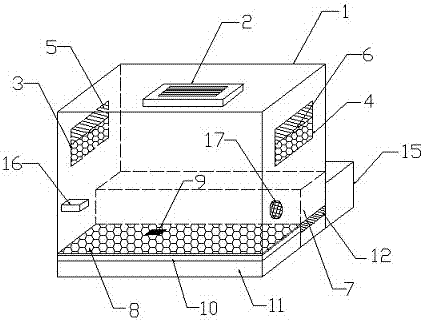

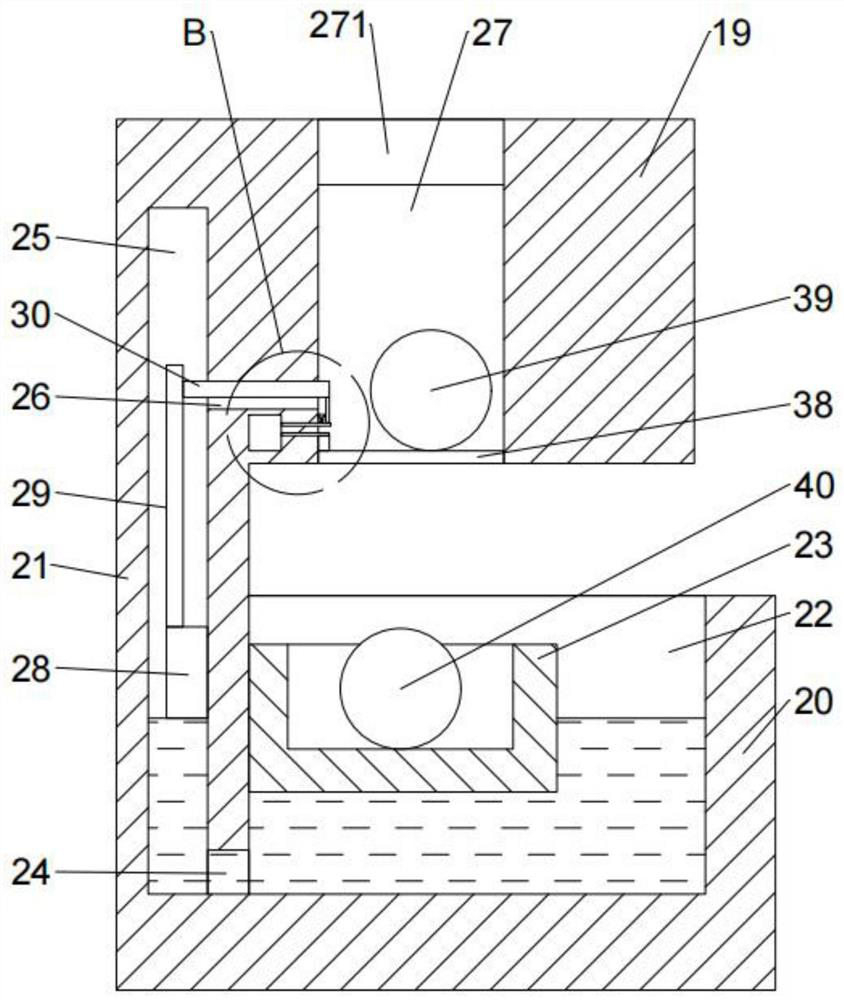

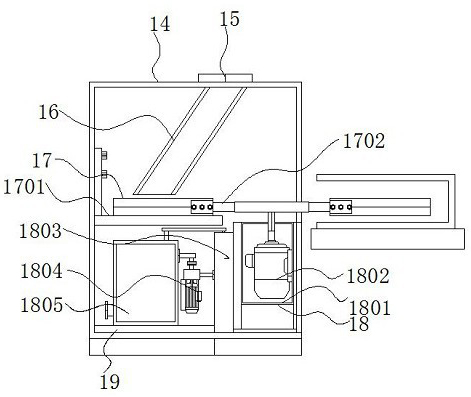

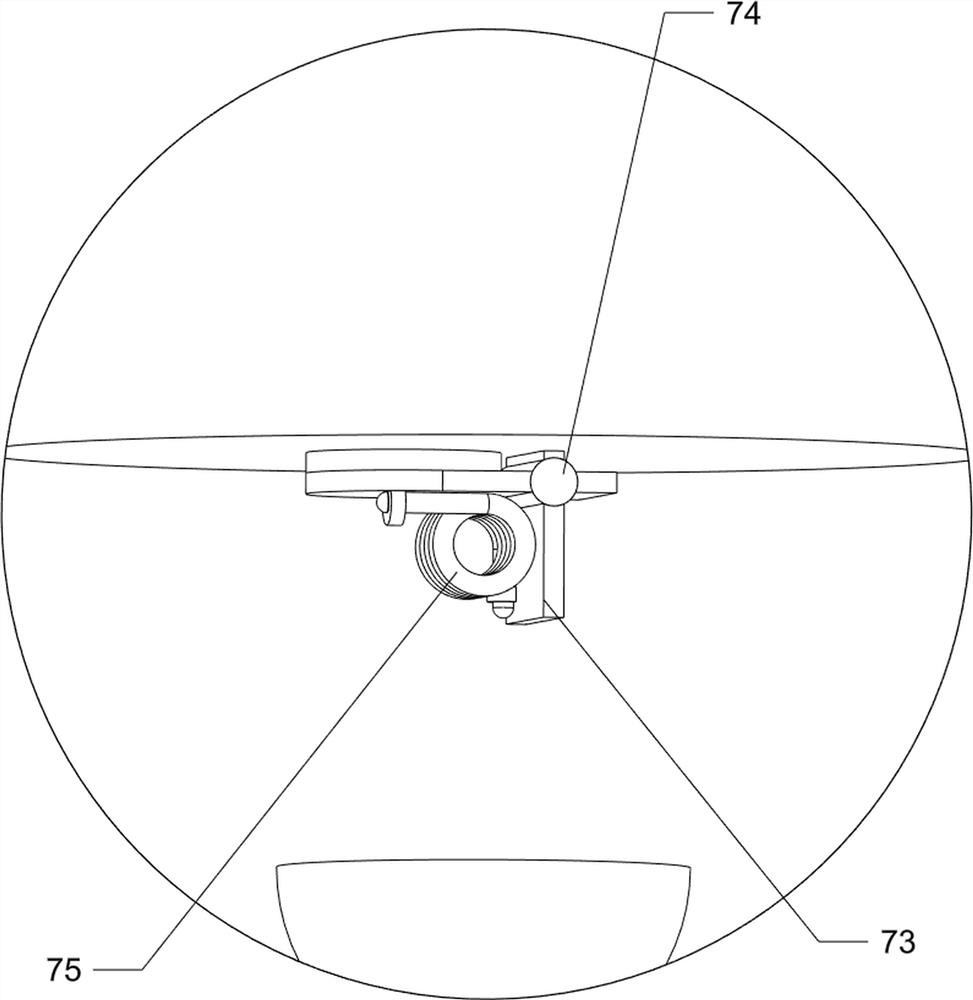

A three-dimensional laser positioning liquid viscosity coefficient measuring instrument

ActiveCN106596341BNo refraction occursEasy to operateFlow propertiesLaser transmitterTemperature control

The invention relates to a three-dimensional laser positioning thermostatic liquid viscosity coefficient measuring instrument and belongs to the technical field of liquid viscosity coefficient measurement. The three-dimensional laser positioning thermostatic liquid viscosity coefficient measuring instrument comprises a measuring cylinder, a first laser emitter, a second laser emitter, a third laser emitter, a fourth laser emitter, a first laser receiver, a second laser receiver, a third laser receiver, a fourth laser receiver, a base, a temperature control belt, a temperature control circuit, a vertical rod, a beam, a steel ball, a ball release device, a digital millisecond meter and a temperature controller. The laser emitters and the laser receivers are sealed in through holes arranged in the side wall of the measuring cylinder, and the measuring cylinder is arranged between each group of the laser emitter and receiver. The laser directly passes through the liquid to be measured so that a complex process of re-adjusting positions of the receivers after multiple-step refraction of laser is avoided and measurement accuracy and efficiency are improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Tin scraping device

PendingCN112872544AAutomatic liftAutomatic dropSoldering auxillary devicesReciprocating motionStructural engineering

The invention discloses a tin scraping device which comprises a scraping plate assembly and further comprises a support, a lifting assembly and a reciprocating type driving mechanism, and an annular groove is formed in the side wall of the support; the lifting assembly is matched with the annular groove, and the scraping plate assembly is connected with the lifting assembly; the reciprocating type driving mechanism drives the lifting assembly to reciprocate along the annular groove, and the lifting assembly is connected with the reciprocating type driving mechanism; the annular groove comprises a first groove section for guiding the lifting assembly to translate, a second groove section, a first guide groove and a second guide groove; the second groove section is used for guiding the lifting assembly to return, and the height position of the second groove section is higher than that of the first groove section; the first guide groove is used for guiding the lifting assembly to descend into the first groove section from the second groove section, one end of the first guide groove is connected with the first groove section, and the other end of the first guide groove is connected with the second groove section; and the second guide groove guides the lifting assembly to ascend from the first groove section to the second groove section, one end of the second guide groove is connected with the first groove section, and the other end of the second guide groove is connected with the second groove section. The tin scraping device has the advantage of stable slag scraping.

Owner:成都华川电装有限责任公司

Three-dimensional ground beetle breeding house

The invention discloses a three-dimensional ground beetle breeding house. A central air-conditioning is installed on the top of a breeding house body, a ground beetle breeding box is arranged in the breeding house body, a filter net is arranged at the bottom of the breeding house body, a pressure sensor is arranged in the filter net, a movable plate is arranged at the bottom of the filter net, a telescopic rod is connected with one side of the movable plate, a hydraulic cylinder is connected with one end of the telescopic rod, the hydraulic cylinder is installed in a control box, and a residuecollecting and storing box is arranged at the bottom of the movable plate. According to the three-dimensional ground beetle breeding house, the filter net is arranged at the bottom of the three-dimensional ground beetle breeding house and the movable plate is arranged at the bottom of the filter net, so that when there are too many residues on the filter net, the pressure sensor senses information, the information is transmitted to the control box, a voice broadcasting machine is controlled by the control box to perform reminding, if there is no one to interfere within a period of time, the hydraulic cylinder is driven under the control of the control box to stretch the telescopic rod, so that the movable plate is pulled into a movable plate placement groove, and therefore the residues onthe filter net automatically drop into the residue collecting and storing box.

Owner:姬志刚

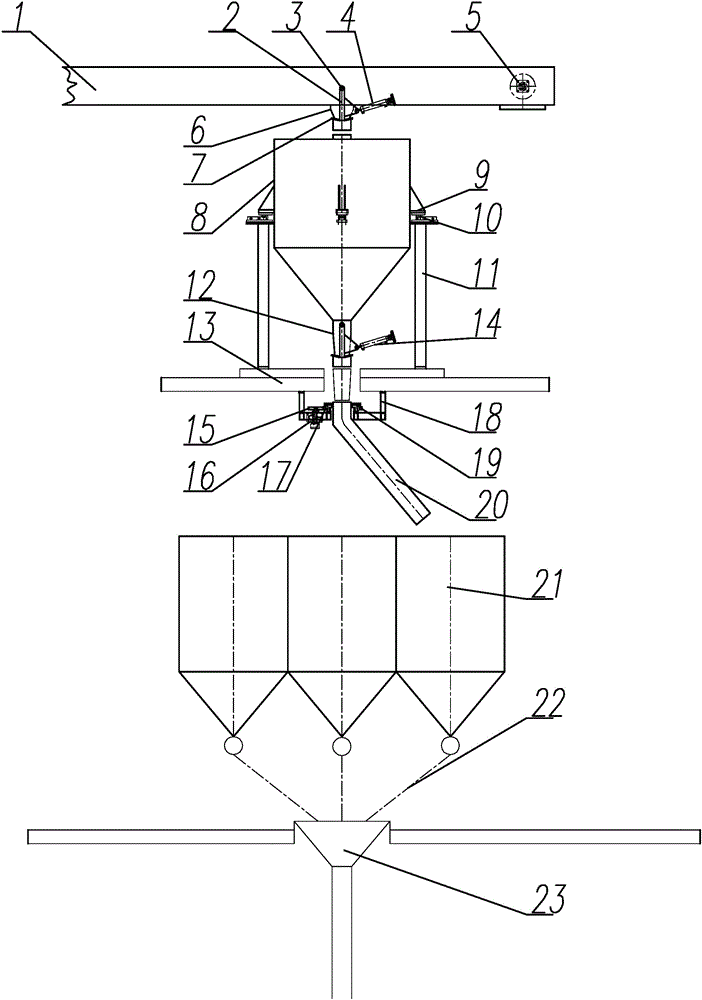

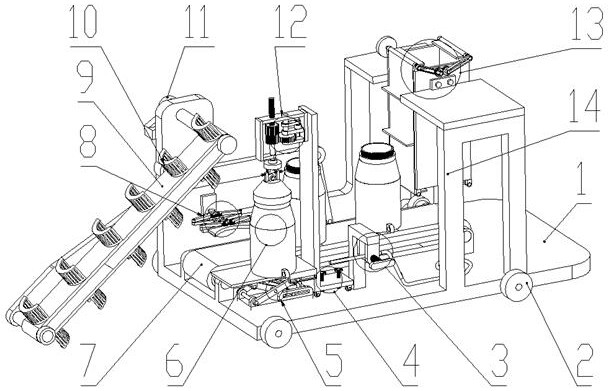

Automatic packing machine of fruit paper bags

PendingCN107128537AAutomate operationImprove aestheticsWrapping material feeding apparatusWrapper twisting/gatheringAgricultural engineeringIndustrial engineering

The invention discloses an automatic packing machine of fruit paper bags. The machine comprises a frame with a tabletop at the upper part, a paper feeding bracket arranged on the frame, a paper feeding roller, a paper tensioning mechanism, a conical paper gathering hopper, a side edge hot sealing mechanism, a paper puller, an end hot sealing mechanism and a discharge conveying device which are arranged in sequence from top to bottom, a paper gathering frame for placing the paper gathering hopper, a protection frame arranged with the side edge hot sealing mechanism side by side, a feed conveying device matched with the paper gathering hopper in position, and a control device. The paper gathering hopper, the side edge hot sealing mechanism, the paper puller and the end hot sealing mechanism are matched for hot sealing and bonding of packing papers on the paper feeding roller to form a paper bag shape; and the feed conveying device is used for feeding fruits into paper bags to realize automatic packing, so that the convenience and the practicability are achieved, the product beauty and grade are improved, and the packing production efficiency is improved.

Owner:CHENGDU TIANXING PRINTING

Forestry disease and pest control device

ActiveCN114680088AEasy to fix and labor-savingAvoid displacementInsect catchers and killersAnimal sciencePest control

The forestry disease and pest control device comprises a machine body, an insect catching cavity, a first transmission cavity, a force transmission cavity and a second transmission cavity are formed in the machine body, the insect catching cavity communicates with the right wall of the machine body, the insect catching cavity communicates with the first transmission cavity through a first connecting channel, and the first transmission cavity communicates with the force transmission cavity; the second transmission cavity communicates with the bottom wall of the machine body through a second transmission channel, and the bottom wall of the machine body is fixedly connected with an elastic telescopic block. An insect catching mechanism and an insect luring mechanism are arranged in the insect catching cavity, a recycling mechanism is arranged in the first transmission cavity, a power mechanism is arranged in the force transmission cavity, the insect catching mechanism is connected with the recycling mechanism, the recycling mechanism is connected with the power mechanism, and a fixing mechanism is arranged in the second transmission cavity. The insect catching device can conveniently catch insects, and insect catching components can be automatically replaced.

Owner:神木市林草病虫和火灾防治中心

Pull type limo carriage production coating equipment

InactiveCN114160337AAutomatic dropTo achieve the effect of automatic declineSpraying apparatusCarriageMechanical engineering

The invention relates to the technical field of travel trailer compartment production, and discloses travel trailer compartment production coating equipment which comprises an equipment body, a telescopic frame is fixedly mounted on the front face of the equipment body, a spraying frame is fixedly connected to the top of the telescopic frame, and a sliding rod is fixedly mounted on the front face of the equipment body; a supporting plate is slidably connected to the front face of the sliding rod, a supporting sliding rod is fixedly connected to the front face of the supporting plate, and a compartment is fixedly installed at the top of the supporting plate. According to the travel trailer compartment production coating equipment, the spraying box is arranged, a rotating screw rod in a spraying frame rotates in an open groove, under the action of an extension spring, a fixing plate is driven to stabilize a compartment, and meanwhile, a spraying pipe on a sliding rod groove in the bottom of the extension spring sprays the compartment; and therefore, the effect of spraying the whole carriage is achieved.

Owner:湖南文辉汽车制造有限公司

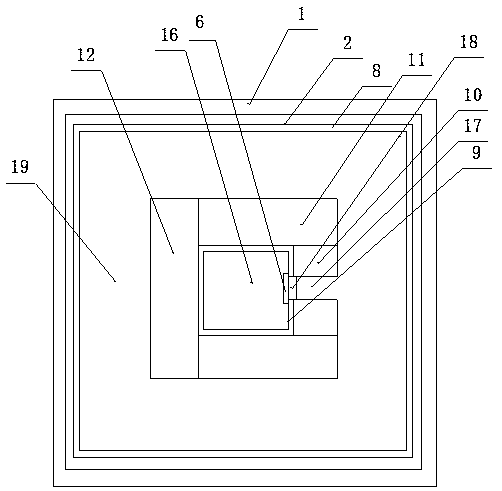

Relay shell automatic assembling equipment with dust removal structure and convenient adjustment

InactiveCN112233936ADust removal structure is easy to adjustAvoid scratchesRelaysDust controlElectric machinery

The invention discloses relay shell automatic assembling equipment with a dust removal structure and convenient adjustment, and relates to the technical field of relay shell assembling. The relay shell automatic assembling equipment comprises a cover plate and a connecting disc, a connecting frame is arranged outside the bottom of the cover plate, a connection frame is installed at the bottom of the connecting frame, and auxiliary devices are arranged at the two ends of the exterior of the top of the connection frame; and adjustment devices are installed at both ends of the auxiliary device. Through the arrangement of a cover pressing device, the cover plate subjected to preliminary positioning can be pressed downwards, so that the cover plate and the connecting frame are buckled together,namely, a movable connecting rod, a connecting rod and the cover pressing device are driven to move by the arrangement of the power motor at the rear end of the connecting disc; a pressure head connected with the cover pressing device can slide up and down in a slide way, and a thickened rubber layer is arranged on the surface of the bottom of the pressure head, so that the outer surface of the cover plate can be effectively prevented from being scratched when the cover plate is pressed down by utilizing the pressure head.

Owner:深圳市康瑞龙数控科技有限公司

Special maintenance vehicle for power equipment maintenance

InactiveCN110844849AEasy to storeHigh degree of automationLifting devicesElectric power equipmentElectric machinery

The invention discloses a special maintenance vehicle for power equipment maintenance. The special maintenance vehicle comprises a base and a maintenance platform; an infrared distance meter and a control box are arranged on the lower end of the maintenance platform, a motor and a first controller are arranged inside the control box, one end of the first controller is connected with the infrared distance meter, the other end of the first controller is connected with a ladder winding shaft through the motor, so that the rotation of the ladder winding shaft is controlled, and a rope ladder is arranged on the ladder winding shaft; the maintenance platform is connected with the base through an electric telescopic rod, and the upper end face of the maintenance platform is provided with an external guardrail, internal guardrail, glove boxes, tool boxes and winding drum grooves; the base is connected with the ground through traveling wheels, and the lower end of the base is provided with counterweight pins; and the outer end face, close to the control box, of the maintenance platform is provided with an RFID tag, and the RFID tag is connected with the first controller inside the control box. According to the special maintenance vehicle for the power equipment maintenance, the infrared distance meter is arranged, so that the distance between the maintenance platform and the base can bemonitored, thus the ladder winding shaft is controlled by the motor through the first controller, and the automation degree is high.

Owner:国网河南省电力公司中牟县供电公司 +1

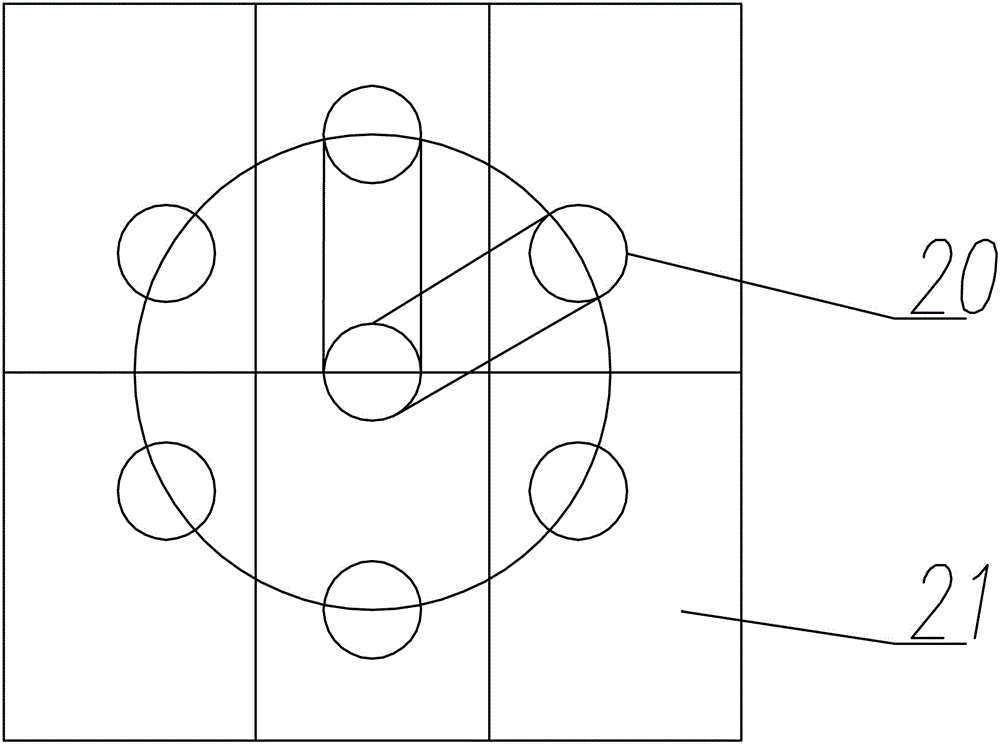

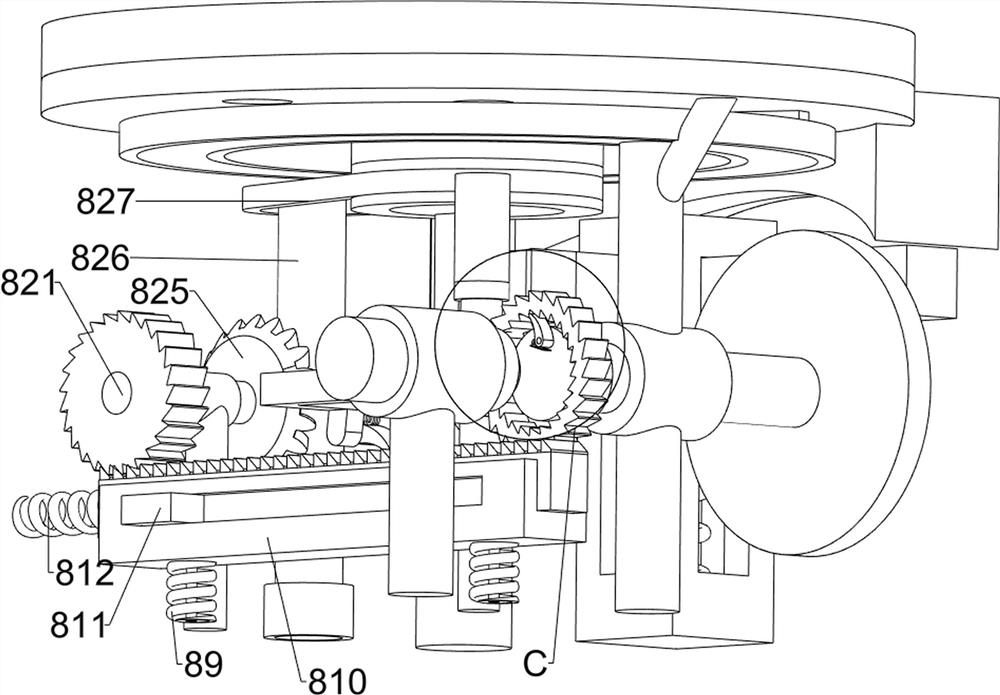

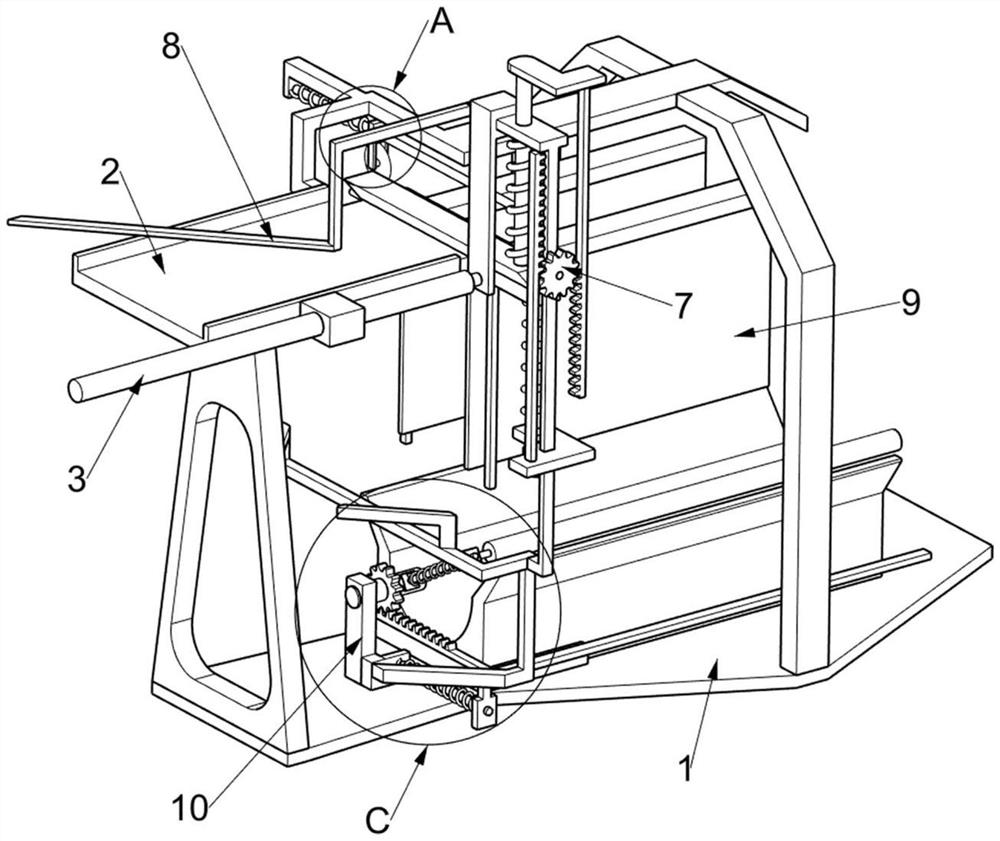

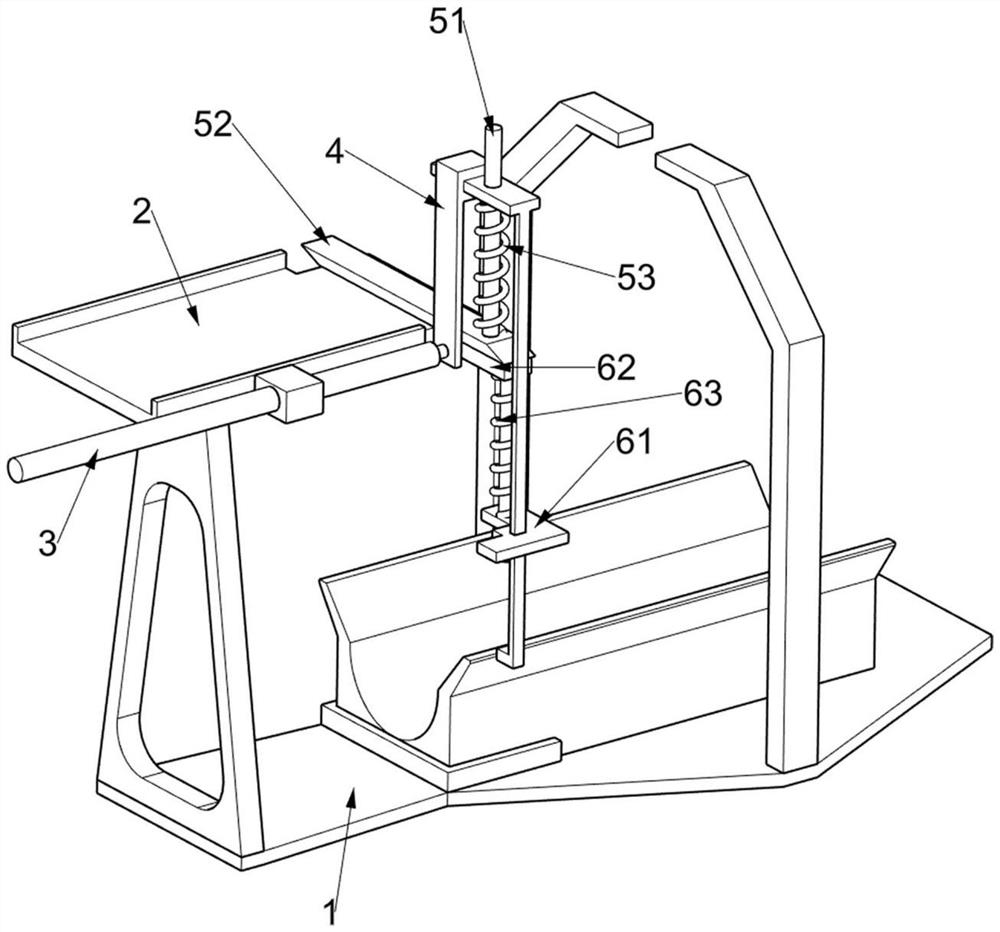

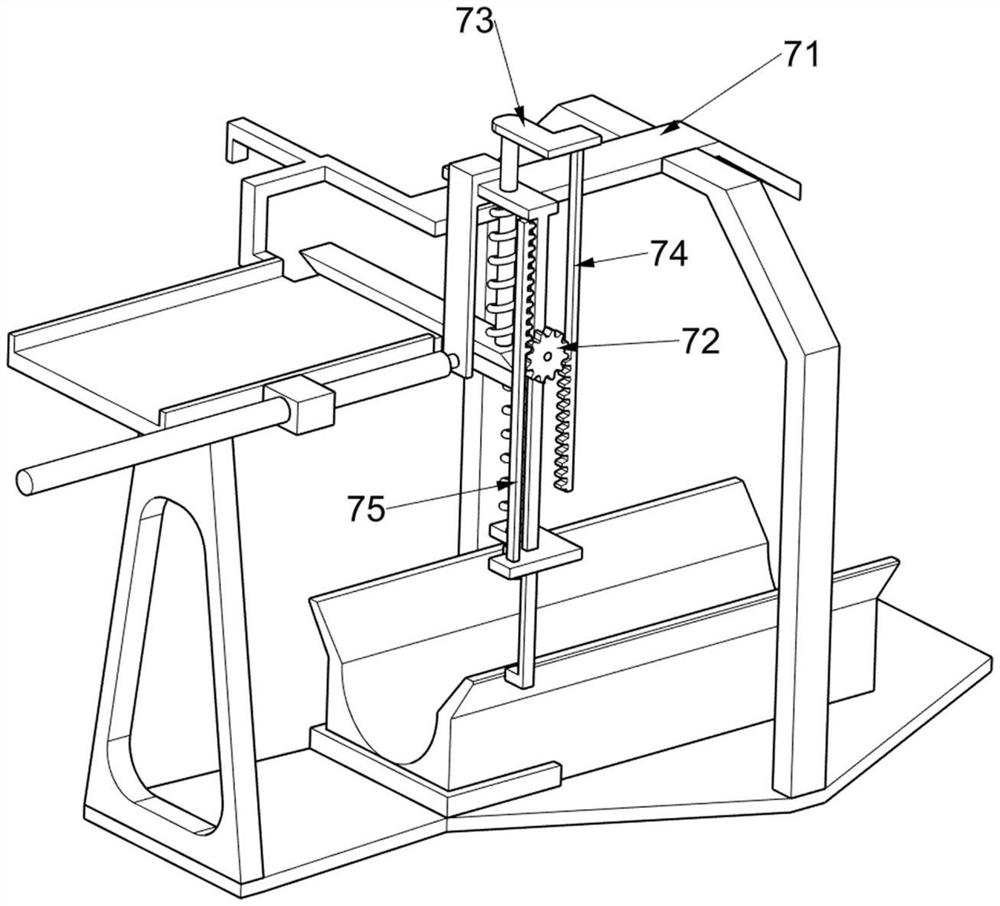

An injection molding flange gasket rotary groove external cutting device

ActiveCN111571689BIncrease productionFeatures that do not require laborious retrievalMetal working apparatusClassical mechanicsStructural engineering

The invention relates to an external cutting device, in particular to an external cutting device for a spiral groove of an injection-molded flange pad. The object of the present invention is to provide a safe, labor-saving and large-capacity injection-molded flange gasket rotary groove external cutting device. The technical embodiment of the present invention is: a kind of injection molding flange gasket rotary groove external cutting device, including lower bracket, support rod 1, upper bracket, support rod 2, mounting plate 1 and intermittent mechanism, etc., support rod 1 is Four are fixed to the lower bracket, the upper bracket is fixed to the first support rod, four support rods are fixed to the upper bracket, and the first mounting plate is fixed to the second support rod. The invention improves the production capacity through the clamping mechanism, and can perform the function of intermittently and automatically turning the groove and cutting the flange pad through the intermittent mechanism, the rotating cylinder, the rotating disk and the turning groove mechanism.

Owner:黄山耀瑞精密模塑科技有限公司

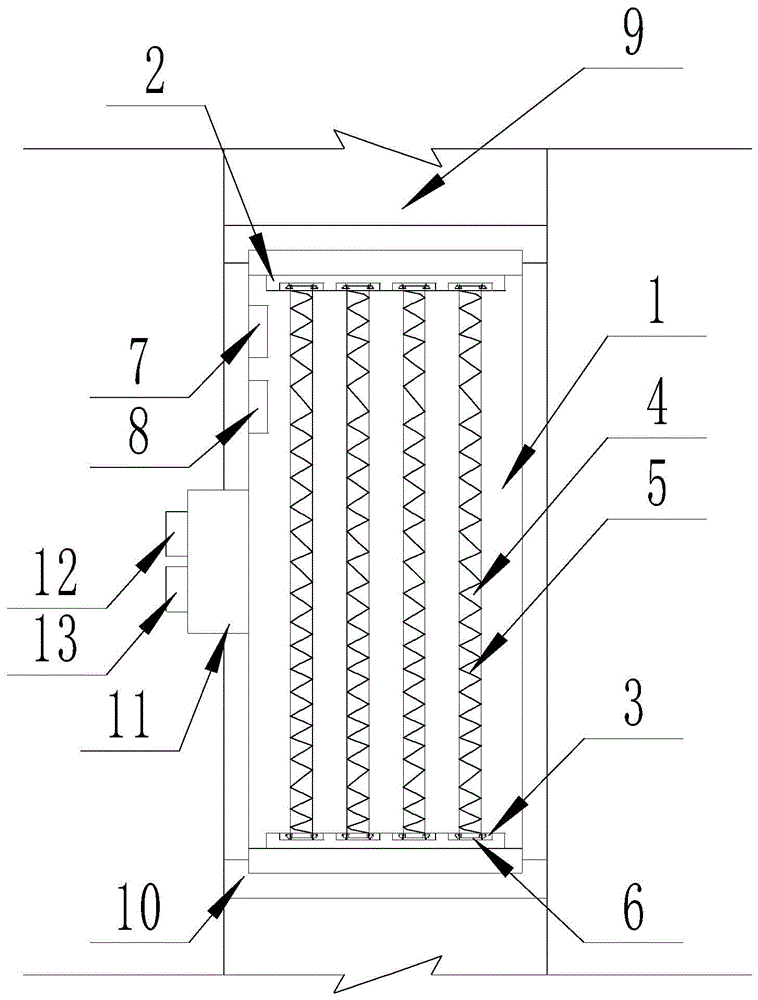

Workshop waste liquid discharge device with iron removal function

ActiveCN105668728AAutomatic dropWater/sewage treatment by magnetic/electric fieldsWaste water treatment from metallurgical processLiquid wasteIron removal

The invention discloses a workshop waste liquid discharge device with iron removal function. The device comprises a rectangular box body, wherein both sides inside the rectangular box body are provided with a set of wiring boards; the set of wiring boards are provided with wiring grooves at equal intervals; a plurality of iron cores are arranged in the rectangular box body; each iron core is provided with an enameled wire; both ends of each iron core are provided with connecting terminals; the upper surface in the rectangular box body is provided with a voltage stabilizer and a transformer; the lower part of the rectangular box body is provided with a waste liquid pipe; the outer surface of the waste liquid pipe is provided with a rectangular opening; the rectangular box body is provided with a controller; and the controller is electrically connected with the voltage stabilizer, iron cores, connecting terminals, enameled wires and transformer.

Owner:台州市三鼎机电股份有限公司

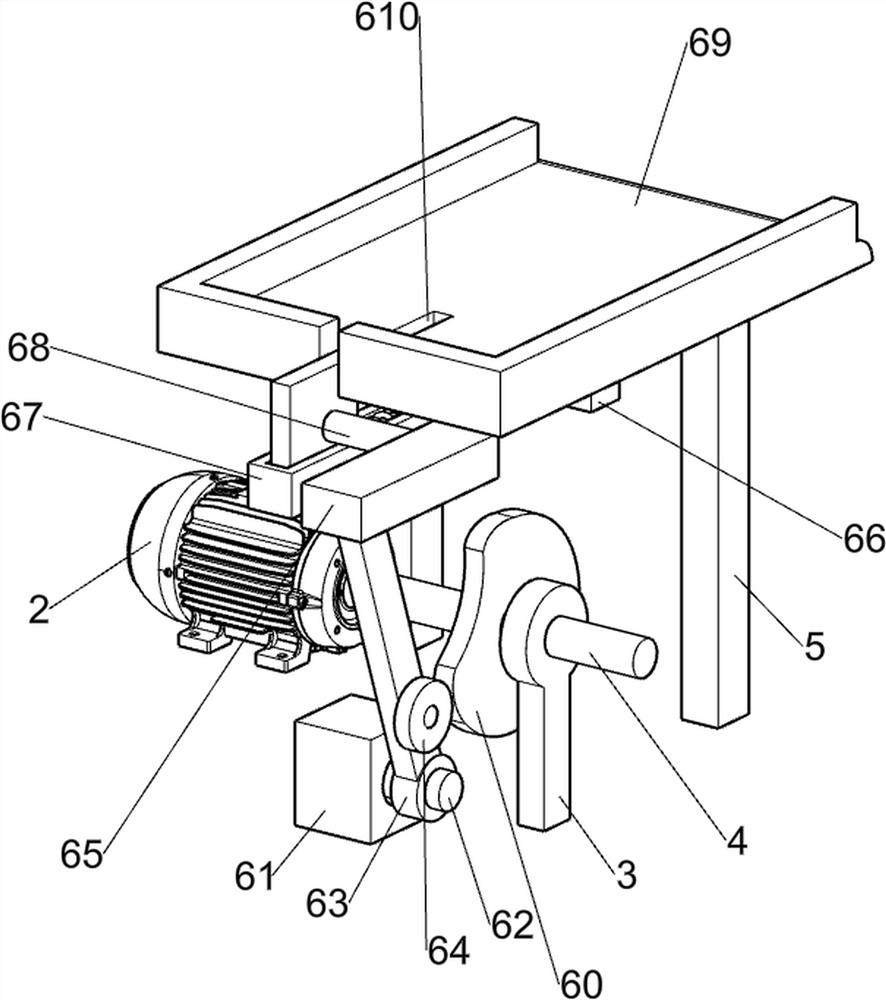

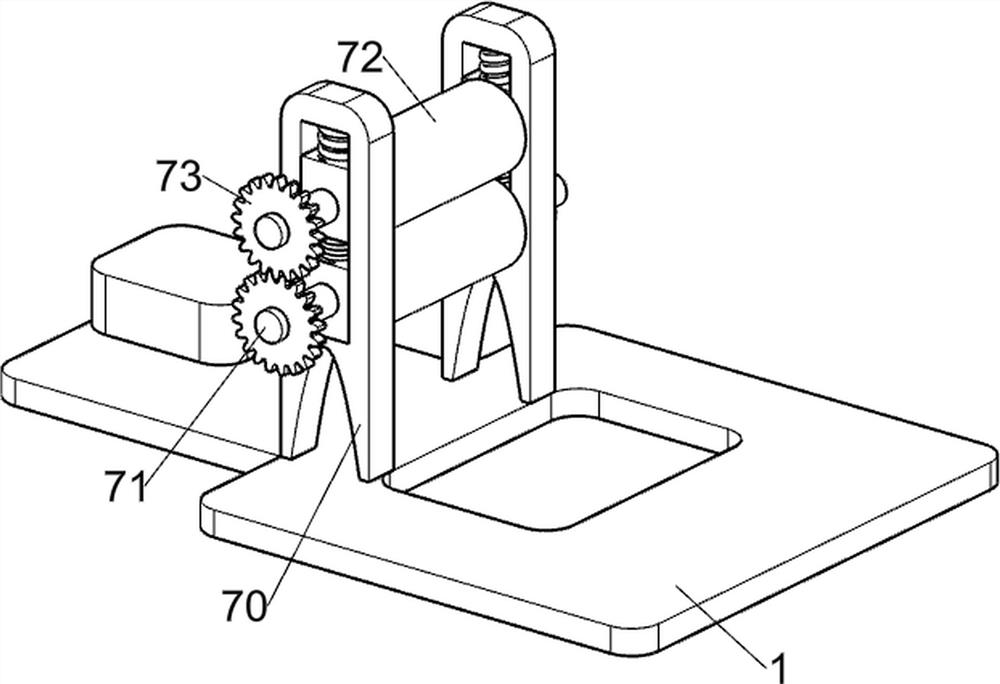

Extrusion forming device for cheese production

InactiveCN112450077AAutomatic cuttingImprove work efficiencyCheese manufactureProcess engineeringWaste material

The invention relates to an extrusion forming device, in particular to an extrusion forming device for cheese production. The extrusion forming device for the cheese production aims to the technical aims that excess materials can be recycled, discharging can be automatically conducted, and the working efficiency is high. The extrusion forming device for the cheese production comprises a bottom plate, a supporting seat, a sliding assembly and an extrusion assembly, wherein a supporting column is connected to the middle of the bottom plate; the supporting seat is arranged in the middle of the supporting column in a rotating mode; the sliding assembly is arranged in the middle of the bottom plate; the extrusion assembly is arranged on the upper portion of the supporting column. According to the device, the effects that the excess materials can be recycled, the discharging can be automatically conducted, and the working efficiency is high are achieved, a scraper blade can scrape off the excess materials below a pressing blocks during rotation and enable the excess materials to automatically fall into a waste material barrel through a small hole, and therefore the excess materials can be recycled, and waste cannot be caused.

Owner:黄凌志

Carbon fiber curing cutting device capable of placing fibers into mold

The invention relates to the field of carbon fiber processing, in particular to a carbon fiber curing cutting device capable of placing fibers into a mold. The carbon fiber curing cutting device comprises a first fixing frame, a fixing table, an electric push rod, a second fixing frame, a first clamping mechanism and the like; and the fixing table is fixedly connected to the upper part of the first fixing frame, the electric push rod is fixedly installed on one side of the fixing table, the second fixing frame is fixedly connected to one end of a telescopic shaft of the electric push rod, and the first clamping mechanism is arranged on the second fixing frame. Through cooperation of a cutting blade and devices on the cutting blade, the cutting blade can cut the carbon fibers to be processed, the position of the first fixing rod is fixed, so that the position of the carbon fibers cut by the cutting blade is accurate, a cutting track is a straight line, so that the flatness of a notch can be ensured, the production efficiency is improved, and the effects that the carbon fibers to be processed can be automatically cut and the cutting precision is guaranteed are achieved.

Owner:吴施宾

Garbage collection and treatment device for sea surface garbage concentration area

ActiveCN110077764BStreamlining the transfer processImprove replacement efficiencyRefuse transferringLoading/unloadingRefuse collectionEnvironmental engineering

The invention provides a garbage collection and treatment device for a sea surface garbage concentration area, which includes a horizontally placed bottom plate, a first transmission mechanism for transferring a buoyant cylinder from one end of the bottom plate to the other end, and is arranged on the first transmission mechanism and used for A buoy for collecting sea surface garbage, an auxiliary lowering mechanism arranged at one end of the bottom plate for lowering the buoy to the first conveying mechanism, and an auxiliary lowering mechanism arranged at the other end of the bottom for conveying sea surface garbage into the buoy Two transmission mechanisms, a cylinder cover opening and closing mechanism arranged on one side of the scissor lift mechanism and used to assist in closing the cylinder cover, and a rope extrusion mechanism for connecting several buoys in series; the garbage collection area for sea surface garbage provided by the present invention The processing device makes it easy to clean up the garbage mountains on the sea far away from the mainland, reduces the amount of single cleaning, reduces the inconvenience of reciprocating and turning back and forth to clean up garbage, and greatly improves the efficiency of cleaning.

Owner:日照一诚信息科技有限公司

Automatic fire extinguishing device for fire disaster of small transformer

InactiveCN114373597AConvenient whereaboutsReduce the fireTransformers/inductances casingsFire rescueKeroseneEnvironmental geology

The invention relates to the technical field of electrical equipment, and discloses a small transformer fire automatic fire extinguishing device which comprises a protection box, a fire sensing mechanism is arranged in the protection box, a supporting rod is arranged in the fire sensing mechanism, a glass tube is connected to the upper end of the supporting rod, kerosene is arranged in the glass tube, and the kerosene is arranged in the protection box. A leakage groove is connected to the upper end of the glass tube, a baffle is connected to the outer portion of the leakage groove, a supporting plate is connected to the lower end of the leakage groove, a feeding door is arranged at the upper end of the storage bin, a discharging door is arranged on the side, close to the supporting plate, of the storage bin, and a hinge rod is movably connected to the lower end of the side, away from the supporting plate, of the storage bin. The end, away from the storage bin, of the hinge rod is movably connected with a rotary disc, and gravel is contained in the storage bin. The device has the advantages that the device can be automatically triggered when a fire occurs, meanwhile, the fire can be automatically extinguished, and the electric shock danger cannot be caused.

Owner:徐州浩海电气有限公司

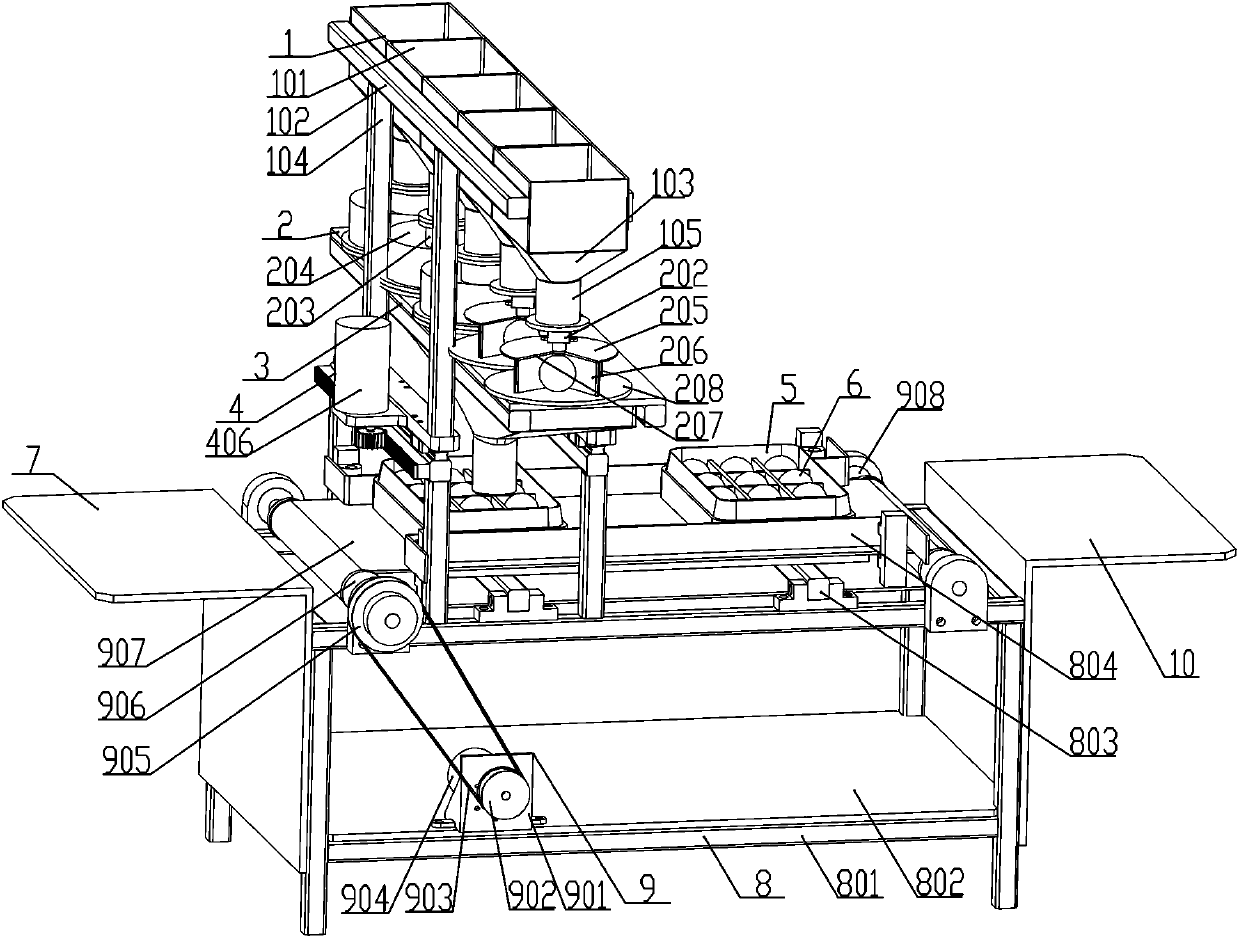

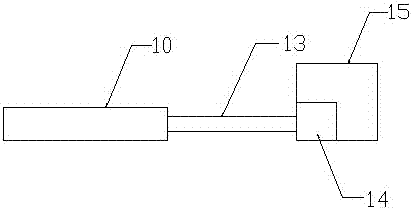

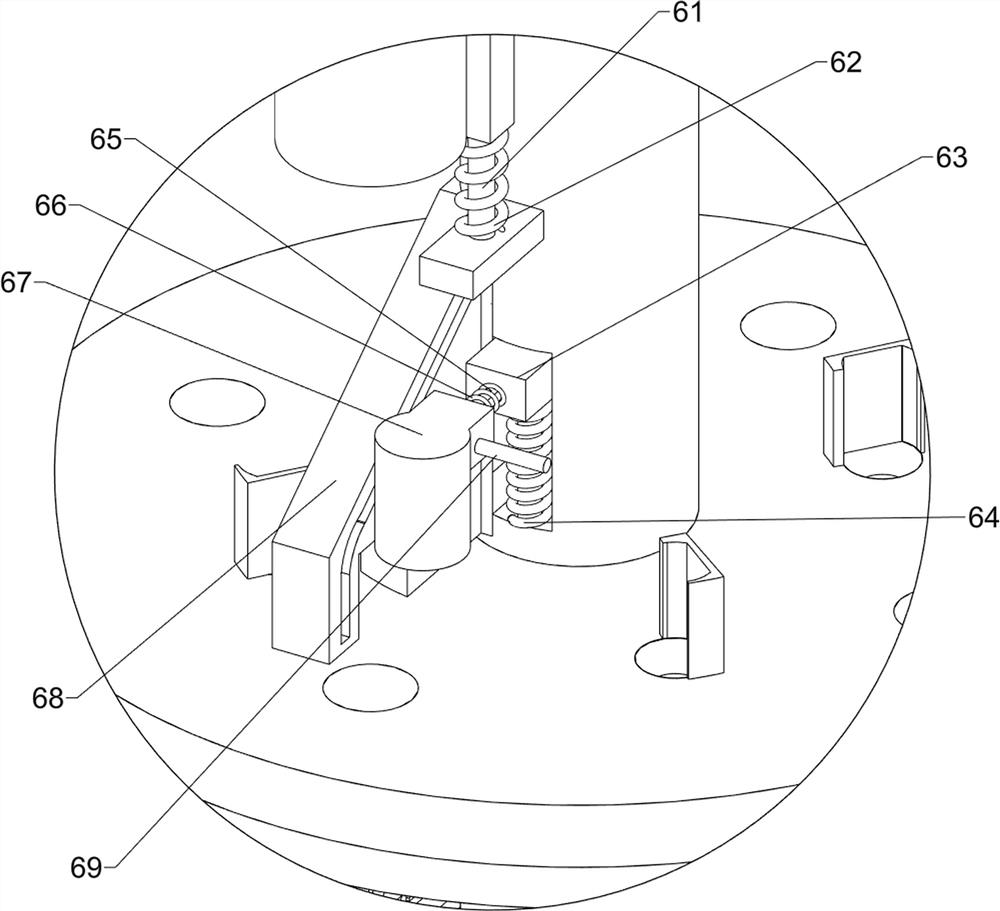

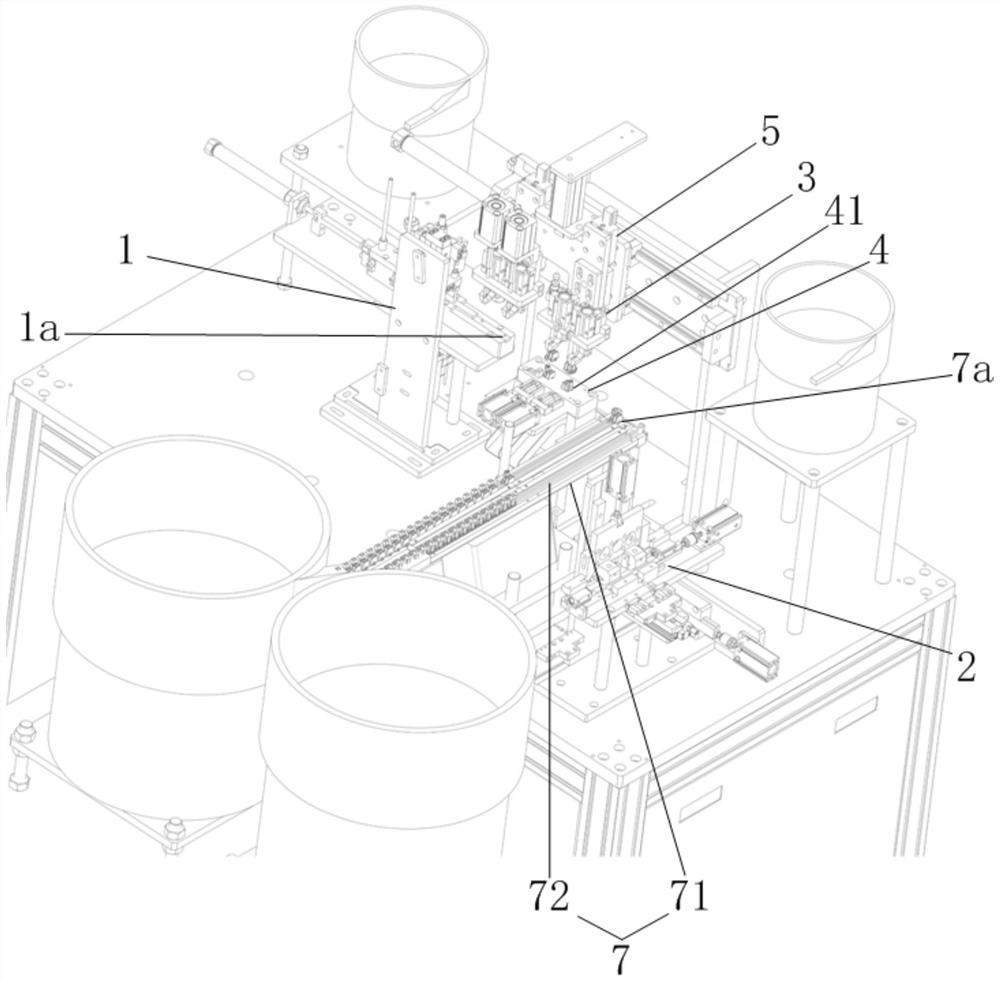

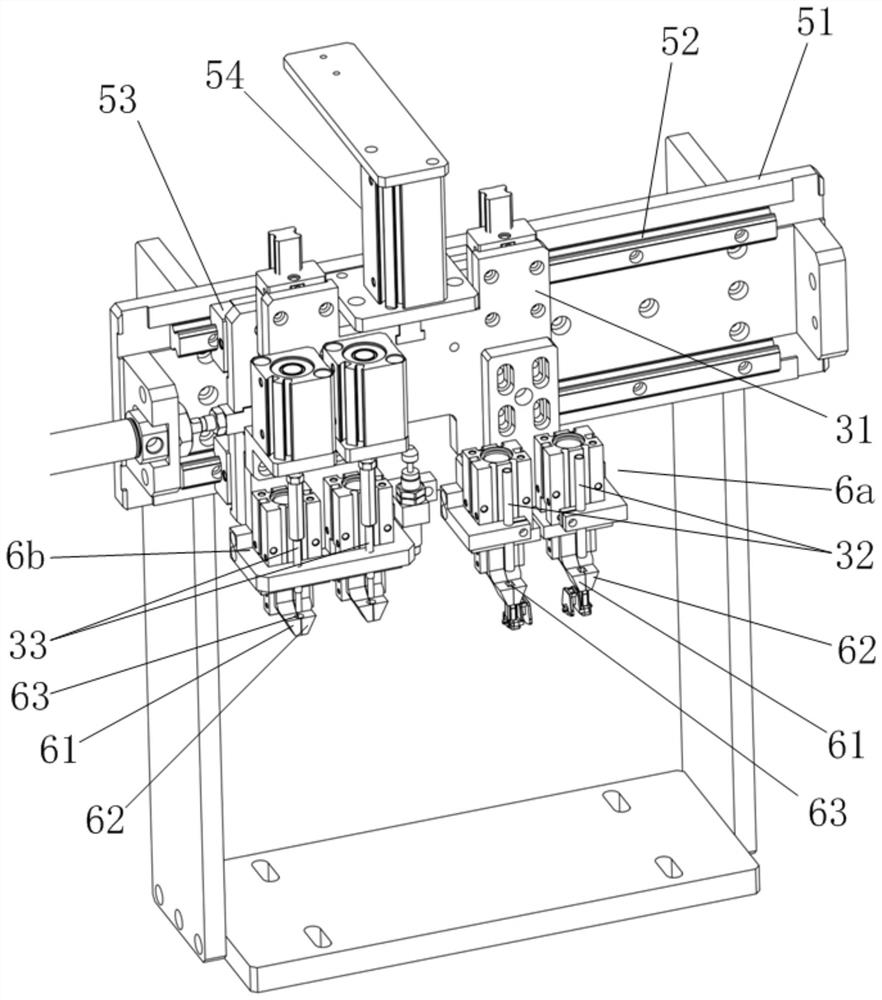

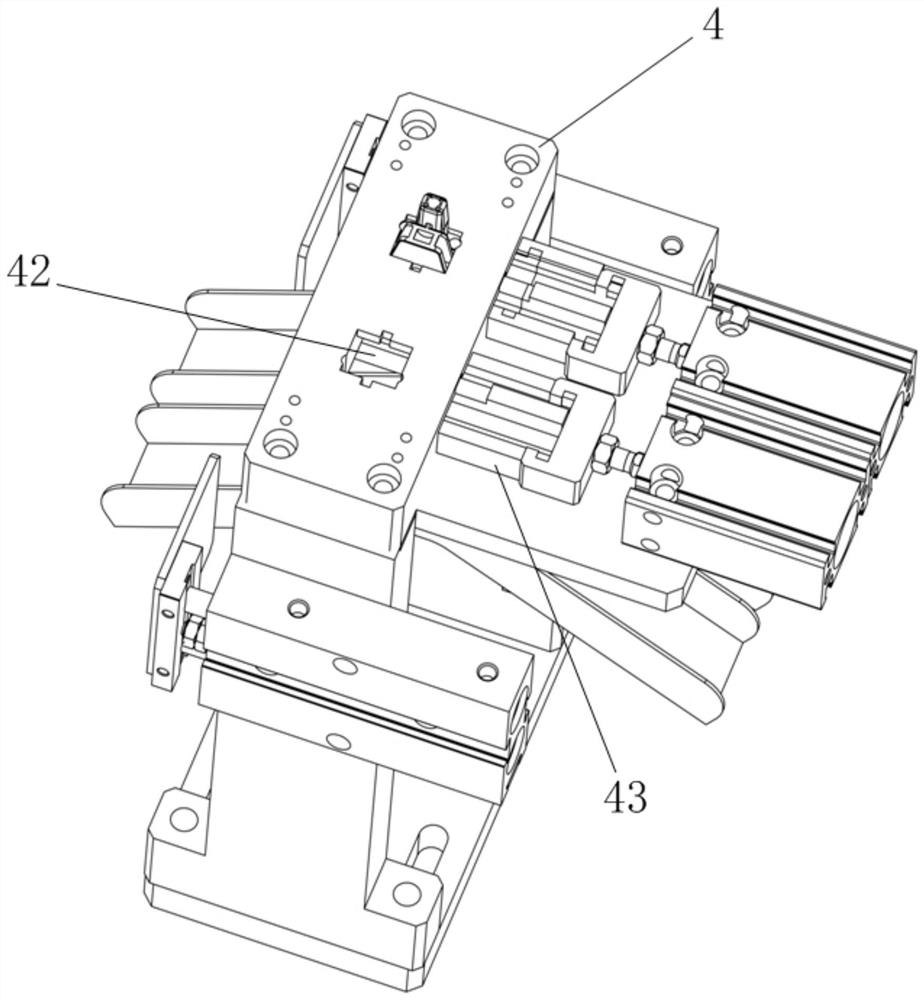

Spring marble assembling machine

The invention discloses a spring marble assembling machine which comprises a marble feeding device, a spring feeding device and an assembling device, and the marble feeding device is provided with a marble station; wherein the assembling device comprises an assembling mechanism, an assembling table and a reciprocating mechanism, the assembling mechanism reciprocates to and fro the marble station and the assembling table through the reciprocating mechanism, and the assembling table is provided with a blanking through hole and a movable baffle used for controlling the blanking through hole to be opened and closed; the assembling mechanism comprises a lifting base plate, a spring discharging pipe and a clamping mechanism. The spring discharging pipe and the clamping mechanism are installed on the lifting base plate. The clamping mechanism comprises a left clamping head and a right clamping head, the left clamping head and the right clamping head are clamped to form a material guiding channel, the material guiding channel corresponds to the station holes, and the spring feeding device conveys springs to the spring discharging pipe. By the adoption of the spring and marble assembling machine, springs and marbles can be automatically assembled into station holes of workpieces, and the assembling efficiency is high.

Owner:FOSHAN LIGHTING ZHIDA ELECTRICIAN TECH CO LTD

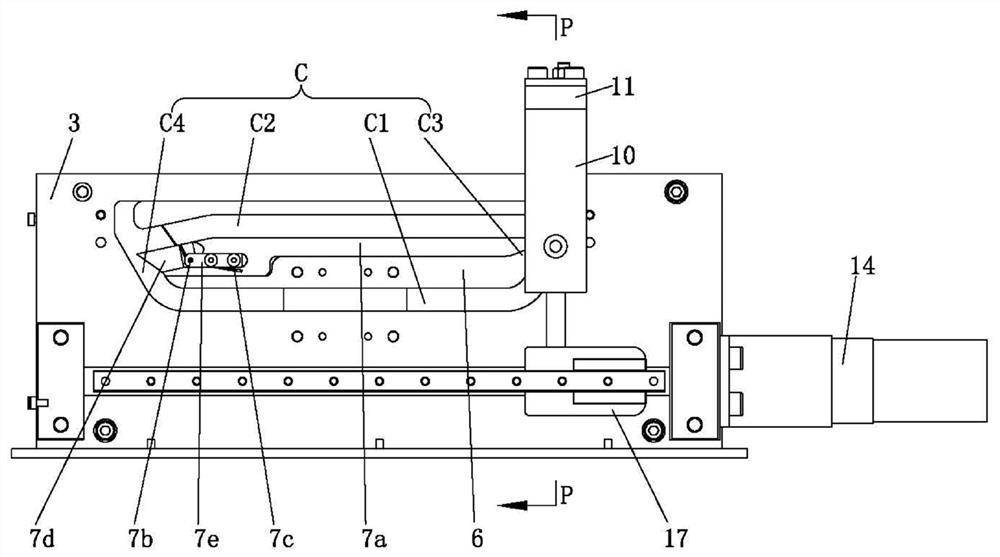

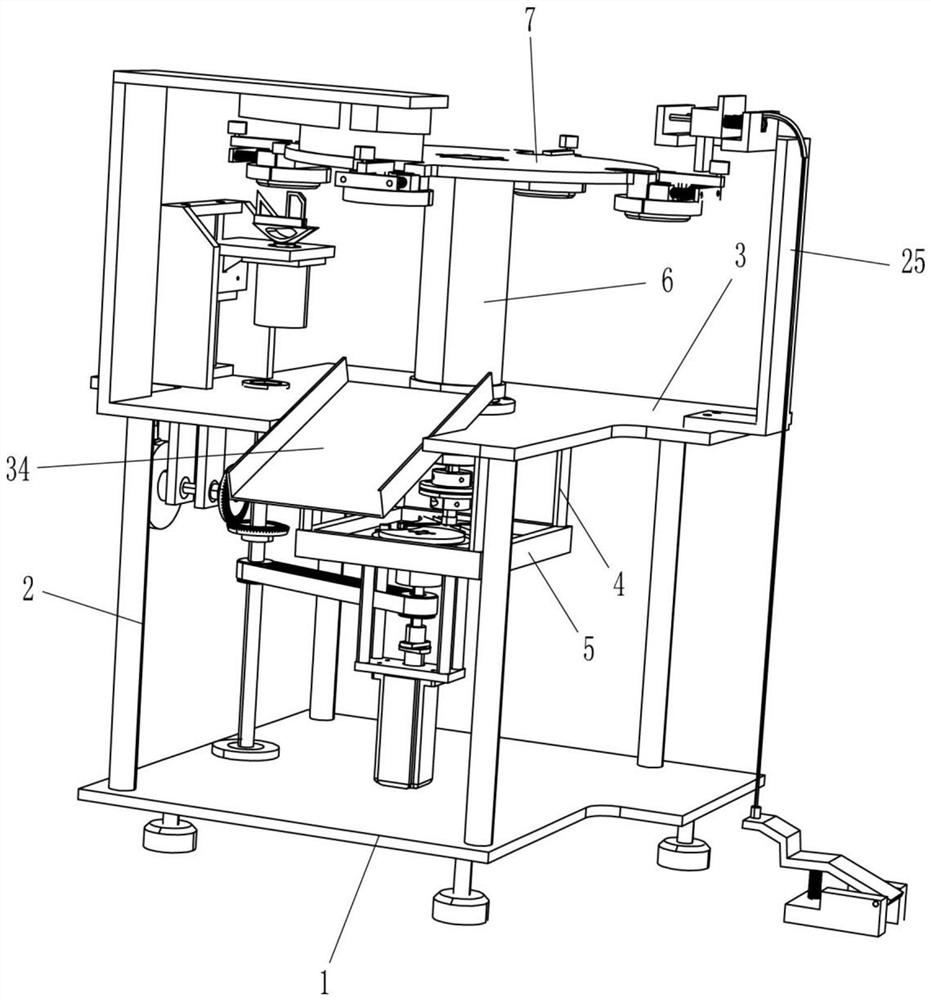

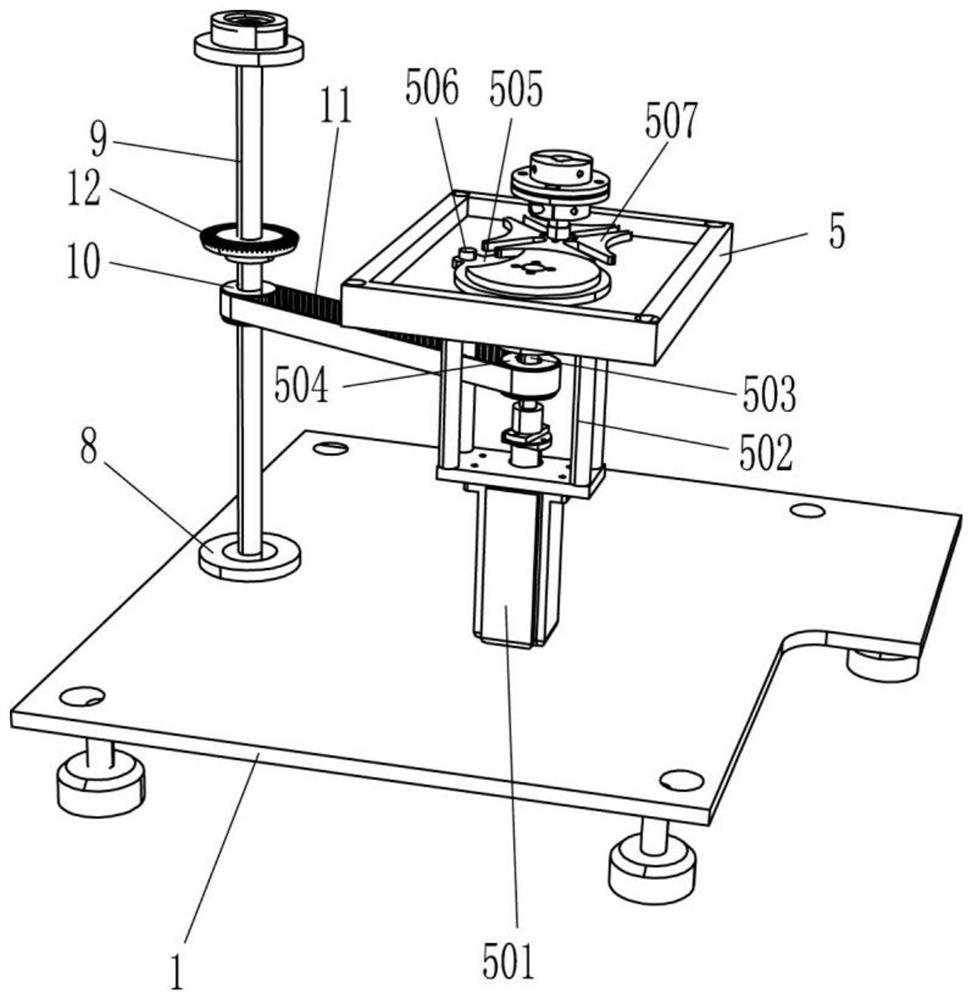

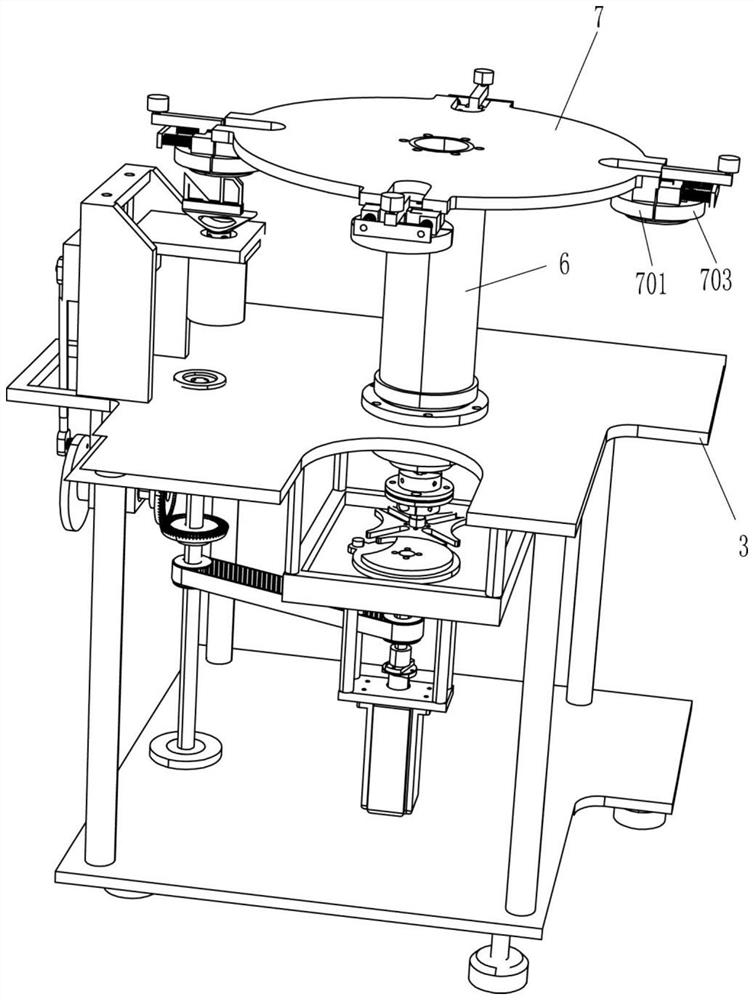

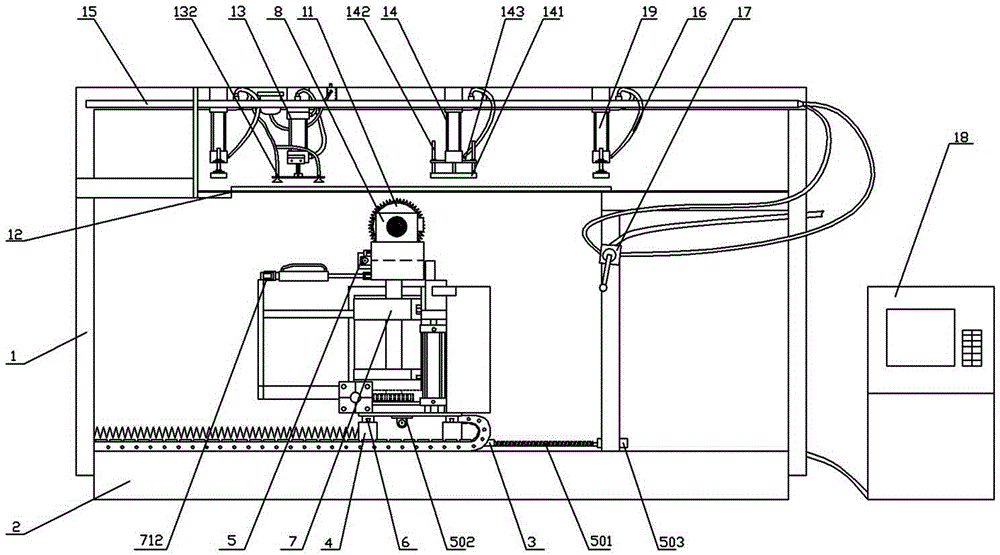

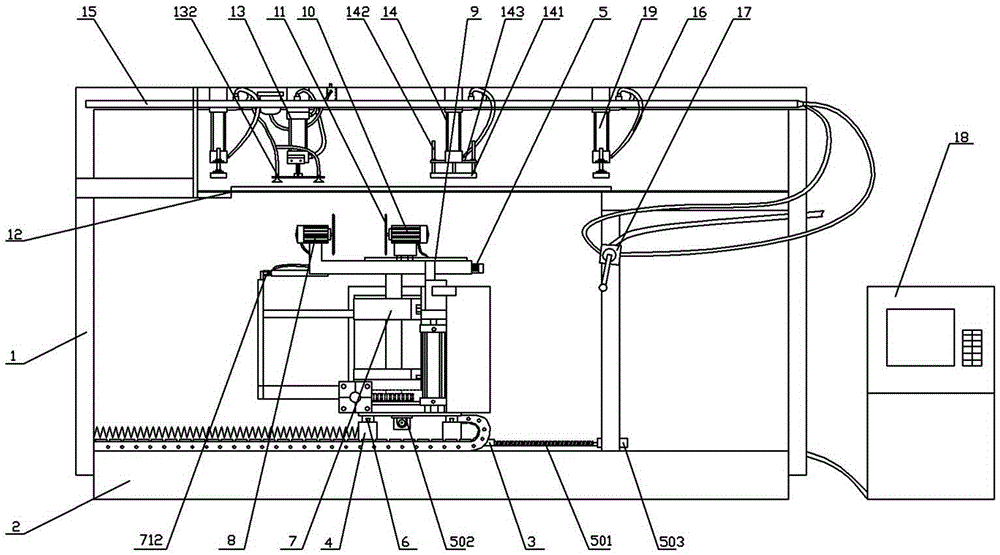

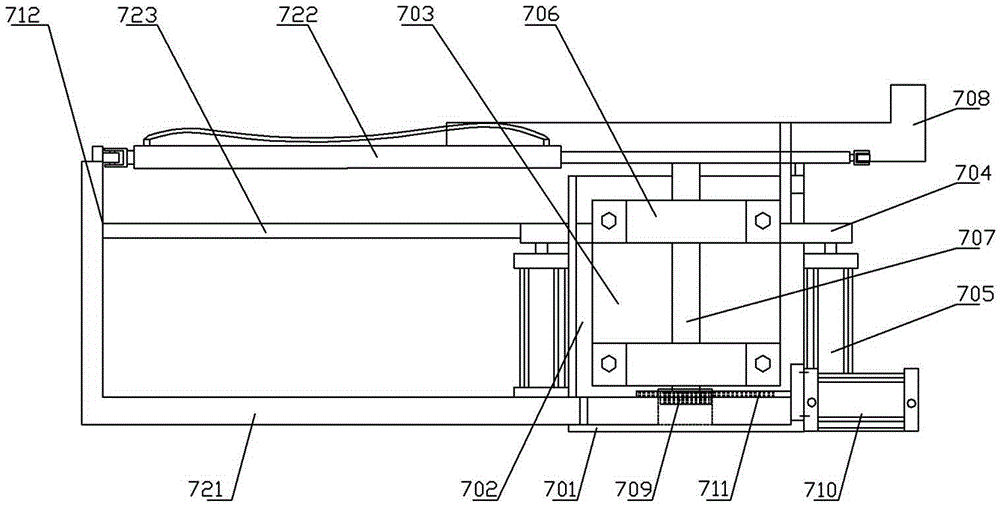

Coffin automatic CNC door digging saw

ActiveCN104385376BReduce labor input costsReduce riskGripping devicesClamping devicesNumerical controlProcessing accuracy

The invention relates to a coffin machining machine, in particular to a full-automatic numerical-control door saw for a coffin. The full-automatic numerical-control door saw comprises a stander and a base, wherein a full-automatic coffin numerical-control door saw base lifting steering mechanism is installed on the base, a cutting saw blade is installed on the base lifting mechanism, a coffin supporting mechanism is arranged on the middle-upper part of the stander, and a full-automatic coffin numerical-control door saw vacuum sucker device and a down pressing fixing mechanism are arranged on the stander above the coffin supporting mechanism; a numerical control unit is also arranged by the side of the stander, and the operation of the door saw is controlled by the numerical control unit. The full-automatic numerical-control door saw is low in manpower investment cost and accident rate, short ins procedure time and high in production efficiency; moreover, by adopting the numerical control unit, the machining precision is high, the automation degree of the device is high, the reliability of the device is high, and the safety production is also guaranteed.

Owner:兰考华美实业有限公司

Quantitative, fixed-point multi-station grain automatic feeding device and method

ActiveCN106219260BRealize automatic blanking operationAutomatic dropConveyorsLoading/unloadingAutomatic controlEngineering

The invention discloses a quantitative and point-fixed multi-station grain automatic unloading device and a method. The device comprises an embedded scrapper conveyor; an automatic unloading device is mounted at the bottom of a conveying belt of the embedded scraper conveyor; a cache barrel is mounted at the bottom of the automatic unloading device; support angle steel is fixed at the outer wall periphery of the cache barrel; a static weighing balance is arranged at the bottom of the support angle steel, and is supported and mounted on a stand column; the stand column is supported on a baseplate; an unloading cylinder is mounted at the bottom of the cache barrel; a pneumatic discharge mechanism is mounted on the unloading cylinder; a fixed-point rotary unloading device is mounted rightly below the unloading cylinder; and multiple dipping cylinders are correspondingly arranged below the fixed-point rotary unloading device. The device can realize automatic grain weighing operation, can realize automatic unloading, can realize fixed-point unloading through automatic control in the unloading process, and can perform the feeding operation of multiple dipping boxes in sequence to improve the dipping efficiency.

Owner:HUBEI DAOHUAXIANG WINE IND +1

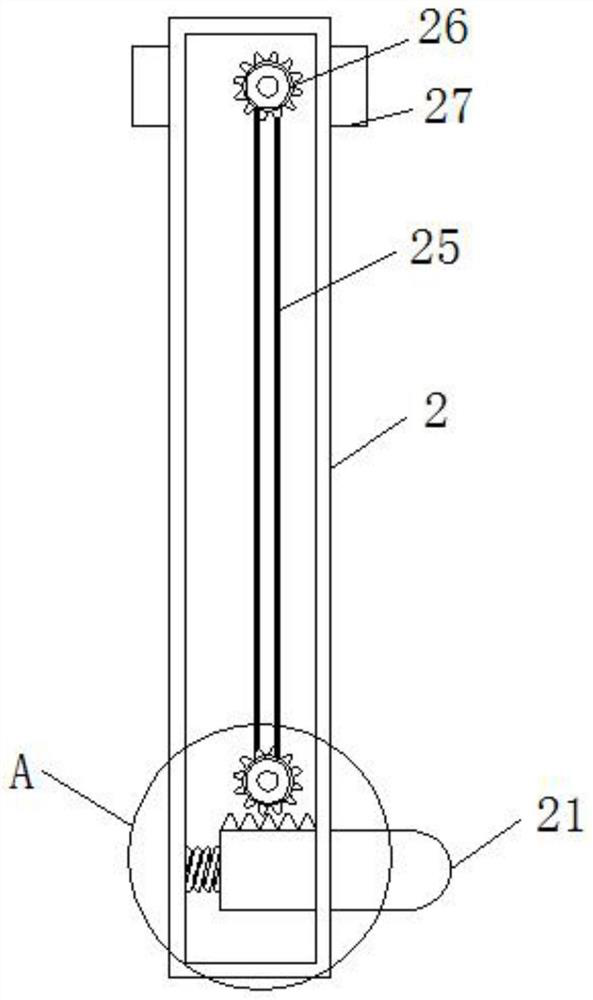

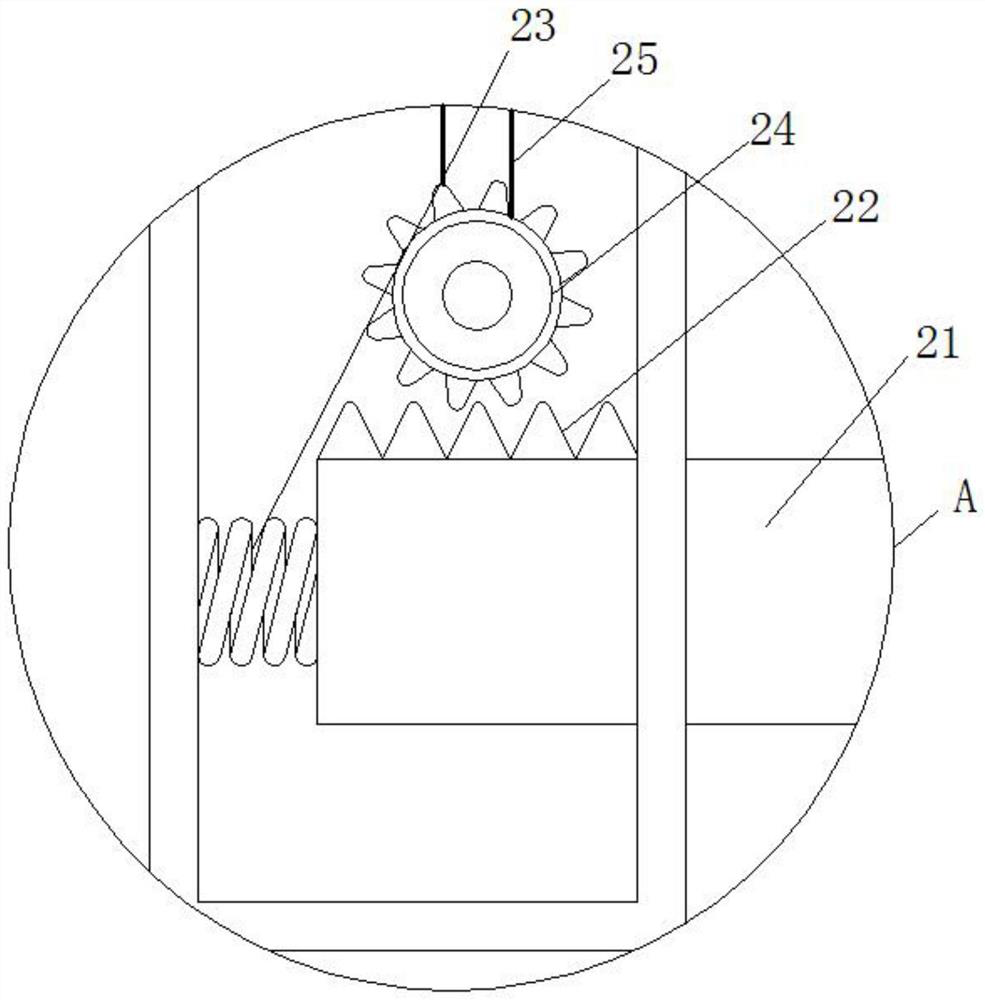

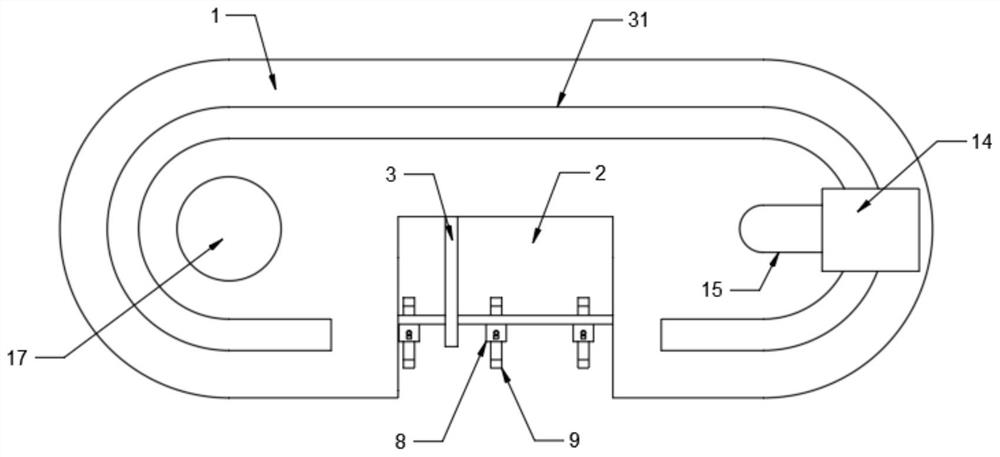

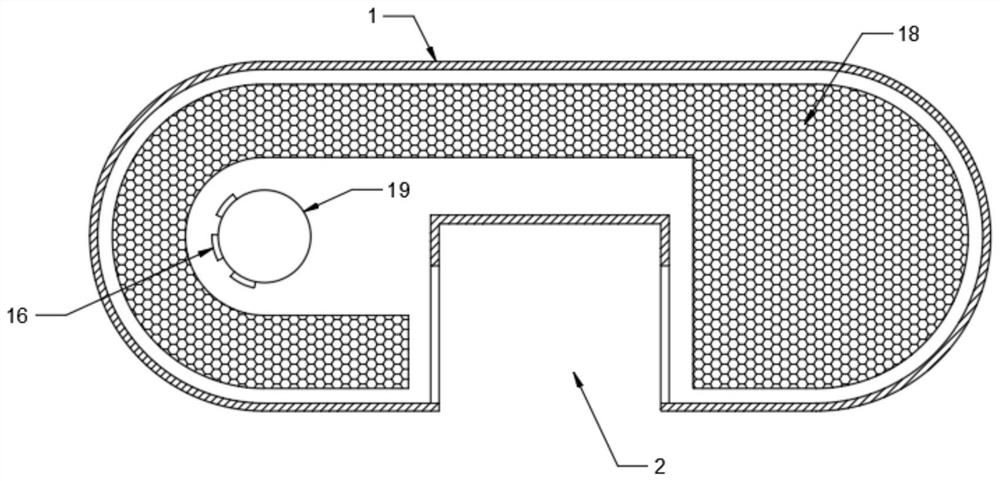

A garment processing device with fast drying function

ActiveCN113584823BImprove drying effectAchieve extrusionTextiles and paperLaundry driersSprocketChain link

The present invention provides a garment processing device with fast drying function, comprising a casing composed of a rectangle and two semicircles, an operation area is arranged on the front side of the casing, and the opposite side walls of the operation area are There is an opening communicating with the shell, and a loop conveyor mechanism is installed on the top of the shell. The loop conveyor mechanism includes a driving sprocket, a driven sprocket and a chain. The rod and the hollow shaft are rotatably connected to the top of the housing, the chain is sleeved on the driving sprocket and the driven sprocket, the chain passes through the two openings and the operating area, and the bottom of the chain is fixed with a plurality of An installation block, a clothes hanging mechanism is installed at the bottom of the installation block, and a drying mechanism is installed at the top of the casing. The device can be hung to separate the clothes from each other and continue to dry, and the water squeezing mechanism and the inner drying mechanism can greatly improve the drying effect and speed up the drying speed.

Owner:SHUYANG BUGU TEXTILE GARMENTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com