Workshop waste liquid discharge device with iron removal function

A technology for workshop waste liquid and utensils, which can be used in metallurgical wastewater treatment, water/sewage treatment, magnetic/electric field water/sewage treatment, etc., and can solve problems such as economic loss and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

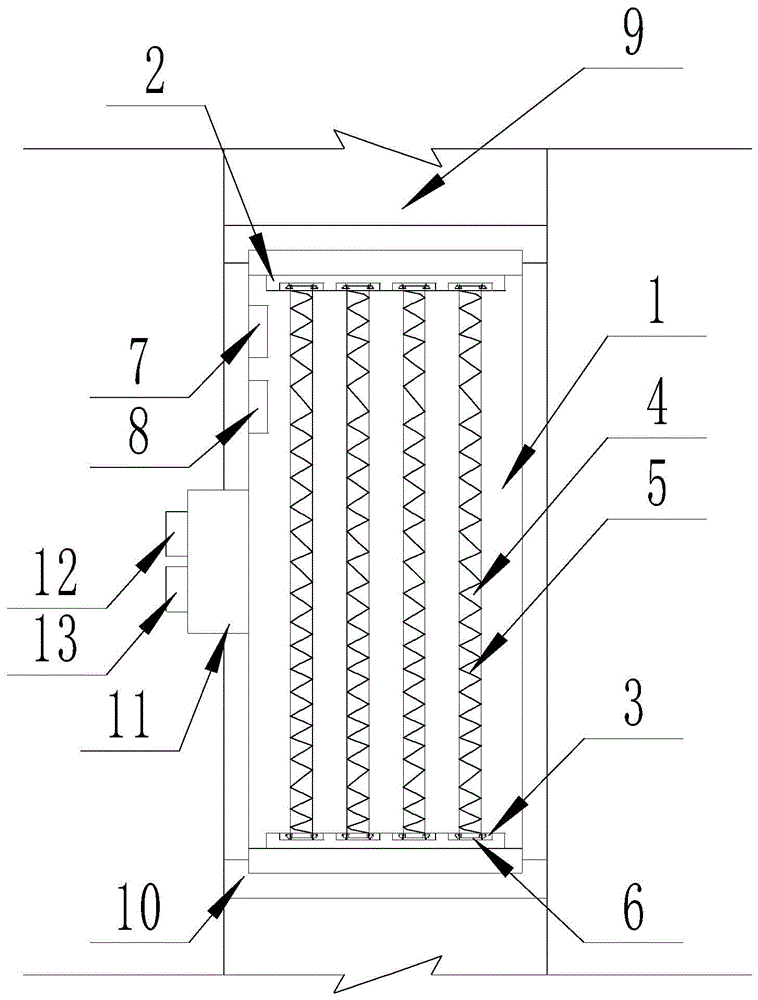

[0012] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, a device with the function of removing iron for waste liquid discharge in a workshop includes a rectangular box (1), and a set of wiring boards (2) are arranged on both sides of the rectangular box (1), and the set of wiring The boards (2) are equidistantly provided with wiring grooves (3), the rectangular box (1) is provided with a plurality of iron cores (4), and the iron cores (4) are provided with enameled wires (5 ), the iron core (4) is provided with terminals (6) at both ends, and the inner upper surface of the rectangular box (1) is provided with a voltage stabilizer (7) and a transformer (8), and the rectangular box (1) The bottom is provided with a waste liquid pipe (9), and the outer surface of the waste liquid pipe (9) has a rectangular opening (10), and the rectangular box (1) is provided with a controller (11). The controller is electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com