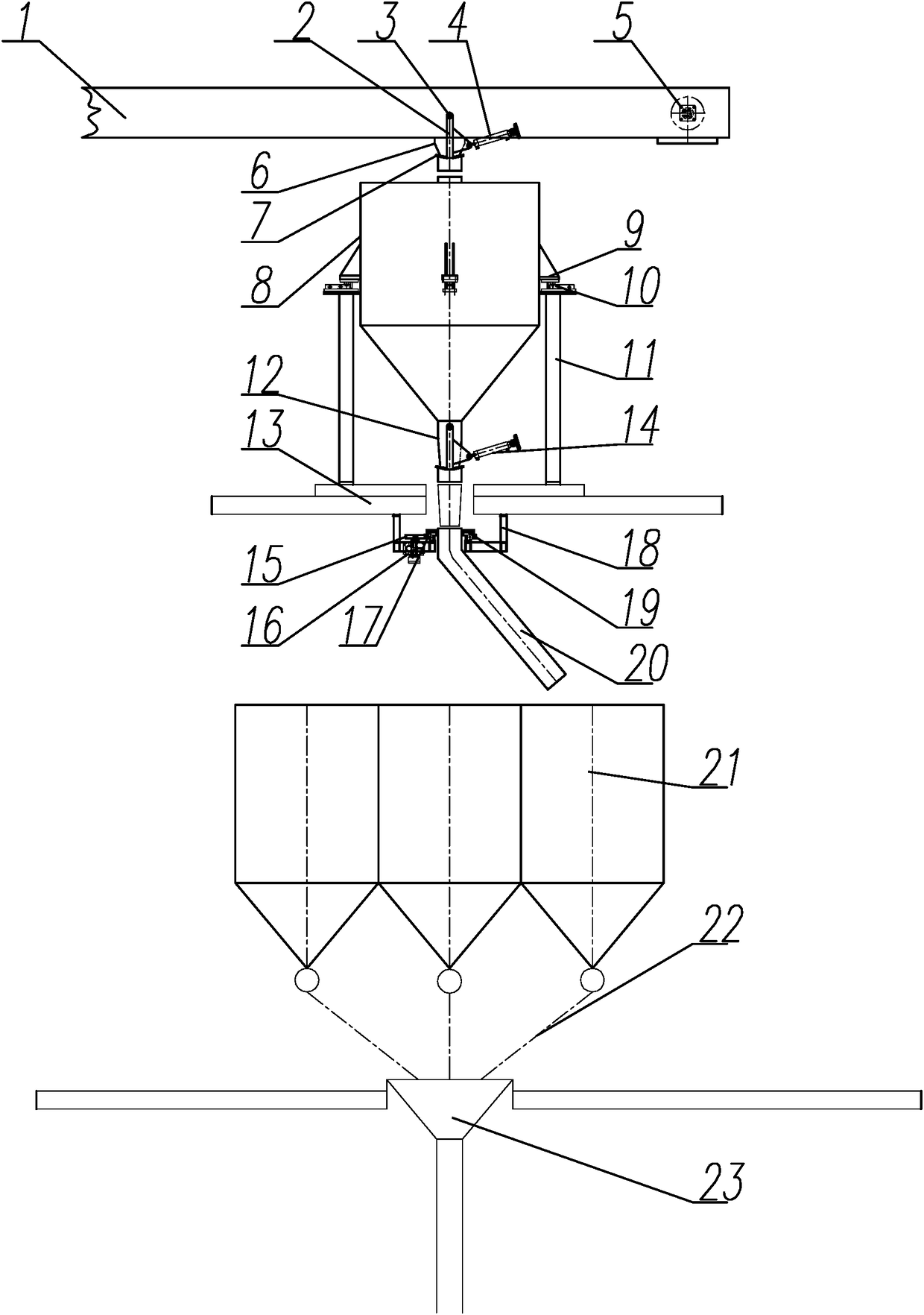

Quantitative, fixed-point multi-station grain automatic feeding device and method

An automatic unloading, multi-station technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of low work efficiency, cumbersome operation, need manual work, etc., to improve the degree of automation, convenient sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

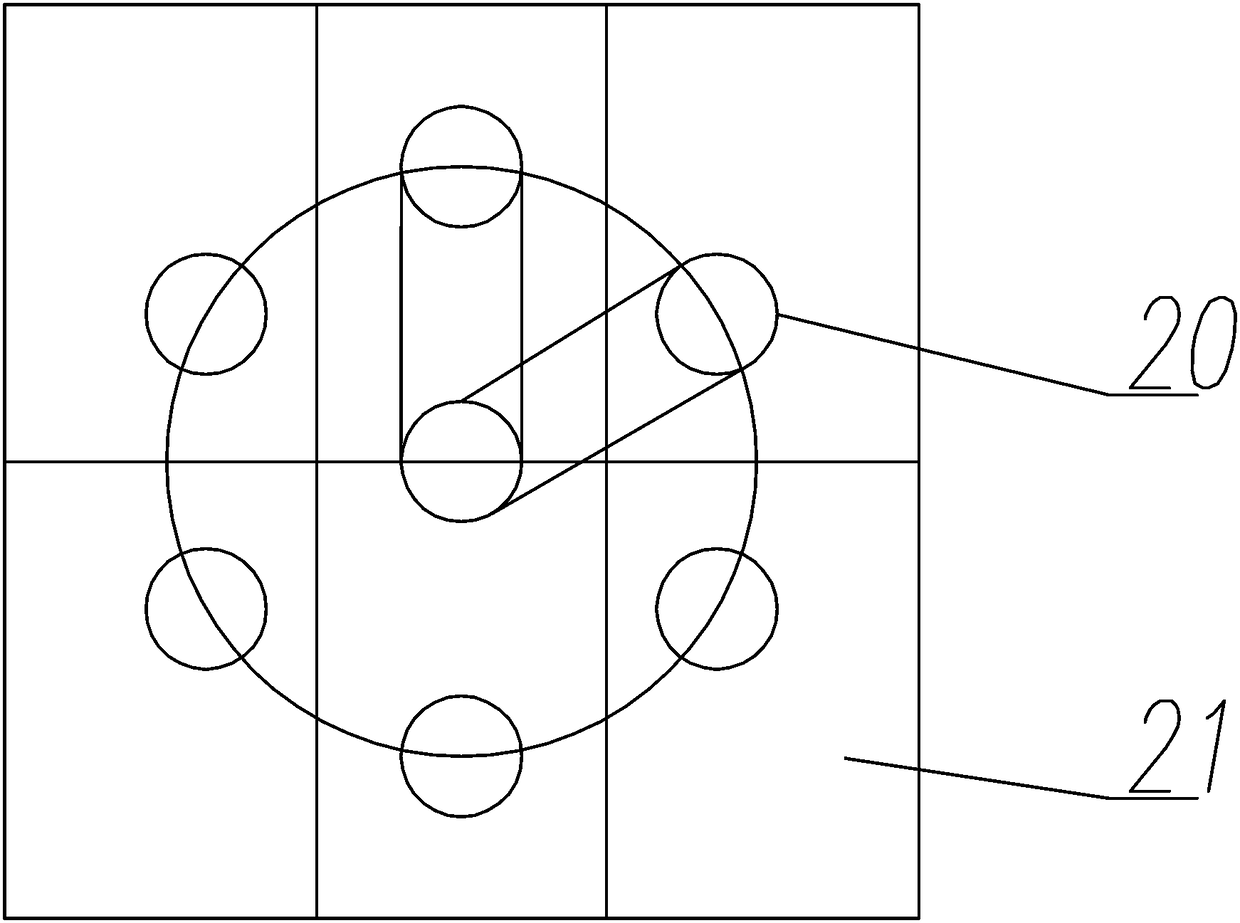

[0036] Adopt the blanking method of any described automatic grain blanking device, it comprises the following steps:

[0037] In the first step, the grain is continuously conveyed through the buried scraper conveyor 1, so that it reaches the automatic feeding device, and the automatic feeding operation of the grain is realized through the automatic feeding device. When the grain reaches the top of the buried scraper conveyor 1 When the material barrel 6 is lowered, the connecting rod 2 is driven by the cylinder 4, and the connecting rod 2 will drive the baffle plate 7 to open the lower material barrel 6 at the top, so that the grain will automatically fall to the inside of the buffer material barrel 8;

[0038] In the second step, the grain is weighed by the static weighing scale 10 arranged outside the buffer tank 8, and when the set weight is reached, the automatic unloading device is turned off, thereby stopping the conveyance of the grain, and at the same time starting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com