Etching knife die and processing method thereof

A technology for etching knife molds and templates, applied in metal processing and other directions, can solve the problems of affecting product accuracy, high price, easy to block blanking holes, etc., and achieve the effect of improving product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

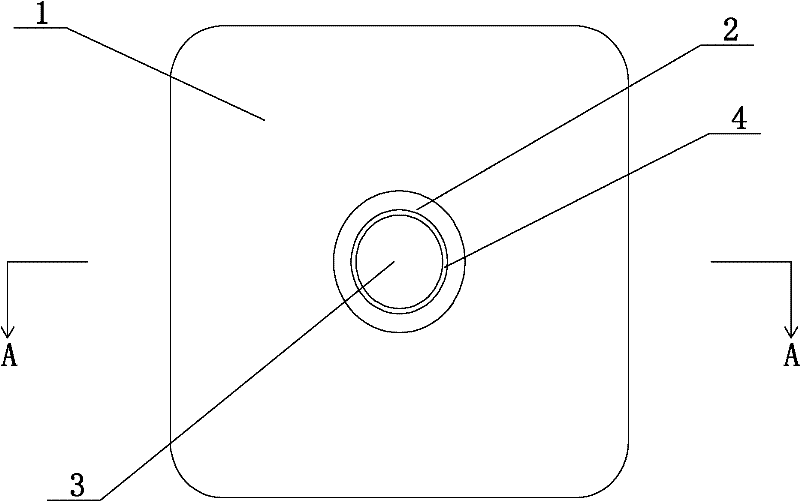

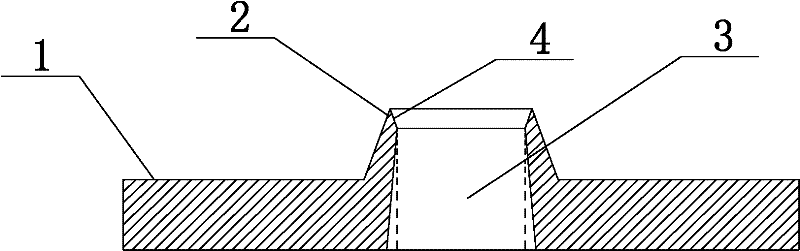

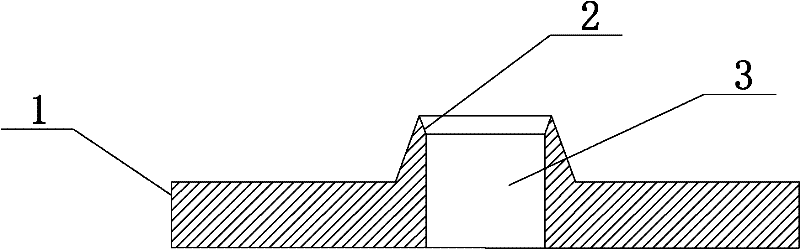

[0023] Such as figure 1 , figure 2 As shown, design a kind of etching knife die, comprise template 1 and the knife 2 that is arranged on the center of template 1, described knife 2 is provided with knife edge 4, and knife edge 4 generally all leaves margin during processing, is convenient to extend knife 2 service life. The shape of the knife 2 in this embodiment is circular, and the knife 2 has a slope 5 on the template 1, and the slope 5 can improve the strength of the knife 2. There is a blanking hole 3 below the knife 2, the cross section of the blanking hole 3 is trapezoidal, and the upper end diameter of the blanking hole 3 is smaller than the lower end diameter. The angle between the inner wall of the blanking hole 3 and the horizontal plane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com