Automatic blanking and feeding device used for polishing workpiece

The technology of a feeding device and a conveying device is applied in the field of automatic blanking and feeding devices of sandblasting machines, which can solve the problems of dust leakage, low production efficiency, and obstruction of workpiece transmission, so as to ensure safe operation, improve processing efficiency, and save manpower and time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with the drawings in the specification:

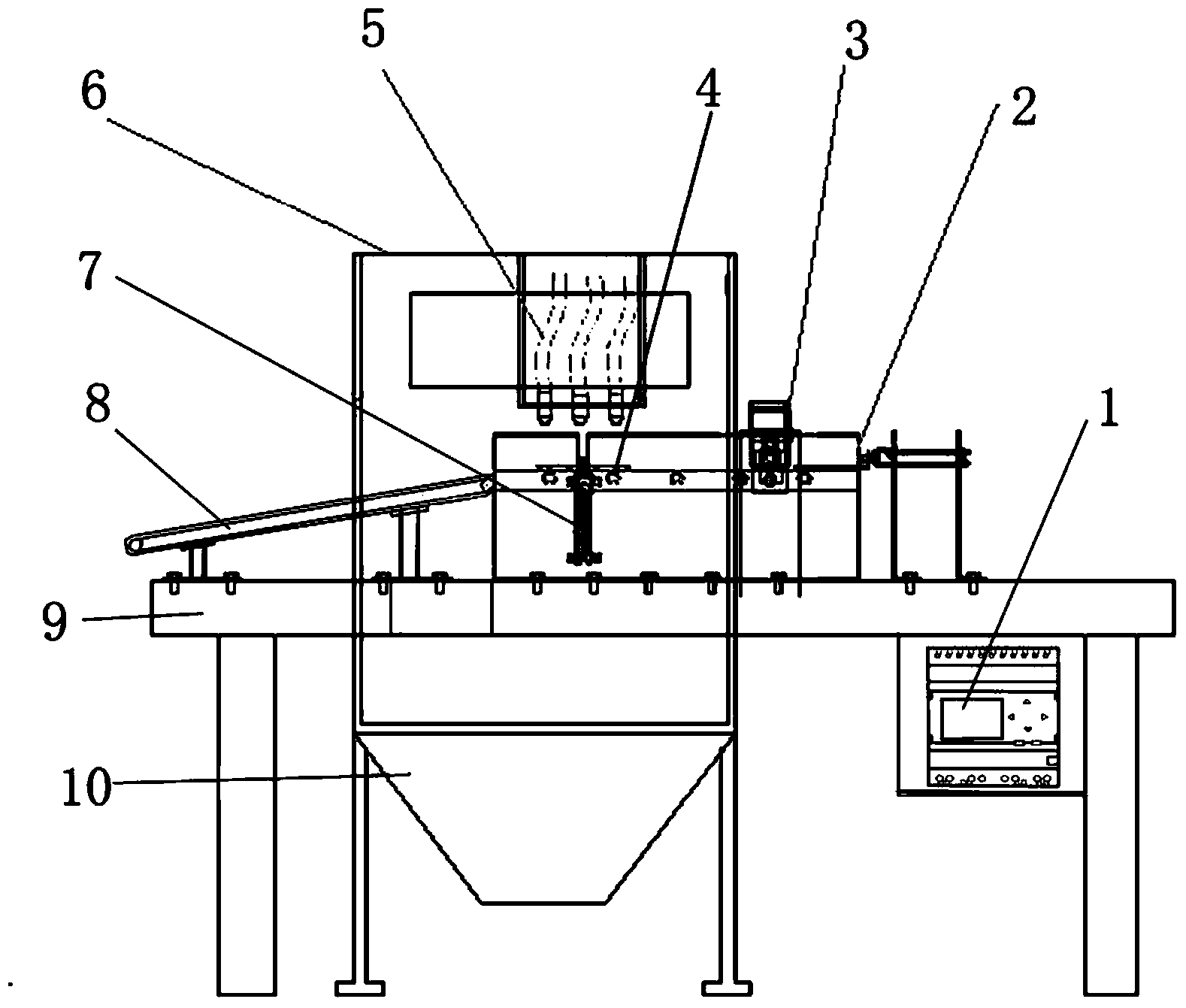

[0033] Such as figure 1 As shown, an automatic blanking and feeding device for grinding workpieces includes a main frame 9 and a conveying device 2 installed on the main frame 9 for conveying the workpiece to be sandblasted; the main frame 9 is provided with a spray Sand machine 6, sand blasting machine 6 is equipped with spray gun 5; spray gun 5 corresponds to the workpiece to be sand blasted compressed by pressing cylinders 7, 33 on the conveyor 2, and the sand blasting machine 6 is arranged below the pressing cylinders 7, 33 There is a sand storage box 10; the end of the conveying device 2 is provided with an output device 8; the conveying device 2 and the sand blasting machine 6 are controlled by the controller 1 to perform automatic feeding, sand blasting and automatic blanking of the workpiece to be sandblasted.

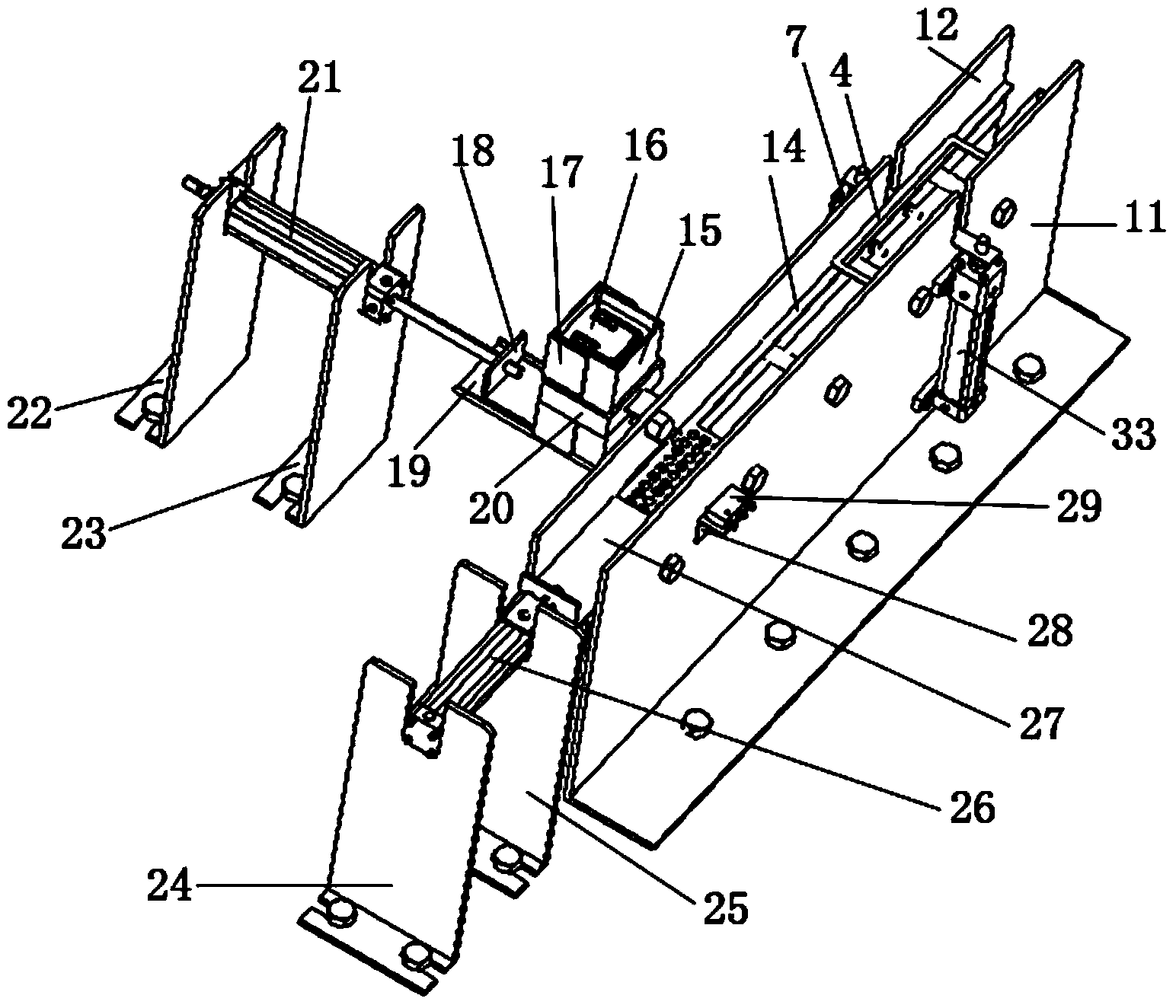

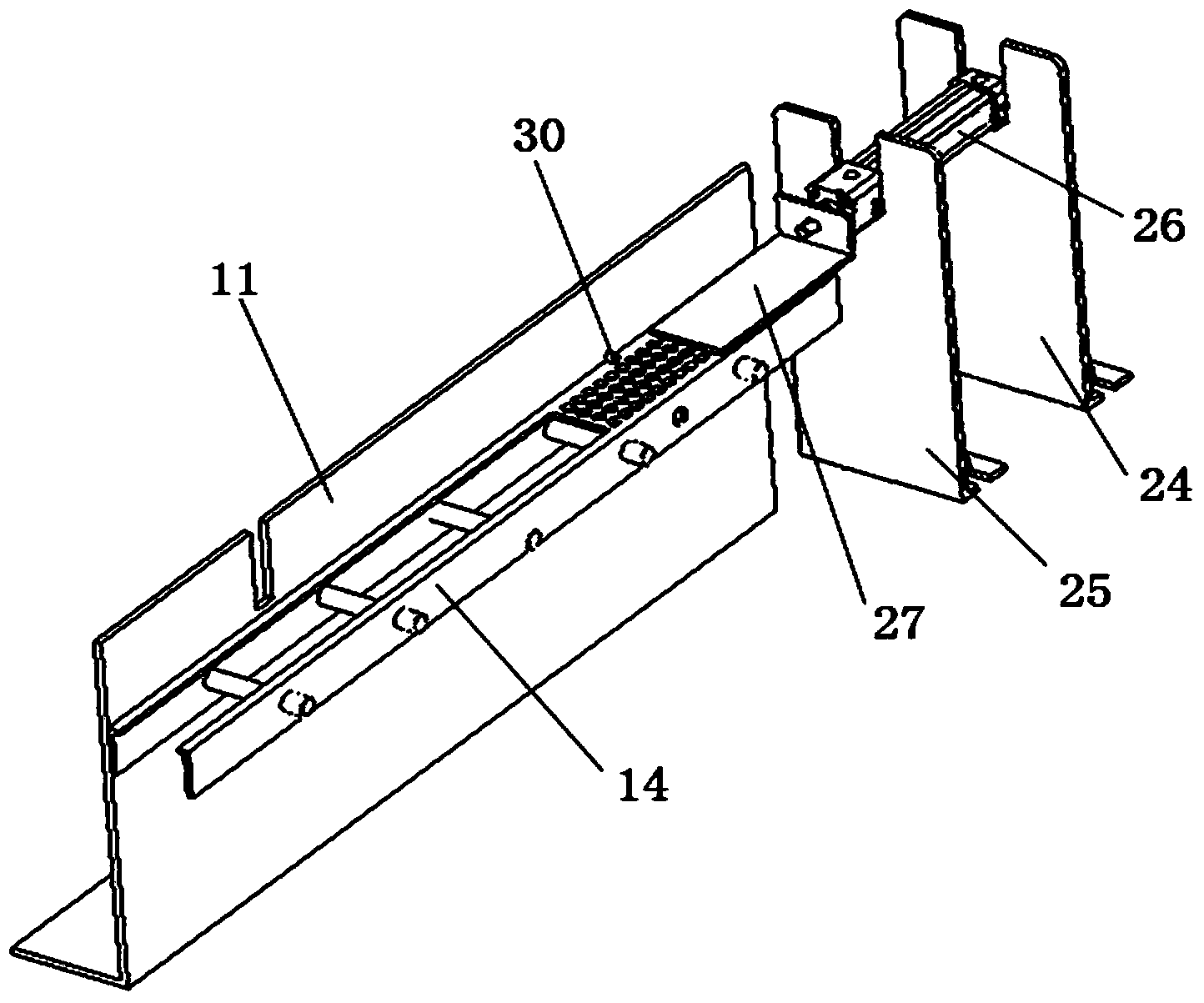

[0034] The automatic blanking and feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com