Stamping system for plate heat exchanger sealing gasket production and machining and stamping method thereof

A technology for plate heat exchangers and gaskets, applied in applications, household components, household appliances, etc., can solve problems such as large thickness errors, difficulty in taking out, and deformation of gaskets, and achieve simple and convenient operation, changing the pouring area, and complete pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

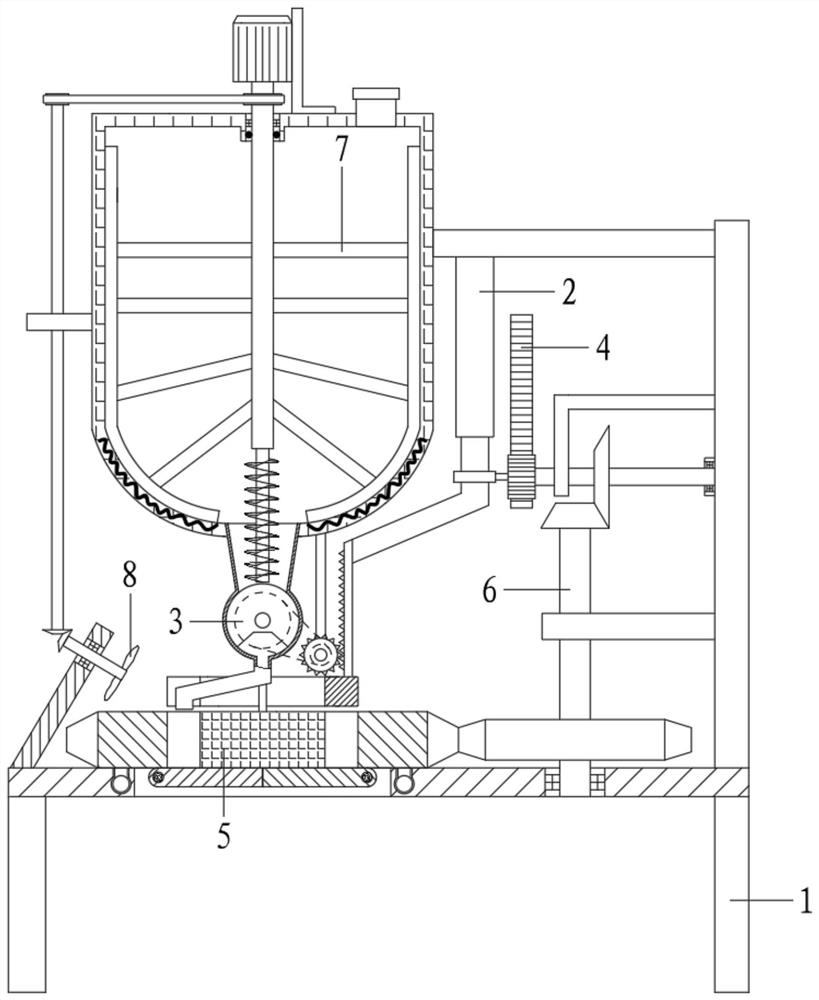

[0062] Referring to the accompanying drawings, a stamping system for the production and processing of plate heat exchanger gaskets includes a frame component 1, a stamping component 2, a casting component 3, a transmission component 4, a mold component 5 and a rotating component 6;

[0063] Frame assembly 1 comprises support 101, support leg 102, side plate 103, ejector rod 104 and raw material bucket 105, and support leg 102 is connected under support 101, and the right end of support 101 is upwardly connected with side plate 103; The top of the seat 101 is connected to the side plate 103 through the push rod 104; the top of the raw material barrel 105 is provided with a feeding port 106, and the bottom is provided with a heater 107;

[0064] The pouring assembly 3 is connected below the raw material barrel 105, and the mold assembly 5 is correspondingly arranged on the support 101; the stamping assembly 2 is connected below the top plate, and the stamping assembly 2 extends a...

Embodiment 2

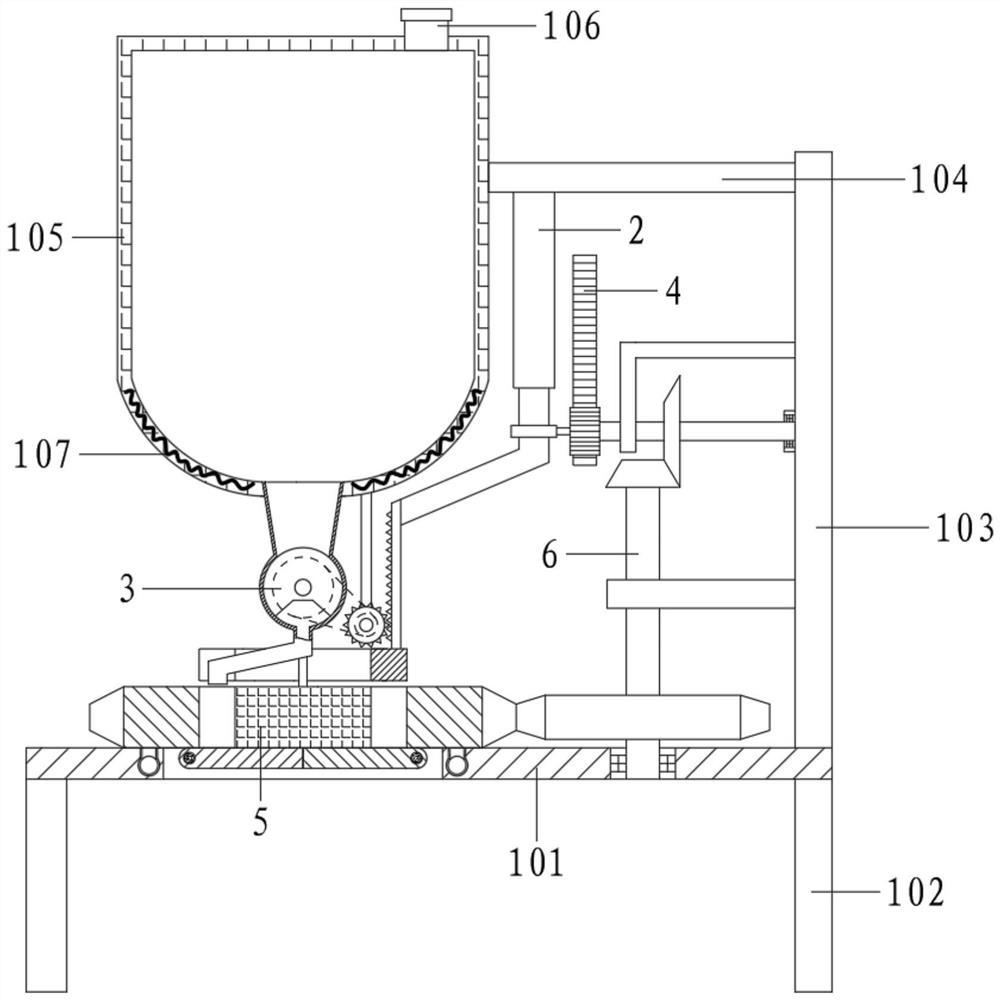

[0066] Referring to the accompanying drawings, a stamping system for the production and processing of plate heat exchanger gaskets includes a frame component 1, a stamping component 2, a casting component 3, a transmission component 4, a mold component 5 and a rotating component 6;

[0067] Frame assembly 1 comprises support 101, support leg 102, side plate 103, ejector rod 104 and raw material bucket 105, and support leg 102 is connected under support 101, and the right end of support 101 is upwardly connected with side plate 103; The top of the seat 101 is connected to the side plate 103 through the push rod 104; the top of the raw material barrel 105 is provided with a feeding port 106, and the bottom is provided with a heater 107;

[0068] The pouring assembly 3 is connected below the raw material barrel 105, and the mold assembly 5 is correspondingly arranged on the support 101; the stamping assembly 2 is connected below the top plate, and the stamping assembly 2 extends a...

Embodiment 3

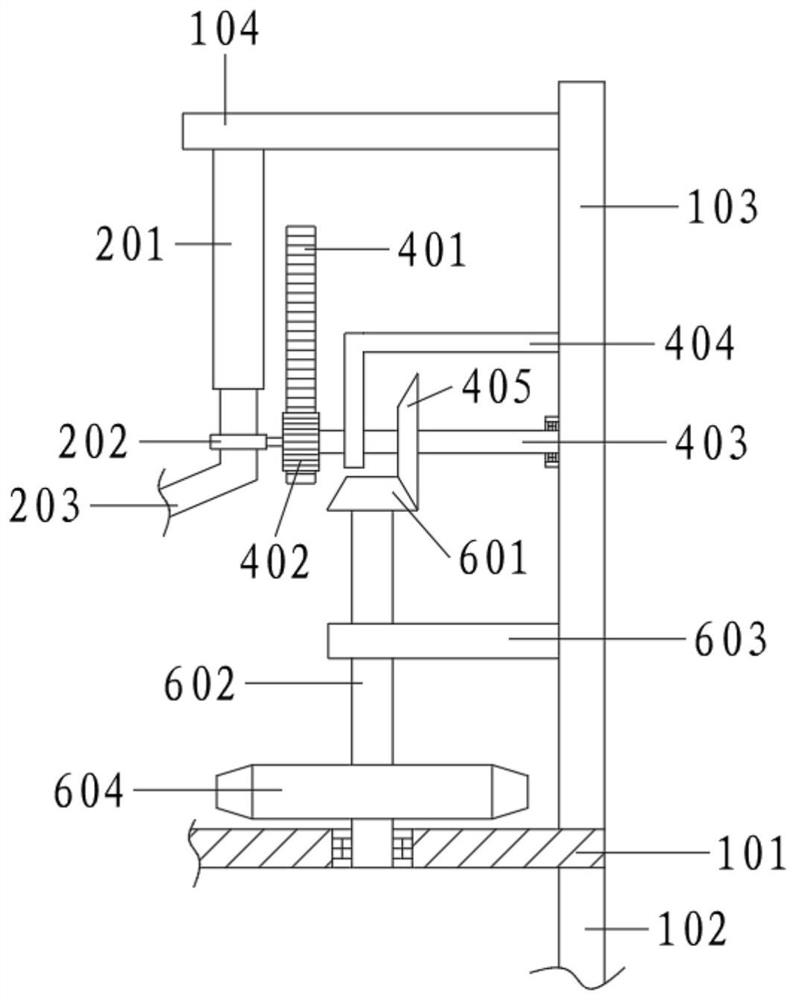

[0088] On the basis of the above examples,

[0089] It also includes a stirring component; the stirring component includes a mounting frame 701, a driving motor 702, a stirring shaft 703, a stirring rod 704 and a scraper 705;

[0090]The driving motor 702 is connected to the outer top of the raw material barrel 105 through the mounting frame 701, and the driving motor 702 is connected with the stirring shaft 703 downward, and the stirring shaft 703 stretches into the raw material barrel 105 and is connected with some stirring rods 704; the outer end of the stirring rod 704 is also connected with a The scraper 705 is attached to the inner wall of the raw material barrel 105 .

[0091] Specifically, the heater 107 heats and melts the raw material, and at the same time starts the driving motor 702 to drive the stirring shaft 703 to rotate, so that the stirring rod 704 rotates with the scraper 705, the stirring rod 704 keeps the raw material fluidity, and the scraper 705 reduces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com