IC packaged chip discharging device

A technology of discharging device and chip loading, applied in transportation and packaging, conveyor objects, stacking of objects, etc., can solve the problems of low production efficiency, low degree of automation, inability to automatically replace material tubes, etc., saving time , High degree of automation, the effect of reducing the frequency of manual replacement of the storage tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

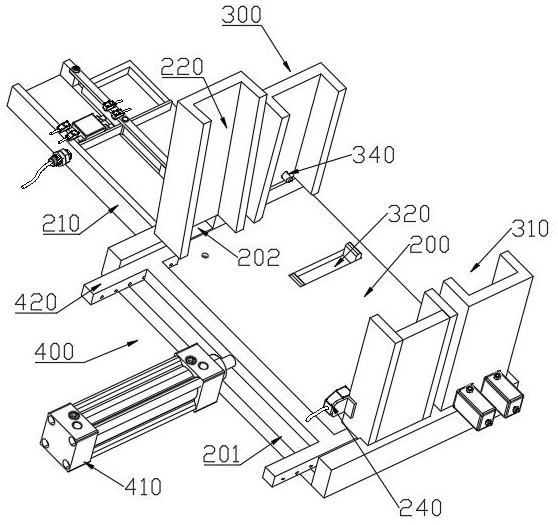

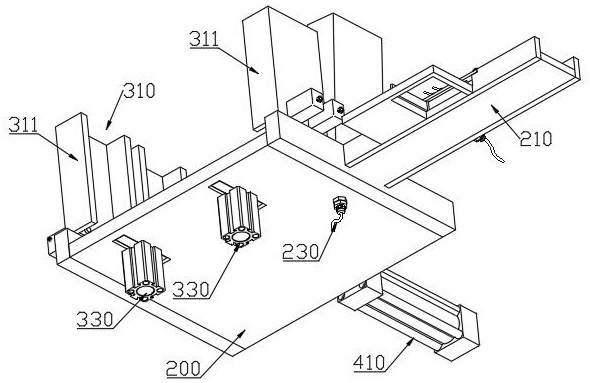

[0053] Specific implementation method: first stack a plurality of empty material storage tubes 100 in the material tube storage tank 220. At this time, the opening of the bottommost material storage tube 100 is directly connected with the feed port 202 through the guide sleeve 120. The push rod 400 in such figure 1 In the recovery state shown, a gap is reserved between the front end of the push rod 410 and the side wall of the storage tube 100 at the bottom to prevent the storage tube 100 from falling smoothly; then the IC package chip can be loaded until the IC package chip Loaded to the position of the through hole 101, because the IC packaged chip cuts off the sensing area of the proximity switch 230, the proximity switch 230 will receive the in-position signal of the IC packaged chip, and the device judges that the IC packaged chip in the storage tube 100 has passed through the signal. When it is full, it will stop and continue to discharge; meanwhile, the push rod 400 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com