Special maintenance vehicle for power equipment maintenance

A technology for power equipment and maintenance vehicles, which is applied in the direction of lifting devices, etc., can solve the problems of delaying the repair time of maintenance personnel, the height of the maintenance platform, and affecting circuit maintenance, etc., so as to facilitate centralized management and deployment, high degree of automation, and delay repair time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

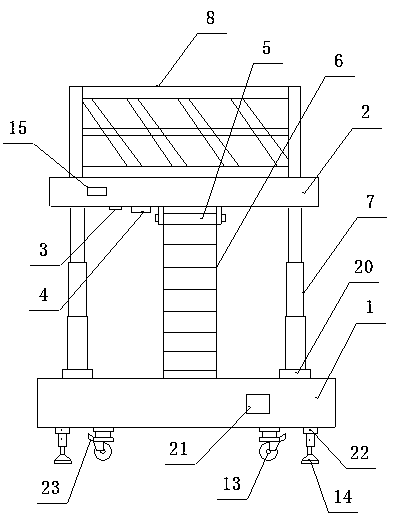

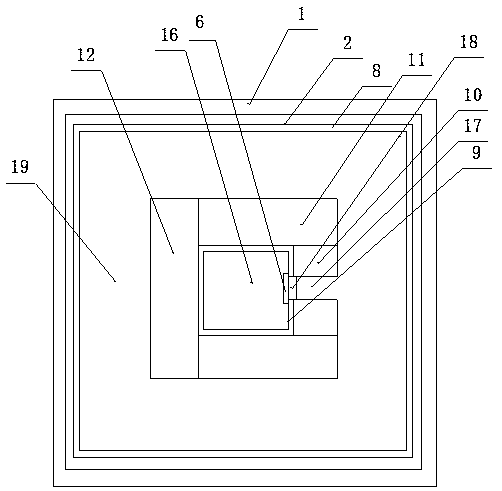

[0018] Embodiment: A special maintenance vehicle for electric equipment maintenance, comprising a base 1 and a maintenance platform 2, an infrared range finder 3 and a control box 4 are arranged on the lower end of the maintenance platform 2, and a motor and a first controller are arranged inside the control box 4 , one end of the first controller is connected with the infrared range finder 3, and the other end is connected with the winding ladder shaft 5 through a motor, thereby controlling the rotation of the winding ladder shaft 5, a soft ladder 6 is arranged on the winding ladder shaft 5, and the maintenance platform 2 is electrically telescopic Rod 7 is connected with base 1, and outer guardrail 8, inner guardrail 9, glove box 10, tool box 11 and reel groove 12 are arranged on the upper end surface of maintenance platform 2, and base 1 is connected with the ground through walking wheel 13, and base 1 A counterweight foot 14 is arranged at the lower end, and an RFID tag 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com