Carbon fiber curing cutting device capable of placing fibers into mold

A cutting device and carbon fiber technology, which is applied in fiber cutting, fiber processing, textiles and papermaking, etc., can solve the problems of low cutting precision and difficulty in fully flattening carbon fiber, so as to improve production efficiency and ensure cutting precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

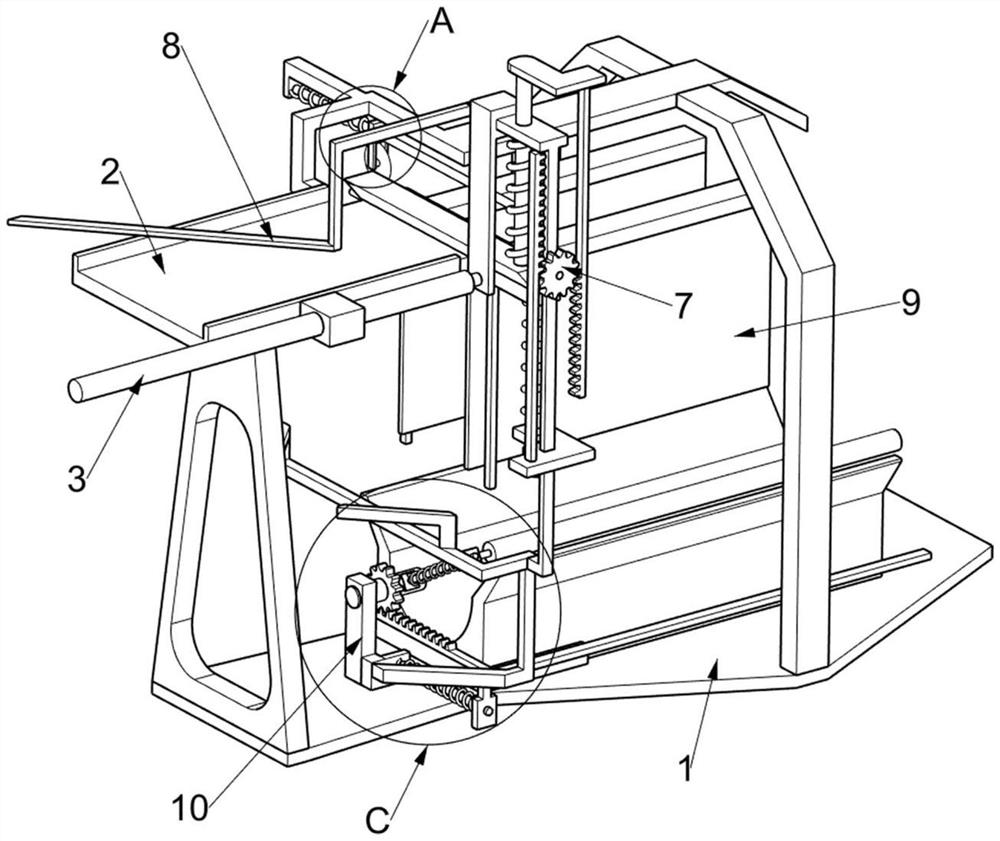

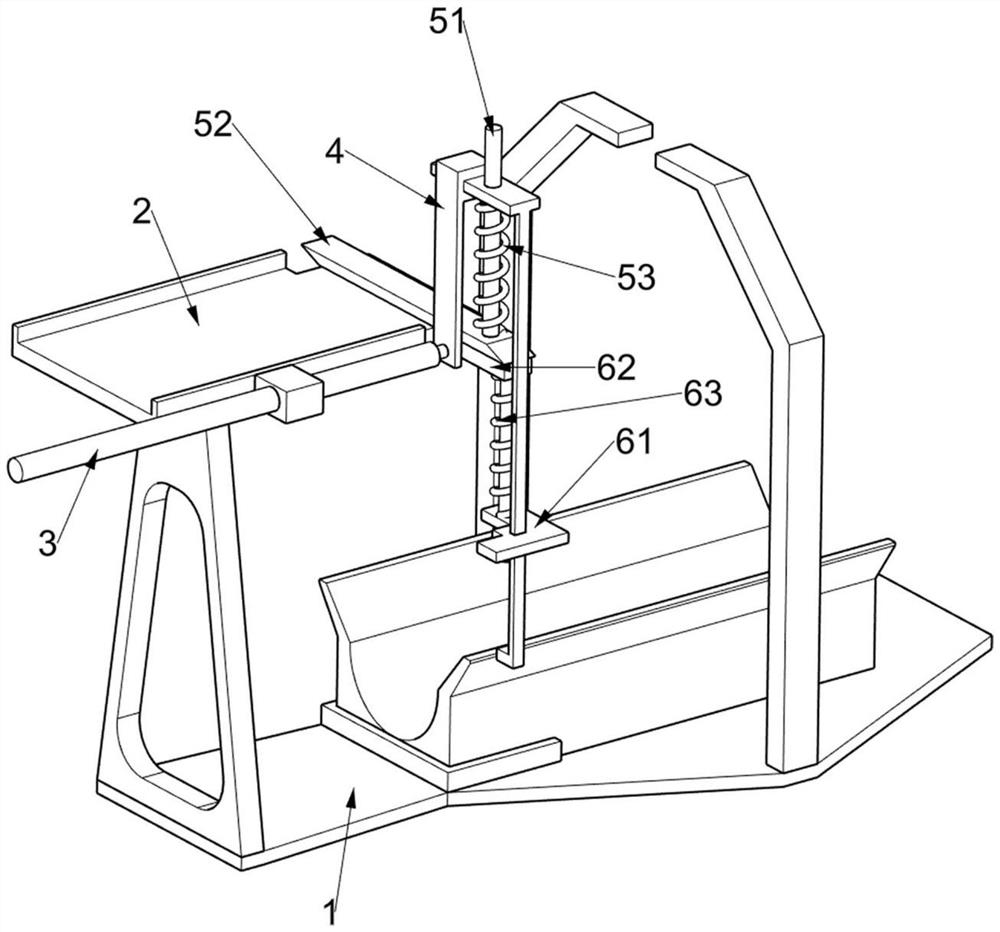

[0031] A cutting device for carbon fiber curing that places the fibers into a mold, such as Figure 1-3 As shown, it includes a first fixed frame 1, a fixed table 2, an electric push rod 3, a second fixed frame 4, a first clamping mechanism 5, a second clamping mechanism 6 and a reset mechanism 7, above the first fixed frame 1 Fixedly connected with fixed table 2, one side of fixed table 2 is fixedly installed with an electric push rod 3 for providing power for the equipment, and one end of the telescopic shaft of electric push rod 3 is fixedly connected with a second fixed mount 4, and a second fixed mount 4 is arranged on the second fixed mount 4. There is a first clamping mechanism 5, a second clamping mechanism 6 for clamping the carbon fiber to be processed is provided on the second fixed frame 4, and a reset mechanism 7 is provided on the first fixed frame 1.

[0032] The first clamping mechanism 5 includes a slide bar 51, a first clamping plate 52 and a first return spr...

Embodiment 2

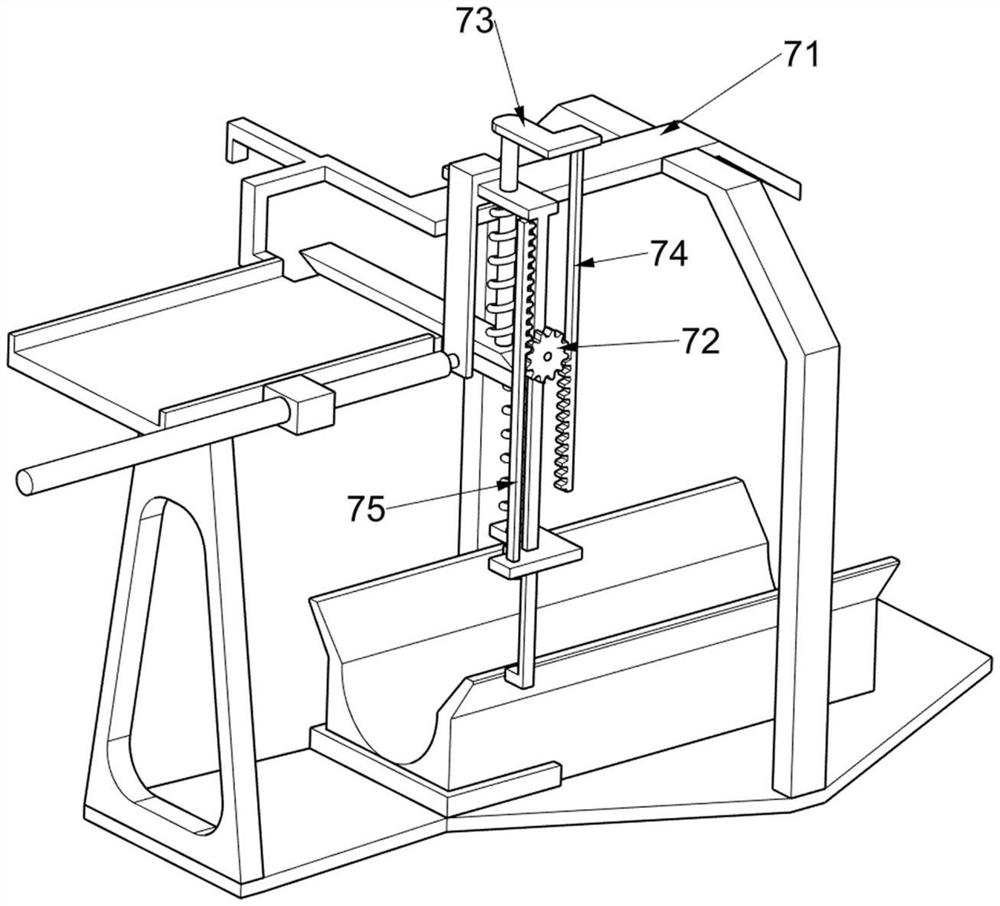

[0037] On the basis of Example 1, such as Figure 4 As shown, a cutting mechanism 8 is also included, and the cutting mechanism 8 for cutting the carbon fiber to be processed is arranged on the third fixed mount 71. The cutting mechanism 8 includes a first wedge frame 81, a first fixed rod 82, a sliding frame 83. The third return spring 84 and the cutting piece 85, the upper part of the second fixed frame 4 is fixedly connected with the first wedge-shaped frame 81, the third fixed frame 71 is fixedly connected with the first fixed rod 82, and the first fixed rod 82 is located on the fixed table 2 above, a slide frame 83 is slidably connected on the first fixed rod 82, and a third return spring 84 for driving the slide frame 83 and the cutting piece 85 to reset is connected between the slide frame 83 and the third fixed frame 71, and the slide frame 83 The upper rotatable is connected with a cutting piece 85, and the cutting piece 85 is in a disc structure.

[0038] When the f...

Embodiment 3

[0040] On the basis of Example 2, such as Figure 5-6 As shown, an opening and closing mechanism 9 is also included, and the opening and closing mechanism 9 is located on the fixed platform 2. The opening and closing mechanism 9 includes a fourth fixed frame 91, a second fixed rod 92, a second sliding plate 93, and a fourth return spring. 94 and the third fixed rod 95, the bottom of the second fixed frame 4 is fixedly connected with the fourth fixed frame 91, and one side of the upper part of the fourth fixed frame 91 is a symmetrical inclined plane structure, and the bottom of the fixed table 2 is slidingly connected with the second fixed frame. Rod 92, on the second fixed rod 92, the symmetrical sliding type is connected with the second sliding plate 93, and two second sliding plates 93 are correspondingly arranged, is connected between the second sliding plate 93 and the fixed table 2 and is used to drive the second sliding plate 93 to reset. The fourth return spring 94, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com