Equal-distance cutting device for grey tiles

A technology of isometric cutting and blue tiles, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problem of inconvenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

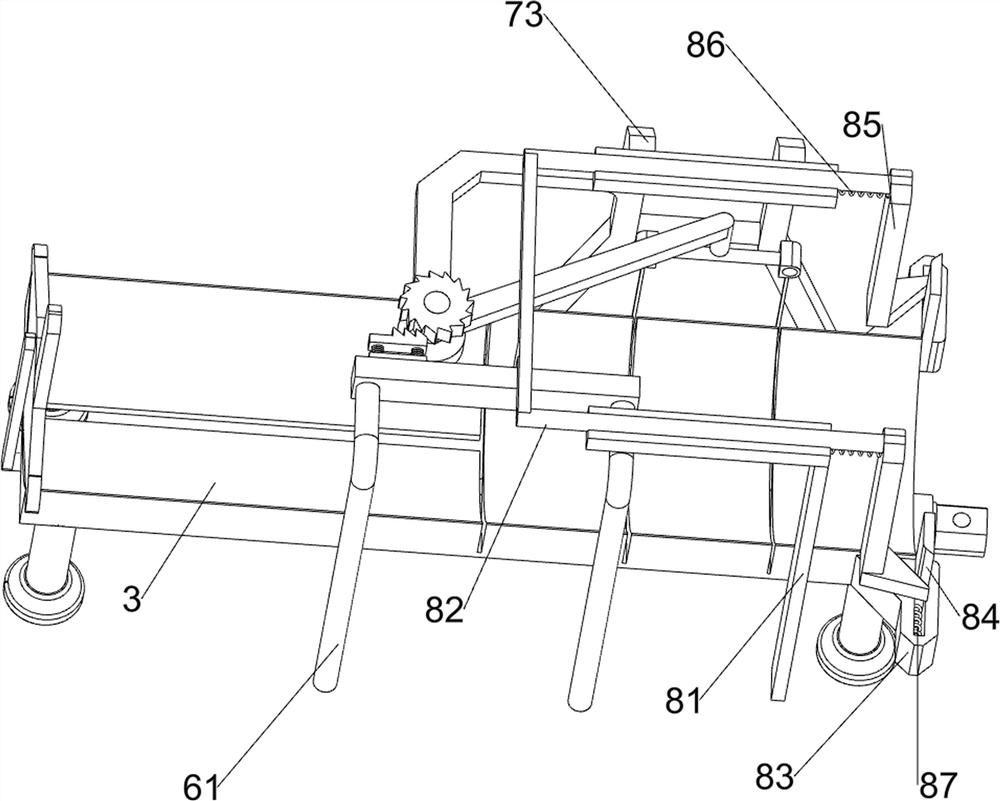

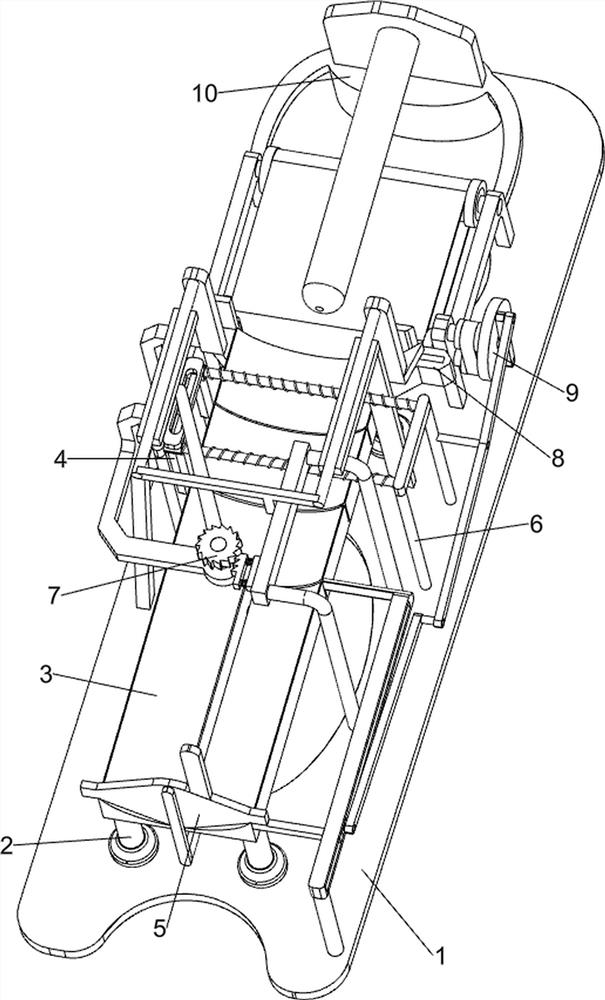

[0026] A blue tile brick isometric cutting device, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a pillar 2, a guide rail 3, a cutting knife 4, a pushing mechanism 5 and a pulling mechanism 6. Two pillars 2 are arranged symmetrically on the top of the base 1, and a guide rail 3 is arranged between the pillars 2. The top of the base 1 A pulling mechanism 6 is arranged in the middle, a cutting knife 4 is arranged on the pulling mechanism 6, and a pushing mechanism 5 is provided in a slide type on the left side of the guide rail 3 .

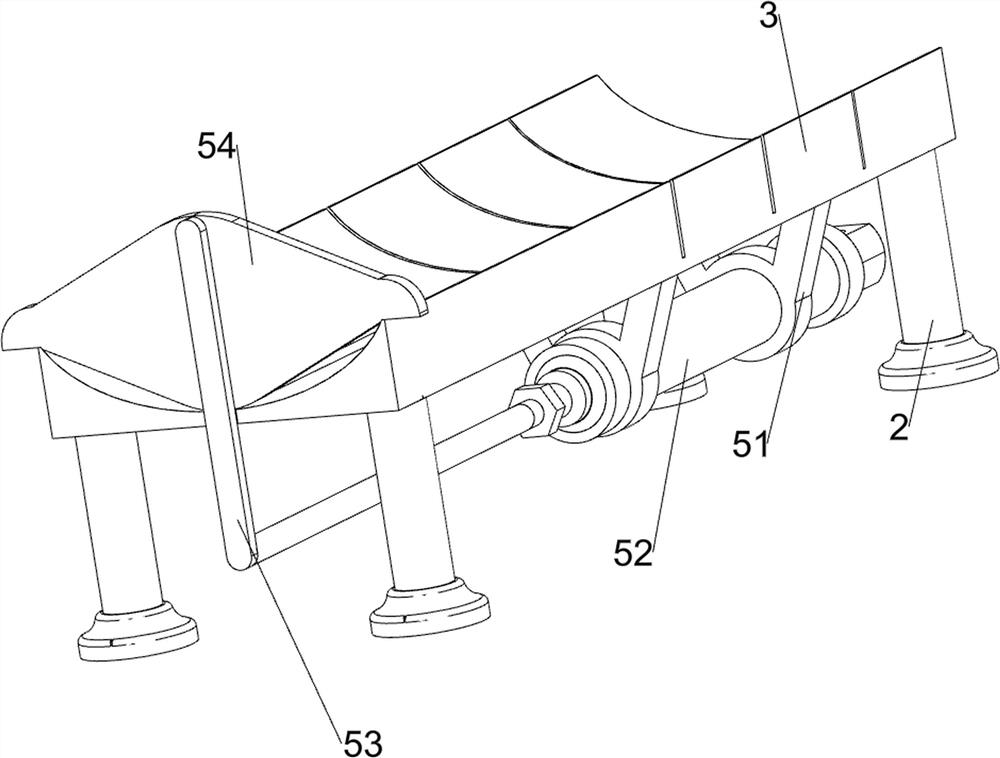

[0027] Propelling mechanism 5 comprises support ring 51, cylinder 52, bonding rod 53 and push plate 54, and guide rail 3 right side bottom is symmetrically provided with support ring 51, is provided with cylinder 52 between support ring 51, and the piston rod left side of cylinder 52 A bonding rod 53 is provided, and a push plate 54 is arranged on the top of the bonding rod 53 , and the push plate 54 cooperates with the...

Embodiment 2

[0031] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a drive assembly 7 is also included, and the drive assembly 7 includes a bracket 71, a first chute 72, a support frame 73, a rotating shaft 74, a rotating rod 75, a ratchet gear 76, a ratchet rack 77, a second spring 78 and an engaging Block 79, base 1 top front side left and right is symmetrically provided with support 71, is provided with first chute 72 between support 71, is provided with ratchet bar 77 slidingly on the first chute 72, first chute 72 and ratchet A second spring 78 is provided between the bars 77, a support frame 73 is provided in the middle of the top rear side of the base 1, and a rotating shaft 74 is provided on the left front side of the support frame 73, and a rotating shaft 75 is provided on the rotating shaft 74, and the rotating shaft 75 and the groove The rod 64 is slidably matched, and the upper part of the rotating shaft 74 is provided with a rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com