Automatic fruit package discharging mechanism and operation method

A technology for automatic cutting and fruiting, applied in packaging, packaging food, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

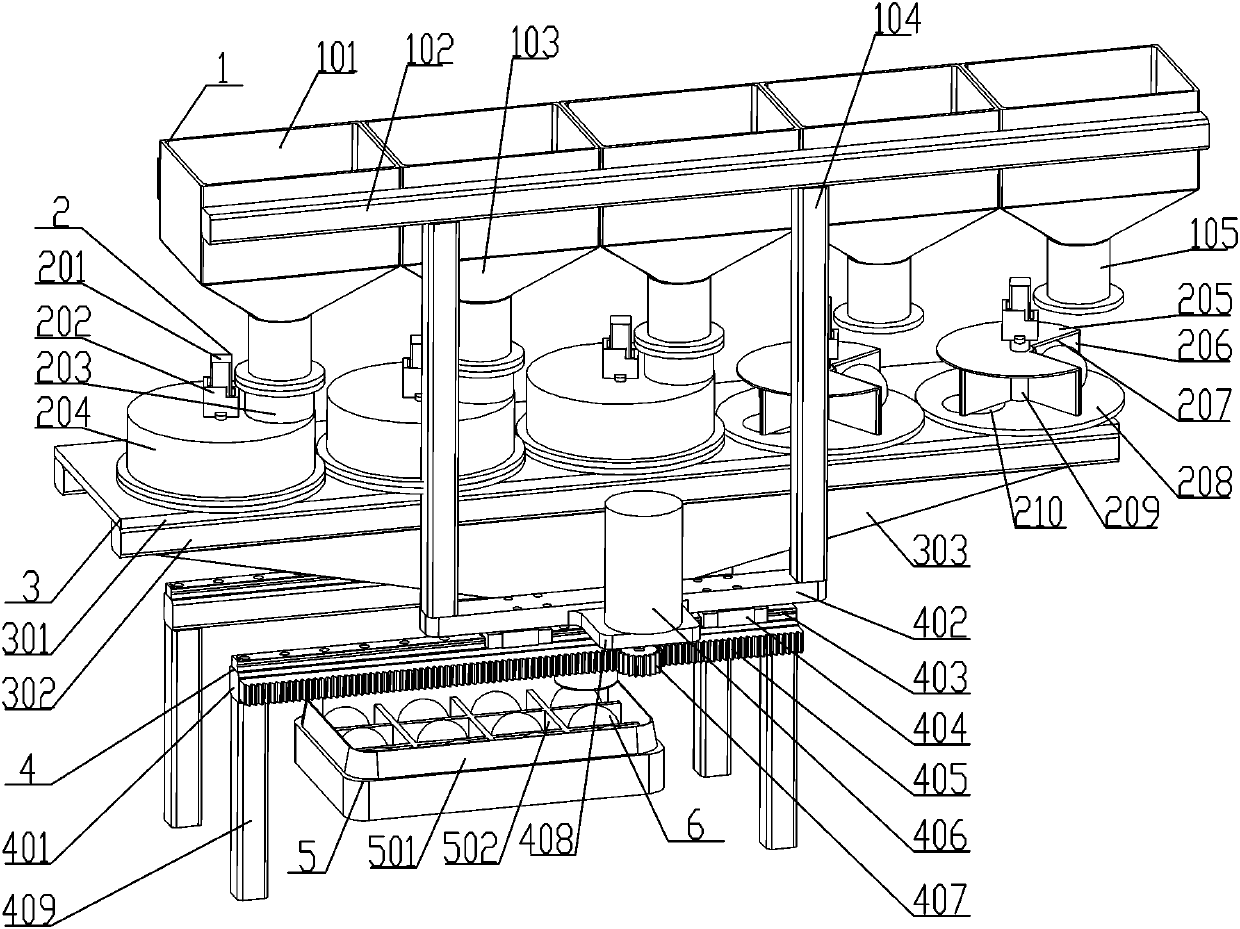

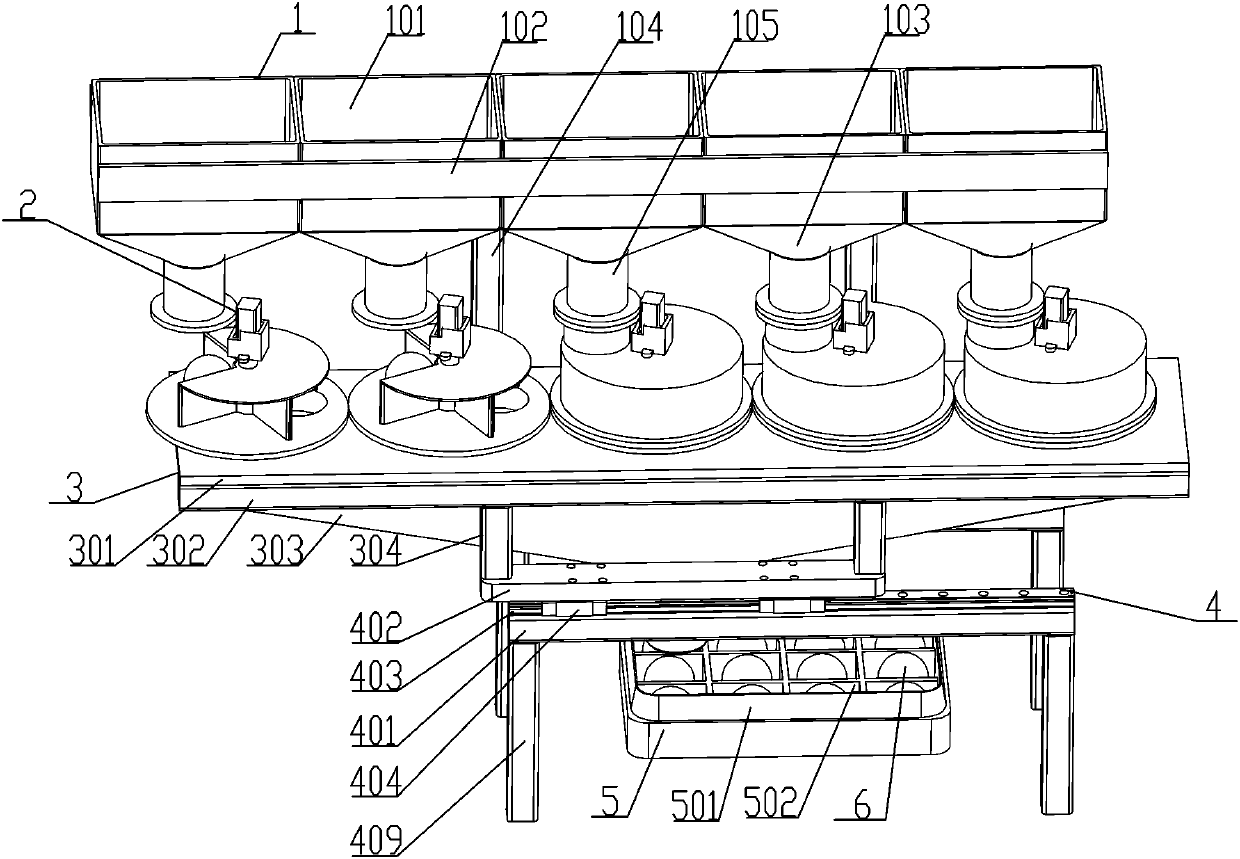

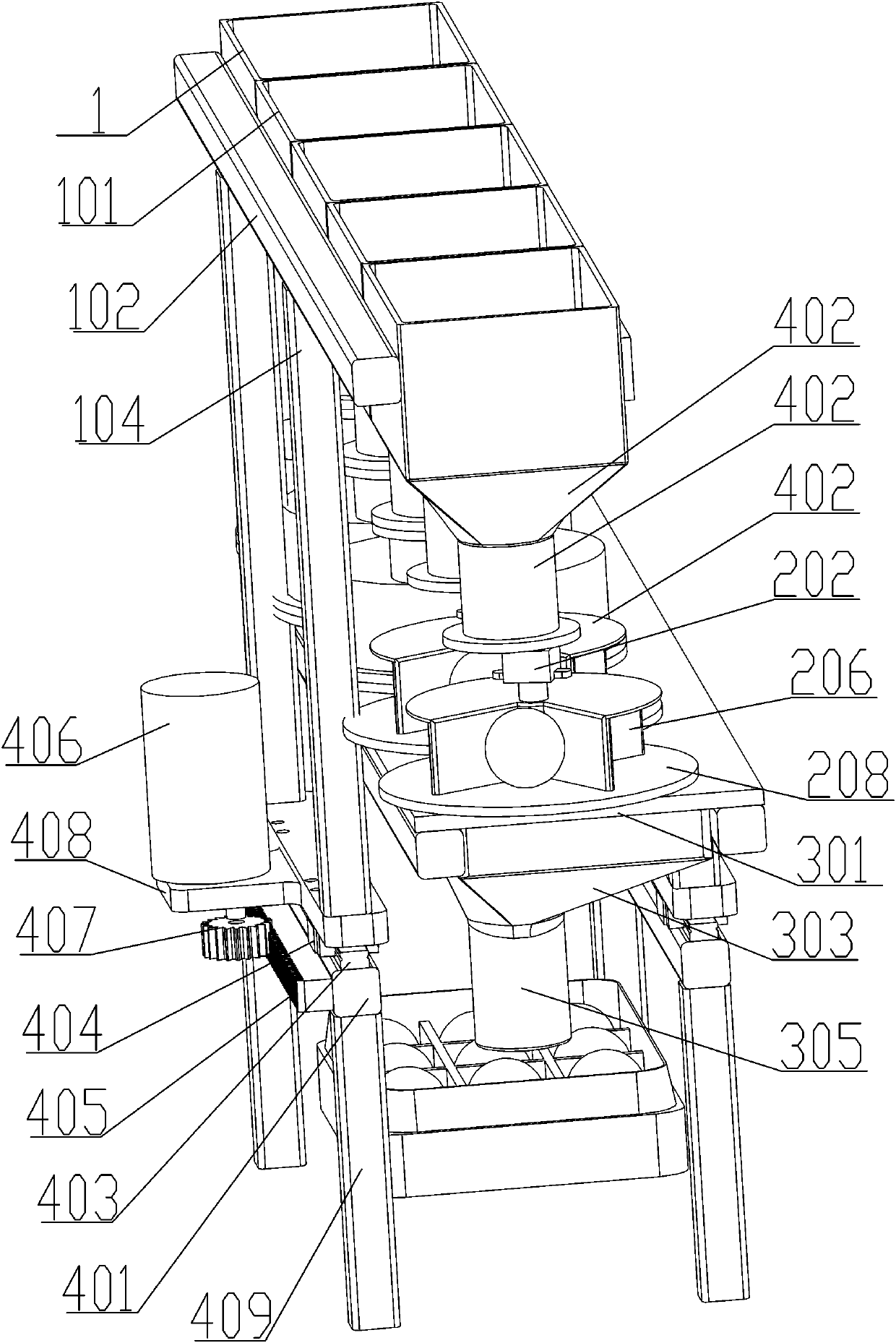

[0041] see Figure 1-5 , fruit packaging automatic unloading mechanism, which includes a total unloading device 1 for holding fruit, the discharge port of the total unloading device 1 is docked with a distributor 2 that enables the fruit to be unloaded sequentially, and the distributor 2 Bottom unloading device 3 is installed at the outlet of the bottom feeder; the total unloading device 1, distributor 2 and bottom unloading device 3 are all supported and installed on the translation mechanism 4 used for the movement of the whole device. By adopting the above-mentioned automatic unloading mechanism, automatic fruit unloading and packaging can be realized, thereby replacing the traditional weighing and packaging method, reducing the work intensity and ensuring work efficiency.

[0042] Further, the total unloading device 1 includes a plurality of square hoppers 101, each of the square hoppers 101 is connected with a top conical lower hopper 103, and the outlet of the top conica...

Embodiment 2

[0052] The operation method of any one of the fruit packaging automatic unloading mechanism, it comprises the following steps:

[0053] Step1: place the fruit inside the square hopper 101 of the total feeding device 1;

[0054] Step2: The fruit will drop from the top conical discharge hopper 103 to the top discharge cylinder 105, and the fruit will be transported to the inside of the distributor cover 204 through the top discharge cylinder 105;

[0055] Step3: Start the first motor 201 of the distributor 2, drive the fan blade of the distributor to rotate through the first motor 201, and drive the fruit to rotate on the chassis 208 through the fan blade of the distributor. When it reaches the position of the lower barrel 210 at the bottom, the fruit It will fall from the bottom feeding barrel 210 and enter the bottom conical lower hopper 303 of the bottom feeding device 3; and put the fruit into the corresponding storage compartment inside the fruit box 5;

[0056] Step4: Sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com