A three-dimensional laser positioning liquid viscosity coefficient measuring instrument

A viscosity coefficient, three-dimensional laser technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of many adjustment steps, high requirements, unacceptable receivers, etc., and achieve the effect of three-dimensional precise positioning and simplified operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

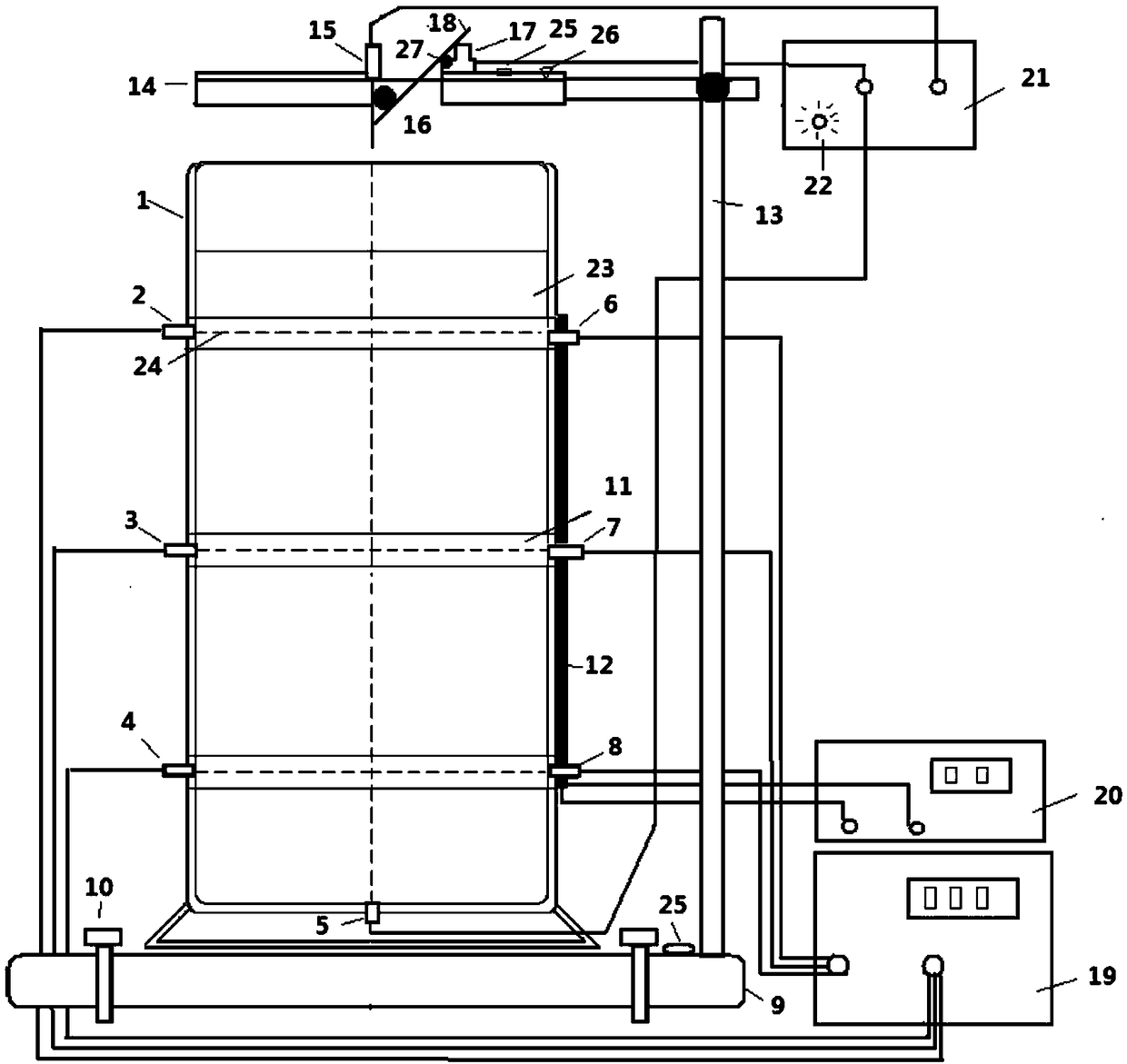

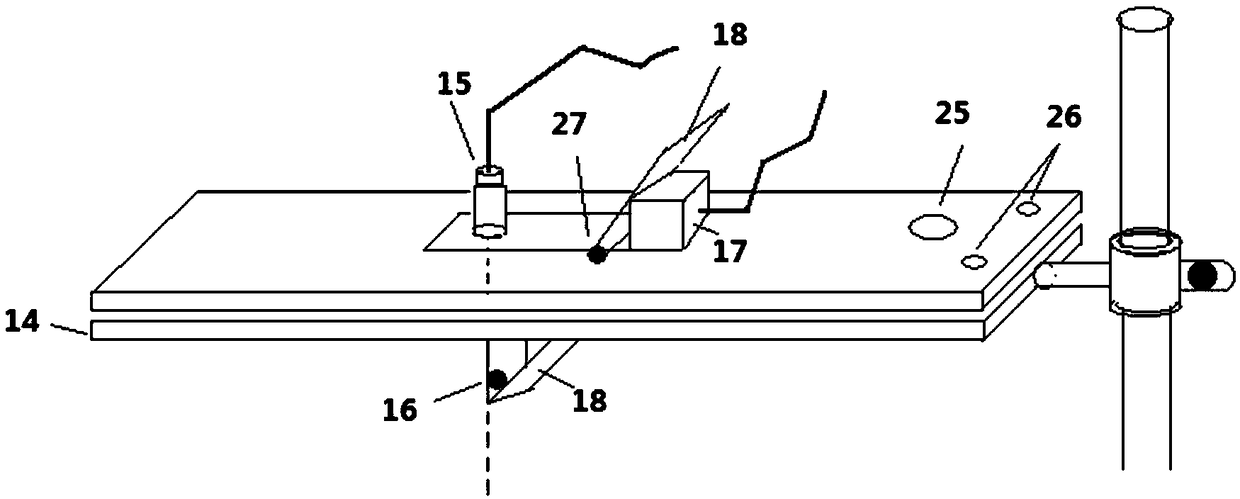

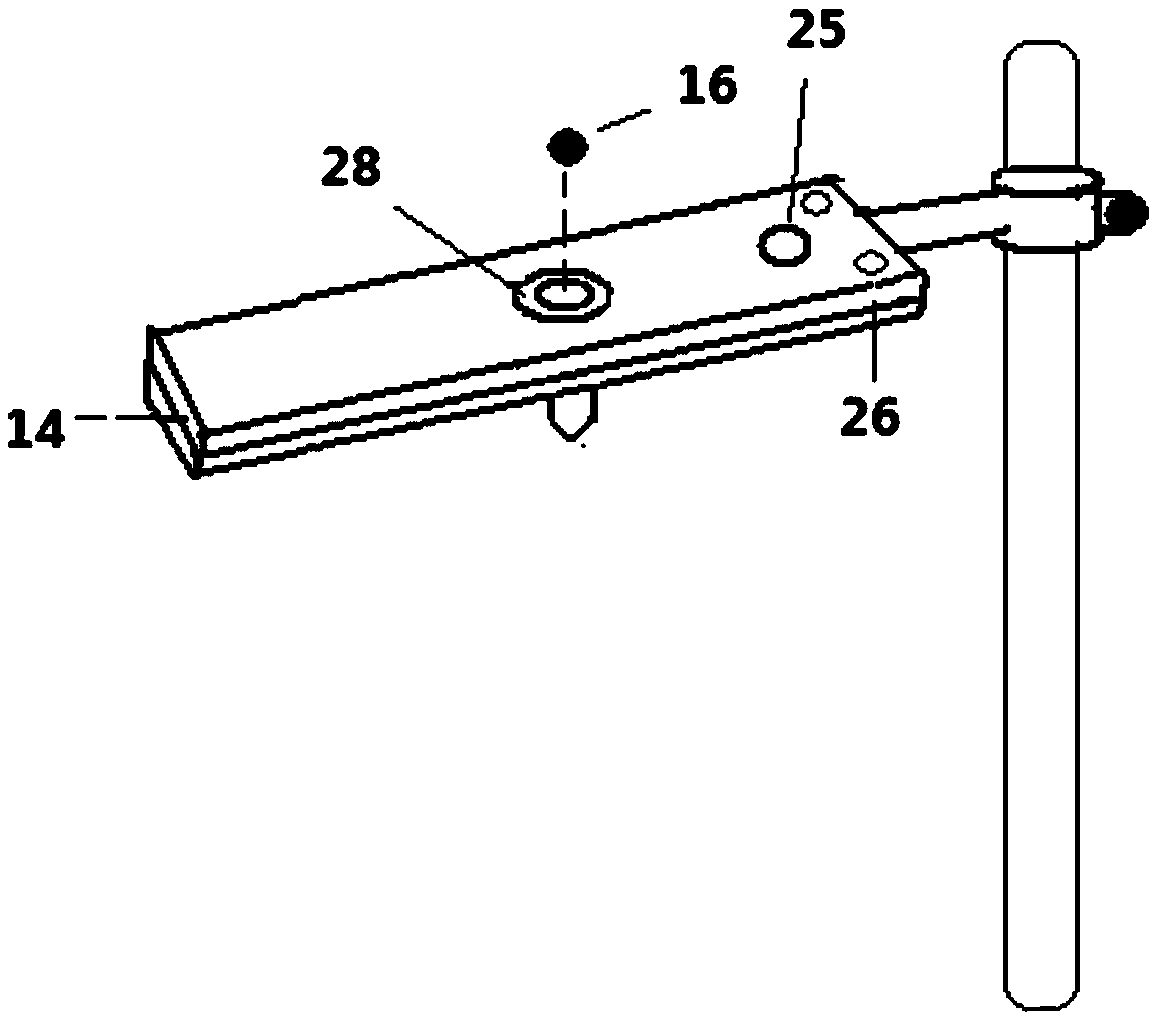

[0032] The invention is a measuring instrument for viscosity coefficient by falling ball method, which uses modern semiconductor laser technology combined with a single-chip microcomputer timing method to measure the falling time of steel balls with different diameters, thereby measuring the viscosity coefficient of liquid. Four groups of photogates with three-dimensional precise positioning are installed in this experimental device. It is characterized by intuitive phenomenon, accurate measurement data, small measurement error and good repeatability. The specific technical scheme is as follows:

[0033] Including graduated cylinder (1), first laser emitter (2), second laser emitter (3), third laser emitter (4), fourth laser emitter (5), first laser receiver (6) , the second laser receiver (7), the third laser receiver (8), the fourth laser receiver (15), the base (9), the temperature control belt (11), the temperature control circuit (12), the vertical rod (13), beam (14), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com