Extrusion forming device for cheese production

An extrusion molding and cheese technology, applied in cheese substitutes, applications, dairy products, etc., can solve problems such as low work efficiency, achieve high work efficiency, and facilitate subsequent collection and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

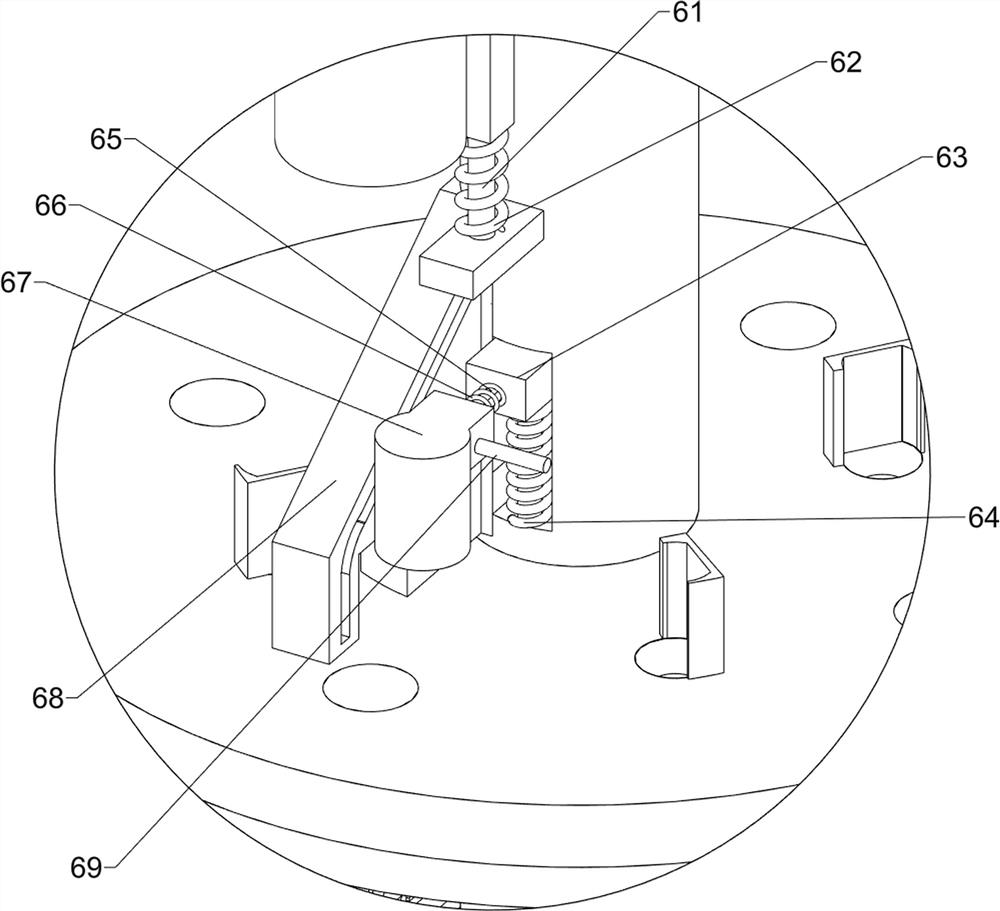

[0035] An extrusion molding device for cheese production, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a bottom plate 1, a support column 2, a support seat 3, a sliding assembly 4, an extrusion assembly 5 and a stamping assembly 6. The upper middle part of the bottom plate 1 is fixedly connected with the support column 2, and the middle part of the support column 2 is rotatably connected with the support seat. 3. The upper and middle part of the bottom plate 1 is provided with a sliding assembly 4 , the upper part of the support column 2 is provided with an extrusion assembly 5 , and the upper part of the support column 2 is provided with a stamping assembly 6 .

[0036] The sliding assembly 4 includes a first chute 41, a first spring 42, a first connecting rod 43 and a push rod 44. The upper middle part of the bottom plate 1 is symmetrically installed with the first chute 41, and the first chute 41 is slidably arranged. There is ...

Embodiment 2

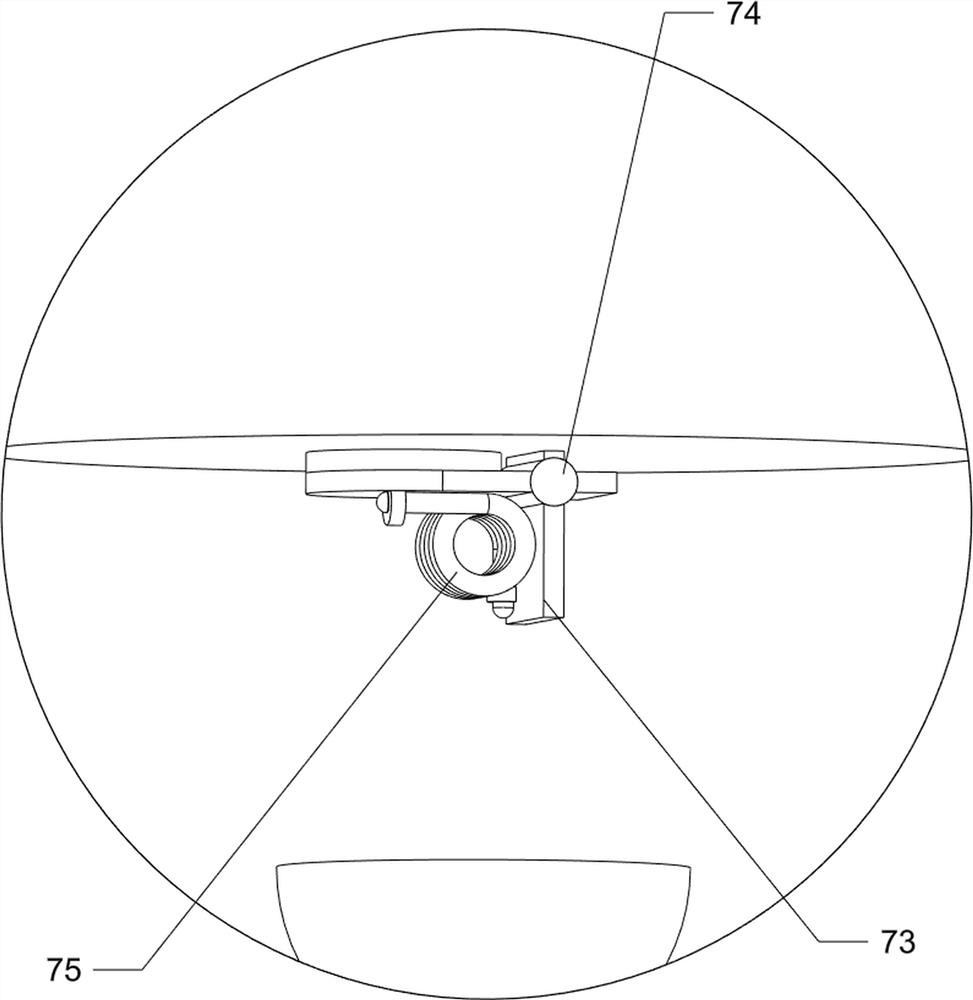

[0041] On the basis of Example 1, such as Figure 5-Figure 14 As shown, it also includes a feeding assembly 7, the feeding assembly 7 includes a conduit 71, a feeding bucket 72, a fifth connecting plate 73, a rotating plate 74 and a first torsion spring 75, and the left part of the charging bucket 52 is connected with a conduit 71, the top of the conduit 71 is connected with a feeding barrel 72 by bolts, and the bottom of the feeding barrel 72 and the charging barrel 52 has a through hole, and the bottom of the feeding barrel 72 and the charging barrel 52 are rotatably provided with a rotating plate 74, and the rotating plates 74 are respectively located Below the through holes of the upper barrel 72 and the charging barrel 52, the fifth connecting plate 73 is fixedly connected in the upper barrel 72 and the charging barrel 52, and the first torsion spring 75 is connected between the fifth connecting plate 73 and the rotating plate 74. .

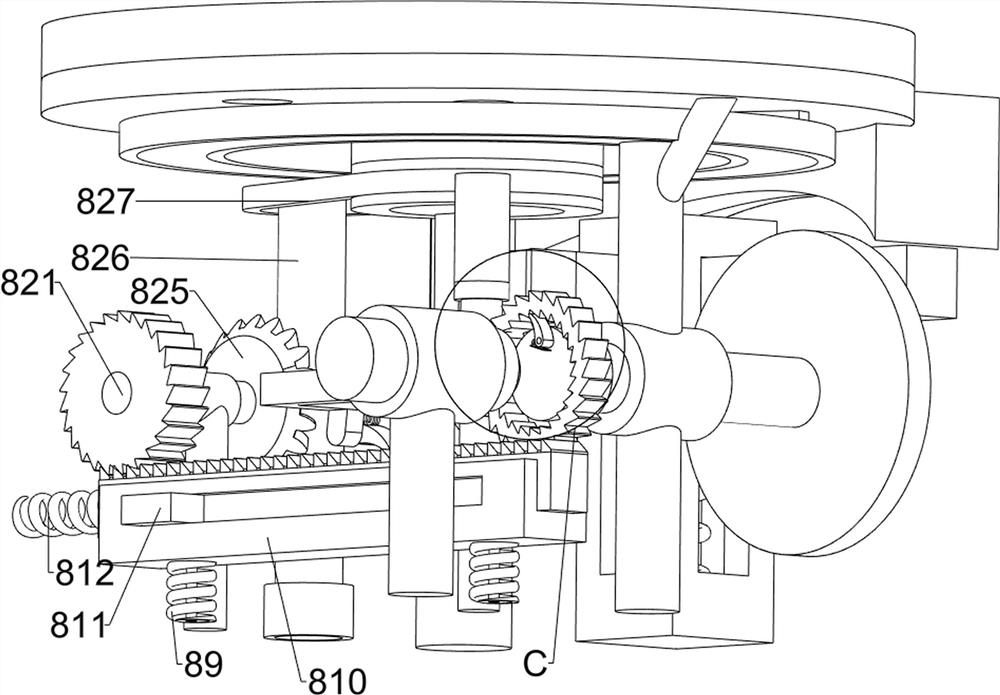

[0042] Also includes a rotating asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com