Rotary peeling device for lower part of mulberry fork

A rotary and rotating technology, which is applied in the field of rotary peeling device at the lower part of the mulberry fork, can solve the problems of unsafe and easily damaged materials, and achieve the effects of improving the success rate, peeling safety, and convenient use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

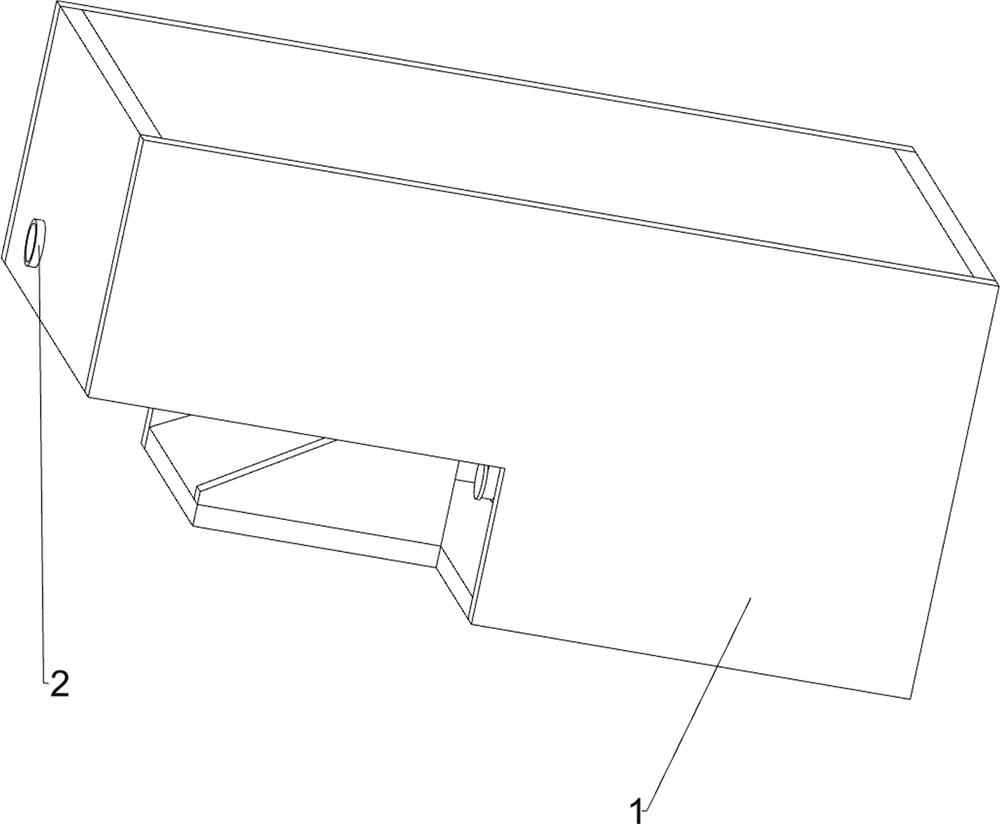

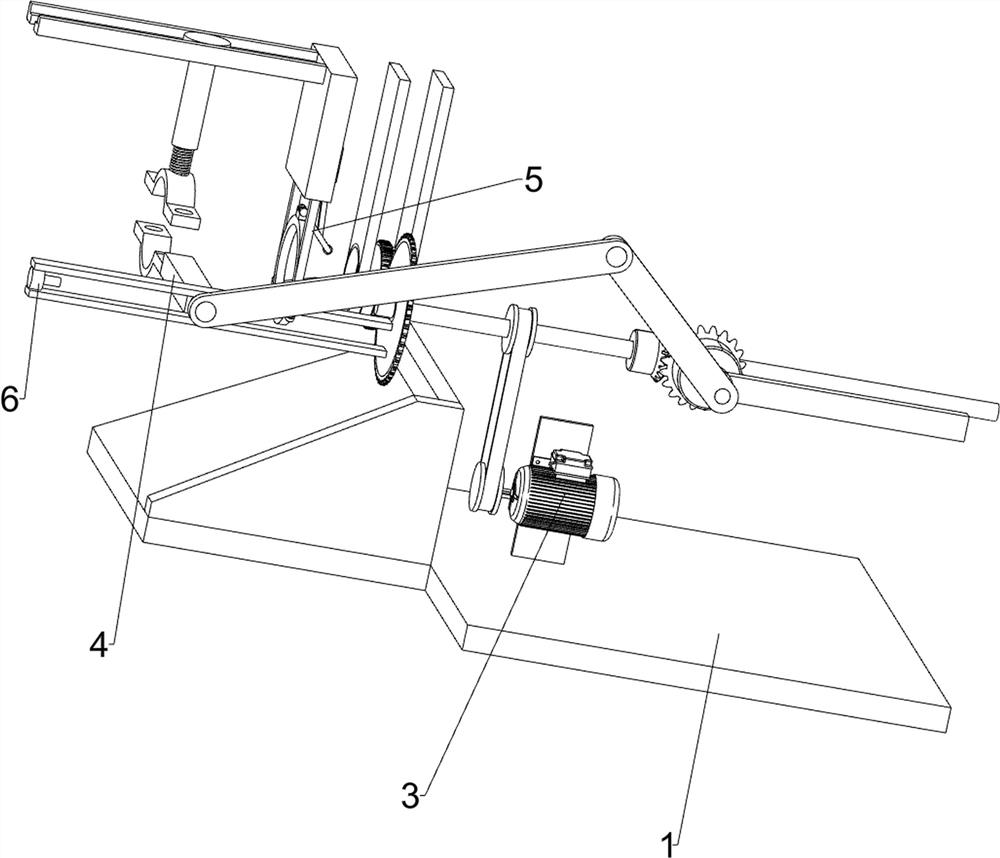

[0021] A rotary peeling device at the lower part of the mulberry fork, such as Figure 1-Figure 4 As shown, it includes an installation box 1, a feeding pipe 2, a peeling assembly 3 and a pulling assembly 4. The feeding pipe 2 is installed on the left part of the installation box 1, and the peeling assembly 3 is installed in the middle of the installation box 1. A pulling assembly 4 is installed in the left part of the installation box body 1 .

[0022] When needing to use the device to peel the mulberry fork, first put the mulberry fork from the feed pipe 2, and the mulberry fork is located in the peeling assembly 3 and the pulling assembly 4, and now the peeling assembly 3 is controlled to work, and the mulberry The fork is peeled, and the mulberry fork is moved to the right by the pulling assembly 4 and peeled. After the mulberry fork has been peeled, the peeling assembly 3 is controlled to stop working, and then the mulberry fork that has been peeled is pulled out.

[002...

Embodiment 2

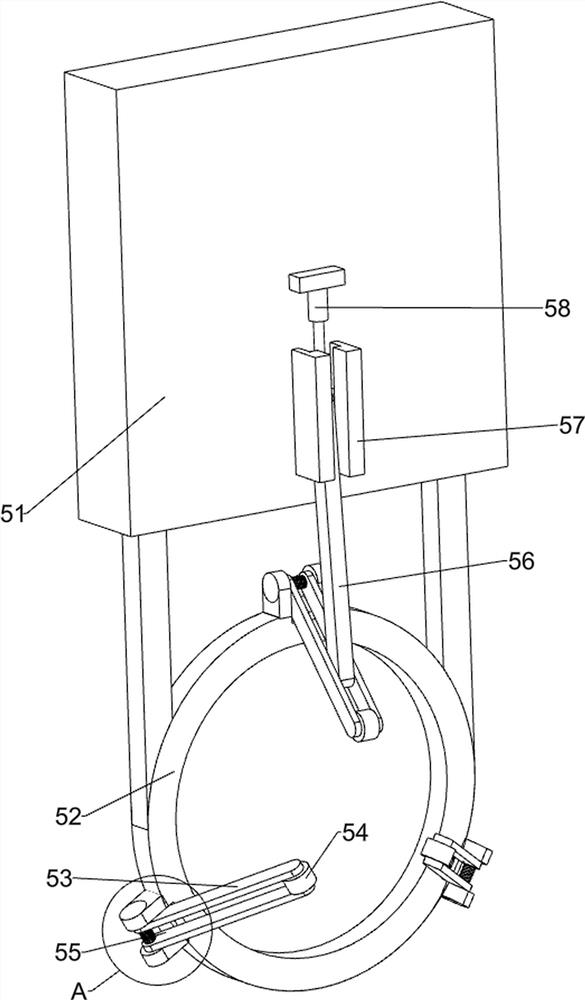

[0028] On the basis of Example 1, such as figure 2 , Figure 5 with Image 6 As shown, trigger assembly 5 is also included. Trigger assembly 5 is installed on the top of installation box 1. Trigger assembly 5 includes second installation plate 51, installation ring 52, clamp rod 53, guide wheel 54, torsion spring 55, lift Rod 56, the third guide rail 57 and the first button 58, the top left side of the installation box 1 is fixedly connected with the second installation plate 51 by bolts, the bottom of the second installation plate 51 is welded with the installation ring 52, and the outside of the installation ring 52 is rotatable Be provided with at least two clamping rods 53, the rotation connection of clamping rods 53 is connected with torsion spring 55, the outer end of clamping rods 53 is provided with guide wheel 54, and the second mounting plate 51 right side sliding type is provided with the 3rd guide rail 57, the upper part The clamping rod 53 of the clamping rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com