Container and bottle perform thereof as well as application

A technology for containers and preforms, applied in the directions of containers, applications, rigid containers, etc., can solve the problems of inability to meet the sealing of the contents, exposure to the outside of the container, cross-contamination of mixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0155] Example 1. A container having an open container neck.

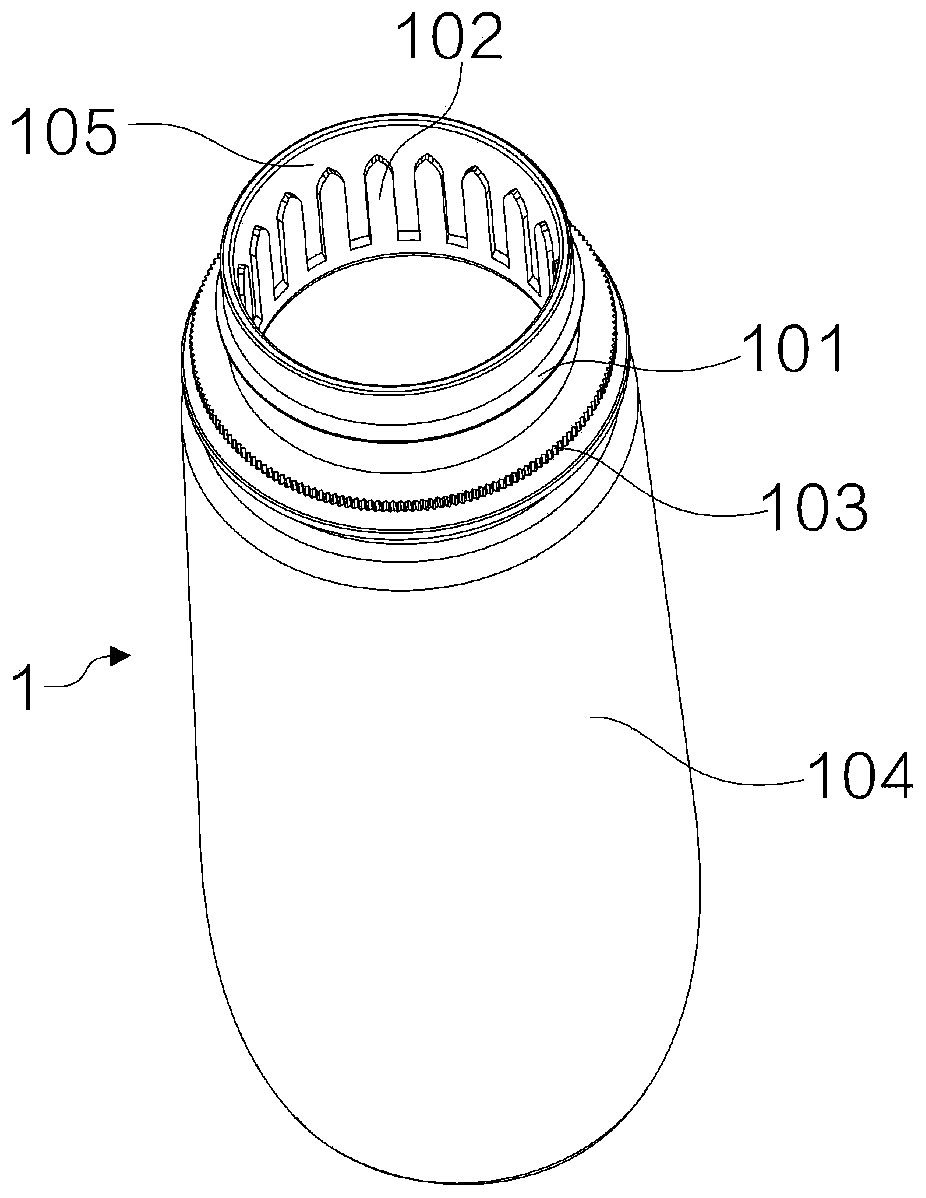

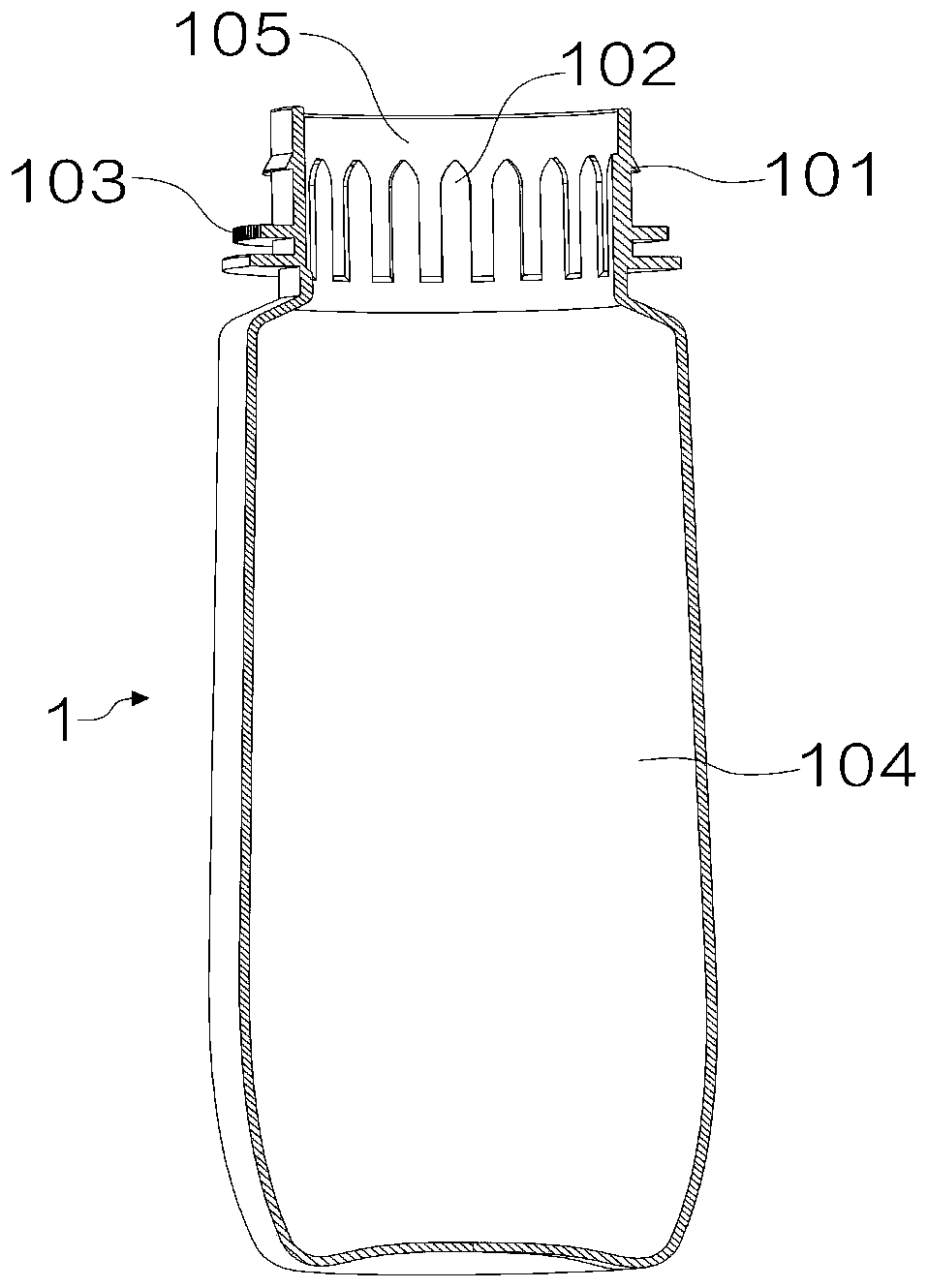

[0156] refer to figure 1 and figure 2 As shown, the container 1 provided by this embodiment has an open container neck and a main body chamber 104 of the container. Buckles 101 and jagged stoppers 103 are arranged on the outer wall, and longitudinal ribs 102 are arranged on the inner wall of the container neck, and a groove-shaped longitudinal track structure is formed between the at least two ribs 102 .

Embodiment 2

[0157] Example 2. A container having an open container neck.

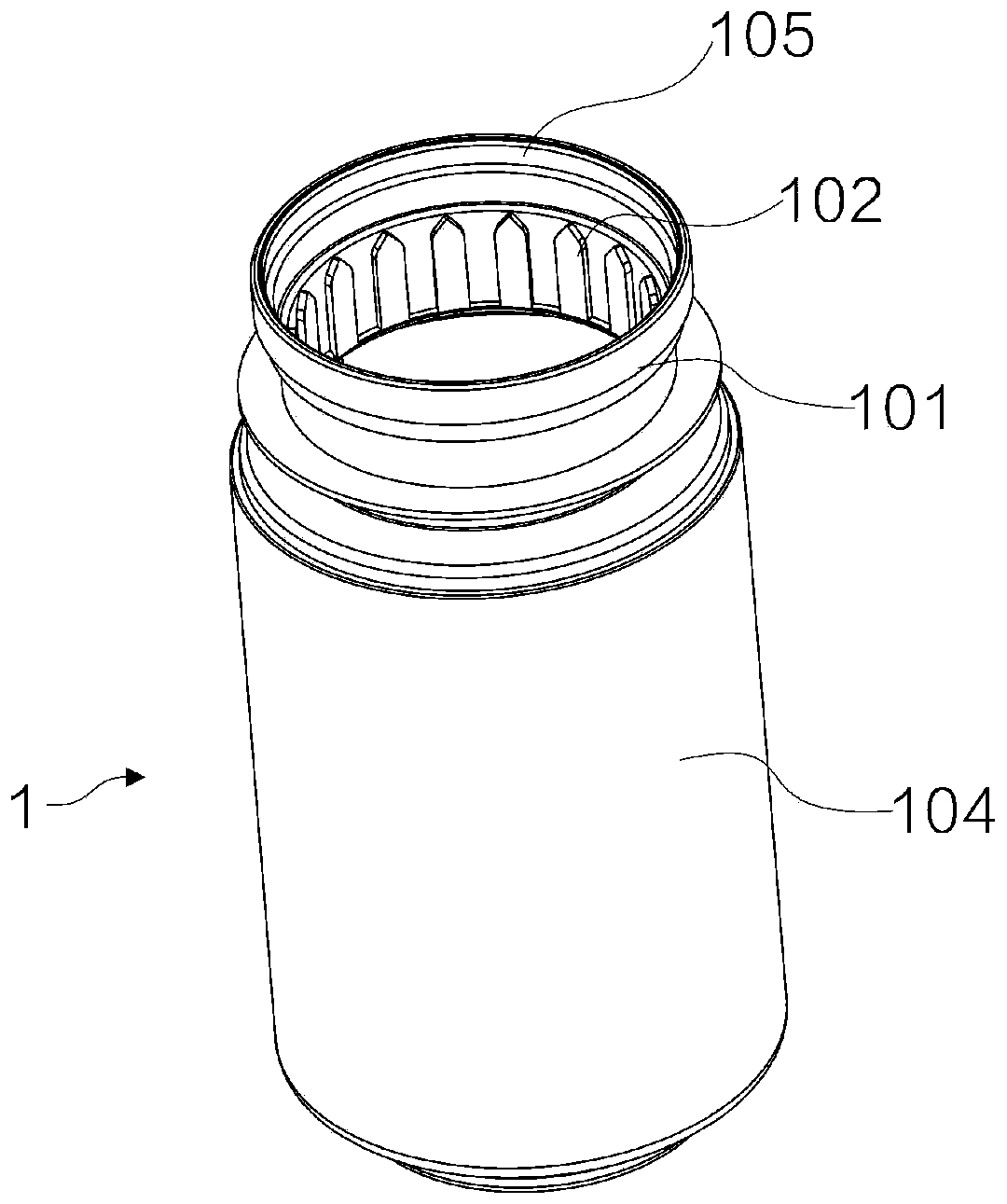

[0158] refer to image 3 and Figure 4 As shown, the container 1 provided by this embodiment has an open container neck and a main body chamber 104 of the container. Buckles 101 are provided on the outer wall, longitudinal ribs 102 are provided on the inner wall of the container neck, and a groove-shaped longitudinal track structure is formed between the at least two ribs 102 .

[0159] Different from Embodiment 1, the buckle 101 on the container neck is formed by enlarging the inner diameter of the wall structure of the container neck. As shown in the figure, the wall structure of the container neck expands its inner diameter twice , two stepped structures are formed on the inner wall of the neck, and two stepped structures are also formed on the outer wall of the neck; the two stepped structures formed on the inner wall of the neck are beneficial to the closure of the container For the arrangement of the tight...

Embodiment 3

[0160] Example 3. A container having an open container neck.

[0161] refer to Figure 5 and Figure 6 As shown, the container provided by this embodiment has an open container neck and a main body chamber of the container, and the neck of the container is arranged on the top of the container. The chamber members 12 are formed by assembling together by welding. The container neck member 11 has a buckle 1101 on the container neck, a rib 1102 on the inner wall of the container neck, an opening 1103 of the container, a welding groove structure 1104, and one of the ribs 1102 on the inner wall of the container neck A groove-shaped longitudinal track structure is formed between them; the container main body chamber member 12 has a main body chamber 1201 of the container and a welding sealing ring 1202; Preferably, the container neck member 11 and the container body chamber member 12 are welded together by spin welding, so that the container neck member 11 and the container body c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com