Material storage and release device, and components and application thereof

A material and material cavity technology, which is applied in the application of closure devices and the field of material storage and release devices, can solve the problems of repeated use of unfavorable packaging containers, unsatisfactory, unable to realize the smooth release of solid materials and viscous materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0212] Embodiment 1. A container closure device including a material storage and release device and its packaging container, its components, its packaging container and its application.

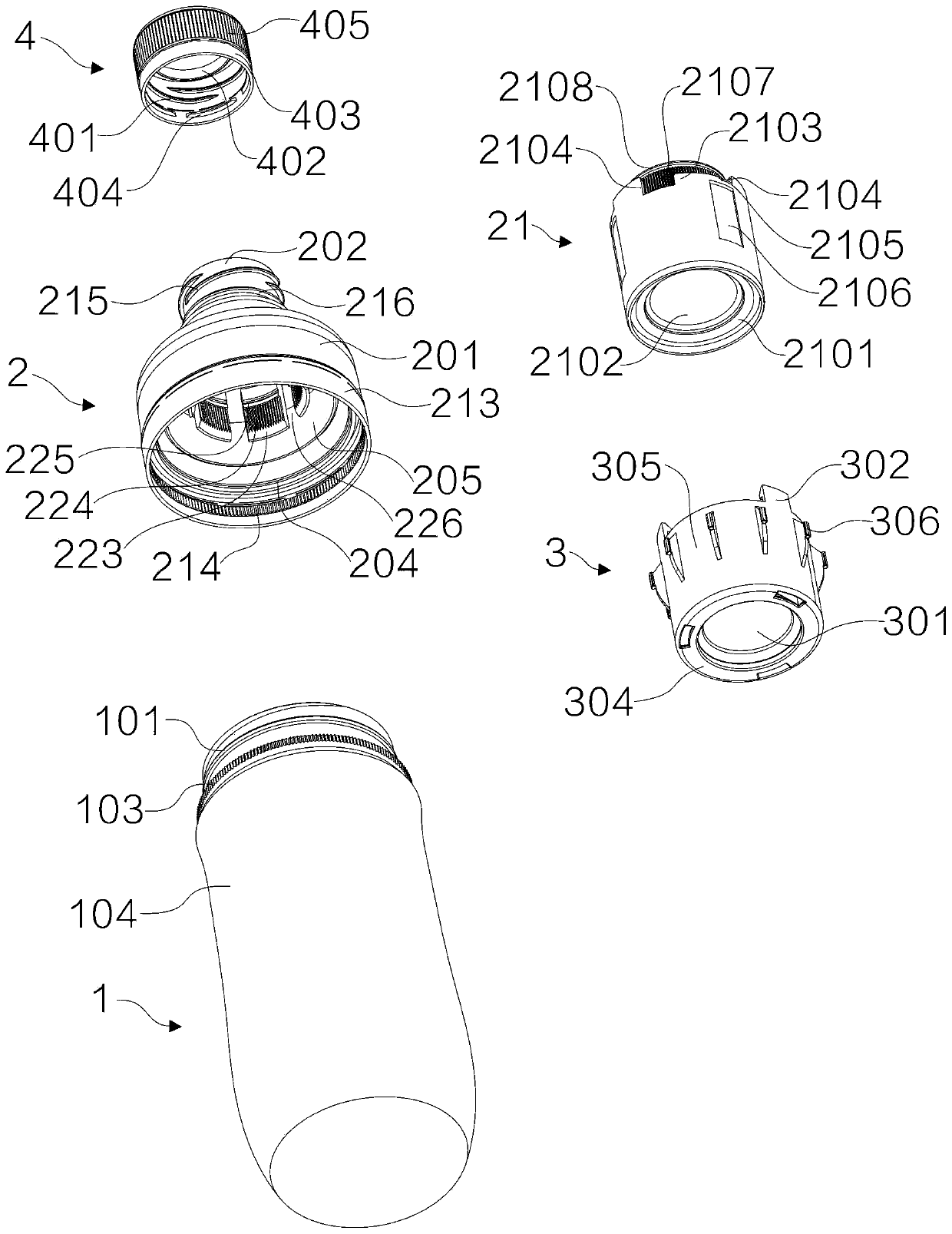

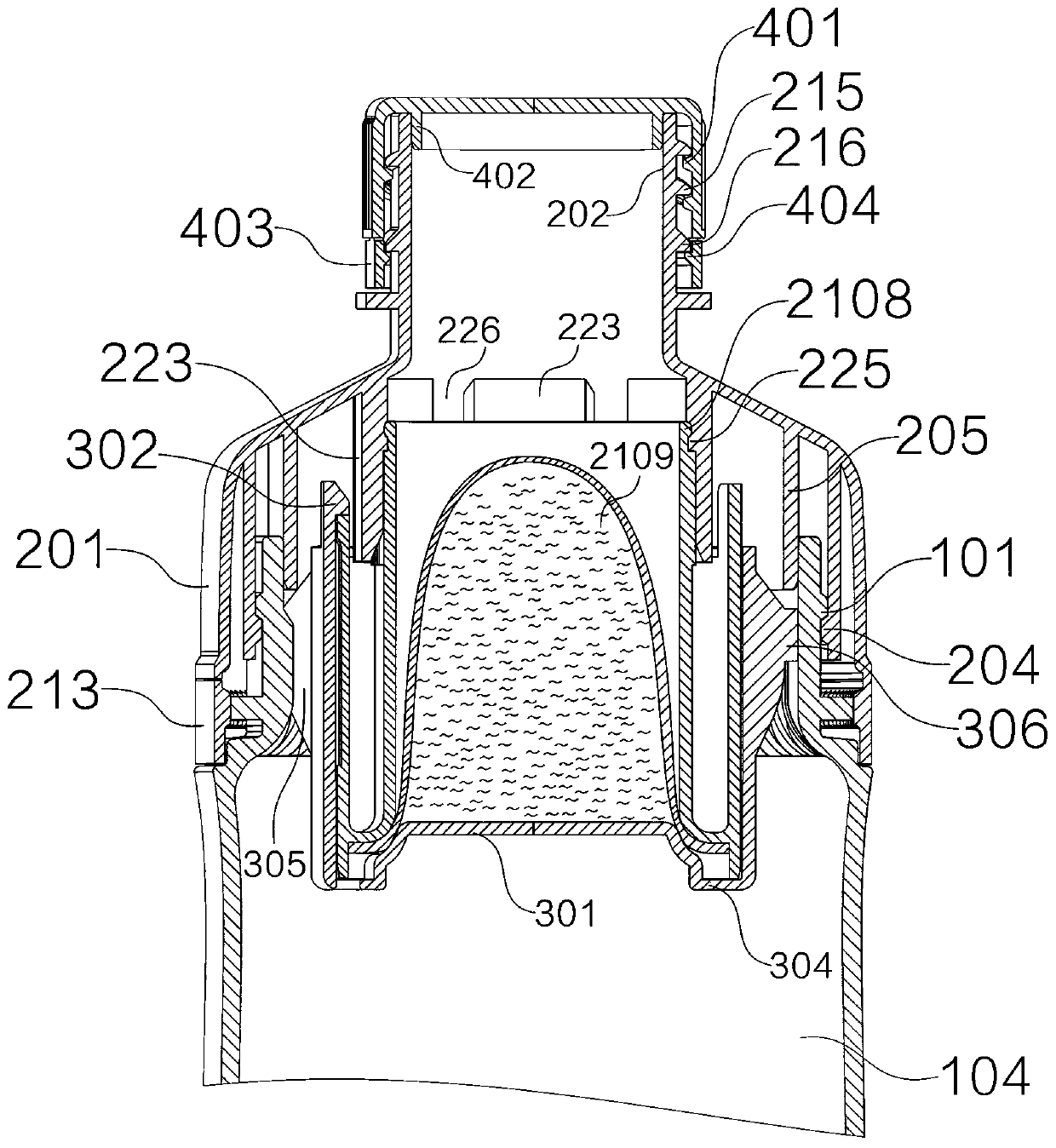

[0213] refer to Figure 1 to Figure 3 As shown, the container closure device provided in this embodiment includes a control cover 2 and a plug member 3, wherein:

[0214] The control cover 2 has a cover structure 201 , a channel structure 202 , and an independent material chamber component 21 installed in the control cover 2 . The buckle 204 of the control cover, the tight ring 205 of the control cover, and the rib structure 223 are arranged on the inner wall of the cover enclosure structure 201, and the rib structure 223 is provided with a rib stop of the rib structure. The buckle 224, the buckle 225 of the rib structure, and the gap 226 of the rib structure is formed between at least two rib structures 223, and the gap 226 of the rib structure communicates with the channel structure 202; ...

Embodiment 2

[0234] Embodiment 2. A container closure device comprising a material storage and release device, its components, its packaging container and its application.

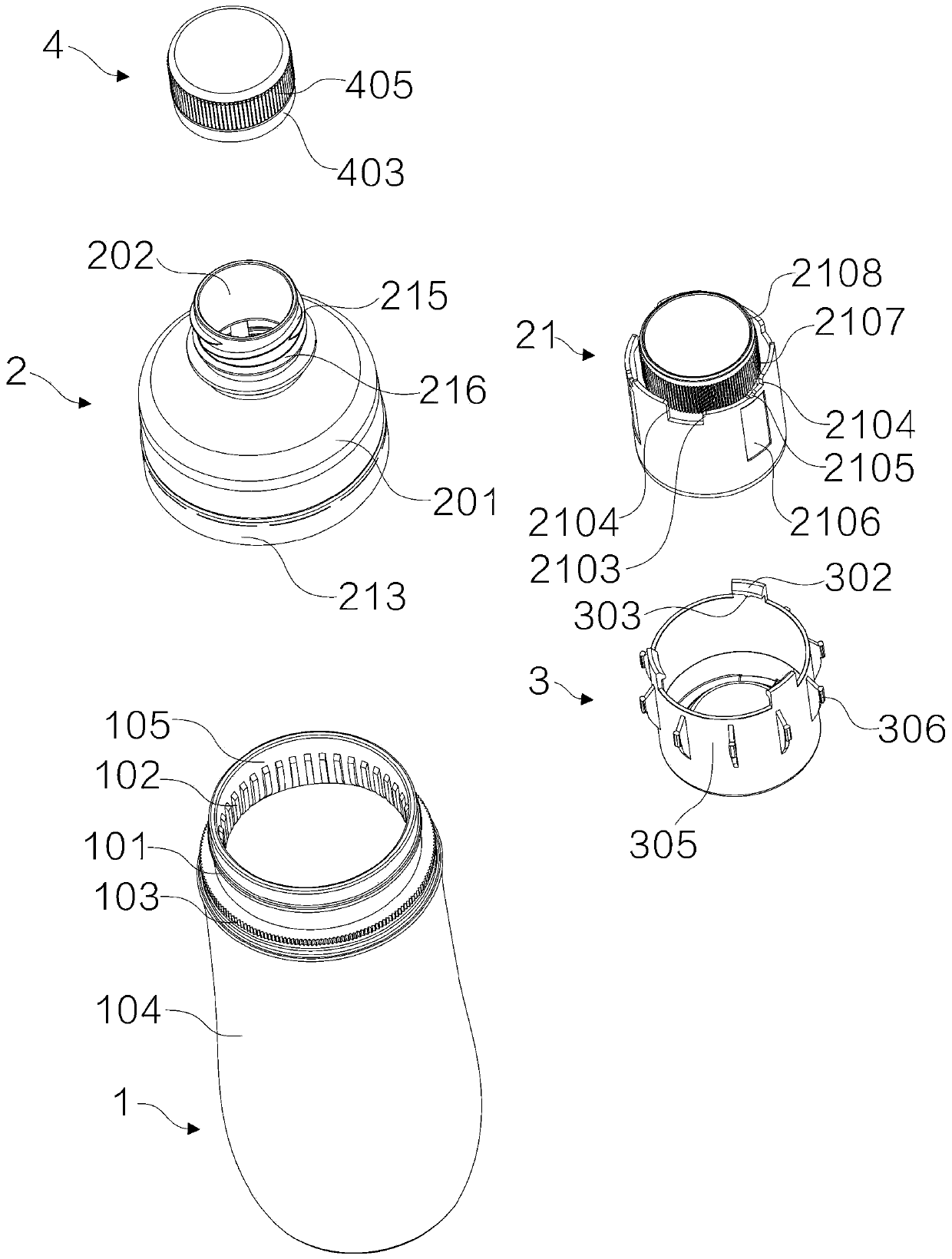

[0235] refer to Figure 4 to Figure 6 As shown, the container closure device provided in this embodiment includes a control cover 2 and a plug member 3, wherein:

[0236] The control cover 2 has a cover structure 201 , a channel structure 202 , and an independent material chamber component 21 installed in the control cover 2 . The buckle 204 of the control cover, the tight ring 205 of the control cover, and the rib structure 223 are arranged on the inner wall of the cover enclosure structure 201, and the rib structure 223 is provided with a rib stop of the rib structure. The buckle 224, the buckle 225 of the rib structure, and the gap 226 of the rib structure is formed between at least two rib structures 223, and the gap 226 of the rib structure communicates with the channel structure 202;

[0237]The channel structu...

Embodiment 3

[0255] Embodiment 3. A container closure device comprising a material storage and release device, its components, its packaging container and its application.

[0256] refer to Figure 7 to Figure 9 As shown, the container closure device provided in this embodiment includes a control cover and a plug member 3, wherein:

[0257] The control cover is formed by assembling and welding the cover surrounding member 25 and the material chamber member 22 with a buckle;

[0258] The cover member 25 has a cover structure 2501 and a channel structure 2502, wherein the inner wall of the cover structure 2501 is provided with a welding positioning groove 2507, the channel structure 2502 is arranged at the tail end of the cover structure 2501, and the channel structure 2502 has an opening Or it is in the shape of an opening, and the channel structure 2502 communicates with the inner space and the outer space formed by the cover structure 2501;

[0259]The material chamber member 22 with bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com