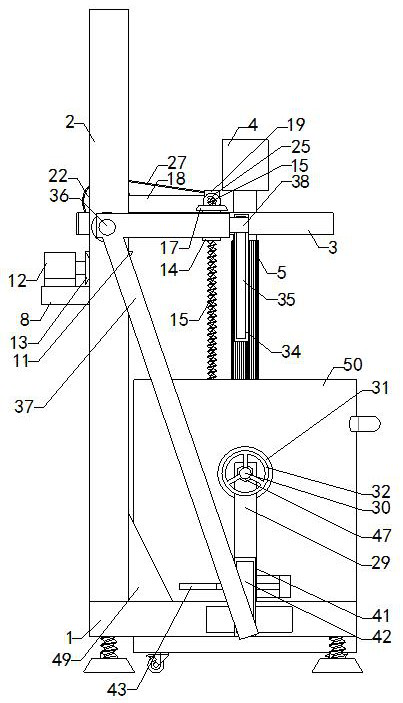

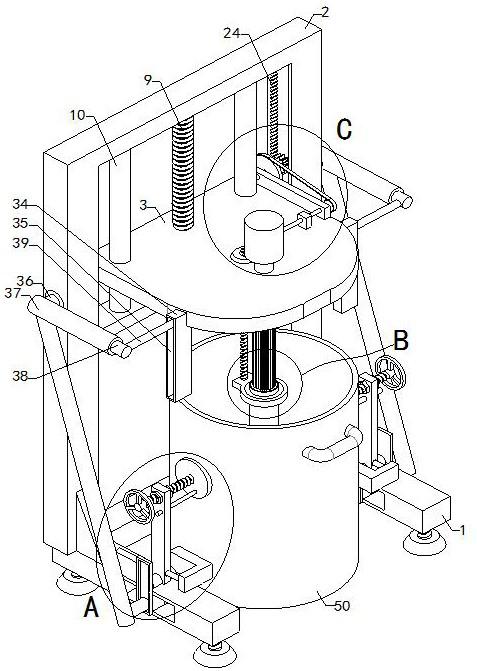

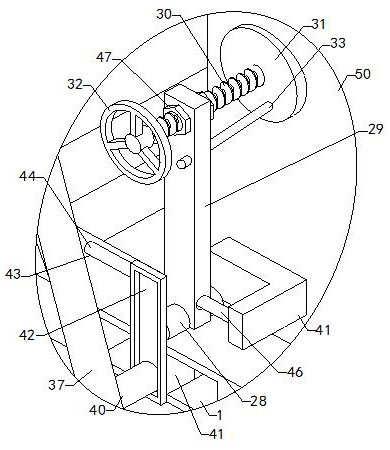

Novel stirring dispersion machine for chemical industry

A dispersing machine, a new type of technology, applied to mixer accessories, mixers with rotating agitating devices, mixers, etc., can solve the problems of inconvenient access to the height space, inconvenient fixing of the dispersion bucket, and high overall height, so as to reduce the use limitation Sex, overall length reduction, height reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0031] A new type of stirring and dispersing machine for chemical industry according to the present invention, the installation, connection or arrangement of all the above-mentioned components are welding, riveting or other common mechanical methods, and the sliding / rotating fixation is sliding / rotating It does not fall off in the state, and the sealing communication means that the two connecting parts are connected and sealed at the same time, and the specific structure, model and coefficient index of all its parts are its own technology, as long as it can achieve its beneficial effect, it can be implemented. All of the above Power modules and appliances are common electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com