Metal-bar peeler

A metal bar and peeling machine technology, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of reducing labor intensity of employees, small size, and high labor intensity, so as to improve automatic control performance and reasonable design , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

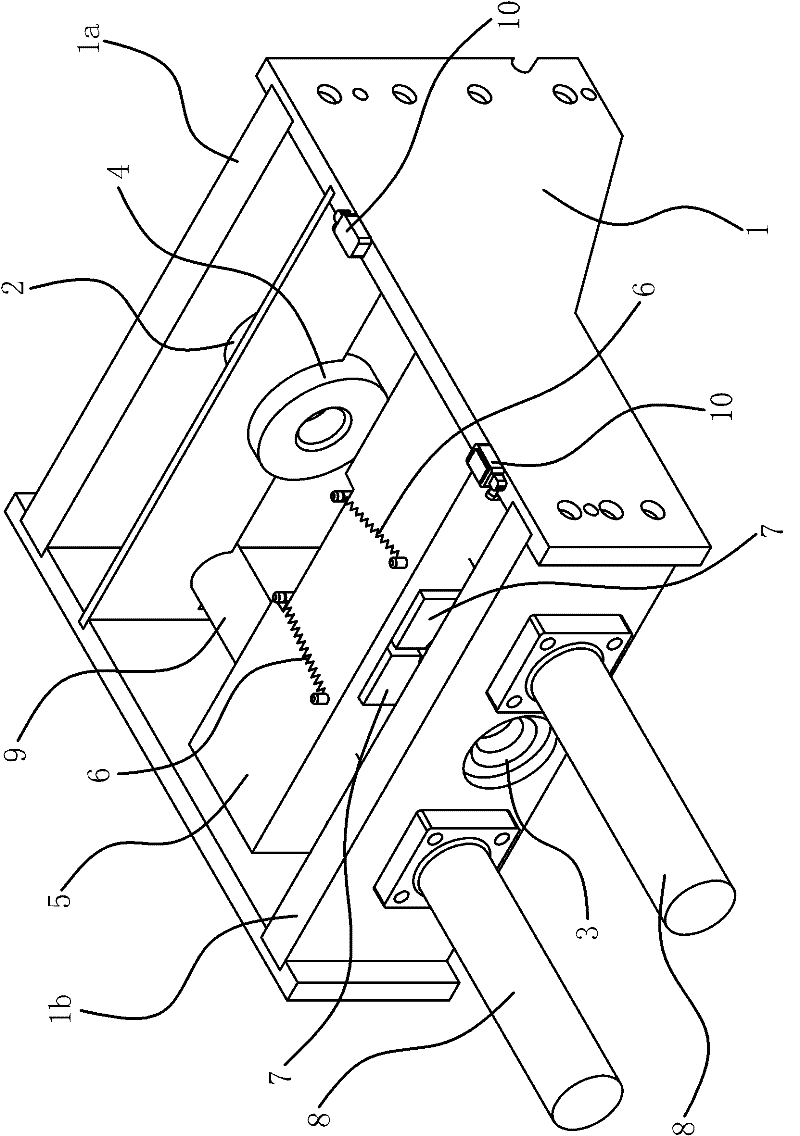

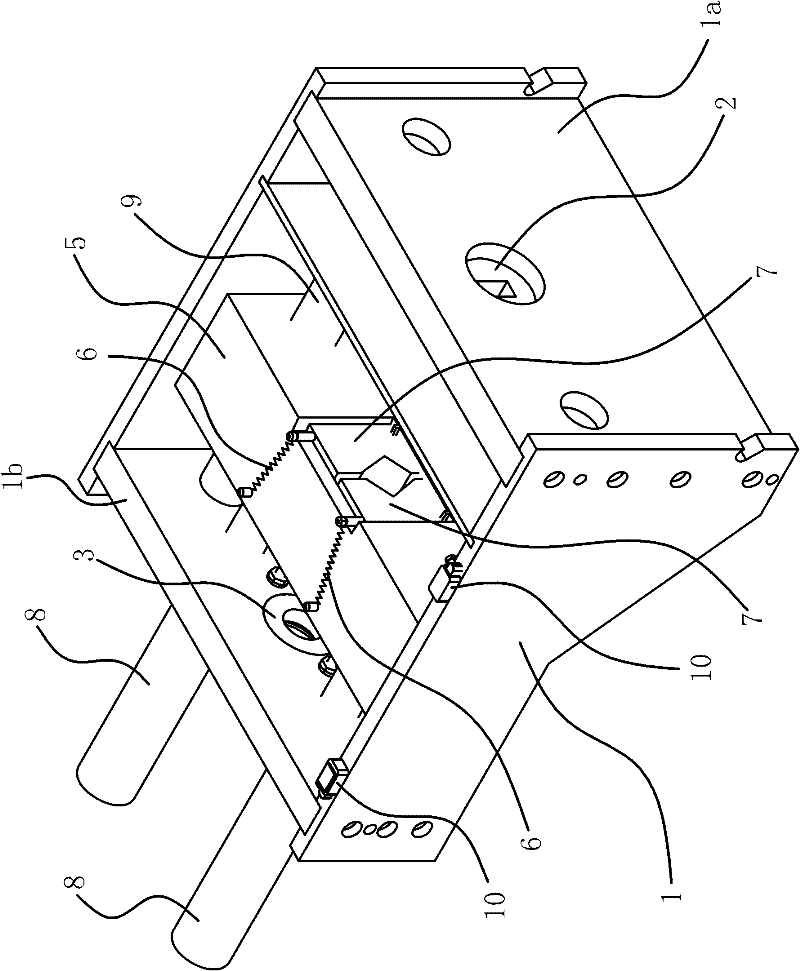

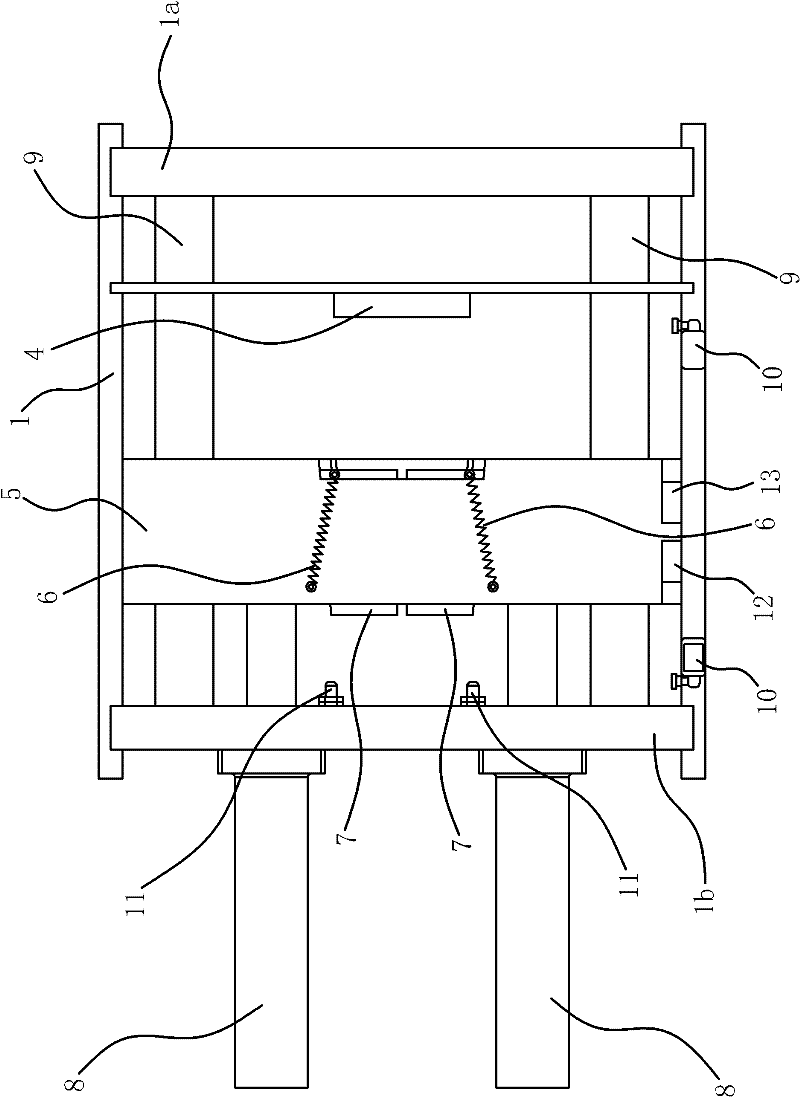

[0034] Such as Figure 1 to Figure 6 Shown, the peeling machine of this metal rod comprises frame 1, peeling die 2, guide member 3, connecting seat 5, power member 8, traction mechanism, clamping mechanism.

[0035] Specifically, there is a fixed seat-1a for fixing the peeling die 2 on the frame 1, and the peeling die 2 is fixed on the fixed seat-1a by bolts, so that the peeling die 2 can The mold corresponding to size selection is fixed on the holder-1a. Obviously, the frame 1 on one side of the peeling die 2 is a feed section, and the frame 1 on the other side of the peeling die 2 is a discharge portion. Frame 1 Frame 1 feeding part is provided with fixing seat 2 1b for fixing guide 3, and guide 3 is fixed on the fixing seat 2 1b by bolt, and the guide hole of round hole is arranged on this guide 3, and guide hole The center line of the center line and the center line of the peeling die 2 die holes are on the same straight line. Therefore, the guide member 3 can also sele...

Embodiment 2

[0049] Such as Figure 7 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference lies in: a cylinder 14 capable of driving the corresponding chuck body 7 to move is provided between each chuck body 7 and the connecting seat 5, The cylinder body of the air cylinder 14 is hinged on the connecting body, and the piston rod is hinged on the corresponding chuck body 7 . Obviously, the hydraulic cylinder can replace the air cylinder 14 in this structure. When the cylinder 14 was in the extended state, the two chuck bodies 7 were in an expanded state, that is, the metal rod could be loosened; when the cylinder 14 was in the retracted state, the two chuck bodies 7 were in a tightened state, that is, the Clamp the metal rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com