Treatment device for drinking water prepared from natural minerals

A treatment device and natural mineral technology, applied in the direction of adding substances to water/sewage treatment, water treatment sites, water/sewage treatment, etc., can solve the problems of short service life, difficult cleaning of drinking water devices, secondary pollution, etc., and reach the service life Long life, low cost of use, easy and quick cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

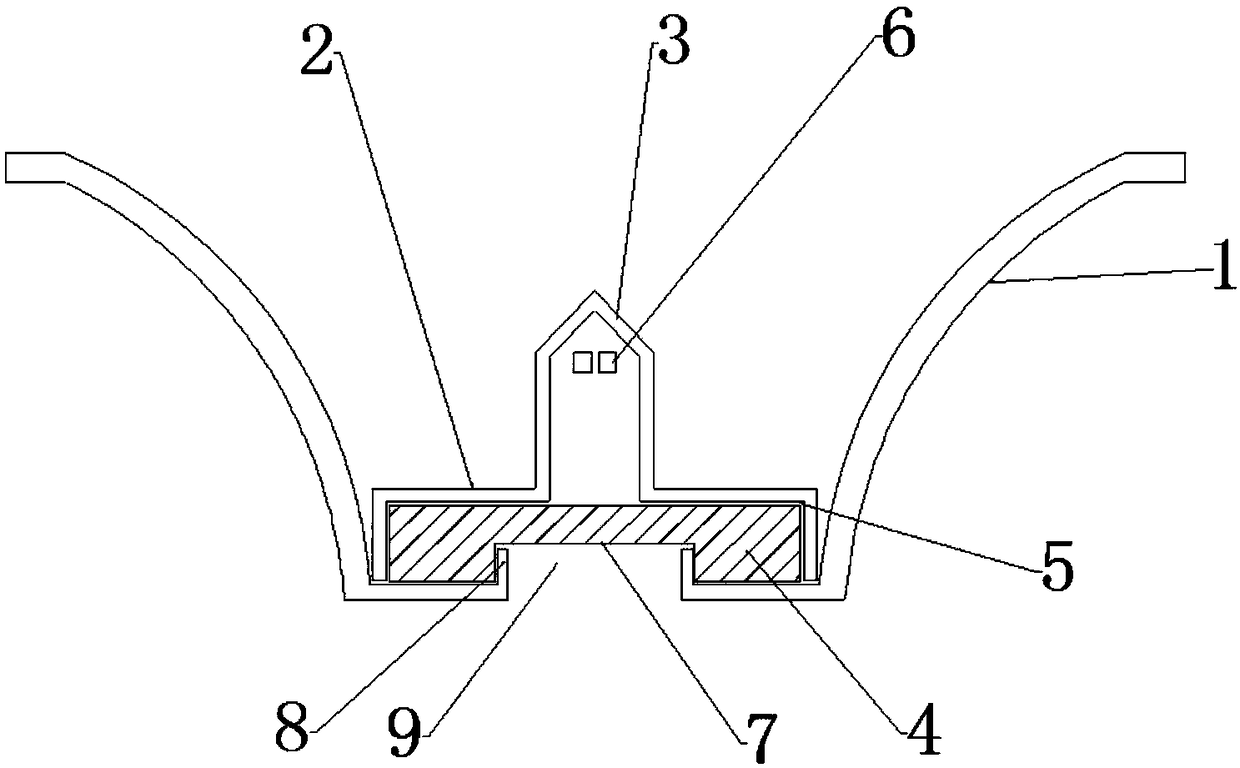

[0026] A drinking water treatment device made of natural minerals. The manufacturing method includes firing trays, firing water diversion top pillars and firing filter elements. The firing process of the tray and water diversion top pillars is as follows: clayey siltstone or Embryos are made of kaolin, and the embryos are naturally dried in the shade, then glazed, and finally sintered at high temperature;

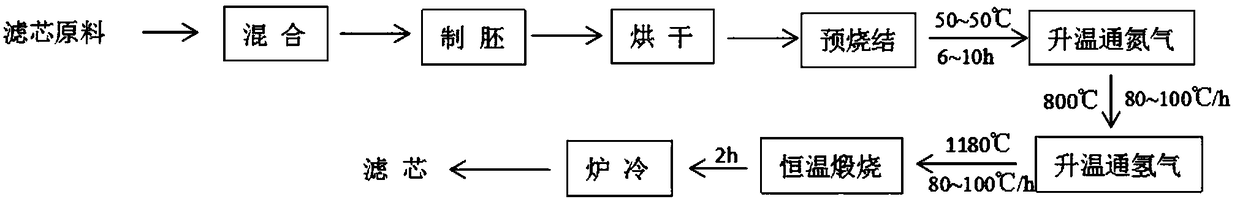

[0027] The firing of the filter element includes the following steps:

[0028] S1. The embryo of the filter element includes the following raw materials in parts by weight: 50 parts of tourmaline, 100 parts of kaolin, 10 parts of zinc oxide, 15 parts of polyvinyl butyral, 5 parts of polyacrylic acid, 15 parts of sodium bicarbonate, water 35 parts, the raw materials are mixed evenly at room temperature and then made into embryos;

[0029] S2. Baking the embryos in S1 at 60°C for 6 hours;

[0030] S3. Then put it into the kiln again, and pre-sinter at 210°C and air atmosphe...

Embodiment 2

[0033] A drinking water treatment device made of natural minerals. The manufacturing method includes firing trays, firing water diversion top pillars and firing filter elements. The firing process of the tray and water diversion top pillars is as follows: clayey siltstone or Embryos are made of kaolin, and the embryos are naturally dried in the shade, then glazed, and finally sintered at high temperature;

[0034] The firing of the filter element comprises the following steps:

[0035] S1. The embryo of the filter element includes the following raw materials in parts by weight: 50 parts of tourmaline, 50 parts of kaolin, 25 parts of zinc oxide, 8 parts of polyvinyl butyral, 2 parts of polyacrylic acid, 5 parts of sodium bicarbonate, water 15 parts, mix the raw materials evenly at room temperature and then make embryos;

[0036] S2. Baking the embryos in S1 at 50°C for 10 hours;

[0037] S3. Then put it into the kiln again, and pre-sinter at 180°C and air atmosphere for 5 hou...

Embodiment 3

[0040] A drinking water treatment device made of natural minerals. The manufacturing method includes firing trays, firing water diversion top pillars and firing filter elements. The firing process of the tray and water diversion top pillars is as follows: clayey siltstone or Embryos are made of kaolin, and the embryos are naturally dried in the shade, then glazed, and finally sintered at high temperature;

[0041] The firing of the filter element comprises the following steps:

[0042] S1. The embryo of the filter element includes the following raw materials in parts by weight: 50 parts of tourmaline, 70 parts of kaolin, 20 parts of zinc oxide, 10 parts of polyvinyl butyral, 3 parts of polyacrylic acid, 10 parts of sodium bicarbonate, water 30 parts, the raw materials are mixed evenly at room temperature and then made into embryos;

[0043] S2. Baking the embryos in S1 at 55°C for 8 hours;

[0044] S3. Then put it into the kiln again, and pre-sinter at 200°C and air atmosphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com