A kind of glass fiber cloth quantitative shearing equipment

A glass fiber cloth and equipment technology, applied in the field of glass fiber cloth quantitative shearing equipment, can solve problems such as low work efficiency and poor cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

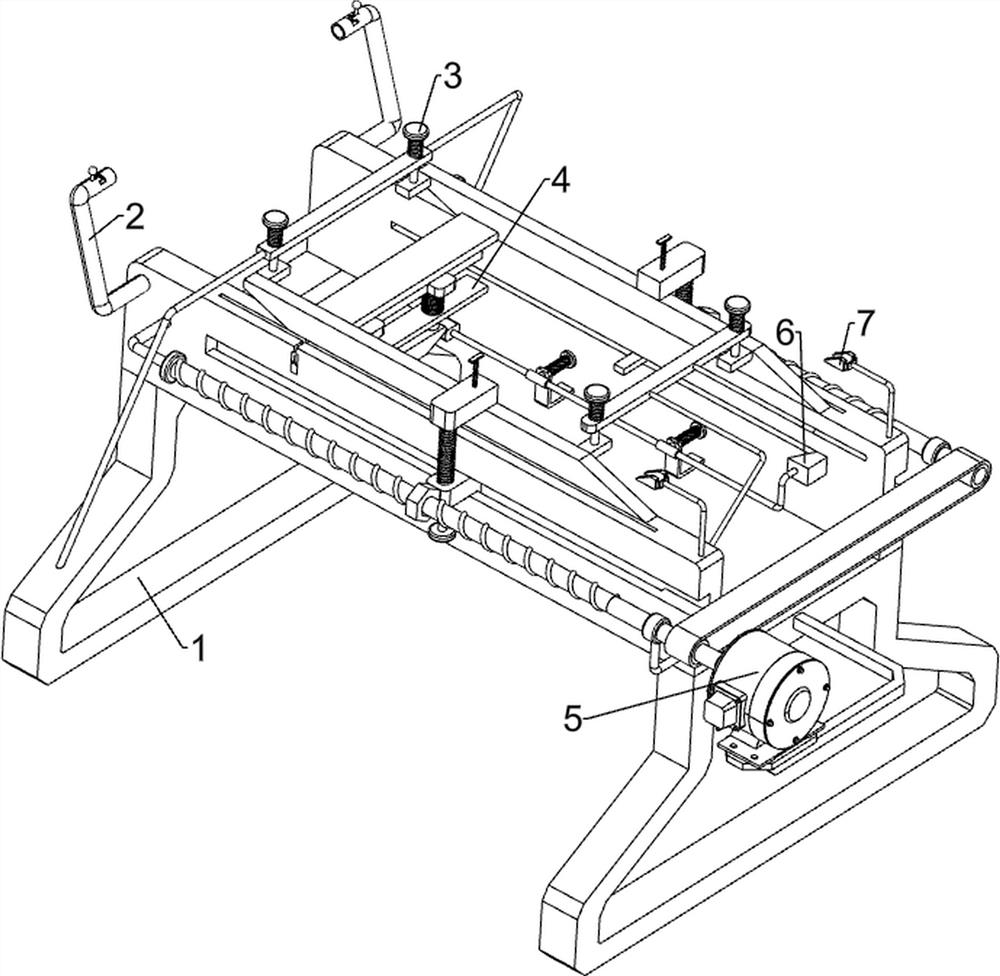

[0026] A glass fiber cloth quantitative shearing equipment, such as figure 1 As shown, it includes a base plate 1, a clamping assembly 2, a pushing assembly 3 and a cutting assembly 4, the clamping assembly 2 on the base plate 1 for clamping by sliding, and the push assembly 3 on the base 1 for pushing by sliding , the cutting assembly 4 on the bottom plate 1 for cutting by sliding.

[0027] When using the device, the staff will clamp the glass fiber cloth roll that needs to be cut quantitatively through the clamping component 2, and then put one end of the glass fiber cloth on the bottom plate 1 and fix it by pushing the component 3. After putting it away, push the The component 3 drives the glass fiber cloth to move, and when the glass fiber cloth moves to an appropriate position, the glass fiber cloth is cut by the cutting component 4 .

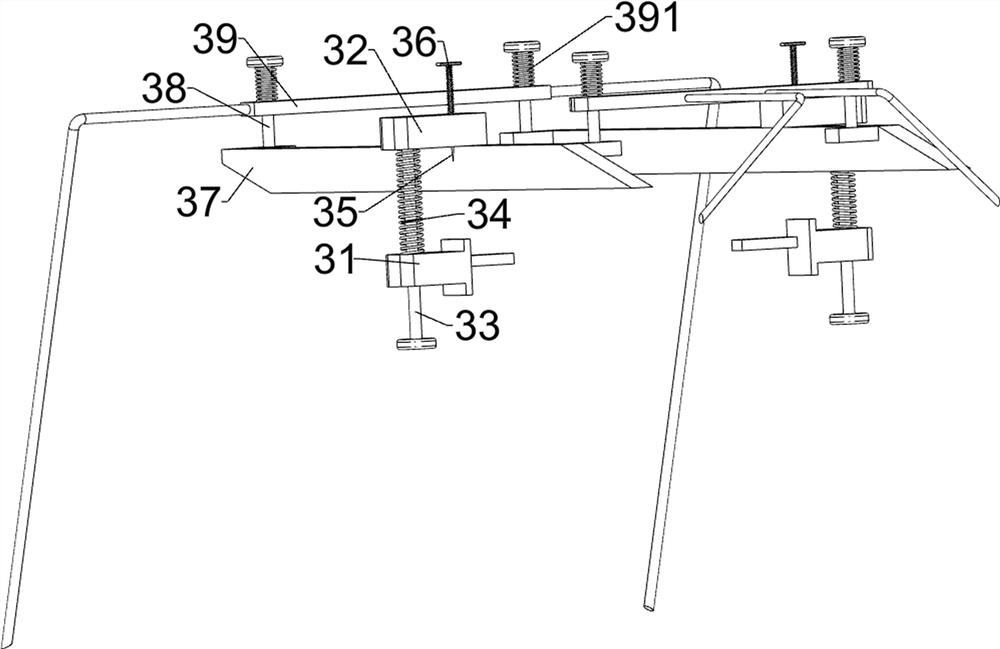

[0028] like figure 1 and figure 2 As shown, the bottom plate 1 includes a bracket 11 and a first mounting plate 12 , and two first m...

Embodiment 2

[0037] On the basis of Example 1, as figure 1 and Image 6 As shown, it also includes an automatic advance and retreat assembly 5. The automatic advance and retreat assembly 5 includes a second mounting plate 51, a motor 52, a lead screw 53, a nut 54 and a drive pulley group 55. The right bracket 11 is provided with a second mounting plate. 51. The motor 52 is fixedly connected to the second mounting plate 51 by bolts, and the first mounting plate 12 is provided with a screw rod 53 that rotates. There is a nut 54, and the nut 54 is connected with the first connecting block 31. A transmission pulley group 55 is arranged between the right parts of the front and rear screw rods 53. The transmission pulley group 55 is composed of two pulleys and a flat belt. Each is provided with a pulley, and a flat belt is wound between the front and rear pulleys.

[0038] When cutting the glass fiber cloth quantitatively, the staff starts the motor 52 to work, and the output shaft of the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com