Rotary polishing device for inner wall of bearing bush

A bearing pad inner and rotating shaft technology, which is applied in the field of bearing pad inner wall rotary grinding device, can solve the problems of low work efficiency, inconvenient fixing, and human hazards caused by debris, and achieve the effect of preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

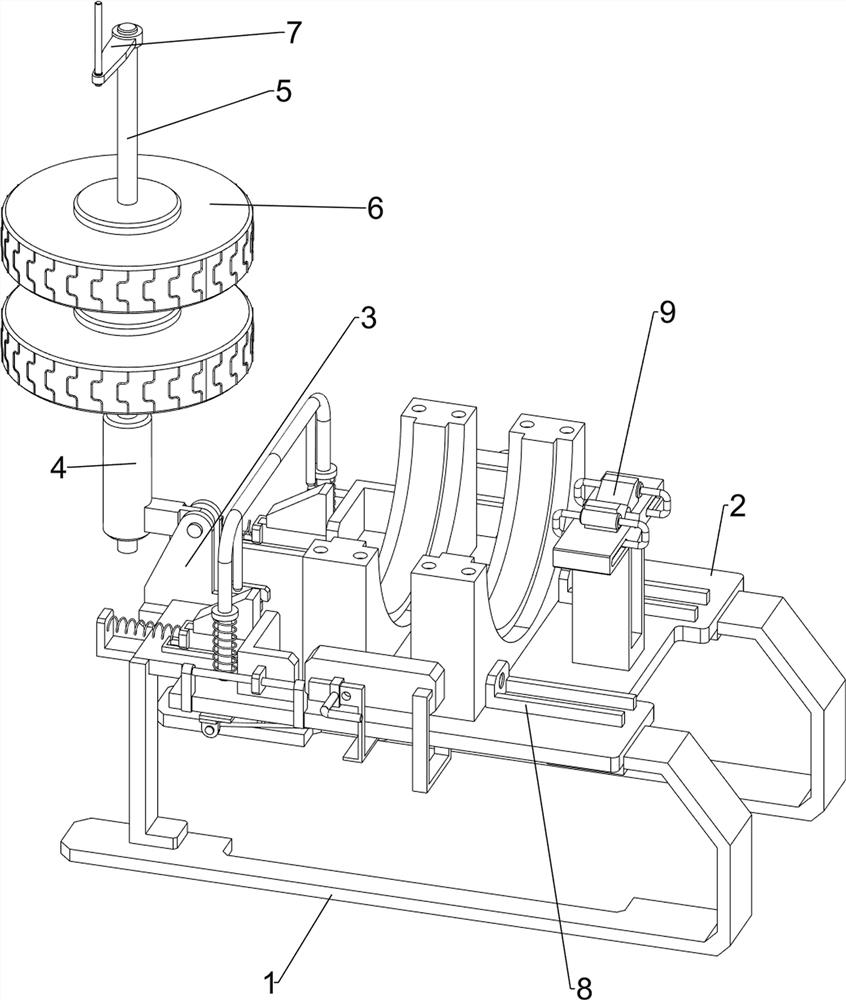

[0027] like figure 1 As shown, a shaft venetical wall rotating grinding device includes a bottom plate 1, a support plate 2, a first bearing housing 3, a rotating shaft sleeve 4, a straight axle 5, a grinding disc 6, a handle 7, a placed mechanism 8, and a locking mechanism 9, A support plate 2 is provided on the bottom plate 1, and the first bearing housing 3 is provided on the left side of the support plate 2. The first housing 3 is provided with a rotating shaft sleeve 4, and the rotating shaft sleeve 4 is rotated. 5 The straight shaft 5 is symmetrically provided with a grinding disc 6, and the vertical rotating shaft 5 is provided with a handle 7, and a placed mechanism 8 is provided on the support plate 2, and a locking mechanism 9 is provided on the right side of the support plate 2.

[0028] When grinding the inner wall of the shaft watt, the staff is placed on the support plate 2, and then the worker rotates the rotating shaft sleeve 4 to rotate downward on the first housi...

Embodiment 2

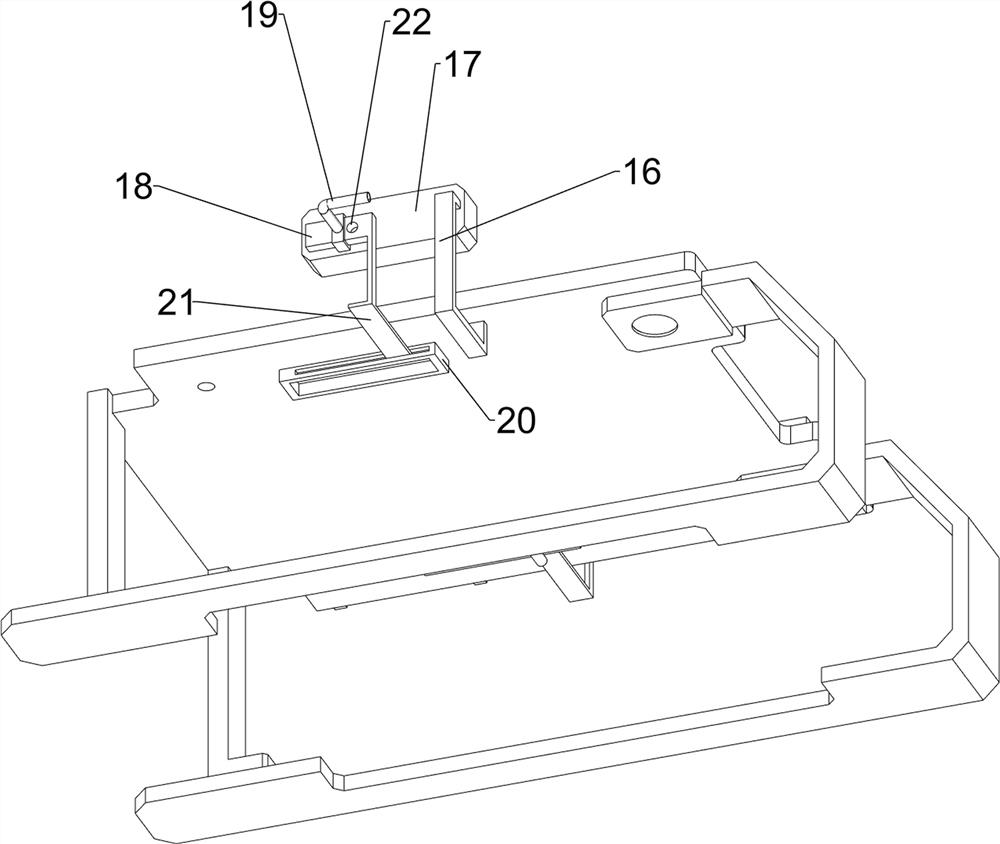

[0030] like figure 2 and image 3 As shown, on the basis of Example 1, the placement mechanism 8 includes a first fixing block 81, a guide bar 82, a first slider 83, a second fixing block 84, a first slide plate 85, and a second slider. 86. The first fixing block 81 is provided on the right side of the support plate 2, and the left side of the support plate 2 is configured with the guide bar 82, and the two guide bar 82 slide, and there is a first slider 83, two first slides. A second fixing block 84 is provided on the block 83, and the left side of the support plate 2 is configured with a first slide plate 85, and the two first slot plate 85 has a second sliding block 86, two first The two slider 86 is connected to the two second fixed block 84 side.

[0031] When the rotating shaft sleeve 4 is rotated downward to rotate downward, the staff pushes the second slider 86 to slide to the right in the first slot plate 85, and the second sliding block 86 slides to the right to drive the...

Embodiment 3

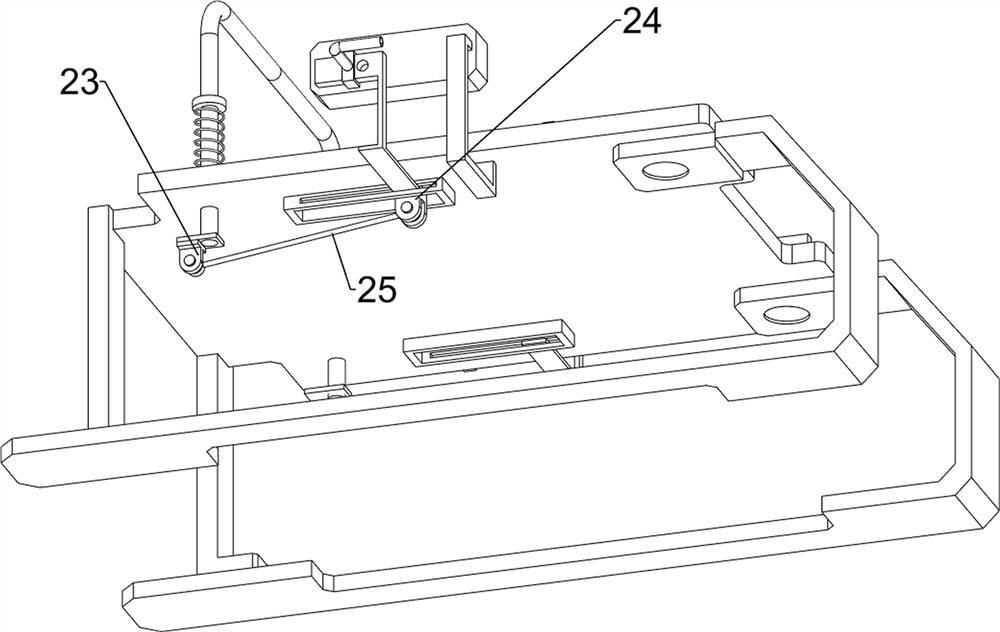

[0035] like Figure 4 , Figure 5 and Image 6 The second slider 10, the second elastic member 11, the fixing rod 12, and the second wedge block 13 are also included. The left side sliding type provided with the support plate 2 has a second slider 10, and the second slider 10 is two. A second elastic member 11 is provided between the front and rear sides of the support plate 2, and the upper portion of the second slider 10 is provided with a fixed bar 12, and the two second sliding blocks 86 are provided with a second wedge block 13, two. The second wedge block 13 is fitted to the two fixing rods 12.

[0036] When the rotating sleeve 4 is rotated downward to rotate downward, the straight shaft 5 is rotated downward to contact the second slider 10, and the second slider 10 is extruded, the second elastic member 11 is compressed, The second slider 10 moves down the second wedge block 13 toward down the second wedge block 13, and the second wedge block 13 moves the second slider 86 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com