Ram cylinder control system for wheel type excavator

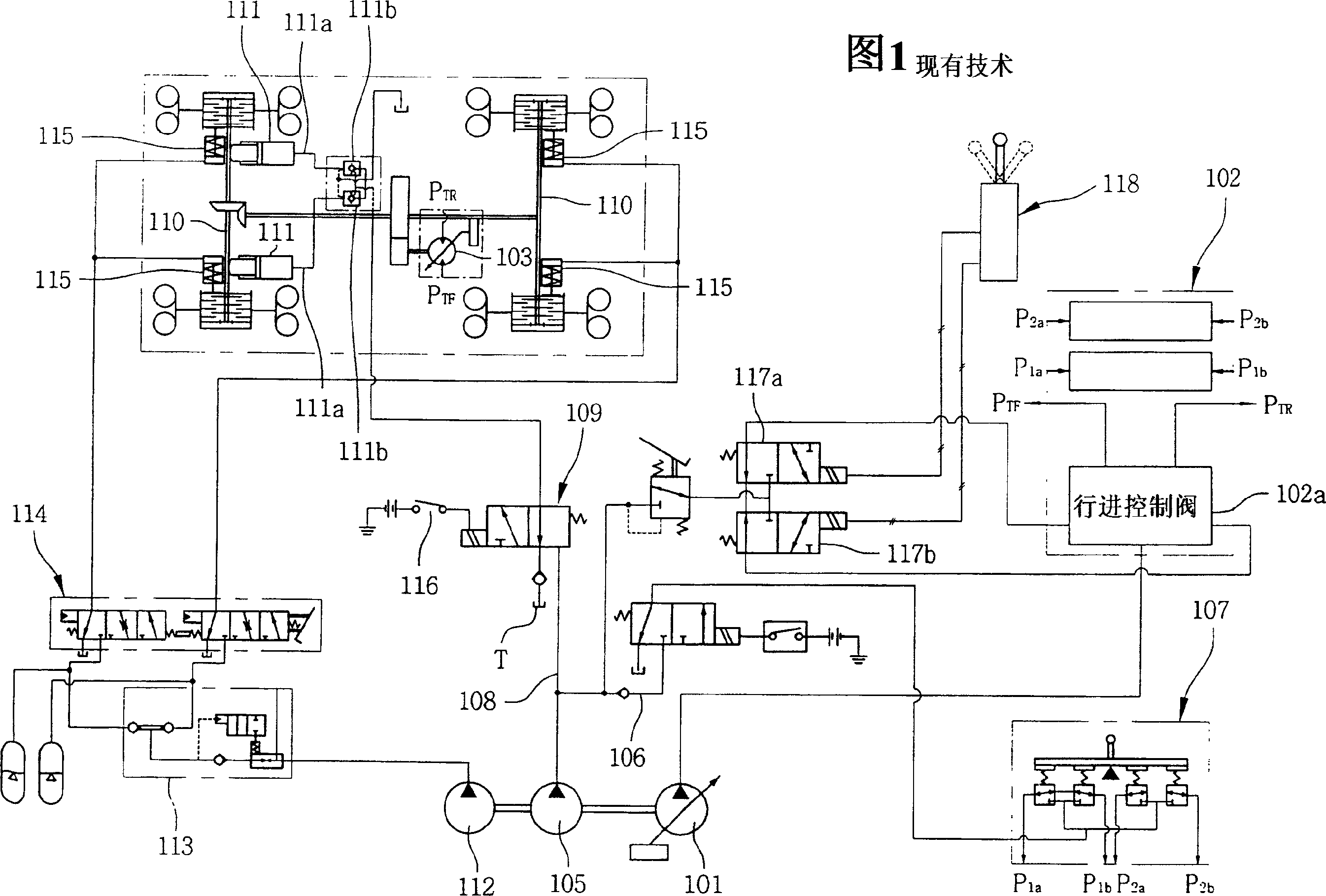

A control system, piston-type technology, applied in the direction of mechanically driven excavators/dredgers, earth movers/shovels, fluid pressure actuation system components, etc., can solve the trouble of locking or loosening piston cylinders Inconvenience and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

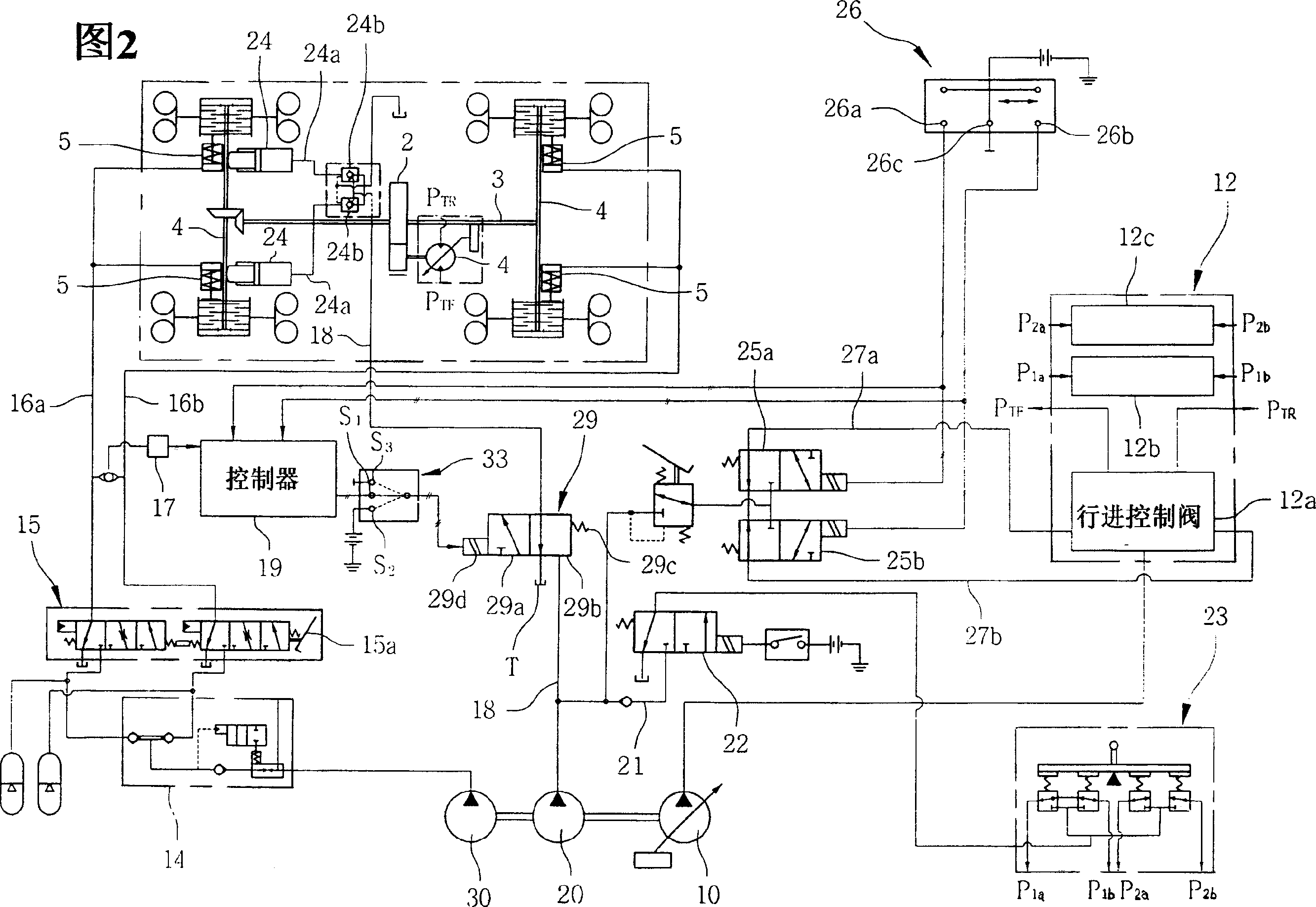

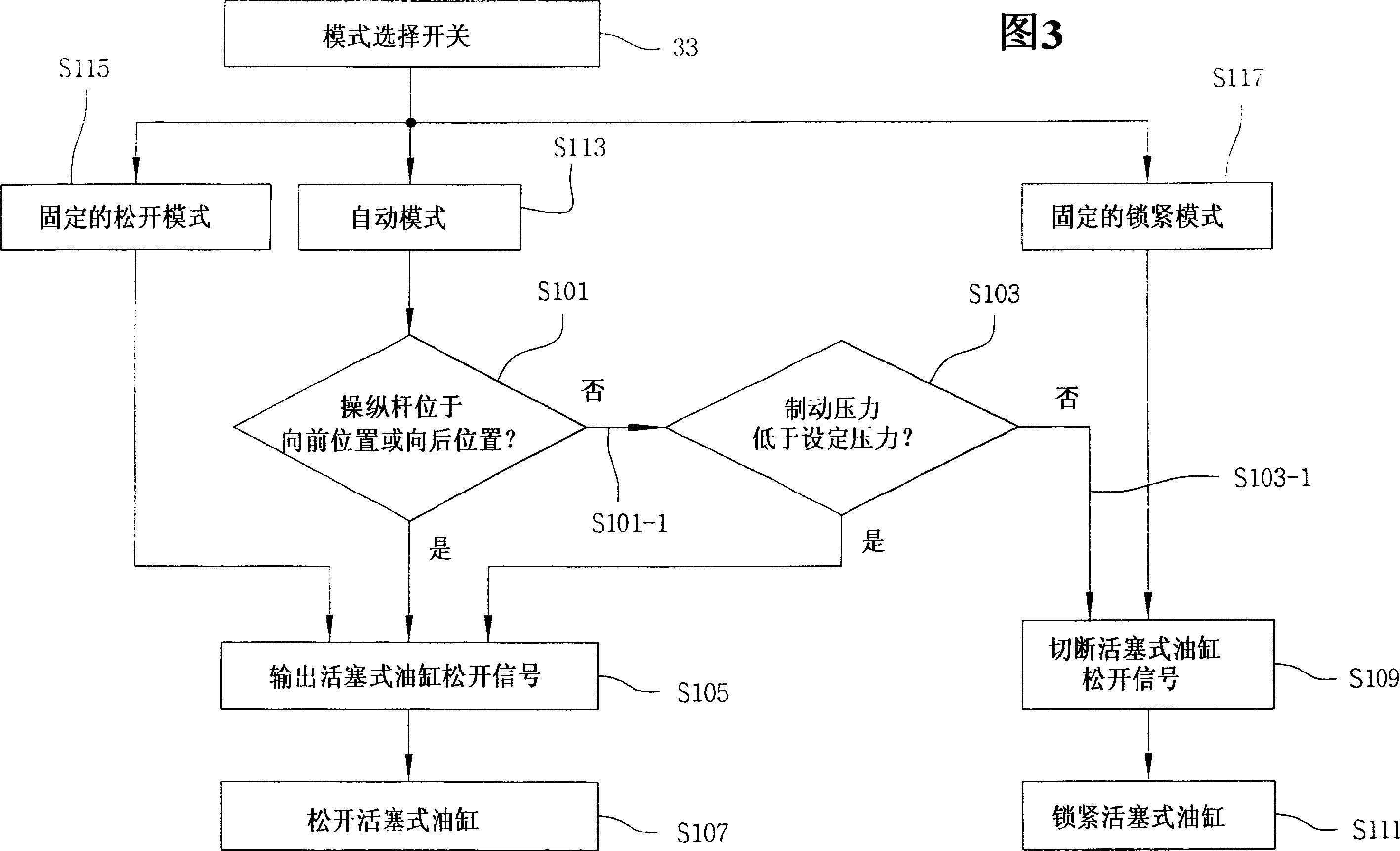

[0022] Preferred embodiments of the present invention are described below with reference to the accompanying drawings.

[0023] Referring first to FIG. 2 , it shows a diagram of the hydraulic transmission system of the piston cylinder control system of the wheel excavator according to the present invention. As shown in the figure, the piston cylinder control system of a wheel excavator includes a main hydraulic pump that provides hydraulic oil to various hydraulic actuators such as the mobile motor 1, an auxiliary hydraulic pump 20 that provides auxiliary pressure to the control valve, and an auxiliary hydraulic pump 20 that supplies hydraulic oil to various hydraulic actuators such as the mobile motor 1. A brake device 5 on the vehicle axle 4 supplies an auxiliary pump 30 of hydraulic pressure.

[0024] Hydraulic oil from the main hydraulic pump 10 is supplied to the travel motor 1 controlled by a plurality of control valves 12b, 12c including the travel control valve 12a, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com