Windscreen wiper and vehicle with windscreen wiper

A windshield and wiper technology, which is applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve problems such as unfavorable spray angles and achieve the effect of preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

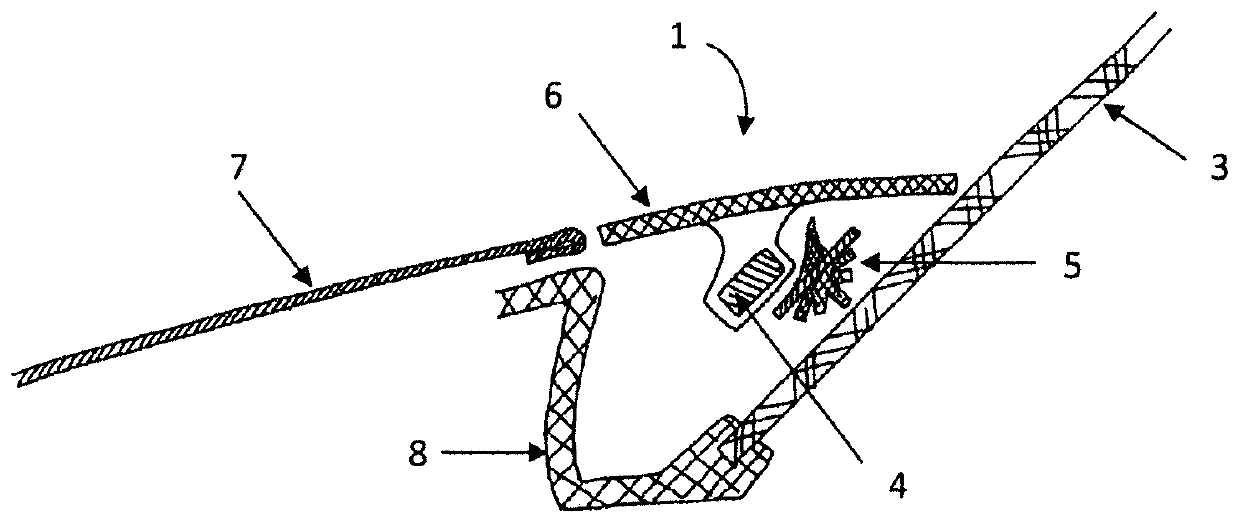

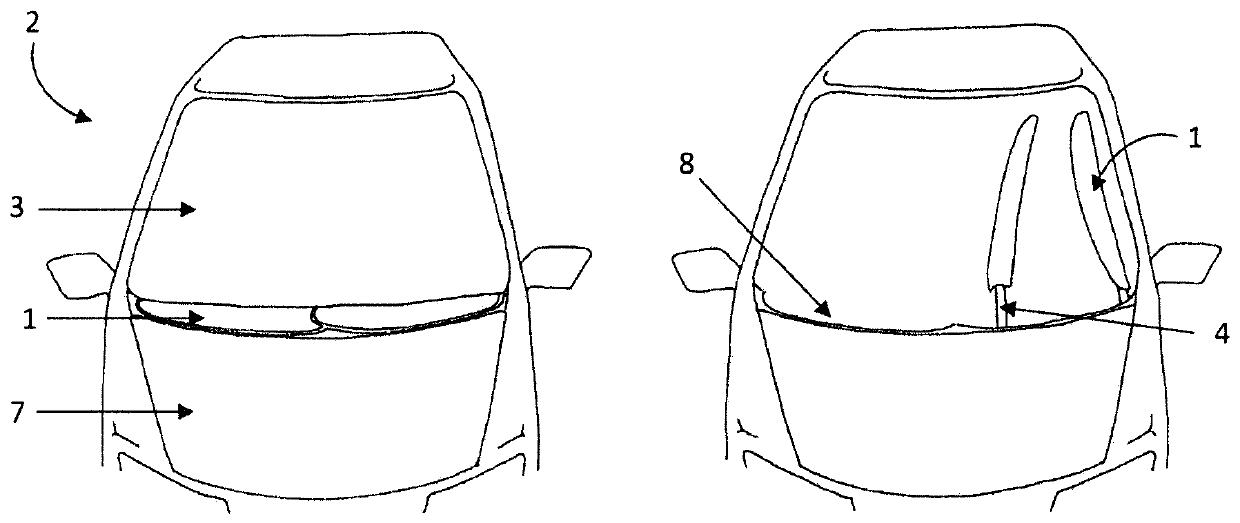

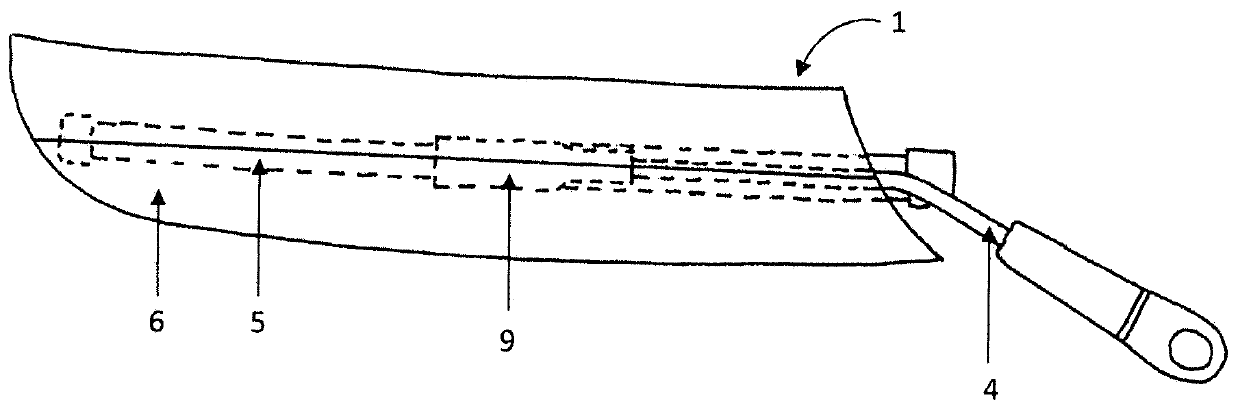

[0073] exist figure 1 shows a sectional view through the front area of a vehicle 2 with a front cowl 7 made of metal or plastic, a windscreen wiper 1 according to the invention in a cavity 8 and a windshield glass3. Here, the front cover 7 is preferably flush with the recess 8 . In particular, the two components can be fastened to one another in a clamped or locked manner. On the side opposite the front hood 7 , the cavity 8 is firmly connected to another component of the vehicle 2 , in particular to the frame of the windshield 3 or to the windshield 3 itself. The connection is preferably glued here, wherein locking or clamping likewise represent possible realizations. The recess 8 or gap between the windshield 3 and the front cowl 7 is at least substantially covered and filled here by the windshield wiper 1 . The cover 6 of the windshield wiper 1 is preferably flush with the two outer edges of the cavity 8 so that a mainly smooth transition from the front cowl 7 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com