Anti-rust oil smearing device for edges of concrete cutting saw blades

A technology for cutting saws and anti-rust oil, which is applied to the device and coating of the surface coating liquid, which can solve the problems of safety risks and difficulty in applying multiple saw blades, so as to improve practicability, facilitate the use of equipment, The safe effect of brushing anti-rust oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

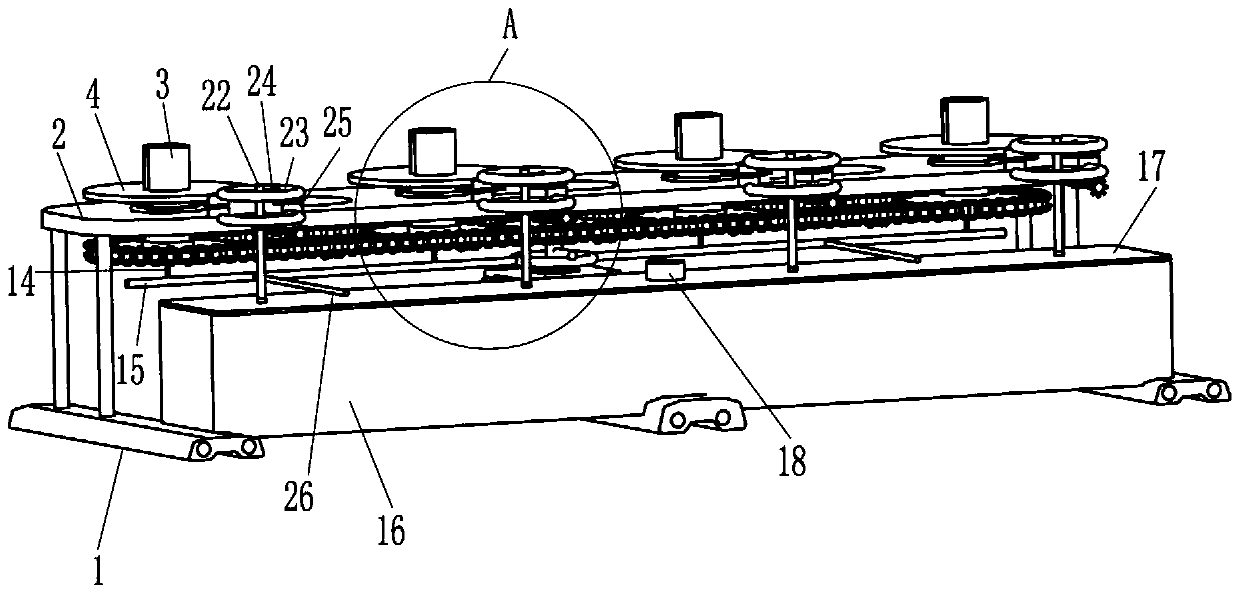

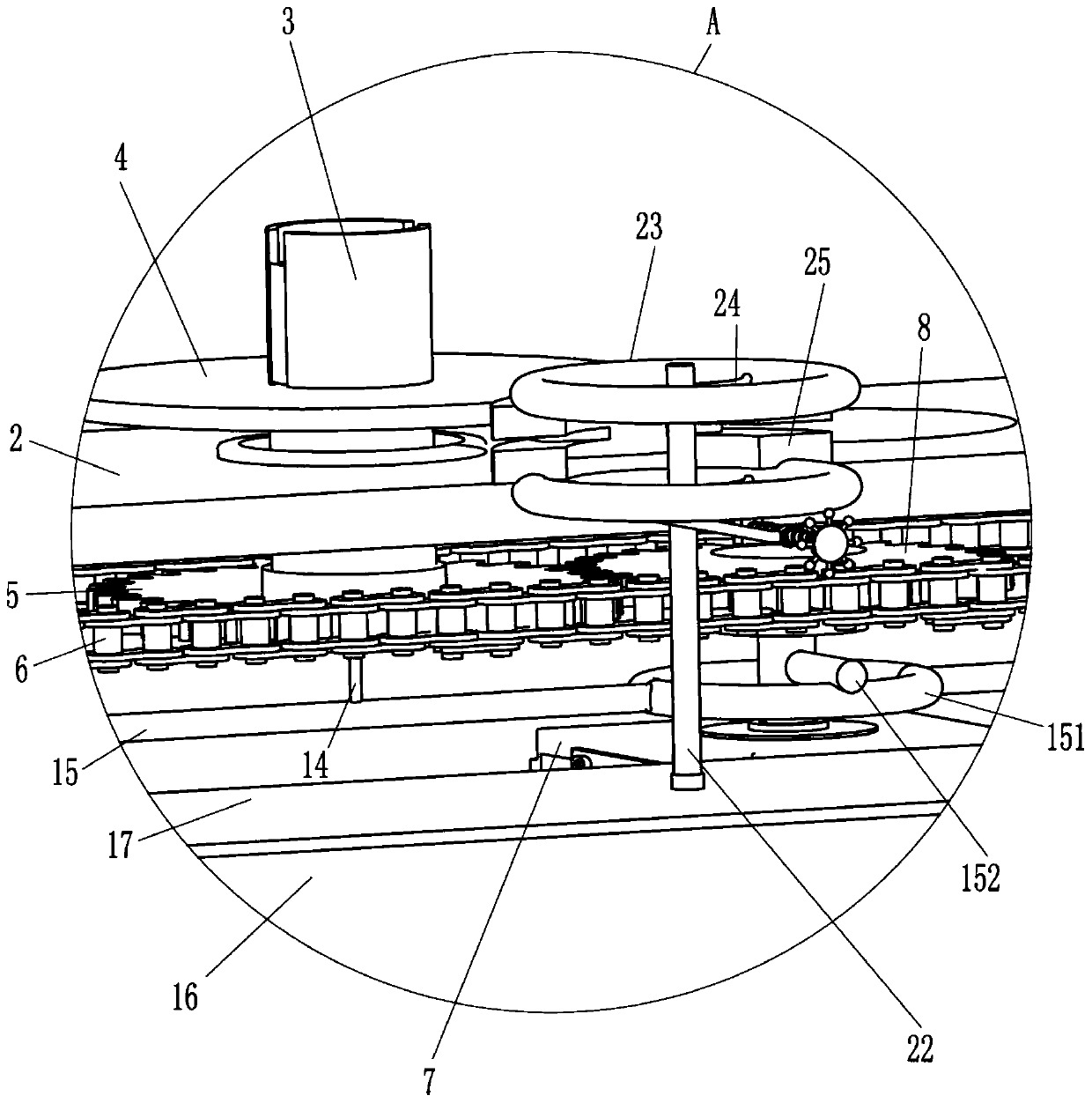

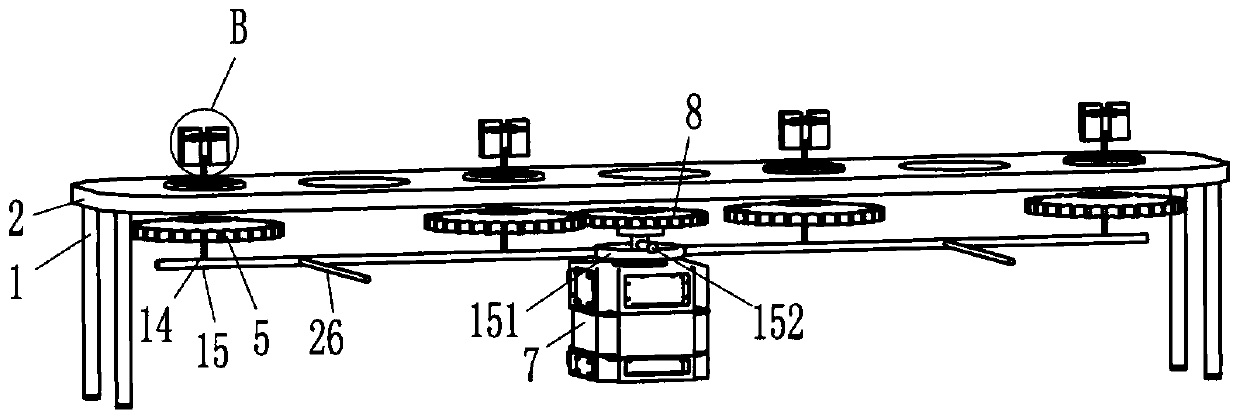

[0020] see Figure 1 to Figure 4 , a kind of antirust oil smearing device of concrete cutting saw blade edge, comprises mounting frame 1, mounting plate 2, rotating assembly, fixing assembly and brushing assembly, mounting frame 1 top is provided with mounting plate 2, and mounting plate 2 is provided with There is a rotating assembly that is powered by a motor to rotate. The rotating assembly is provided with a fixed assembly that fixes the saw blade for concrete cutting by lifting and lowering. The mounting frame 1 is provided with a brush that applies anti-rust oil to the edge of the saw blade by pressing down. components.

[0021] see figure 2 and image 3 , the rotating assembly includes a hollow rotating rod 3, a circular plate 4, a sprocket 5, a chain 6, a reduction motor 7 and a gear 8, and four hollow rotating rods 3 are rotated on the mounting plate 2, and the key on the upper part of the hollow rotating rod 3 Connected with a circular plate 4, the bottom of the ...

Embodiment 2

[0029] On the basis of Example 1, see Figure 5 , in order to improve the practicability of the equipment, it also includes a guide rail 27, a slider 28, a nut 29 and a bolt 30, the liquid inlet pipe 22 is fixedly connected with a guide rail 27, and the slide type in the guide rail 27 is provided with a slider 28, and the slider 28 and The annular hollow pipe 23 is connected, and the front side of the guide rail 27 is provided with a nut 29, and the nut 29 is rotatably provided with a bolt 30, and the bolt 30 is rotatably connected with the slide block 28 through a rotary joint.

[0030] The specific operation method of the above embodiment: when the saw blade needs to be oiled, the rotating bolt 30 moves back and forth in the nut 29, and then drives the annular hollow tube 23 to move back and forth, so that the saw blades of different sizes can be applied with anti-rust oil Brush.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com