Polishing equipment for stainless steel dinner plate machining

A stainless steel, dinner plate technology, applied in metal processing equipment, grinding/polishing equipment, machine tools with surface polishing, etc., can solve the problems of slow polishing speed, low work efficiency, more time and energy, etc. High polishing speed and anti-movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

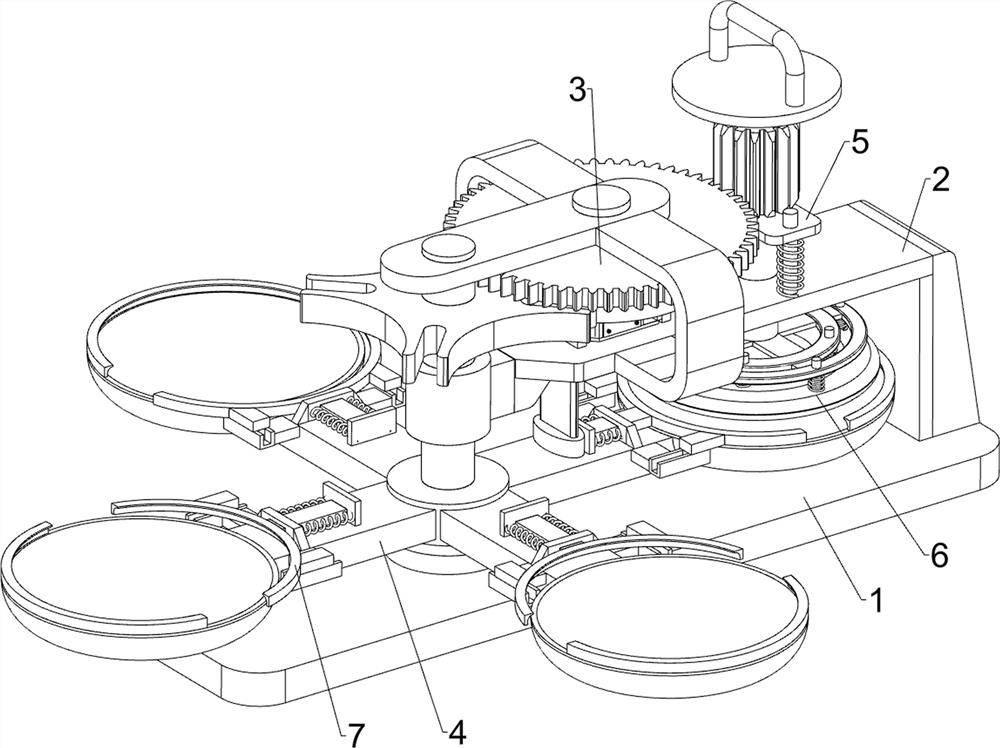

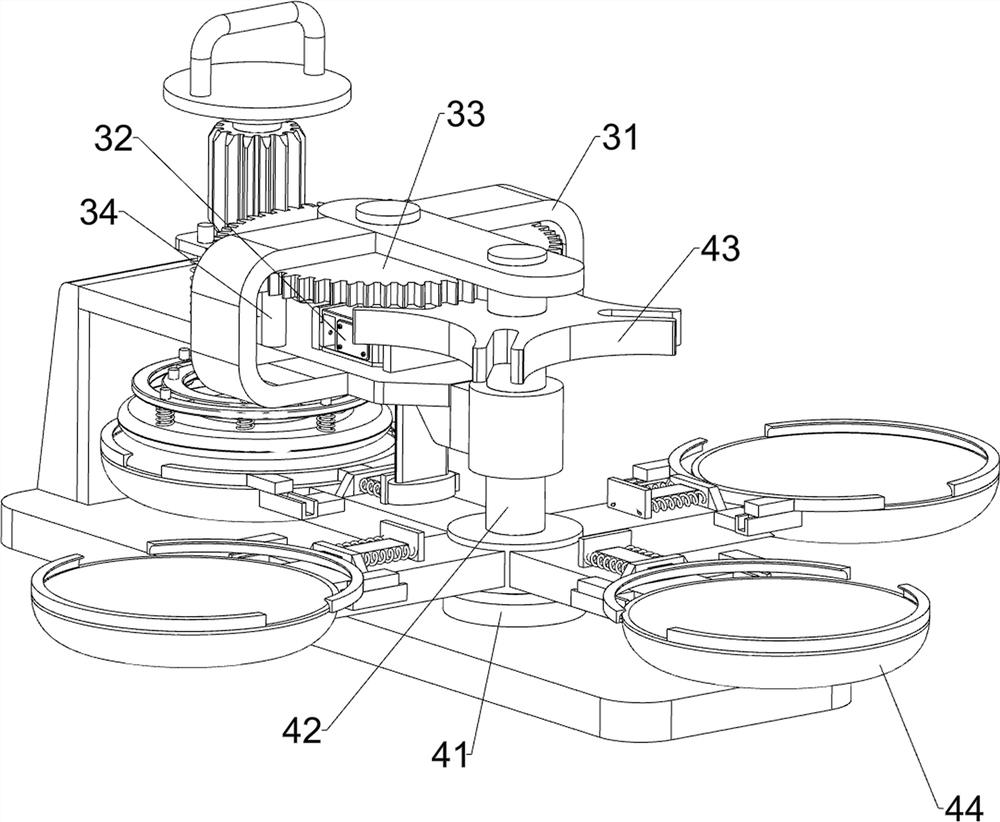

[0024] A kind of polishing equipment for stainless steel dinner plate processing, such as Figure 1 to Figure 4 As shown, it includes a bottom plate 1, a mounting frame 2, a power mechanism 3, a rotating frame mechanism 4, a movable frame mechanism 5, and a polishing mechanism 6. The top right side of the bottom plate 1 is connected with a mounting frame 2, and a power mechanism is respectively installed on the mounting frame 2. 3 and the movable frame mechanism 5, the movable frame mechanism 5 is connected with the power mechanism 3 by transmission, the bottom plate 1 top left side is equipped with a rotary frame mechanism 4, the rotary frame mechanism 4 is connected with the power mechanism 3 by transmission, and the movable frame mechanism 5 is equipped with a polishing mechanism 6.

[0025] The power mechanism 3 includes a fixed frame 31, a servo motor 32, a first gear 33 and a push rod 34, the left part of the mounting frame 2 is connected with the fixed frame 31, the top...

Embodiment 2

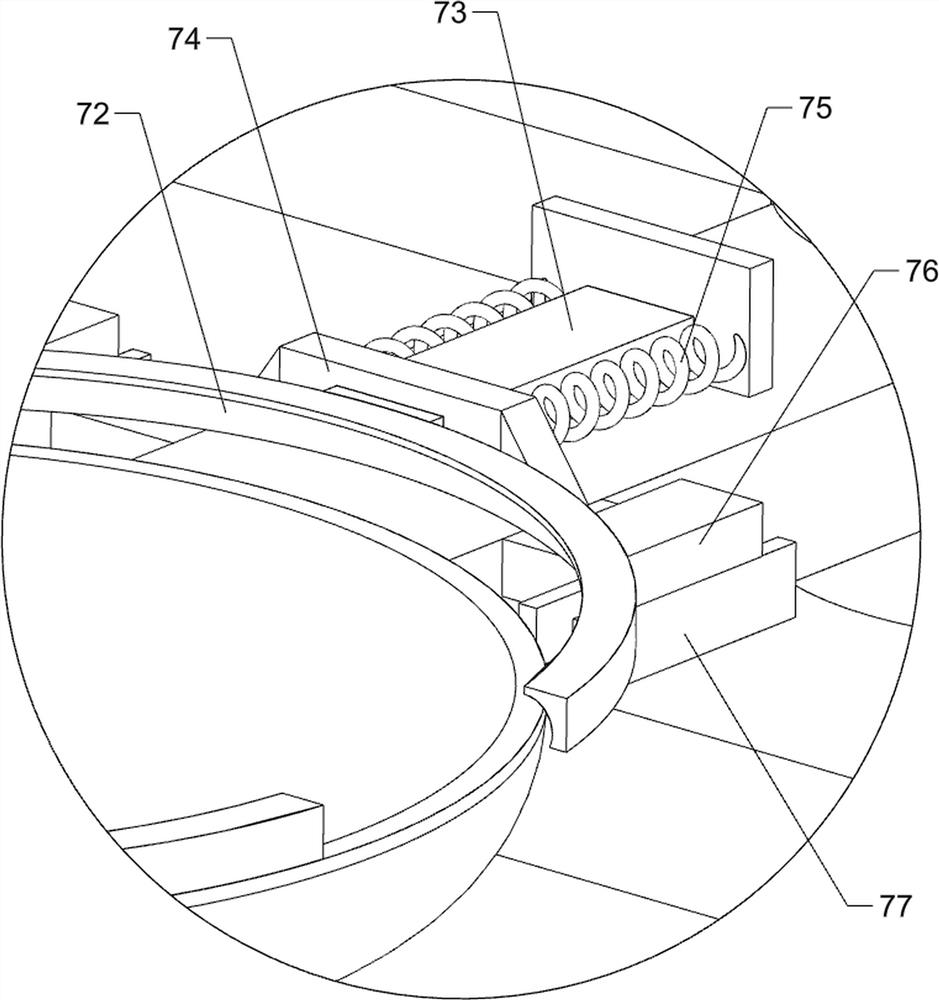

[0031] On the basis of Example 1, such as image 3 with Figure 5As shown, a clamping mechanism 7 is also included, and the clamping mechanism 7 includes a fixed arc collar 71, a movable arc collar 72, a sliding push block 73, a guide block 74, a return spring 75, a guide slider 76, a guide rail 77 and top block 78, bracket 44 top outsides are connected with fixed arc collar 71, bracket 44 top insides are connected with guide block 74, are connected with sliding push block 73 in the guide block 74, are connected on the slide push block 73 There are movable arc-shaped collars 72, two return springs 75 are connected between the sliding push block 73 and the guide block 74, two guide sliders 76 are connected to the outer wall of the movable arc-shaped collar 72, and the lower part of the guide slider 76 is slidingly connected Guide rail 77 is arranged, and guide rail 77 is connected with the outer surface of bracket 44, and top left side is connected with top block 78 in mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com