Vertical rod automatic pouring robot for grape ridge cultivation

A robot and grape technology, applied in cultivation, application, construction, etc., can solve the problems of time-consuming and labor-intensive, increased labor costs, low production efficiency, etc., and achieve the effect of liberating productivity, high work efficiency, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

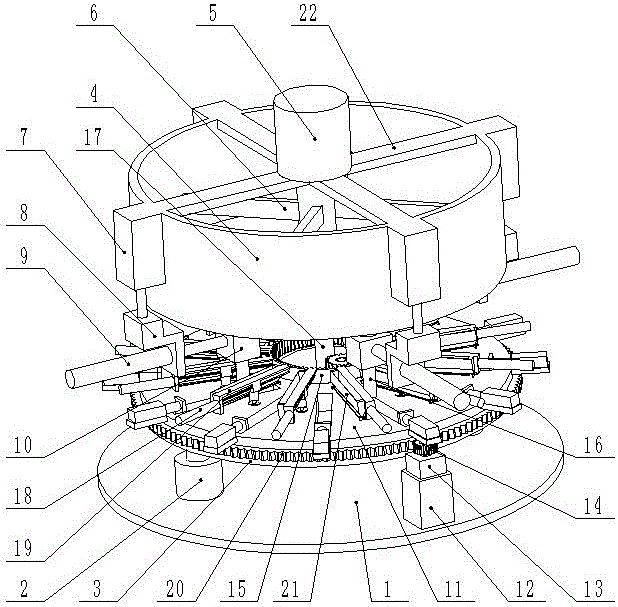

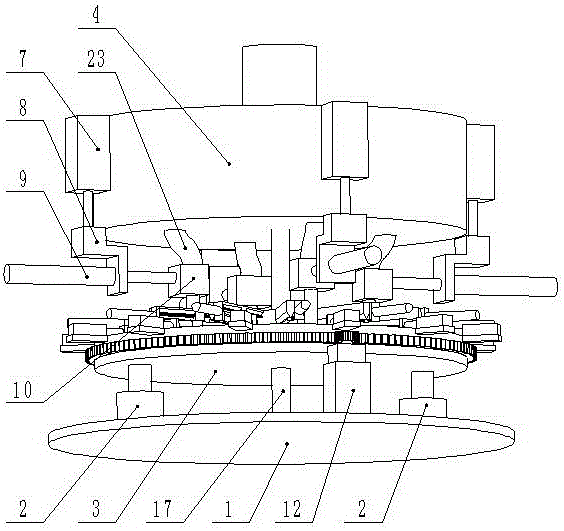

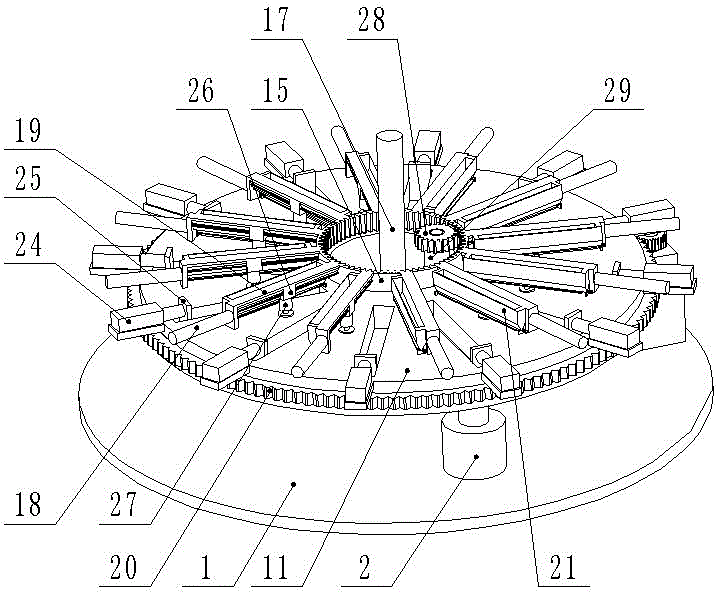

[0026] Example: such as Figure 1 to Figure 9 As shown, it is a vertical pole automatic pouring robot for border planting grapes of the present invention, the base 1 is set as a thin disc structure, and the main shaft 17 is vertically installed in the center of the base 1 . The rotating disc 11 is rotatably mounted on the main shaft 17 for pouring the vertical poles. The rotating gear 20 is a hollow structure coaxially and fixedly mounted on the outer circumference of the rotating disc 11 . One side of the base 1 is provided with a rotating motor mounting bracket 12 for installing the rotating motor 13. The rotating pinion gear 14 is coaxially installed on the output shaft of the rotating motor 13 and meshes with the rotating gear 20, that is, the rotating motor 13 drives the rotation Disk 11 rotates about spindle 17 .

[0027] The base 1 is also symmetrically provided with two support plate adjustment hydraulic cylinders 2, the support plate 3 slides up and down and is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com