Diamond wire production process with quantitative sanding and online monitoring function

A production process, diamond wire technology, applied in program control, measuring device, computer control, etc., can solve the problems of difficult control of detection sampling interval, inability to timely feedback, slow detection speed, etc., to improve stability, reduce labor costs, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

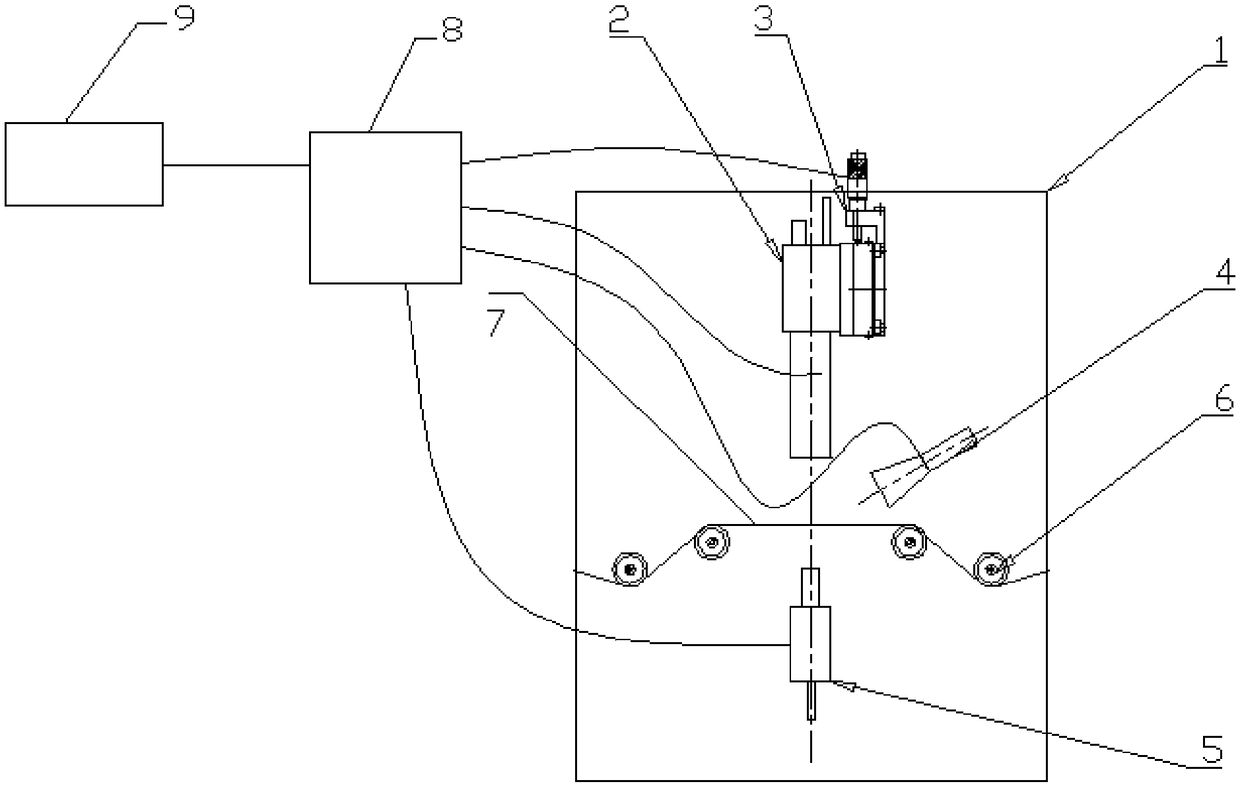

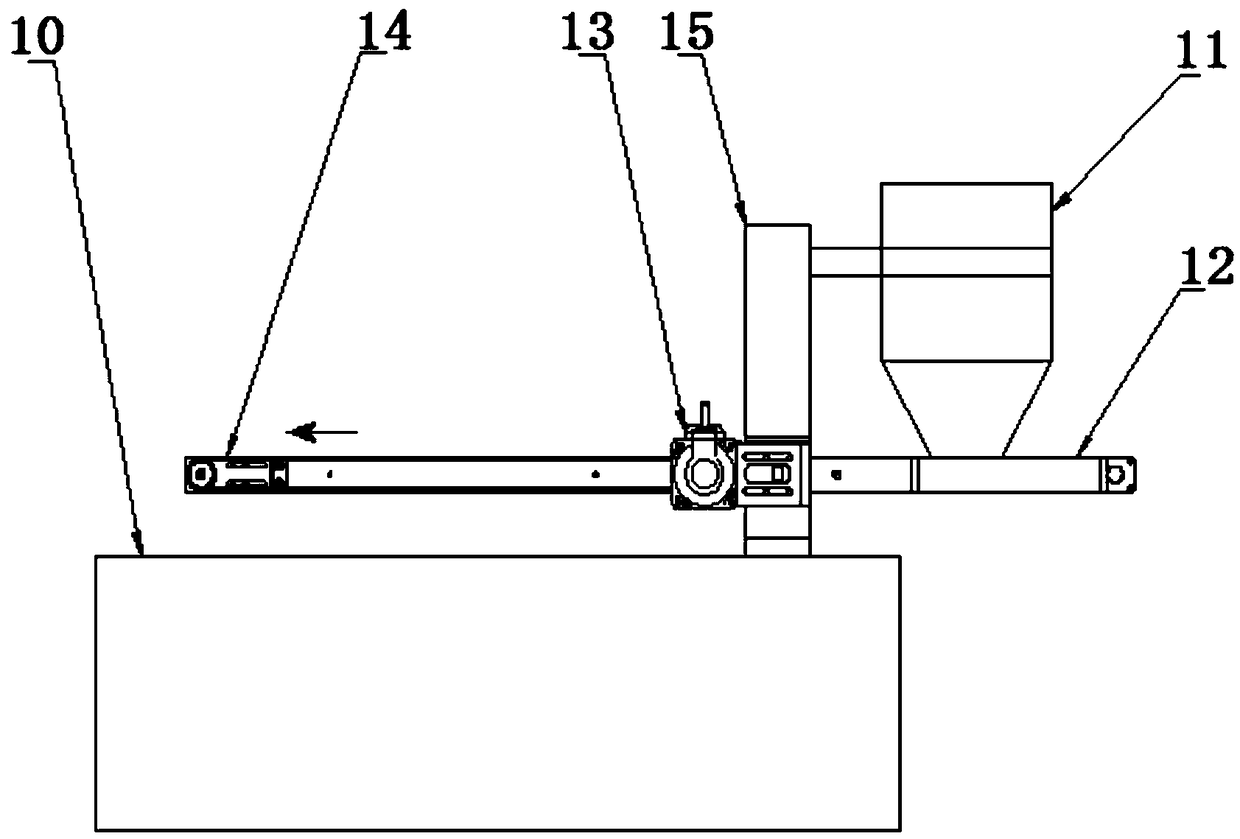

[0032] Structure like figure 1 with figure 2 As shown, the diamond wire production process with quantitative sand addition and online monitoring functions provided in this embodiment includes the following specific steps:

[0033] A pay-off, B surface cleaning, C surface pretreatment, D diamond adhesion, E diamond consolidation, F anti-friction coating coating and G drying, an online monitoring device is set between step E and step F;

[0034] The online monitoring device includes the bottom plate 1, the camera 2, the camera installation slide 3, the main light source 4, the backlight source 5, and the wire guide wheel 6, the wire guide wheel 6, the camera installation slide 3, the main light source 4, and the backlight source 5. Installed on the bottom plate 1, characterized in that: the wire guide wheel 6 is provided with a diamond wire 7, a camera mounting slide 3 and a main light source 4 are installed on the bottom plate 1 on the side of the diamond wire 7, and the camera 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com