Automatic material mixing stirrer

A mixer, automatic technology, applied in mixers, mixer accessories, mixers with rotating mixing devices, etc., can solve problems such as inconvenience, achieve the effect of convenient use of equipment and speed up material mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

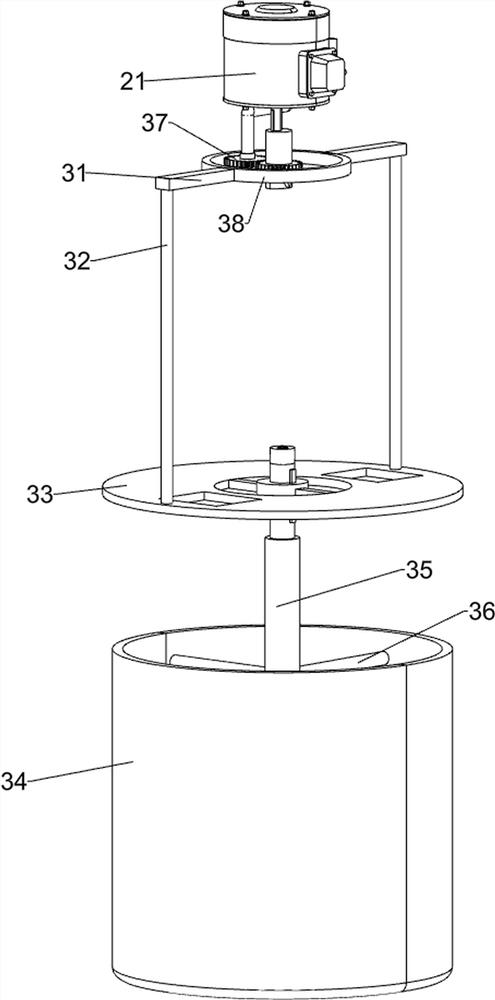

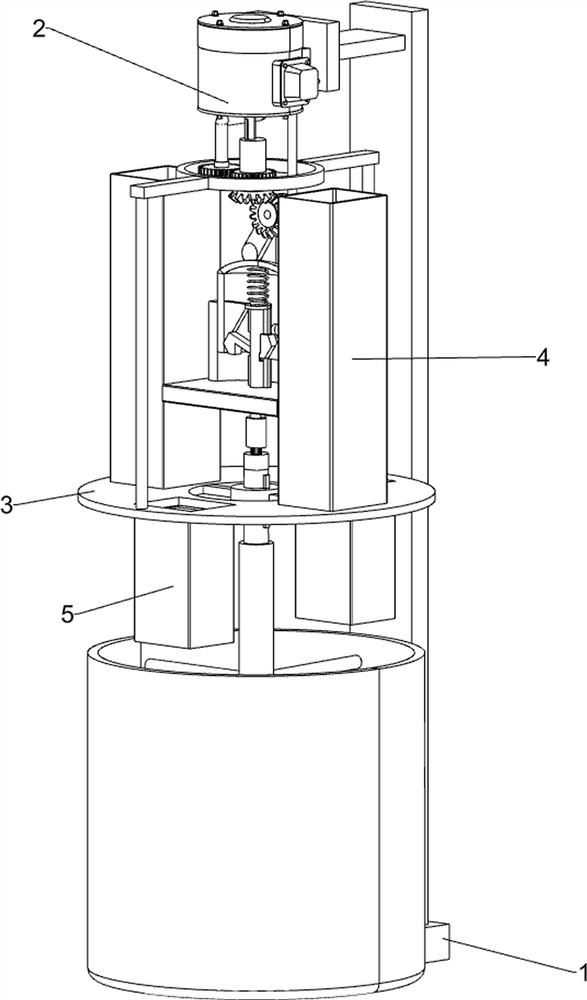

[0018] A material automatic mixing mixer, such as Figure 1-3 As shown, it includes a support 1, a lifting assembly 2 and a stirring assembly 3. The lifting assembly 2 is installed on the front side of the top of the support 1 for lifting and lowering by rotation, and the stirring assembly 3 for stirring by rotating is installed below the lifting assembly 2.

[0019] When it is necessary to use the device to mix materials, first pour the materials to be mixed into the mixing component 3, then control the lifting component 2 to start working, the lifting component 2 drives the stirring component 3 to start working, and the materials are mixed. After finishing, control lifting assembly 2 to stop working.

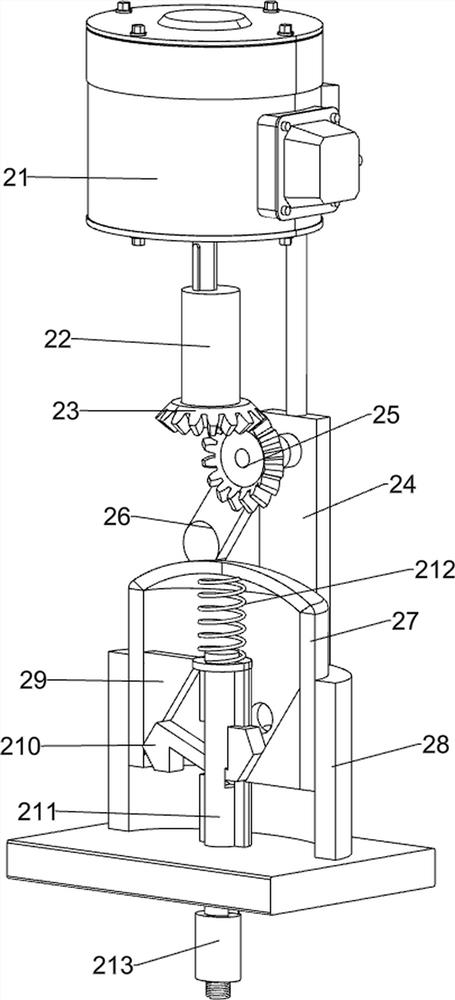

[0020] The lifting assembly 2 includes a reduction motor 21, a rotating shaft 22, a first bevel gear 23, a first connecting plate 24, a second bevel gear 25, a push block 26, a sliding cylinder 27, a mounting plate 28, a wedge block 29, and a push block 210 , connecting rod 2...

Embodiment 2

[0025] On the basis of Example 1, such as figure 1 As shown, the rotating rod 35 can only slide up and down on the connecting plate 33 and cannot rotate, and the top of the rotating rod 35 is connected with the connecting rod 211 through the rotating joint 213 .

[0026] Because the rotating rod 35 needs to move up and down with the connecting rod 211, so the connecting rod 211 can move up and down, and simultaneously because of the swivel joint 213, so the rotating rod 35 can also rotate.

[0027] It also includes a material storage pipe 4 and a feeding pipe 5, the left and right sides of the mounting plate 28 are fixedly connected with the material storage pipe 4 by bolts, the bottom of the material storage pipe 4 cooperates with the connection plate 33, and the bottom of the connection plate 33 is equipped with a discharge pipe 5.

[0028] When the material is mixed, the material can be put into the storage pipe 4, and when the connecting plate 33 rotates, it drives the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com