Garbage pulverizer

A pulverizer and garbage technology, applied in the field of garbage treatment equipment, can solve the problems of difficult to know the principle of pulverization, insufficient technology disclosure, etc., and achieve the effect of large torque, long service life, and low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

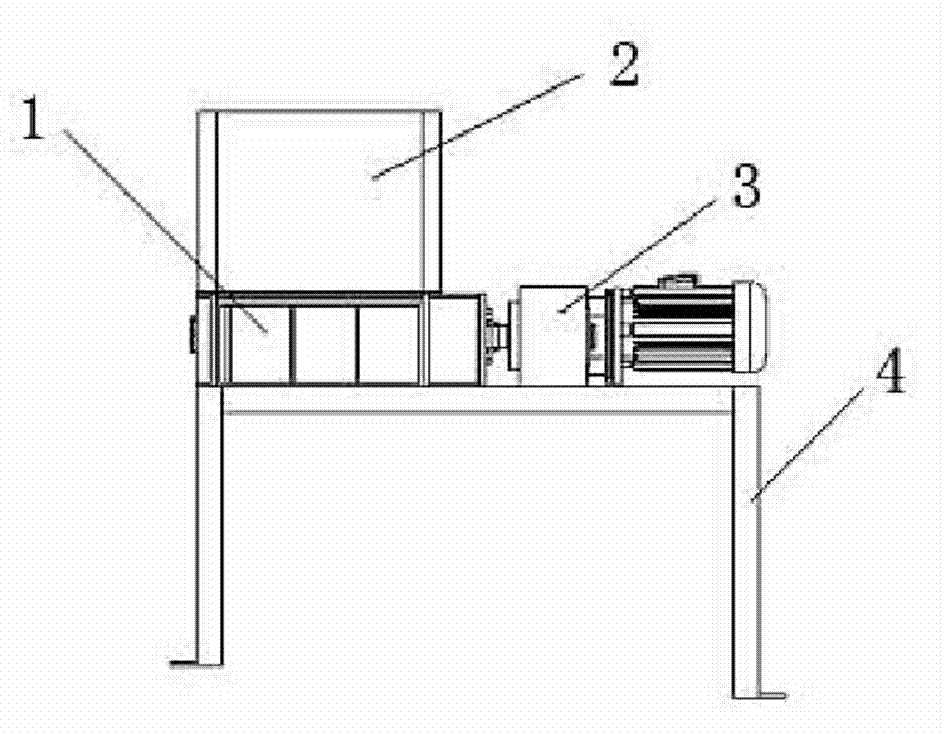

[0032] Example : A garbage pulverizer, as shown in the figure, comprises a pulverizer main body 1, a driving mechanism 3, a feed hopper 2 and a support 4; the pulverizer main body 1 and the driving mechanism 3 are installed on the bracket 4, and the pulverizer main body 1 The operation is driven by the drive mechanism 3, and the feed hopper 2 is installed on the main body 1 of the pulverizer.

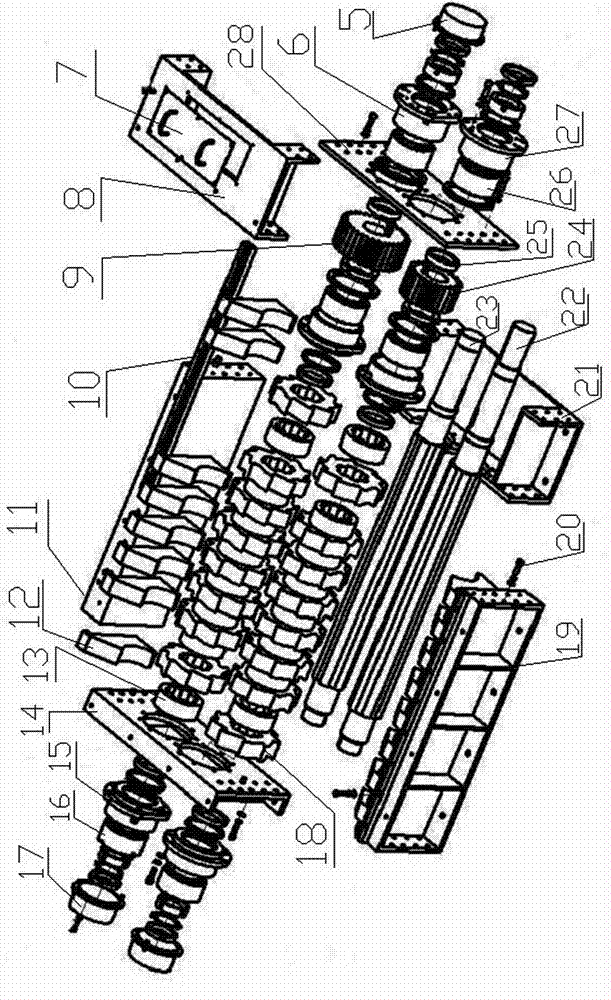

[0033] Pulverizer main body 1, including main shaft 22, driven shaft 23, driving cylindrical gear 24, driven cylindrical gear 9, blade 18, gasket 13, comb plate 12, comb plate hanging plate 10, left side plate 19, right side plate 11. Upper front frame 8, lower front frame 21, front cover 28 and rear liner 14. Blade 18 has a plurality of, and blade 18 is installed on main shaft 22 and driven shaft 23 by spline, and the number of blade 18 that is installed on main shaft 22 and driven shaft 23 is equal, is also installed with on each shaft There are spacers 13 equal in number to the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com