Tool and method for smashing hard rock in large-diameter pile hole

A hard rock, large diameter technology, applied in the field of geotechnical engineering, can solve the problems of high cost, difficult selection, and few types, and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

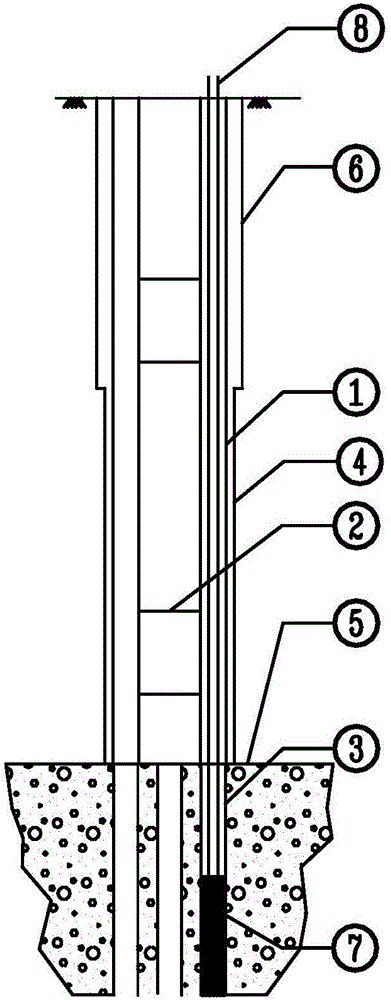

[0022] The hard rock crushing tool and method in the large-diameter pile hole of the present invention can be applied to large-diameter piles, and is mainly suitable for large-diameter piles with a diameter of not less than 800 mm. There is hard rock in the pile hole. Hard rock refers to saturated uniaxial Hard rock with a compressive strength greater than 60Mpa.

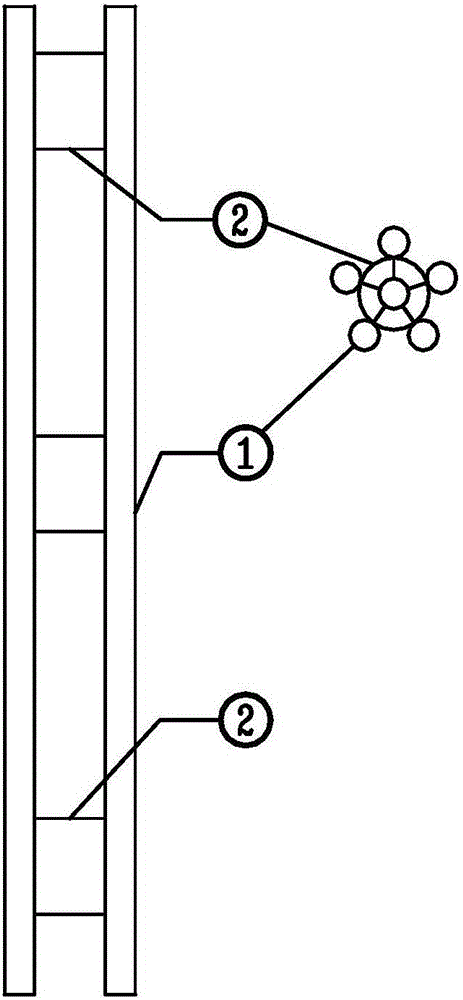

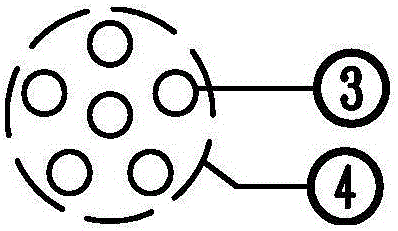

[0023] Wherein the crushing tool comprises a guide pipe 1 and an inner support frame 2 of the guide pipe bent frame, a pile hole retaining wall 6 and a small-aperture drilling rig bit 7, generally mostly a diamond drill bit or a down-the-hole hammer. see figure 1 and Figure 5 , first weld the inner bracket 2 of the guide tube bent frame, then adjust and weld the guide tube 1 to the inner bracket of the guide tube bent frame, the guide tube bent frame is welded firmly, and each guide tube 1 is parallel and aligned. The guide tube bent frame is generally in the form of a ring, with a guide tube in the middle and 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com