Car front bumper mounting bracket

A front bumper and mounting bracket technology, applied in the field of mounting brackets, can solve problems such as poor mold release, difficulty in controlling the fitting accuracy of the step difference, uneven clearance between the fender and the front bumper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

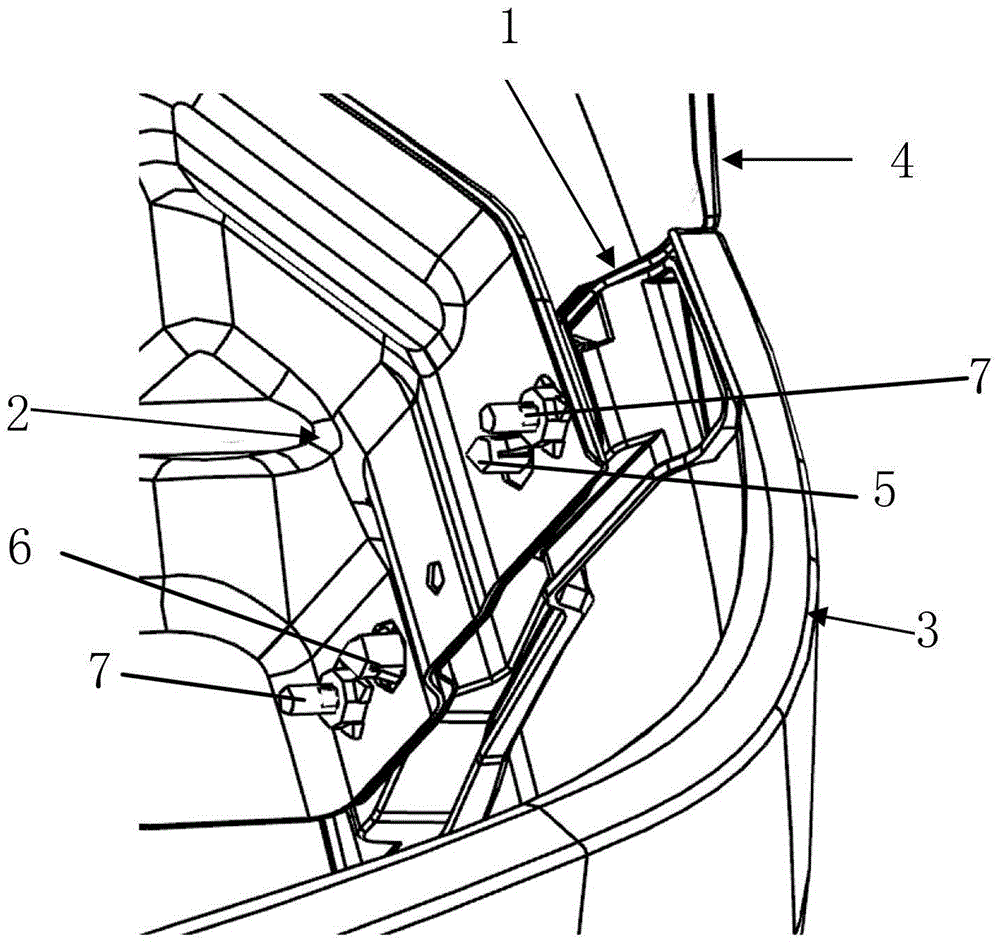

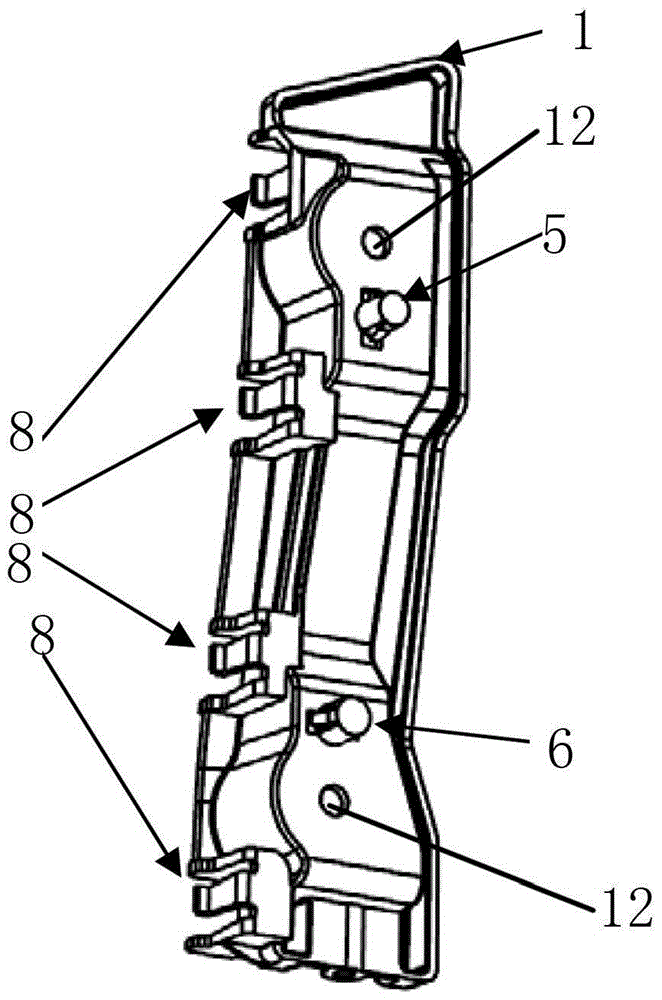

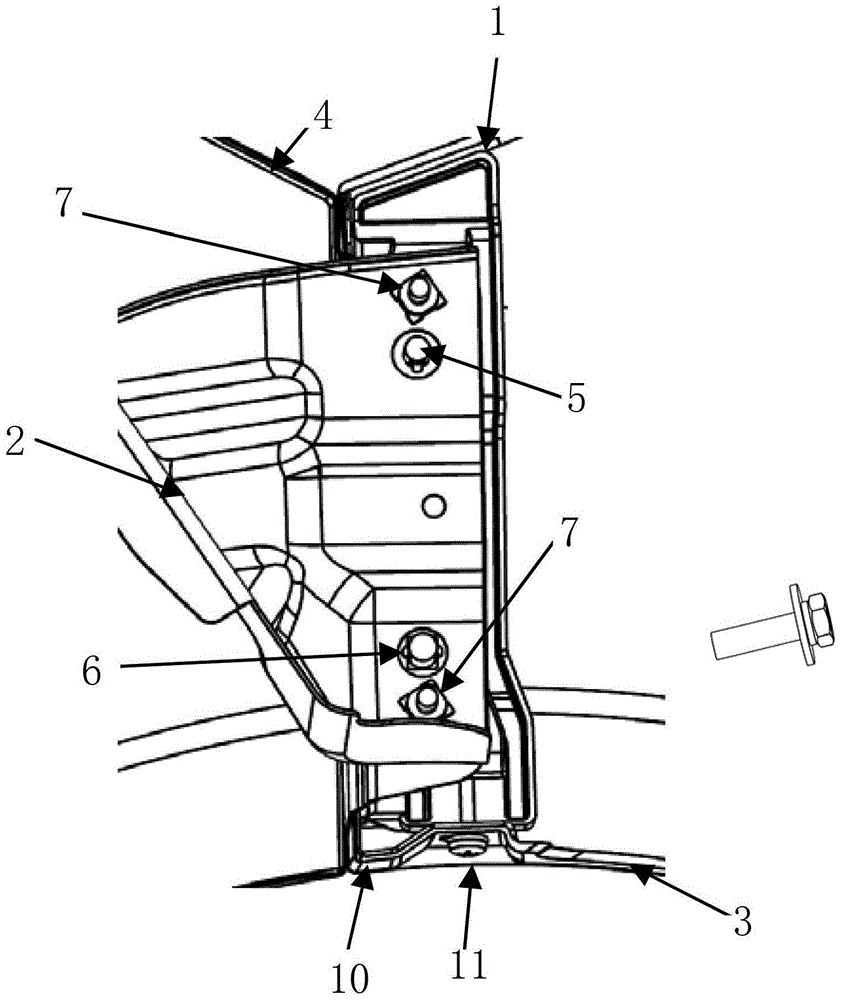

[0021] The following with attached Figure 1 to Figure 4 A car front bumper mounting bracket of the present invention will be further described in detail.

[0022] A kind of automobile front bumper mounting bracket of the present invention, please refer to Figure 1 to Figure 4 , including a bracket body 1, the bracket body 1 is connected to the fender 4, the body bracket 2 and the front bumper 3, and the upper and lower parts of the bracket body 1 are respectively provided with a first positioning pin 5 and a second positioning pin 6 , the first locating pin 5 and the second locating pin 6 are clamped with the fender 4, the body bracket 2 is fixedly connected with the bracket body 1 and the fender 4 through bolts 7, and the bracket body 1 and the front The bumpers 3 are clamped and fixed, and one side of the bracket body 1 is provided with at least two clips 8 extending toward the bottom, and the front bumper 3 is provided with clips 9, and the clips 8 are connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com