Patents

Literature

70results about How to "Fix the tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

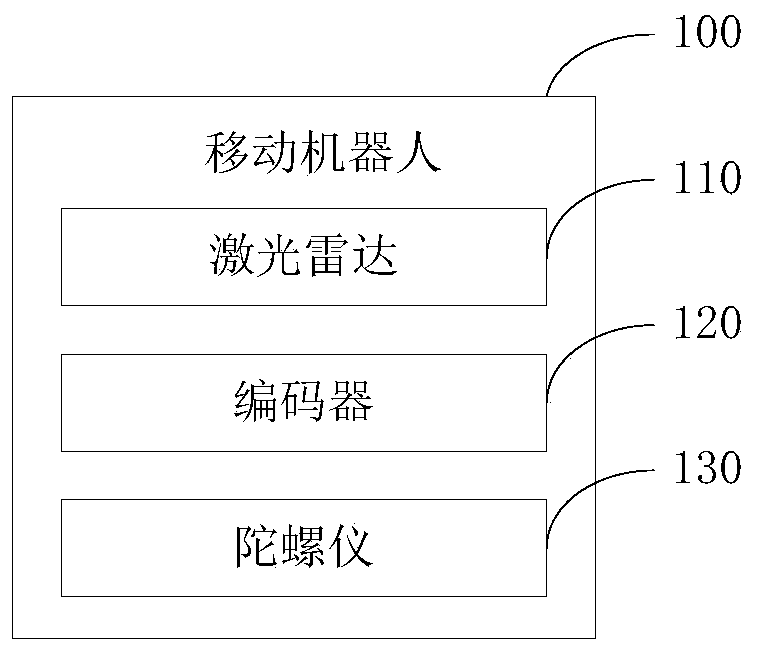

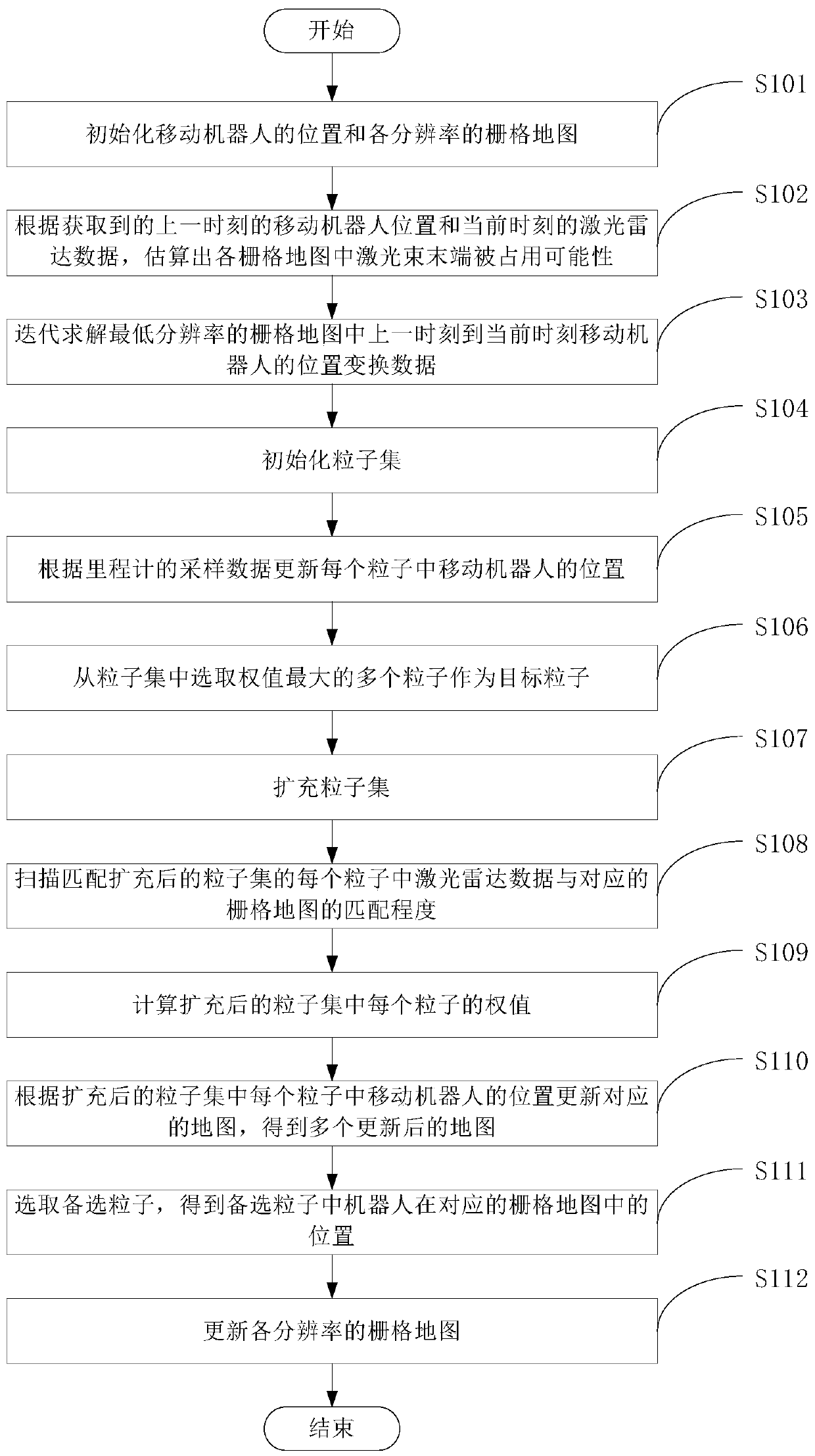

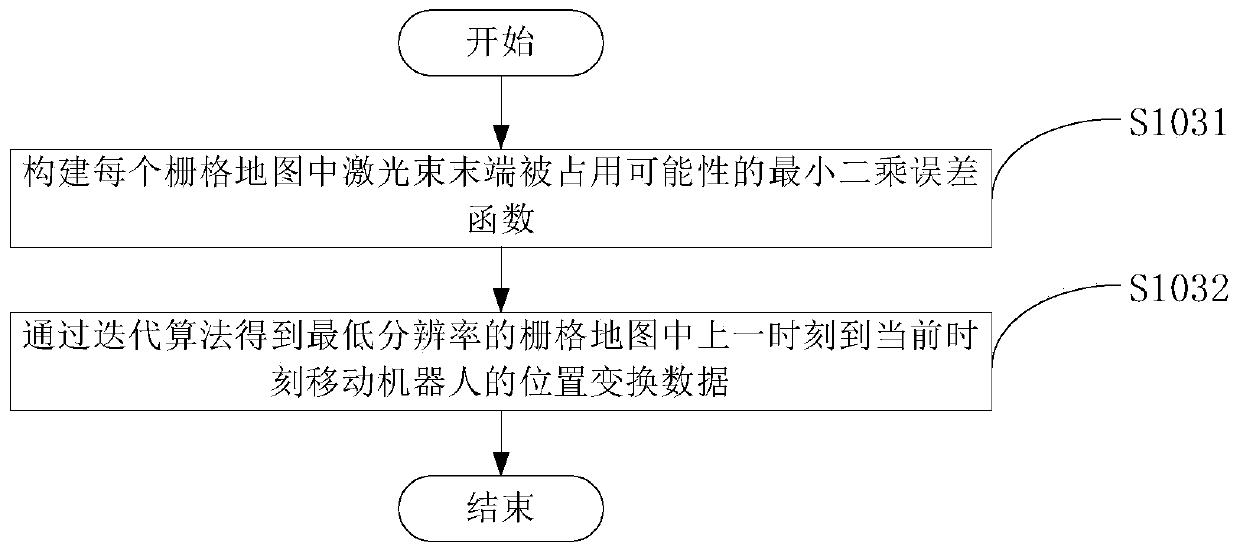

Mobile robot positioning and mapping method

ActiveCN110007670AHigh positioning accuracySolve the problem of inaccurate positioning caused by large odometer errorsInstruments for road network navigationElectromagnetic wave reradiationImage resolutionComputer graphics (images)

The invention discloses a mobile robot positioning and mapping method, and relates to the technical field of robot positioning. The mobile robot positioning and mapping method comprises the steps of initializing the position of a mobile robot and a raster map of each resolution; estimating the possibility that the tail ends of laser beams in each raster map is occupied; iteratively solving the position change data, in the raster map with the lowest resolution, of the mobile robot from the last moment to the current moment; initializing a particle set; updating the position of the mobile robotin each particle; selecting a target particle and expanding the particle set; scanning the matching degrees between the particles in the particle set and the corresponding raster maps; calculating theweights of the particles in the expanded particle set; updating the corresponding maps according to the positions of the robot in the expanded particle set; selecting standby particles; and updatingthe raster map with the lowest resolution. The mobile robot positioning and mapping method is capable of solving the problem that the traditional particle filter-based SLAM systems are relatively large in positioning error and inaccurate in map due to wheeled speedometer errors.

Owner:SICHUAN ARTIGENT ROBOTICS EQUIP

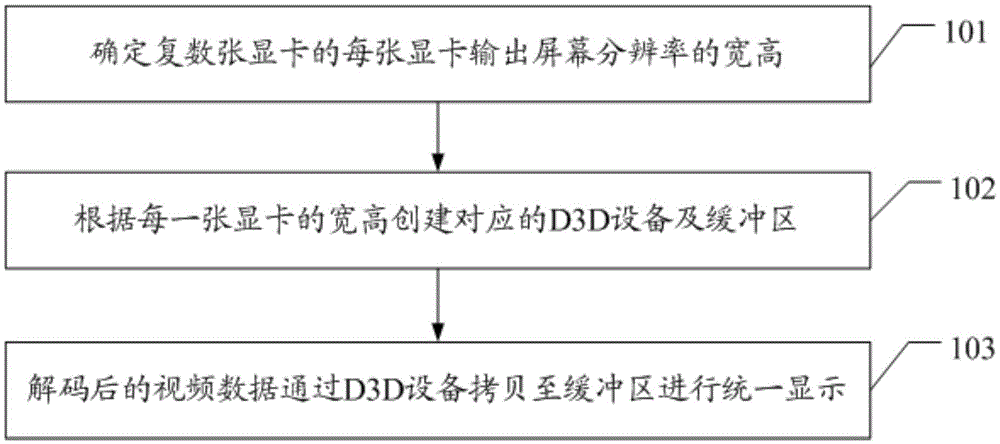

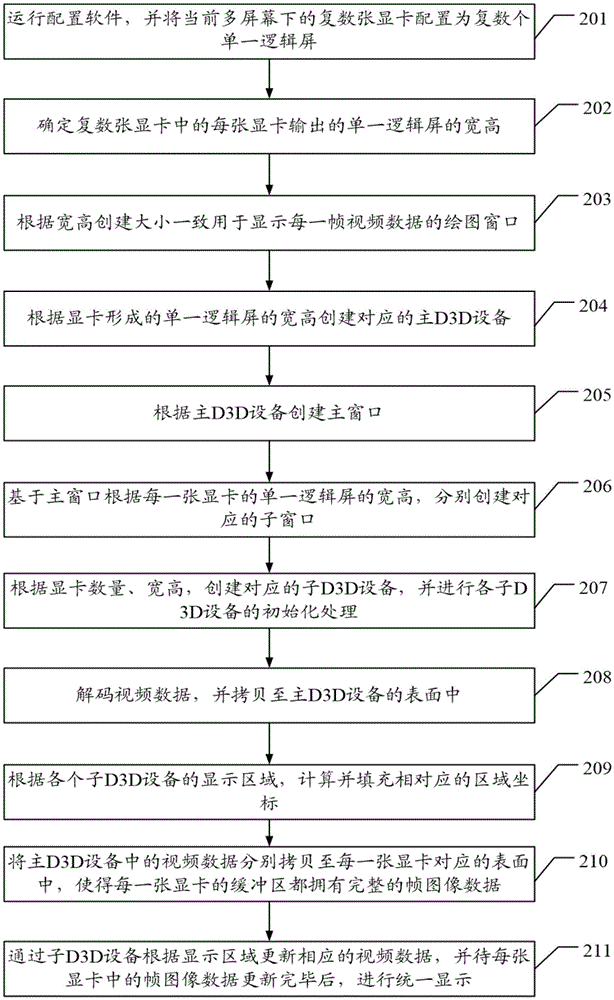

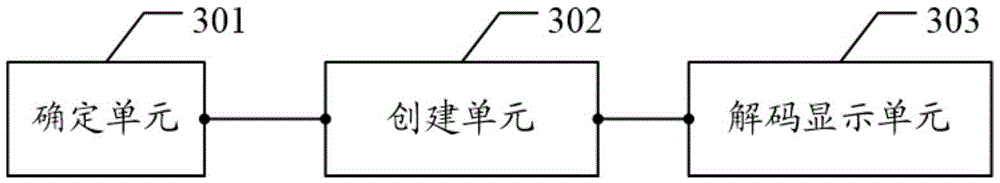

Multi-video-card video data processing method and device

ActiveCN105578104ASignificant improvementNo tearingVideo signal spatial resolution conversionImage resolutionLarge screen display

The embodiment of the invention discloses a multi-video-card video data processing method and device, and aims to solve the technical problems of lag, tearing, excessively-low frame rate and the like under a multi-screen and multi-video-card situation due to playing of local video files with a common player in a work station in current large-screen display applications of monitoring rooms and meeting rooms. In the embodiment of the invention, the multi-video-card video data processing method comprises the following steps: determining widths and heights of output screen resolutions of video cards; creating corresponding D3D equipment and buffering areas according to the widths and the heights of single logical screens formed by the video cards; and copying decoded video data into the buffering areas through the D3D equipment in order to uniformly display the decoded video data.

Owner:GUANGDONG VTRON TECH CO LTD

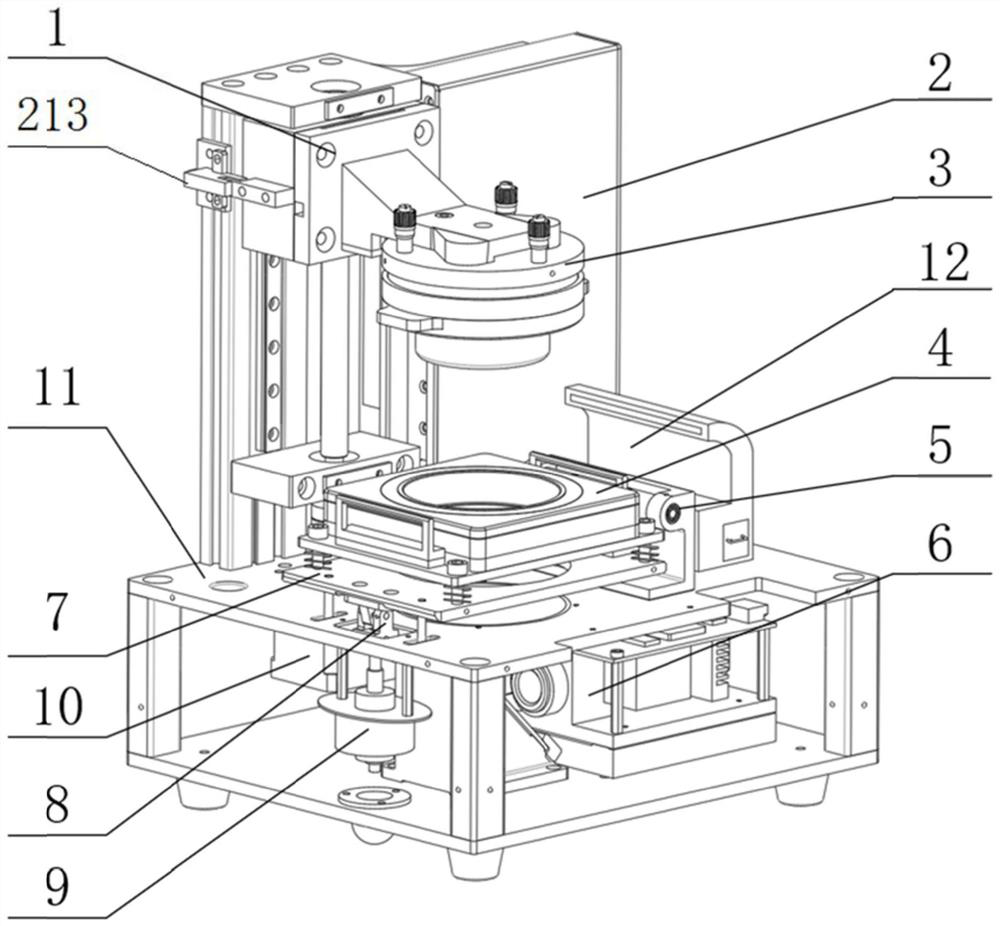

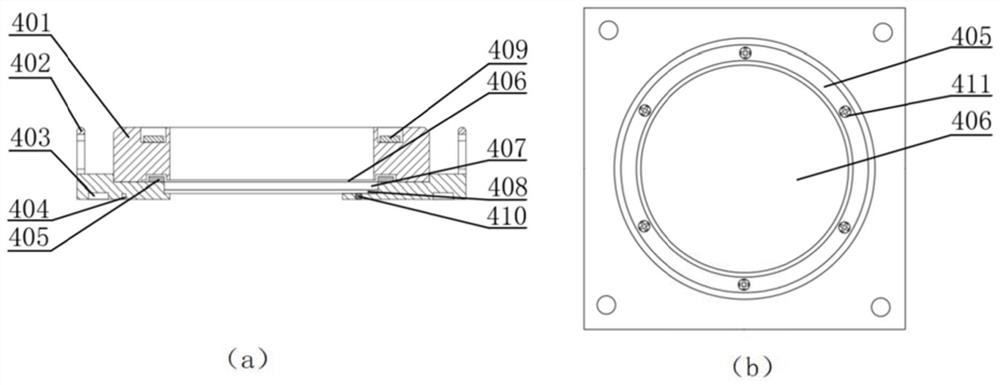

Projection type photocuring 3D printing device

InactiveCN111745958AReduce damageReduce capacityManufacturing platforms/substratesManufacturing driving means3d printMechanical engineering

The invention discloses a projection type photocuring 3D printing device. The projection type photocuring 3D printing device comprises a rack and further comprises a printing forming platform assembly, a trough assembly, a light source generator and a controller which are fixed in the rack. The trough assembly comprises a trough, a trough platform used for fixing and supporting the trough, and a drive mechanism I capable of driving the trough platform to conduct peeling overturning and return overturning. One side of the trough platform is hinged to the rack, and the other side of the trough platform is in shaft connection to the output end of the drive mechanism I. Under driving of the drive mechanism I, the trough platform conducts peeling overturning with the low speed and conducts return overturning with the high speed. The projection type photocuring 3D printing device meets the requirement for wide printing material coverage while the printing precision is ensured, and the forming performance and biology applicability of projection type photocuring 3D printing are improved.

Owner:苏州永沁泉智能设备有限公司

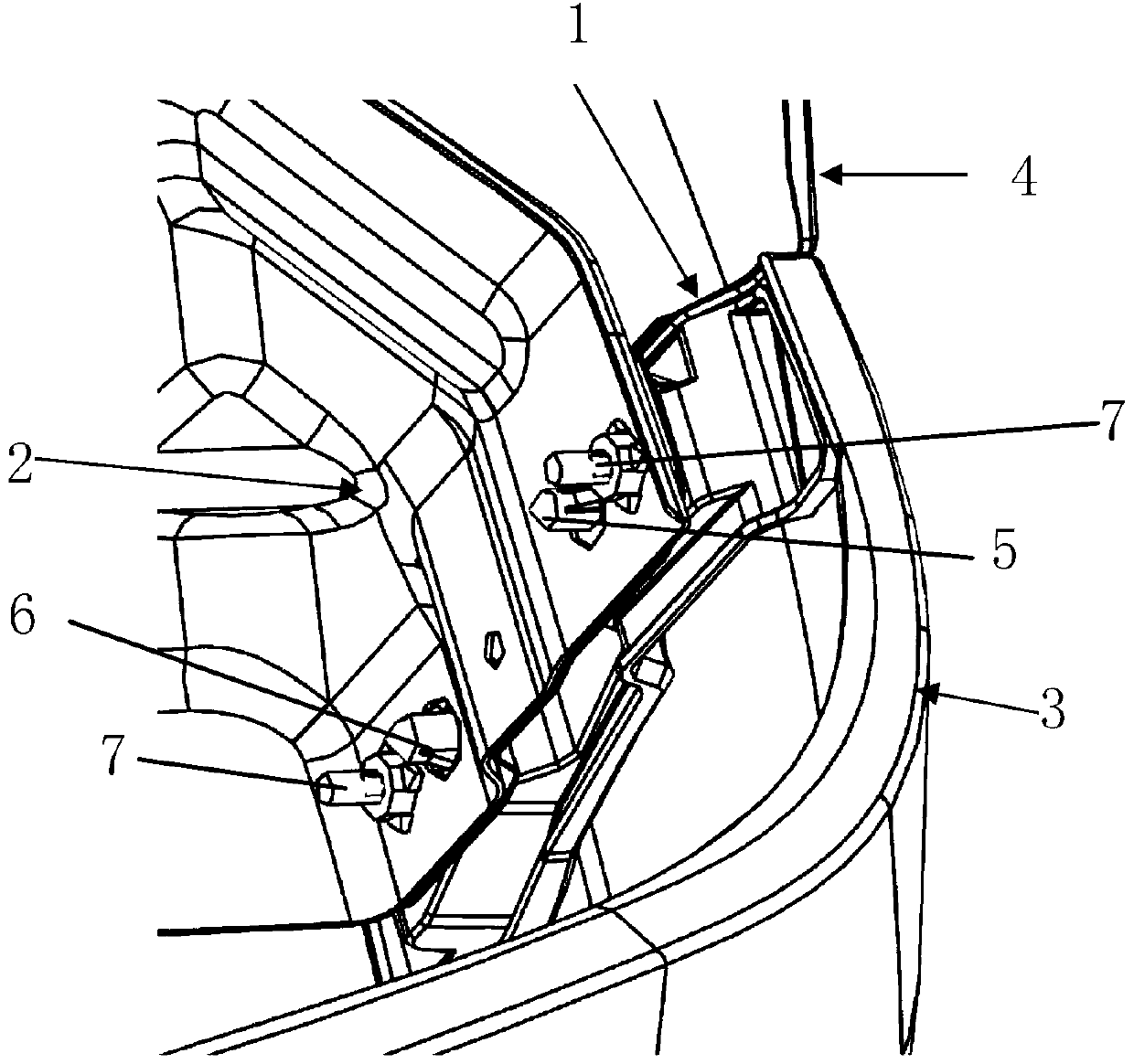

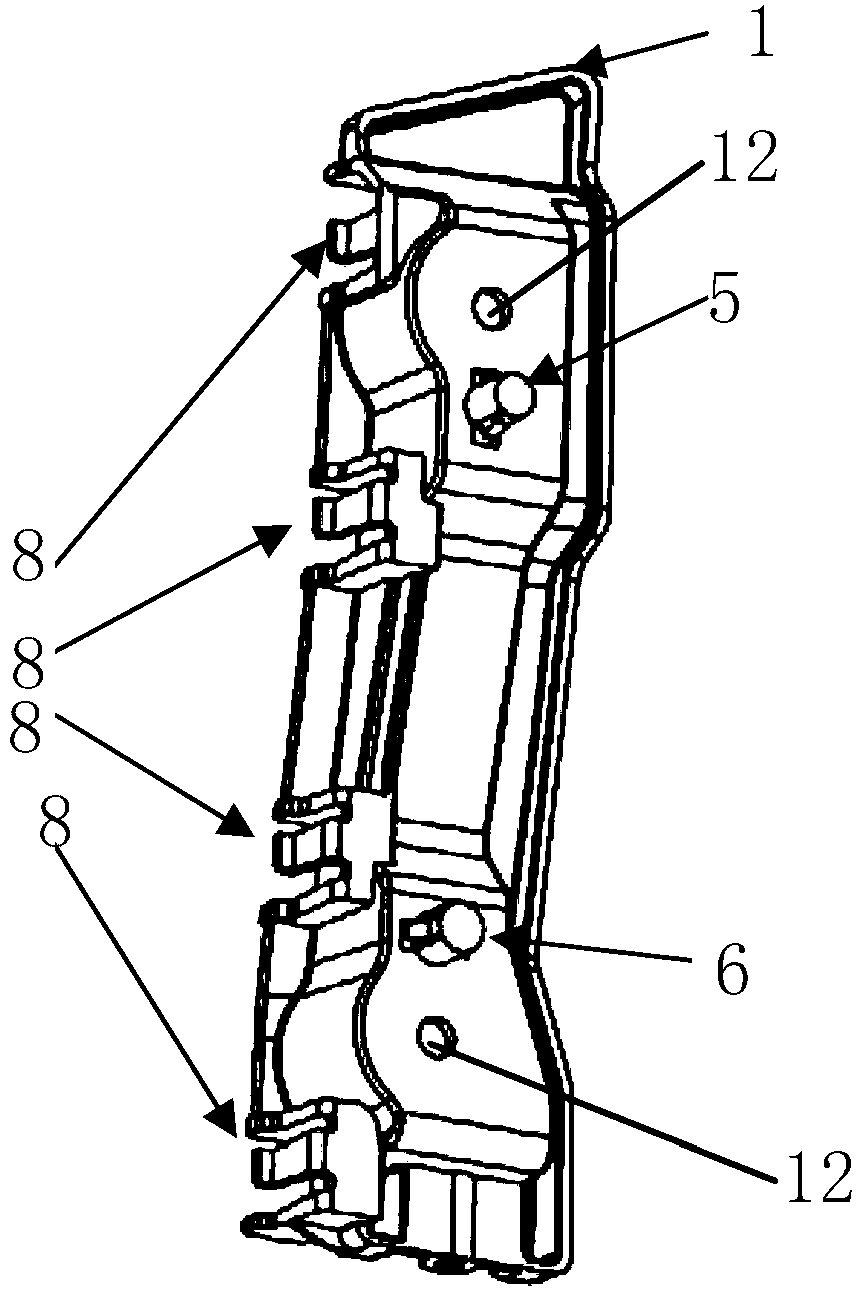

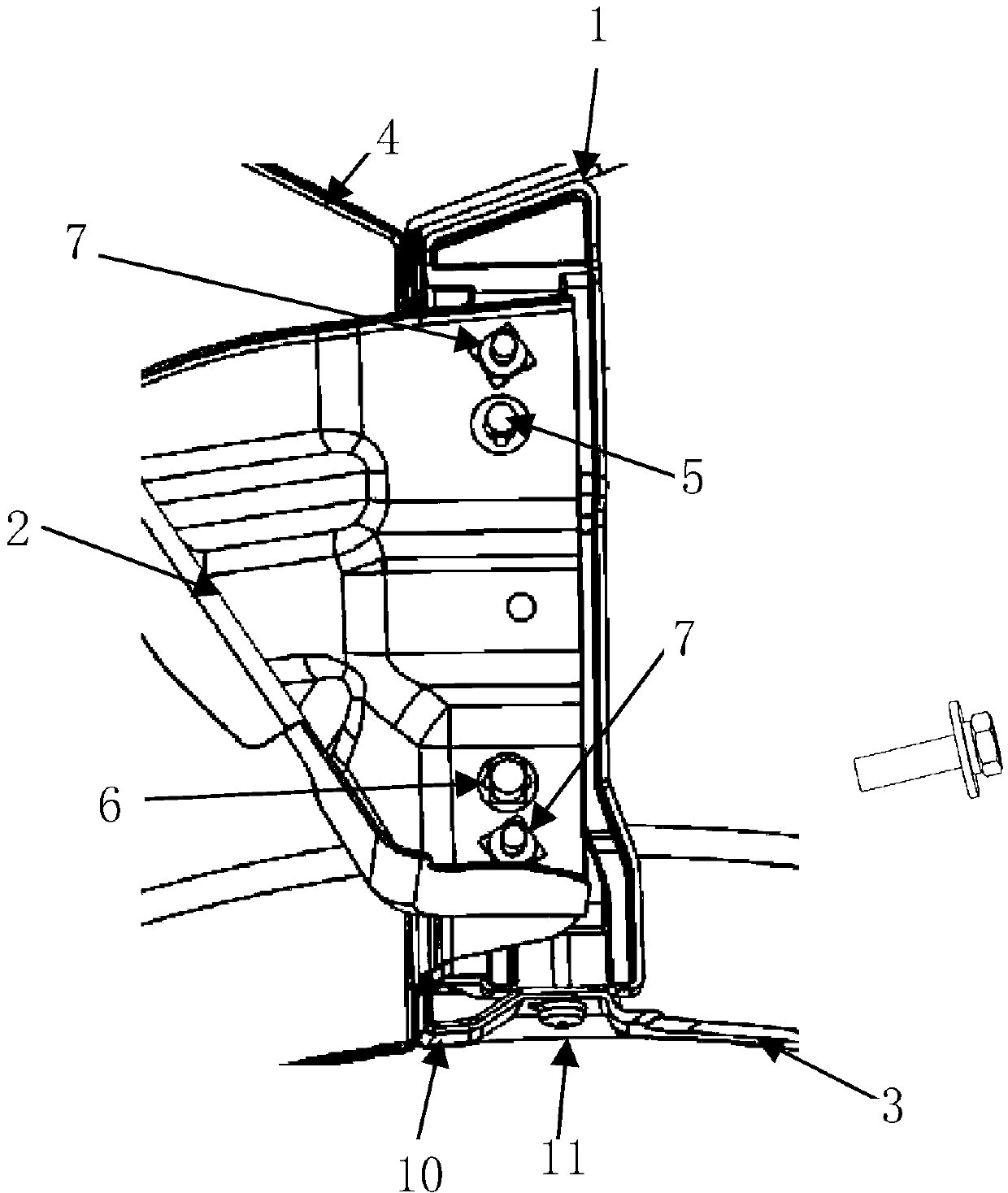

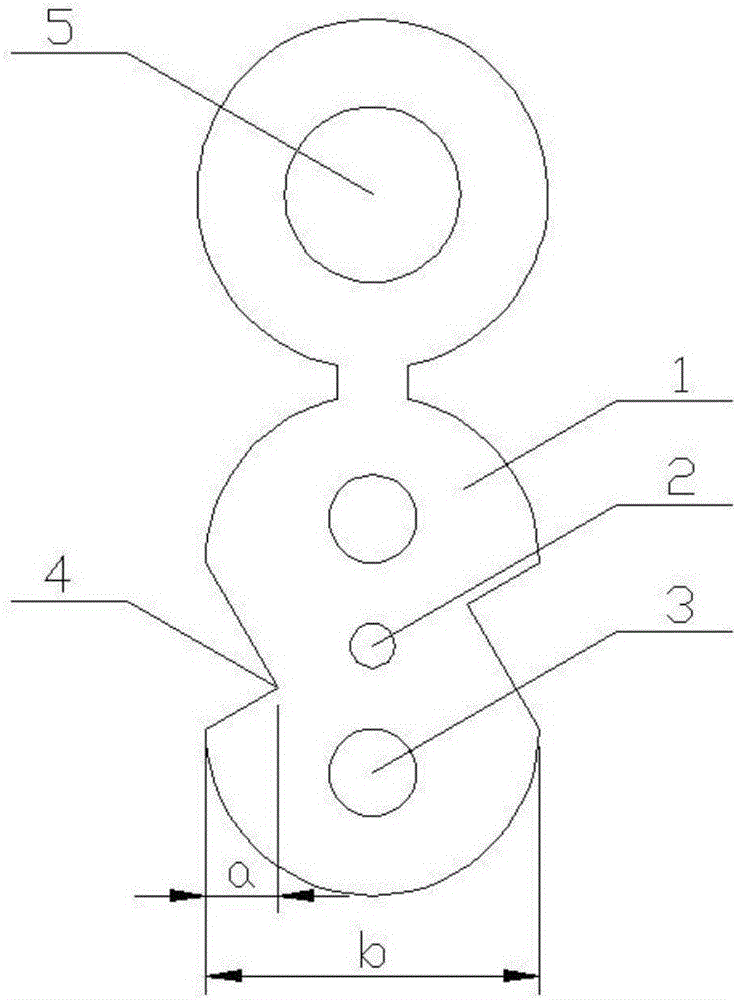

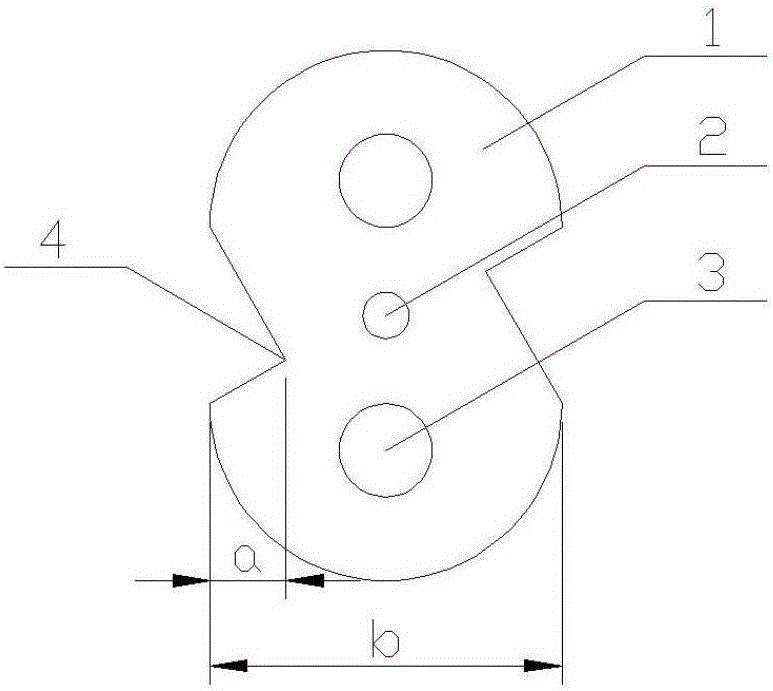

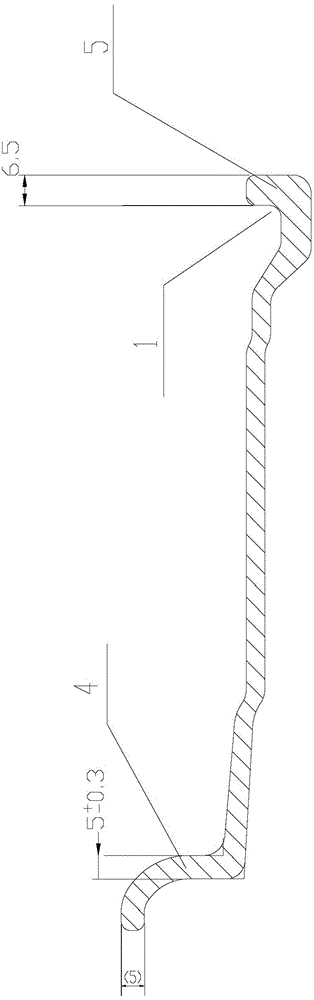

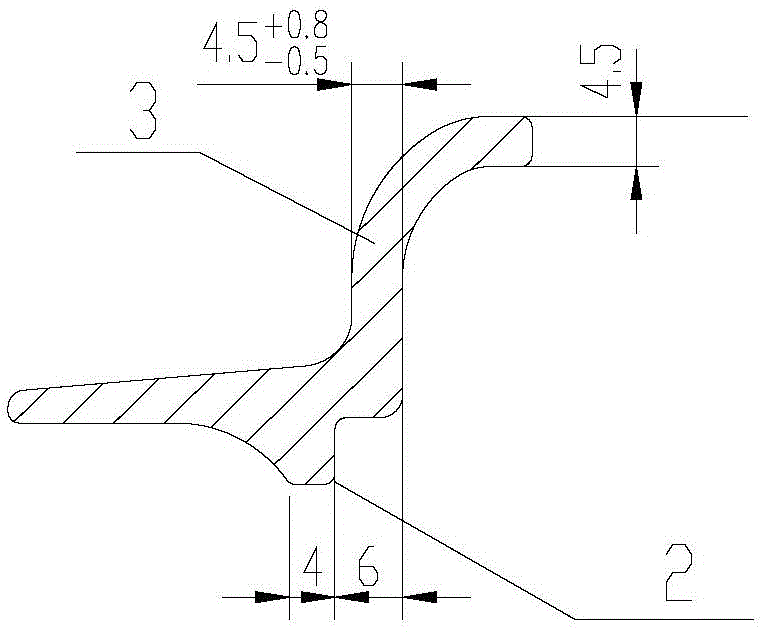

Automotive front bumper mounting bracket

The invention discloses an automotive front bumper mounting bracket comprising a bracket body. The bracket body is connected with a wheel fender, an automotive frame and a front bumper respectively. The upper portion of the bracket body and the lower portion of the bracket body are provided with a first positioning pin and a second positioning pin which are connected with the wheel fender in a clamping manner. The automotive frame and the wheel fender are fixed through bolts. The automotive frame and the front bumper are fixed in a clamping manner. One side of the bracket body is provided with at least two clamp claws extending downwards, and clamp claw fasteners are arranged on the front bumper. The clamp claws are connected with the clamp claw fasteners in a clamping manner. The bracket body is made of plastic material. The automotive front bumper mounting bracket is simple in structure, low in cost, high in mounting efficiency, ergonomic, light in weight and environment-friendly; parts strength is increased; and the problems that limited flange shape of the front bumper influences demoulding, a gap between the wheel fender and the front bumper is uneven, segment difference is difficult to control and matching accuracy of parts is low are solved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

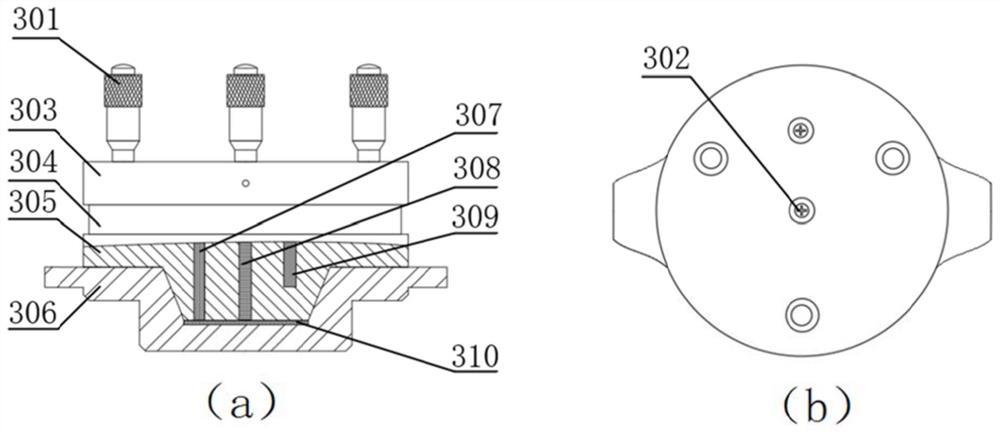

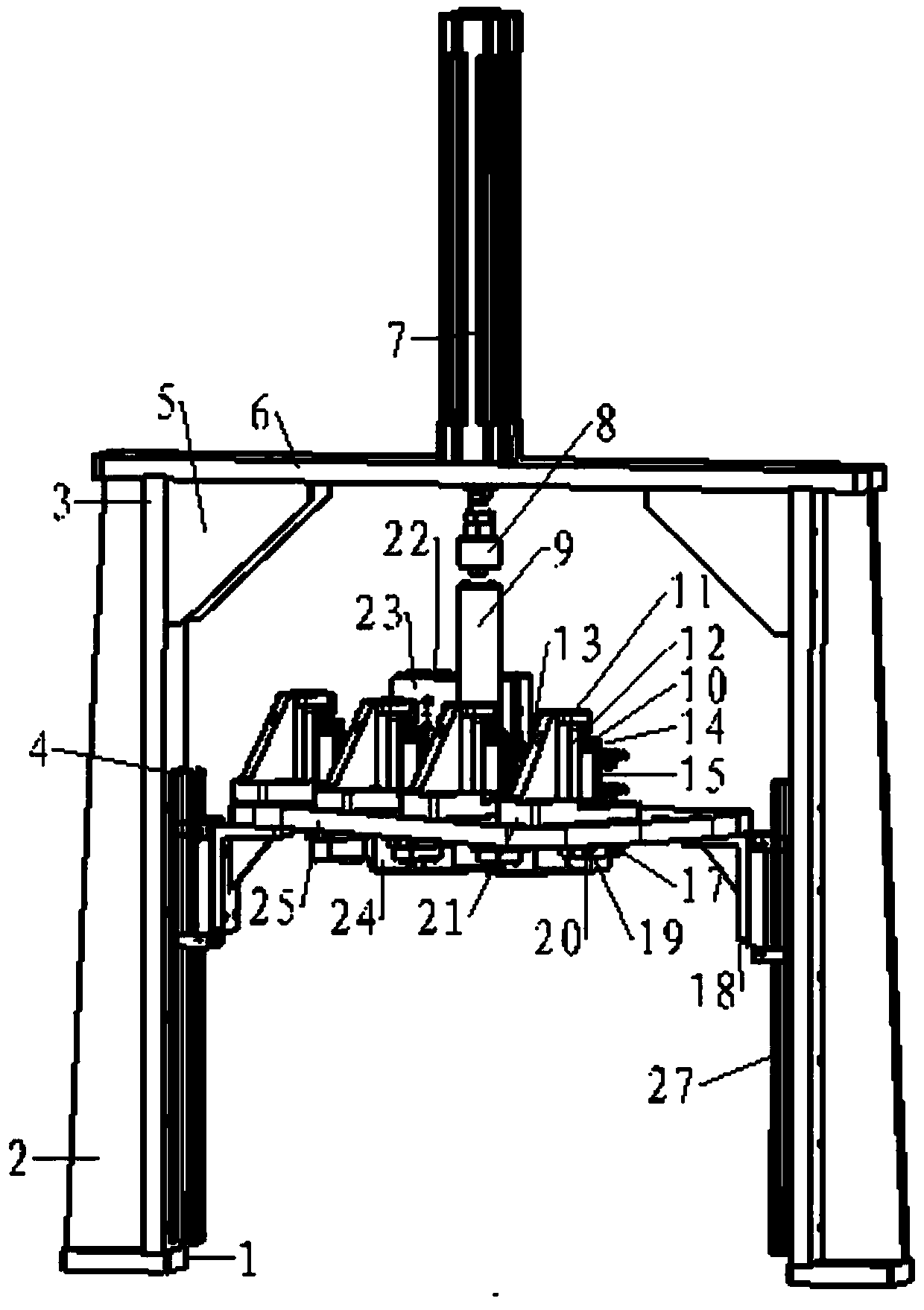

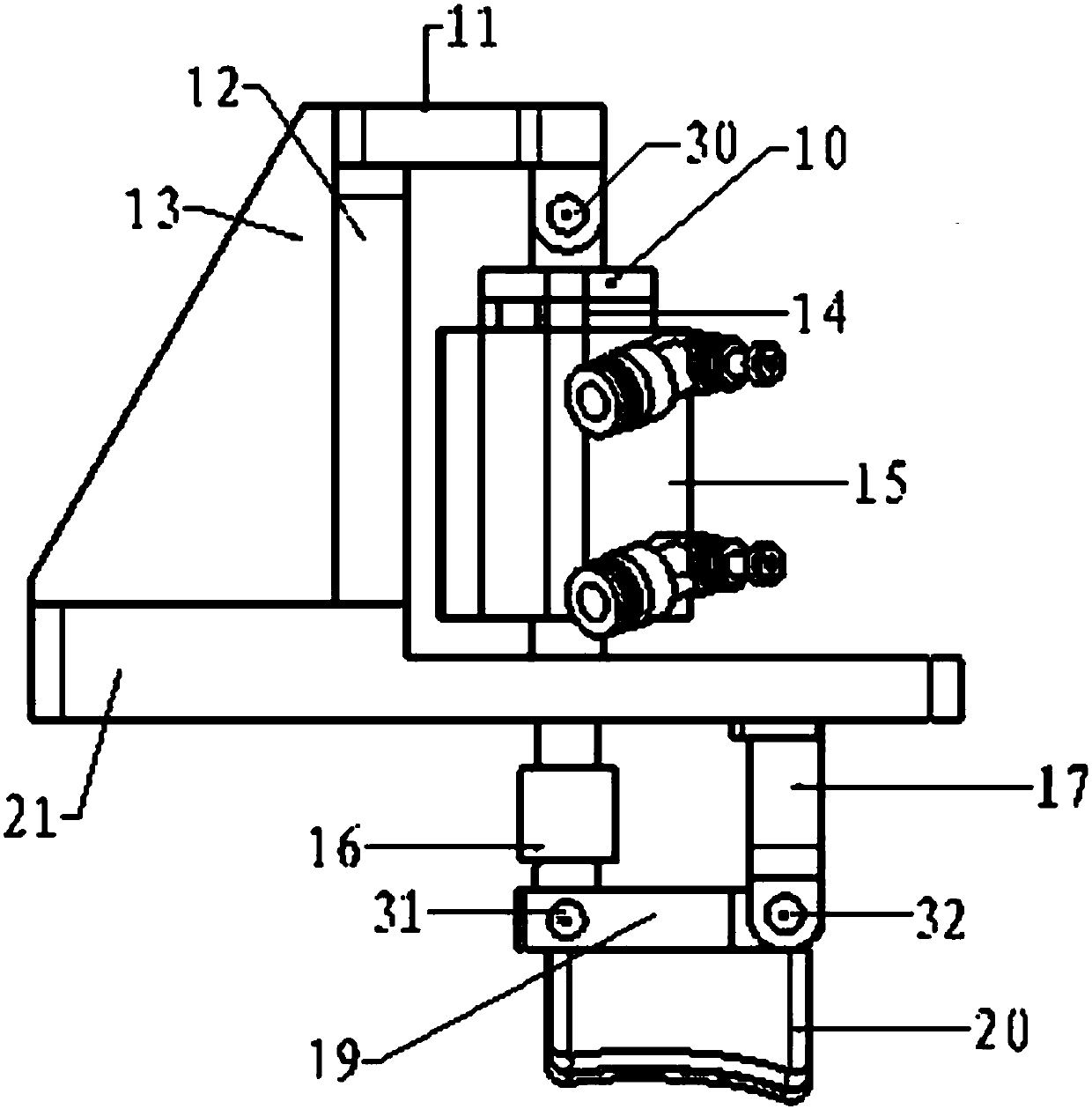

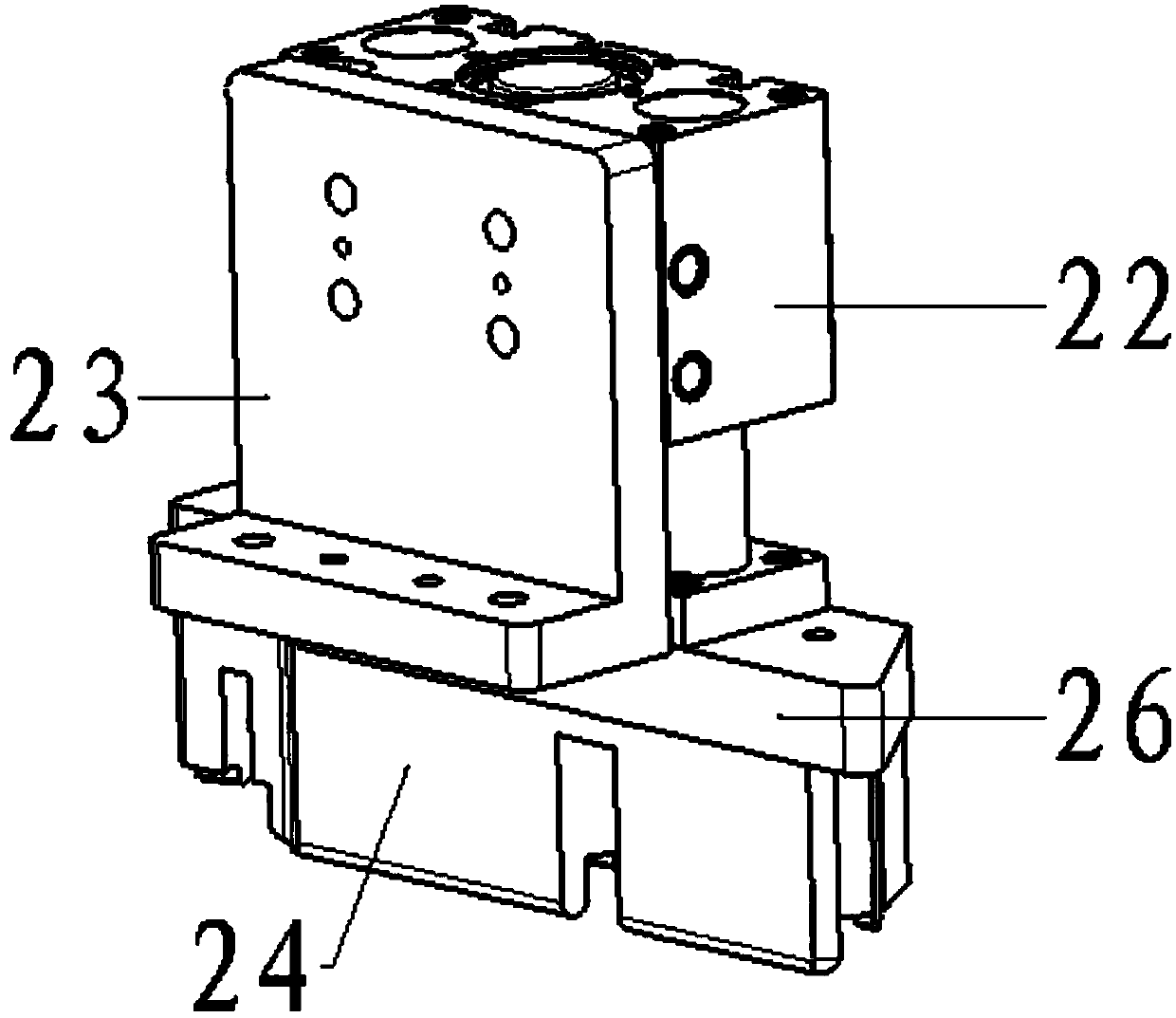

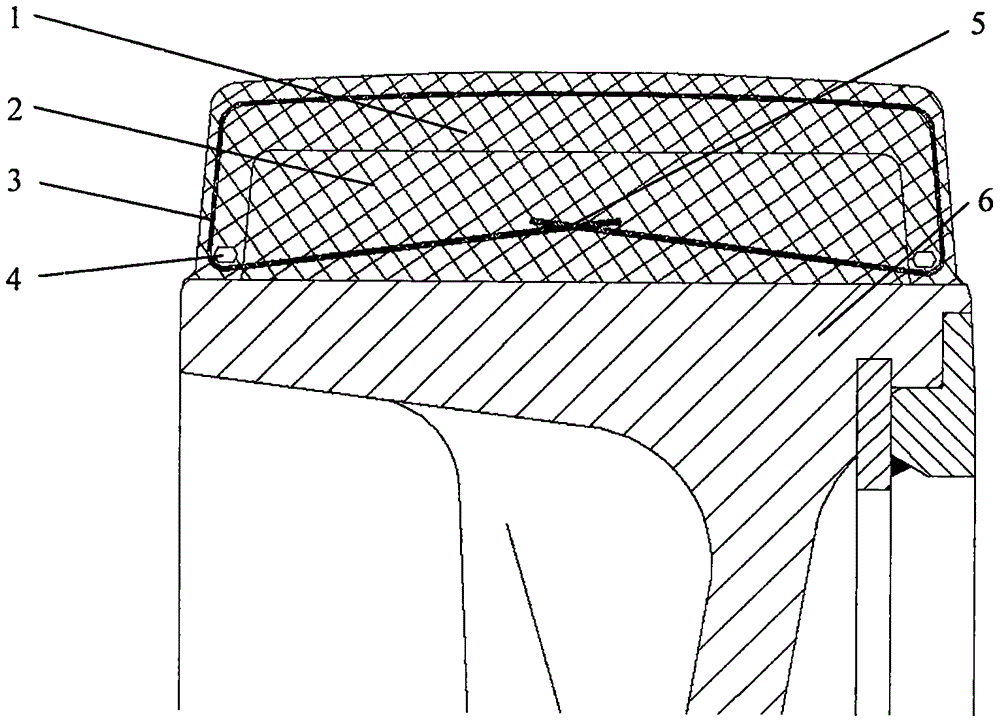

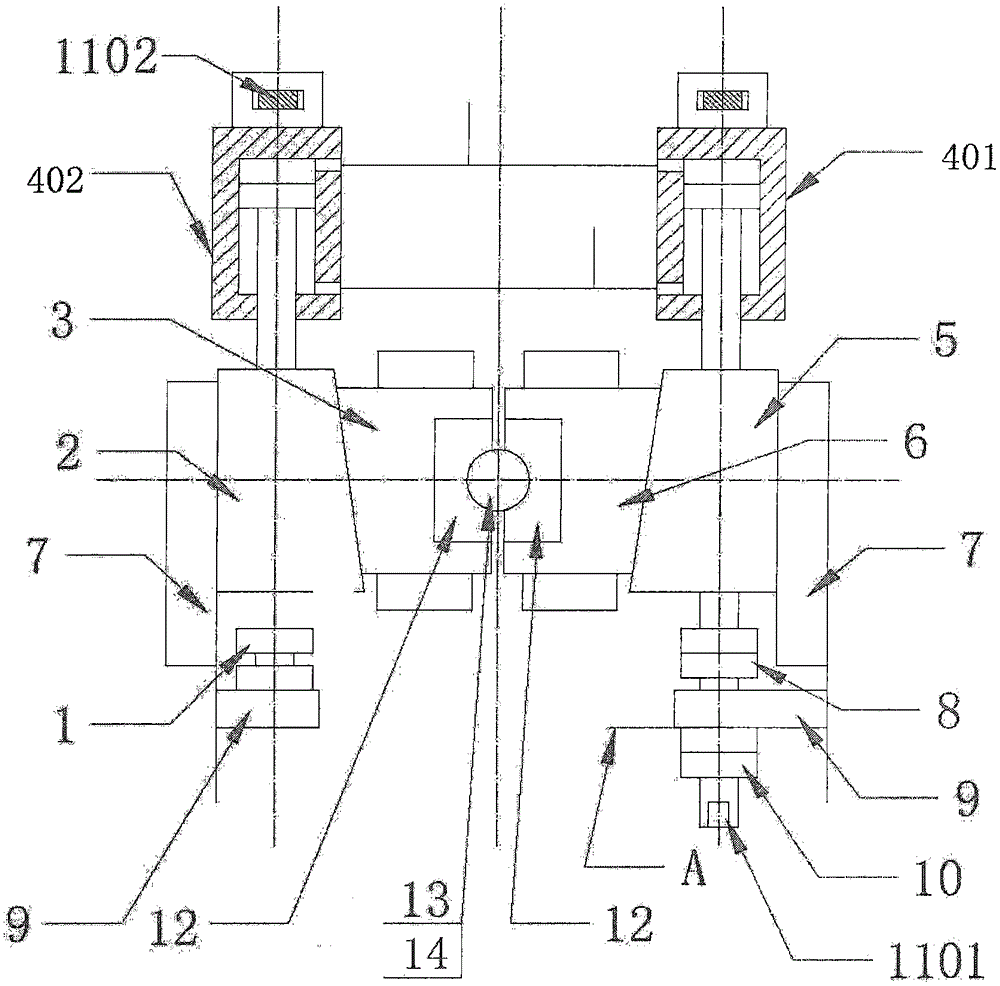

Rotary pressure welding mechanism used for automatically mounting automobile rear quarter window glass bright molding

ActiveCN107813257AAvoid damageSolve the photopolar changeMetal-working hand toolsRear quarterInterference fit

The invention discloses a rotary pressure welding mechanism used for automatically mounting an automobile rear quarter window glass bright molding, and belongs to the technical field of industrial automation. The rotary pressure welding mechanism comprises a portal supporting base, a portal supporting vertical plate, a guide rail, a portal cross beam, a lifting air cylinder, a floating connector,a connecting column, a rotary pressure welding mechanism body, a sliding block fixing plate, a straight-sided mechanism, a main fixing plate and a sliding block. The rotary pressure welding mechanismis mainly formed by combing an air cylinder with the rotary pressure welding mechanism body for achieving the mounting function, and is manufactured by completely copying the shape of the bright molding, the effects that one side of a bright molding buckle is buckled into a glass buckle and then the other side of the bright molding buckle is buckled in can be achieved, the bright molding can be mounted in place only with few effort, and the bright molding can be prevented from being damaged. The problem that optical distortion, tearing cracks, deformation, scratches and flushness of the brightmolding are caused when the bright molding is mounted through snap fasteners in an interference fit mode is effectively solved, and the production efficiency is improved.

Owner:长春吉田快速成型科技有限公司

Formed foil connection method

A formed foil connection method comprises the following steps that the roll tail end of a front aluminum foil roll is trimmed to be smooth and free of burrs, and the roll head end of a rear aluminum foil roll is trimmed to be smooth and free of burrs; a connection aluminum foil is selected to be connected between the roll tail end of the front aluminum foil roll and the roll head end of the rear aluminum foil roll in a lapping mode, wherein the thickness of the connection aluminum foil differs from the thicknesses of the front aluminum foil roll and the rear aluminum foil roll by 30 [mu]m; the roll tail lap joint area between the connection aluminum foil and the roll tail end of the front aluminum foil roll is fixed; and the roll head lap joint area between the connection aluminum foil and the roll head end of the rear aluminum foil roll is fixed to complete foil connection. Compared with a common method, according to the mode that the front aluminum foil roll and the rear aluminum foil roll are directly connected in a lapping mode for fixing, the tensile strength is reinforced, the bending resistance capacity is high, and the problems of breakage and tearing are fundamentally solved.

Owner:NINGXIA HAILI ELECTRONICS

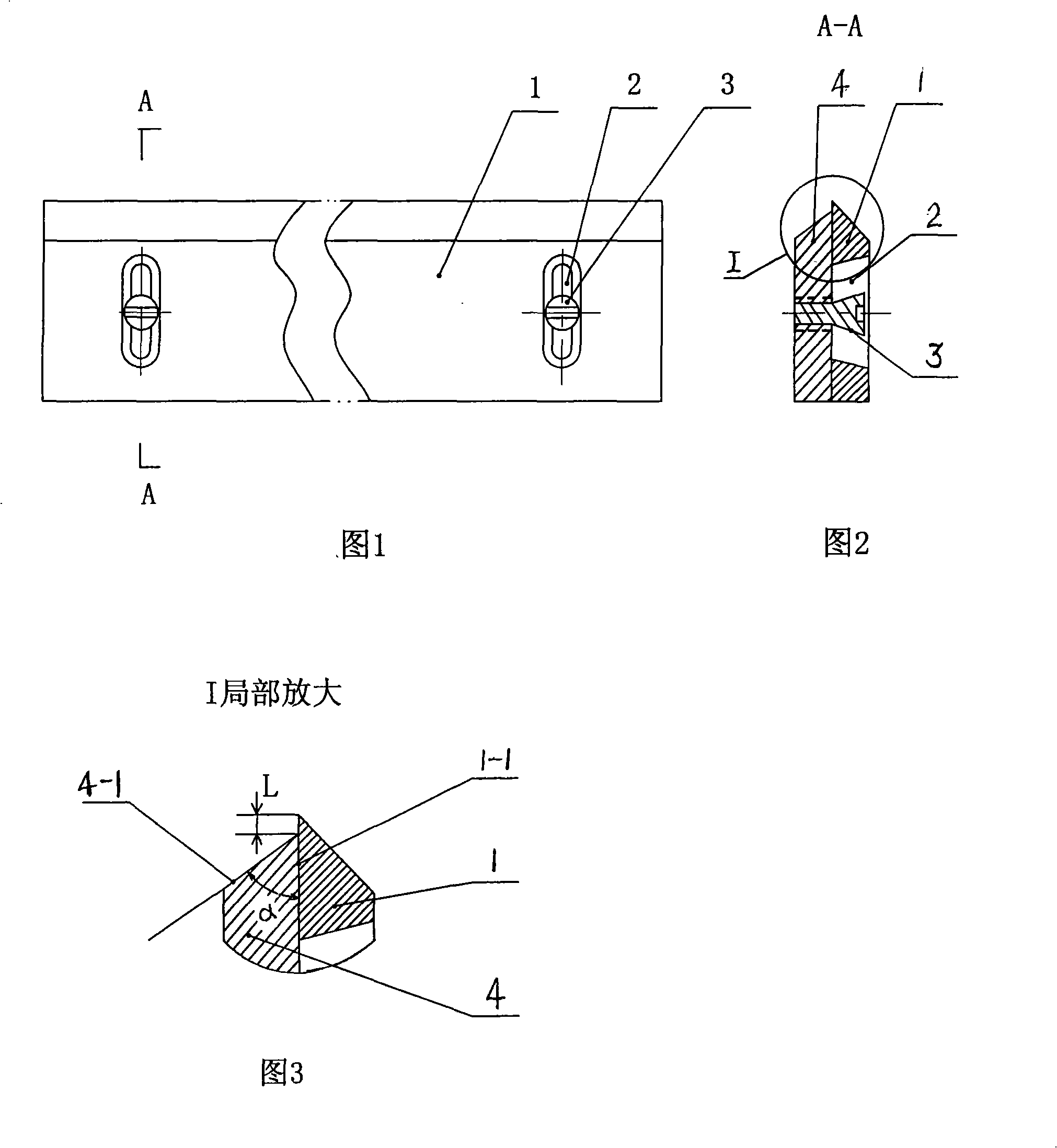

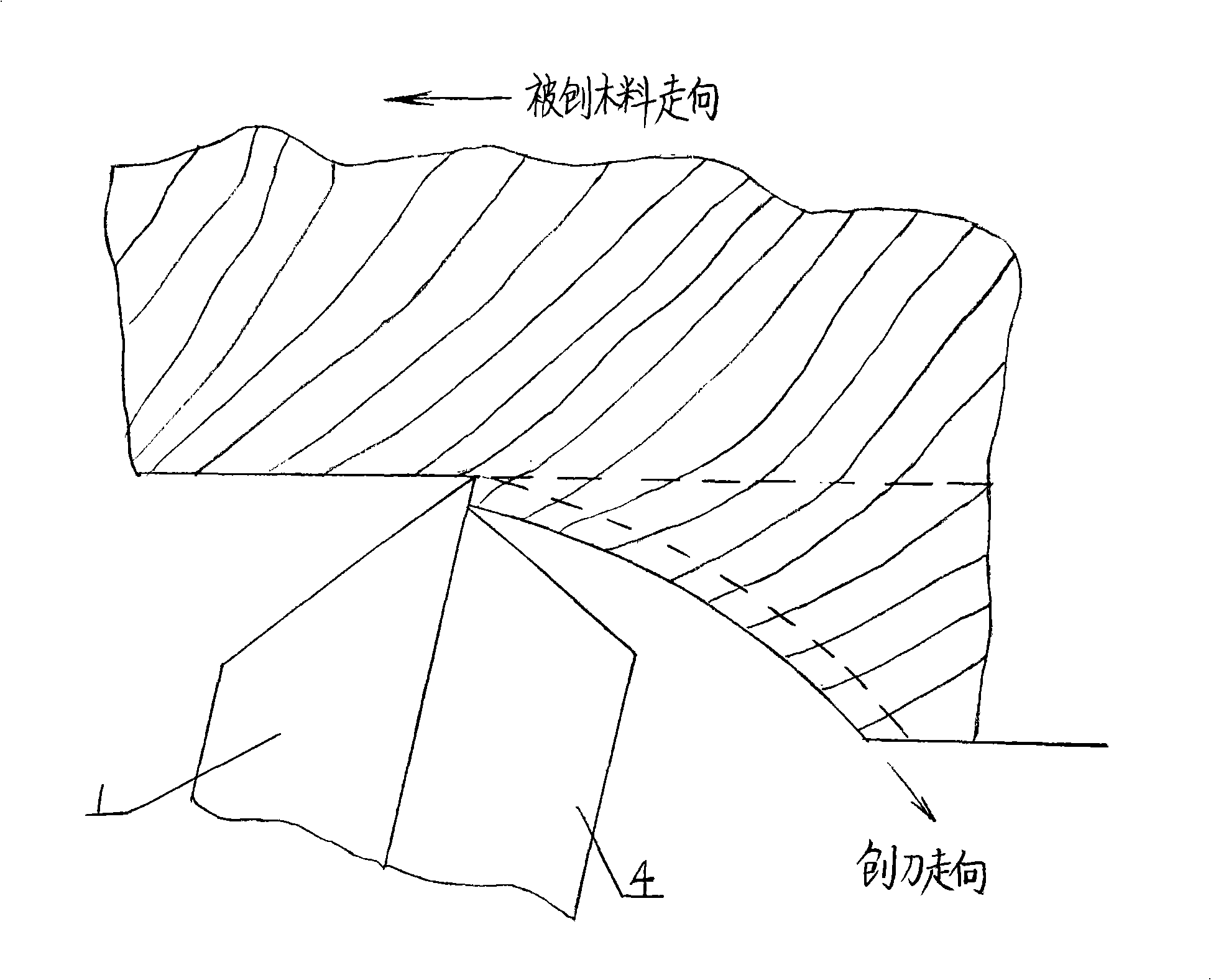

Inverse texture plane blade for planning

InactiveCN101279451AFix the tearSolve the jumpFlat surfacing machinesEngineeringWoodworking machinery

The invention provides an against-the-grain surfaced planning tool, which relates to a planning tool on woodworking machinery. The against-the-grain surfaced planning tool is provided with a main blade and a supporting body is arranged in front of the main blade. The top end face of the supporting body is inclined to the front side surface of the main blade and the tip of the supporting body is slightly lower than the cutting edge of the main blade. After the planning tool is arranged on a planning machine for use, the problem of timber tearing when the planning tool encounters with a reverse texture or the phenomena of timber jump or fracture when the planning tool encounters with a fag is solved or eliminate, thus greatly enhancing the planeness and smoothness of the planned surface and reaching or exceeding the planning effect of a high-speed planning machine by using an ordinary planning machine. The finish degree of timbers can exceed the polishing effect of a 100-120# accurate grinding resinder so as to avoid the grinding procedure, thus enhancing the working efficiency and utilization rate of the timber and lowering the labor intensity. The supporting body also has protective effect on the main blade, thus extending the service life of the blade and preventing human bodies from being hurt by collapsed planning tool fragments. The against-the-grain surfaced planning tool has the advantages of simple and reasonable structure and low production cost.

Owner:周建力

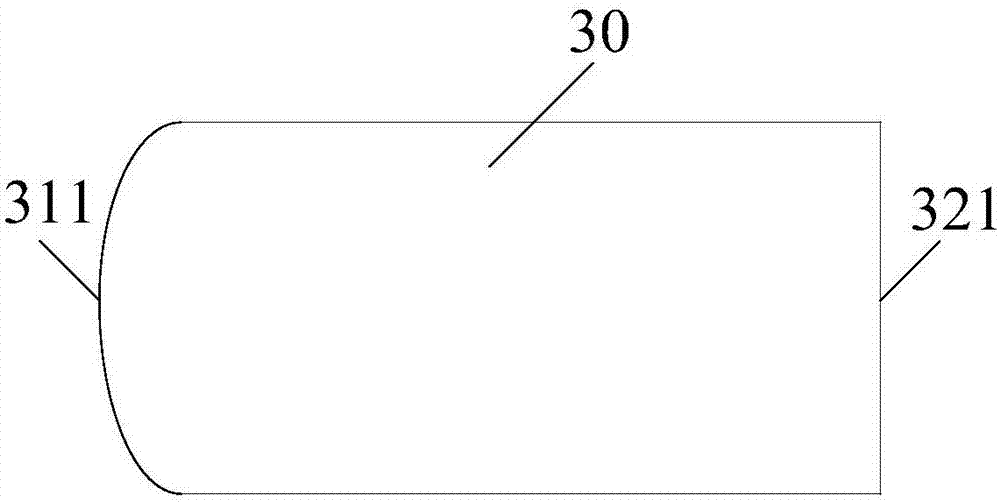

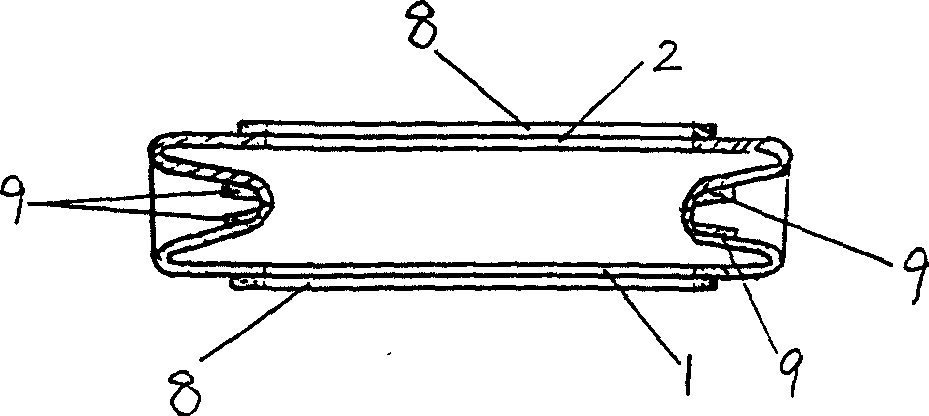

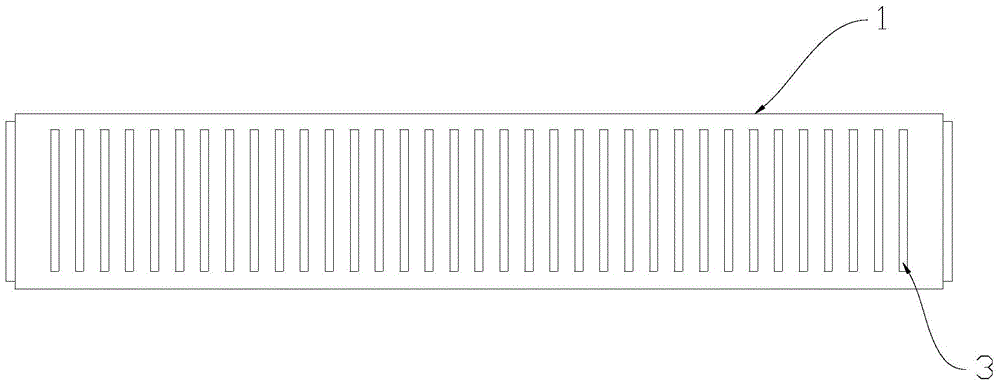

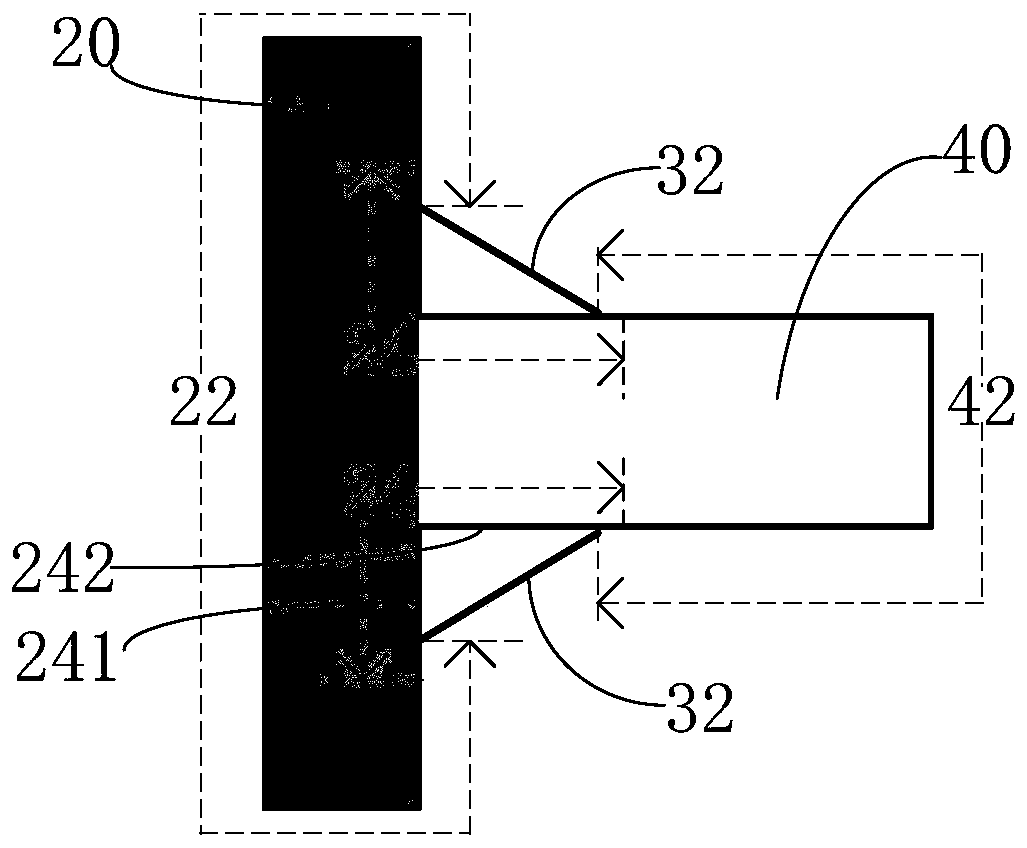

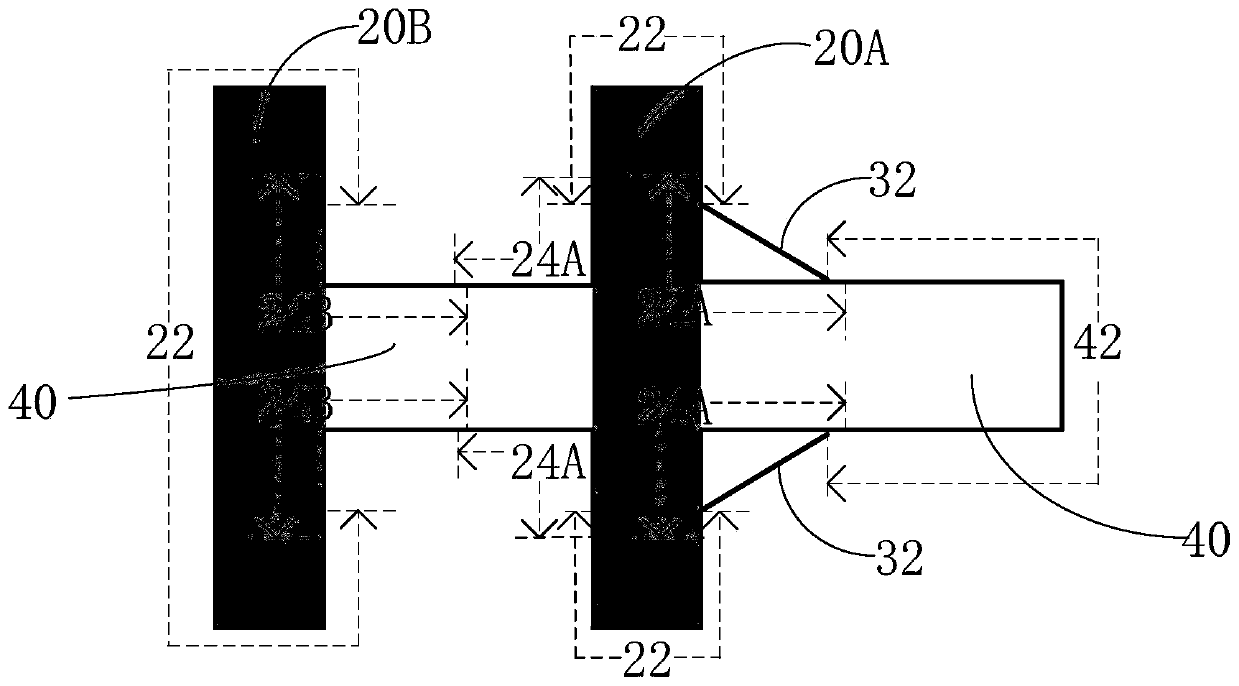

Side-slot-reinforced leading-in optical cable and production process

InactiveCN105866908AIncrease wall thicknessHigh strengthFibre mechanical structuresStress concentrationUltimate tensile strength

The invention provides a side-slot-reinforced leading-in optical cable and a production process. The side-slot-reinforced leading-in optical cable comprises an optical fiber, a sheath and reinforcement pieces and is characterized in that the playground type sheath covers the outer side of the optical fiber; diagonal side slots are formed in straight side surfaces of the playground type sheath and are triangular slots; the optical fiber is arranged at the center of the playground type sheath; the reinforcement pieces are placed on the circular ends of the playground type sheath and are symmetrically arranged on the two sides of the optical fiber. According to the side-slot-reinforced leading-in optical cable and the production process, the utilized side slots are diagonally staggered, and a stress centralizing point avoids the optical fiber, so that walls on the two sides of the optical fiber are thickened; the optical fiber is protected, the integral wall thickness of the optical cable is increased, and the improvement on the integral strength of the optical cable is ensured; by means of the designed staggered side slots, tearing of slotted parts due to the weight outdoors for a long term can be avoided; according to application environments, the tearing force of the optical cable can be freely controlled; the effective section area is further shortened, and the utilization rate of materials is further increased; a prefabricated end forming process and the traditional butterfly-shape leading-in optical cable are not different and can match with the existing devices.

Owner:SHENYANG HENGTONG OPTICAL COMM CO LTD

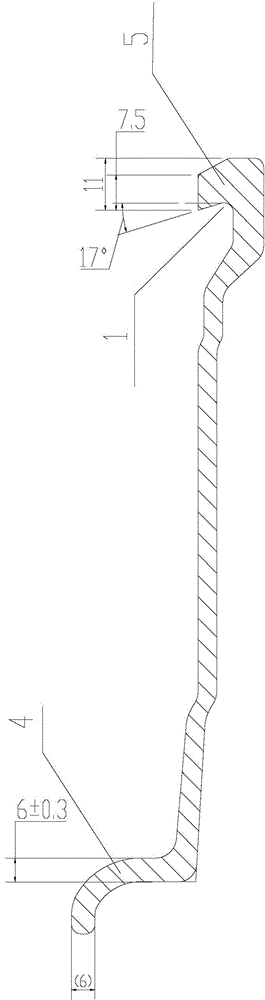

Engineering truck wheel

The invention discloses an engineering truck wheel. The wheel comprises spokes, a rim and a retaining ring. The wheel is characterized in that the rim and the spokes are assembled in an interference mode and are welded and fixed. The retaining ring is an elastic retaining ring and is matched and mounted with the rim through an elastic locking principle. Particularly, the rim comprises a rim retaining ring groove, a ditch is 17 degrees, and the angle of the corresponding matched and mounted position of the retaining ring and the rim retaining ring groove is 17.5 degrees. The retaining ring comprises a retaining ring bead seat, and the thickness is 5.5 millimeters. The rim comprises a rim bead seat, and the thickness is 6 millimeters. The width of the rim retaining ring groove is 7.5 millimeters. According to the engineering truck wheel, the matching degree between the retaining ring and the rim retaining ring groove is high, and the strength of the rim retaining ring groove and the strength of the rim bead seat are further enhanced, so that the problems of falling of the retaining ring off the rim retaining ring groove, the fracture of the rim retaining ring groove and the tearing of the rim bead seat are solved.

Owner:山东英顿车轮科技有限公司

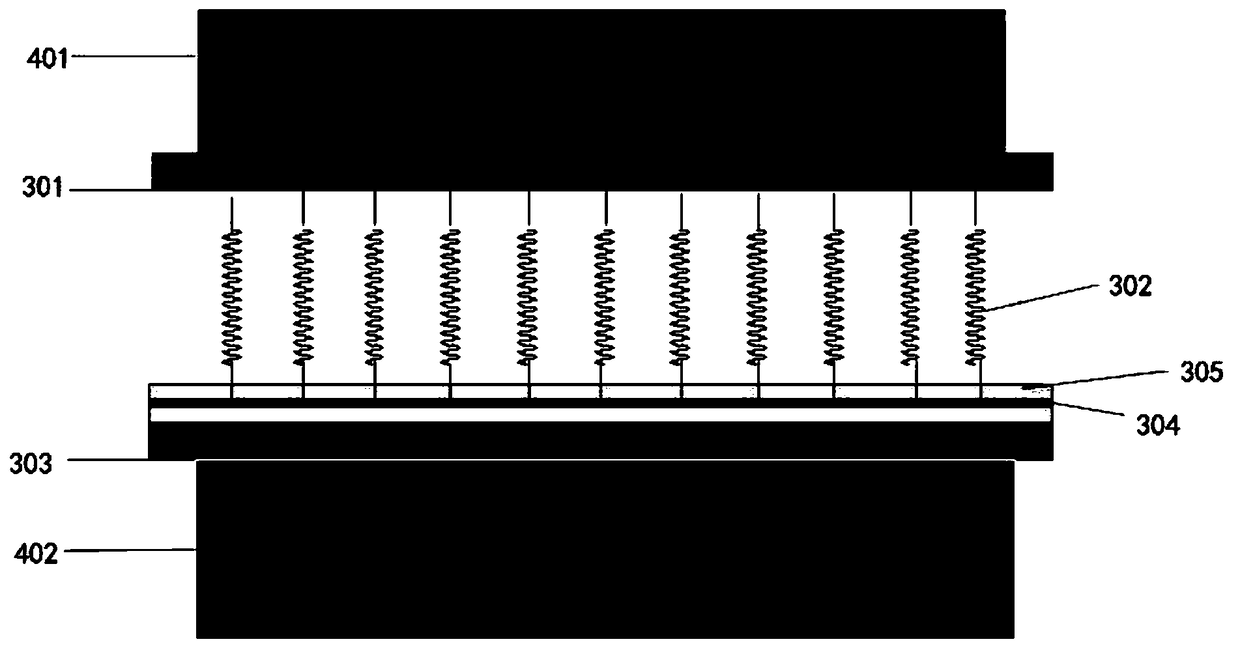

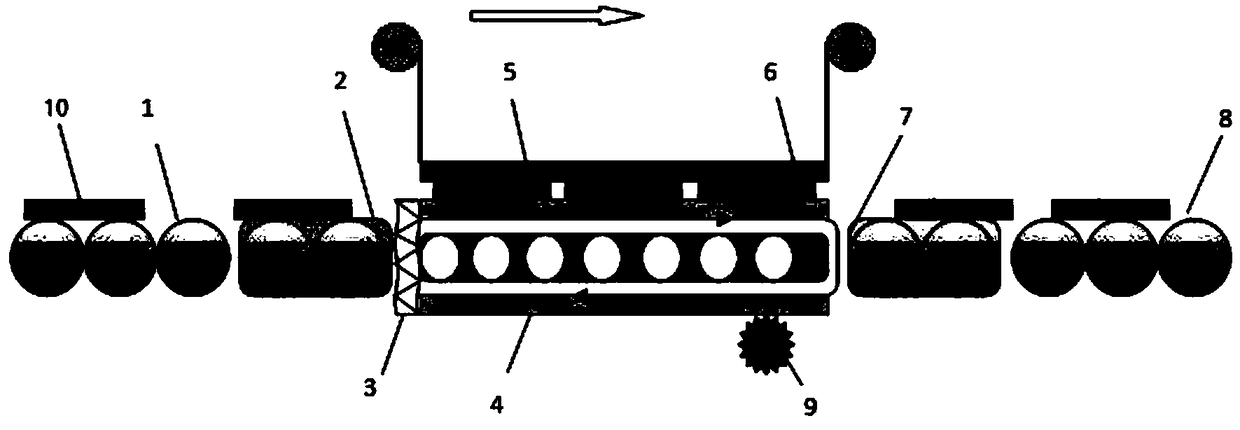

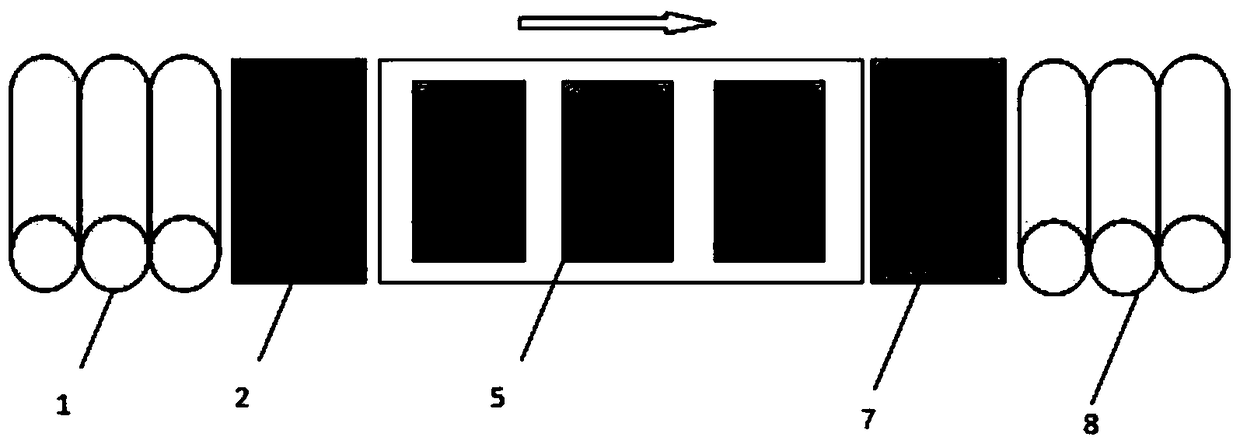

Laminated cloth tensioning device of solar module laminator

InactiveCN109334206ASolve the problem of offset printingFix the tearLaminationLamination apparatusForeign matterEngineering

The invention provides a laminated cloth tensioning device of a solar module laminator. A module enters a feeding table along a feeding assembly line, passes through the feeding table and the laminated cloth tensioning device and enters a laminating station clockwise along laminated cloth, high temperature cloth is pressed at the laminating station for laminating process, the module enters a cooling table after lamination is finished, the cooled module is fed into a recycling device along a blanking assembly line, and residual foreign matter of the laminated cloth is cleaned by a cleaning brush after lamination; the laminated cloth tensioning device comprises an upper cross bar, elastic devices and a lower cross bar, wherein the upper cross bar is connected with the upper laminated cloth,the lower cross bar is connected with the lower laminated cloth, and the upper cross bar and the lower cross bar are connected together through the elastic devices. In the laminating process chamber section of the laminated cloth tensioning device, instantaneous tension of the laminated cloth during the process can be relieved by stretching of the laminated cloth tensioning device, and thus, the problem of tearing of base cloth when the base cloth is installed too tightly is solved.

Owner:江苏彩虹永能新能源有限公司

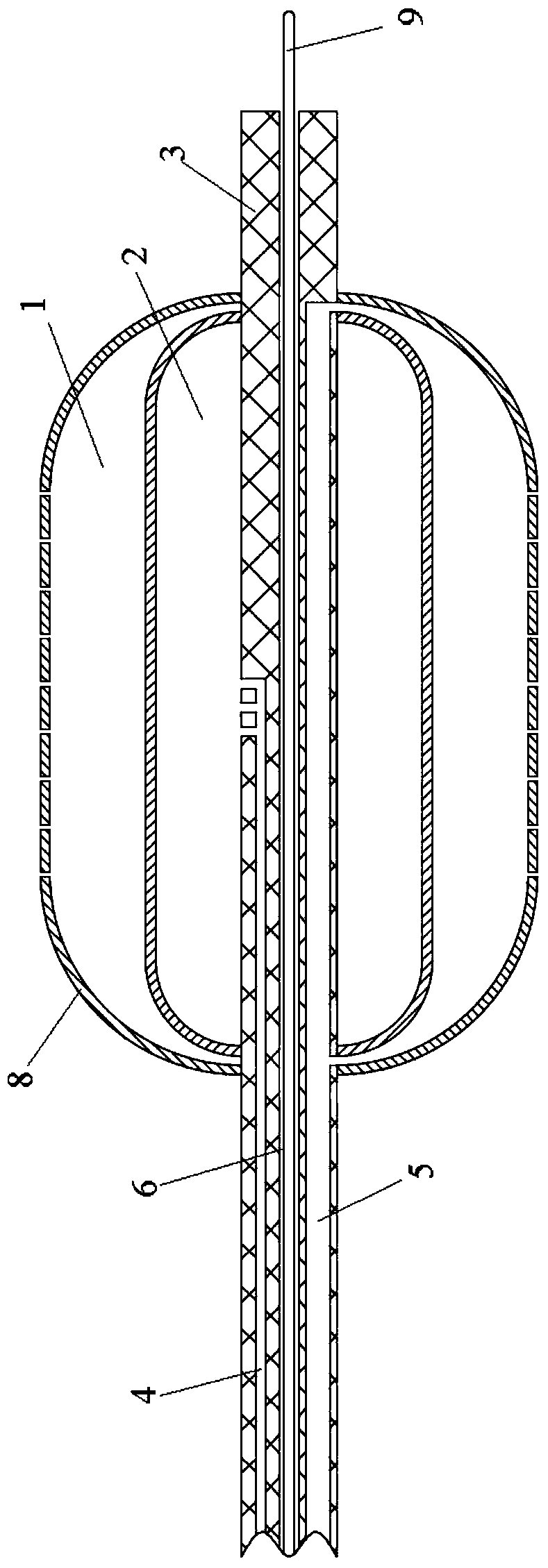

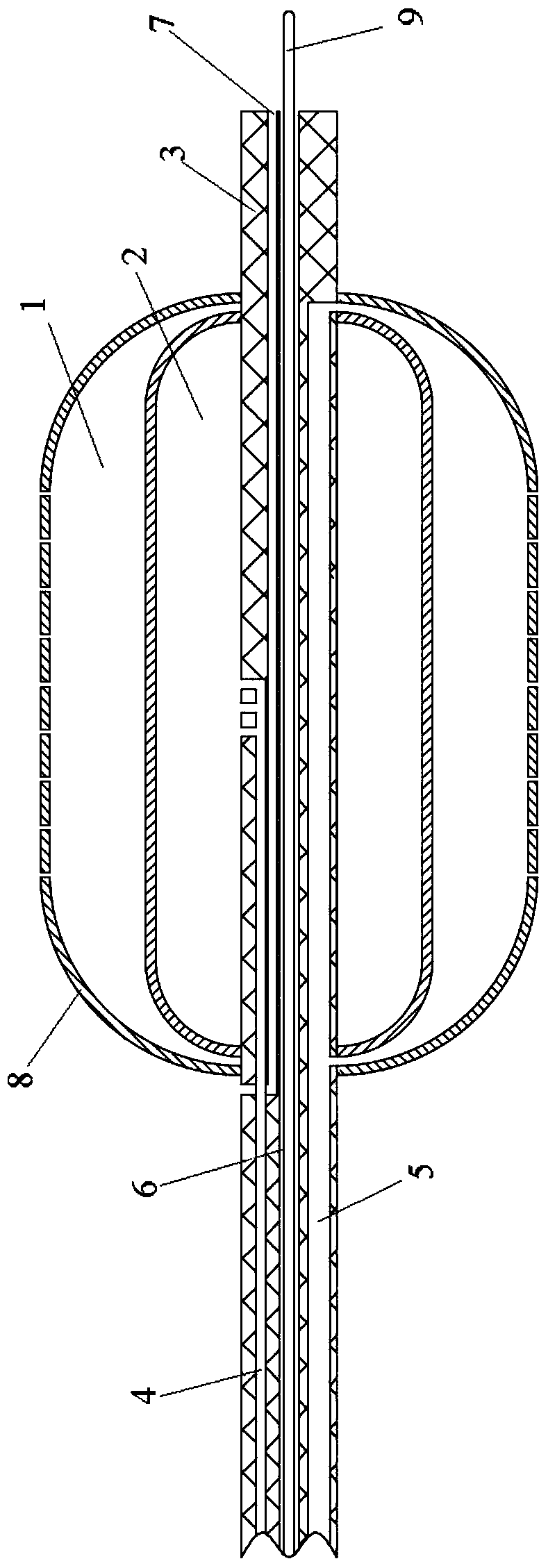

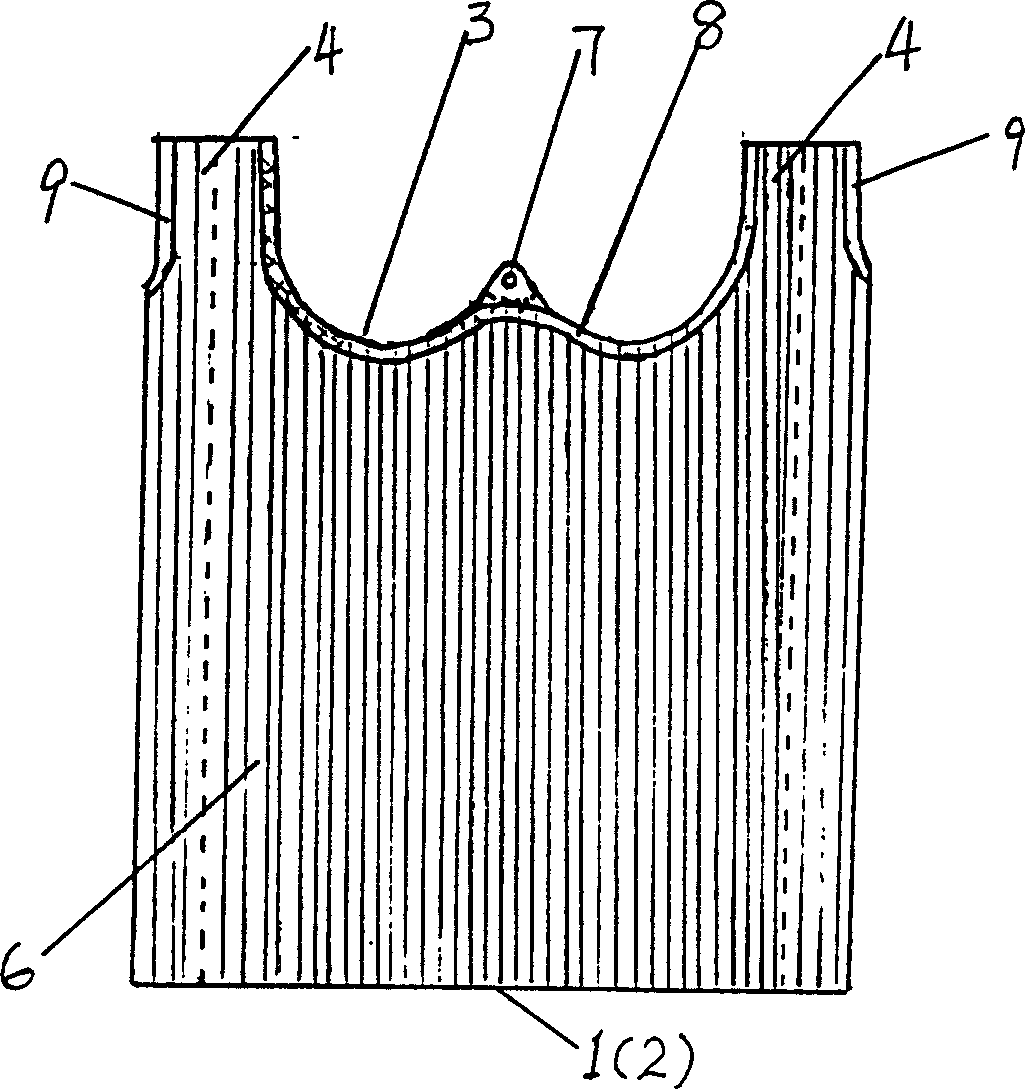

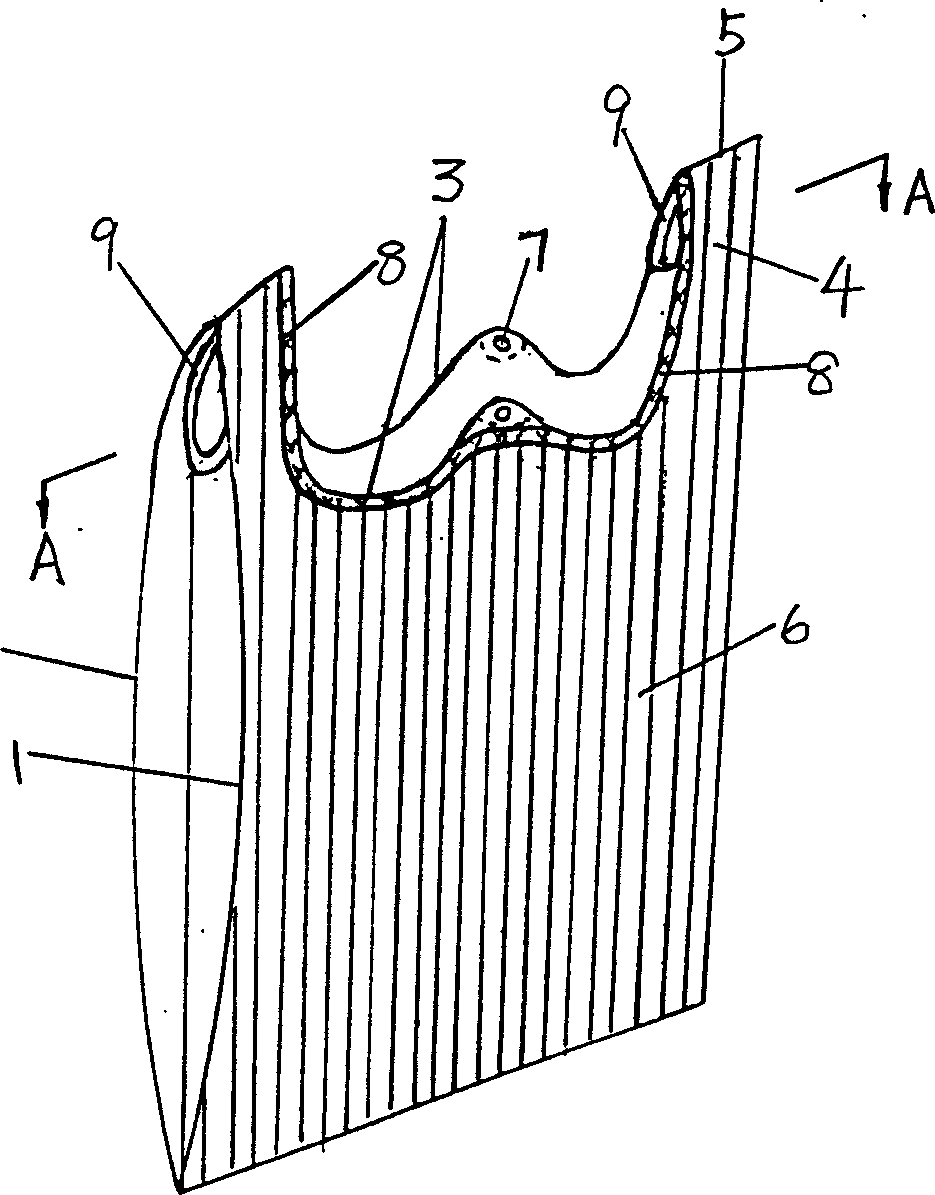

Instantaneously molded intravascular stent system

InactiveCN108703826AGood immediate blocking effectReduce foulingStentsBalloon catheterTransport systemPercent Diameter Stenosis

The invention relates to an instantaneously molded intravascular stent system. The instantaneously molded intravascular stent system comprises a sacculus system, a transport system and a drug stent system; the sacculus system comprises a mother sacculus and a child sacculus, the child sacculus is arranged in the mother sacculus, and an axis of the child sacculus is collinear with an axis of the mother sacculus; the periphery of the surface of the mother sacculus is provided with micropores distributed uniformly, and each micropore is an unidirectional via hole; the transport system comprises acatheter, and the catheter comprises a first channel, a second channel and a guidewire channel; the drug stent system comprises temperature sensibility degradable liquid substances, and the temperature sensibility degradable liquid substances form a drug stent on the outer side of the mother sacculus. The instantaneously molded intravascular stent system has the advantages that the disadvantage of stent meshes without therapeutic drug is eliminated, the local drug loading concentration of a vascular wall is low and even, endothelialization delay caused by high local drug loading concentrationcan be reduced, and the instability of the curative effect caused by uneven local drug concentration is reduced; and the degradable characteristic is suitable for treating a patient with recurrent restenosis.

Owner:AFFILIATED HUSN HOSPITAL OF FUDAN UNIV

Environmental-protection bag of paper

InactiveCN1528644ASolve the load-bearing problemFix the tearBagsSacksEnvironmental resistanceEngineering

The invention is a papery environmental protection bag, composed of front piece and back piece, their bottoms and two sides mutually button and then are linked by heat rolling or sticking, their tops have unconnected bag mouths, there are two carrying pieces on two sides of the bag mouth, respectively, the tops of the carrying pieces in the opposite position of the front and back pieces mutually button and are linked by heat rolling or sticking to form a carrier, and the bag mouth is linked with the carrier in an arc transition, and its character is that there is a component force tearproof strip. The front and back pieces both have bearing component force impresses. It has characters of prevent the bag mouth from being torn, no pollution and environmental protection, able to be used as packaging bag in supermarket and marketplace to replace the plastic bag.

Owner:杜斌

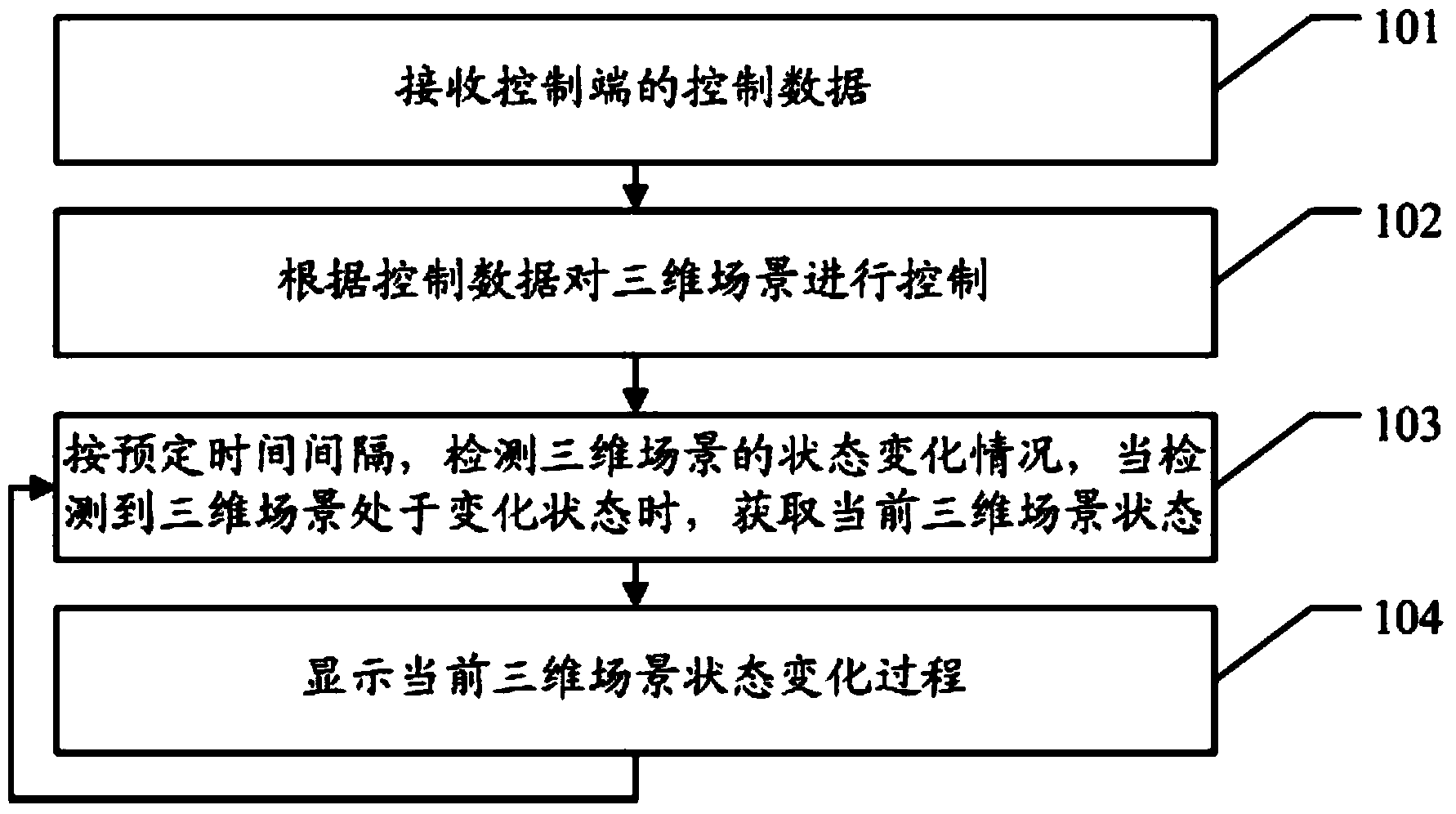

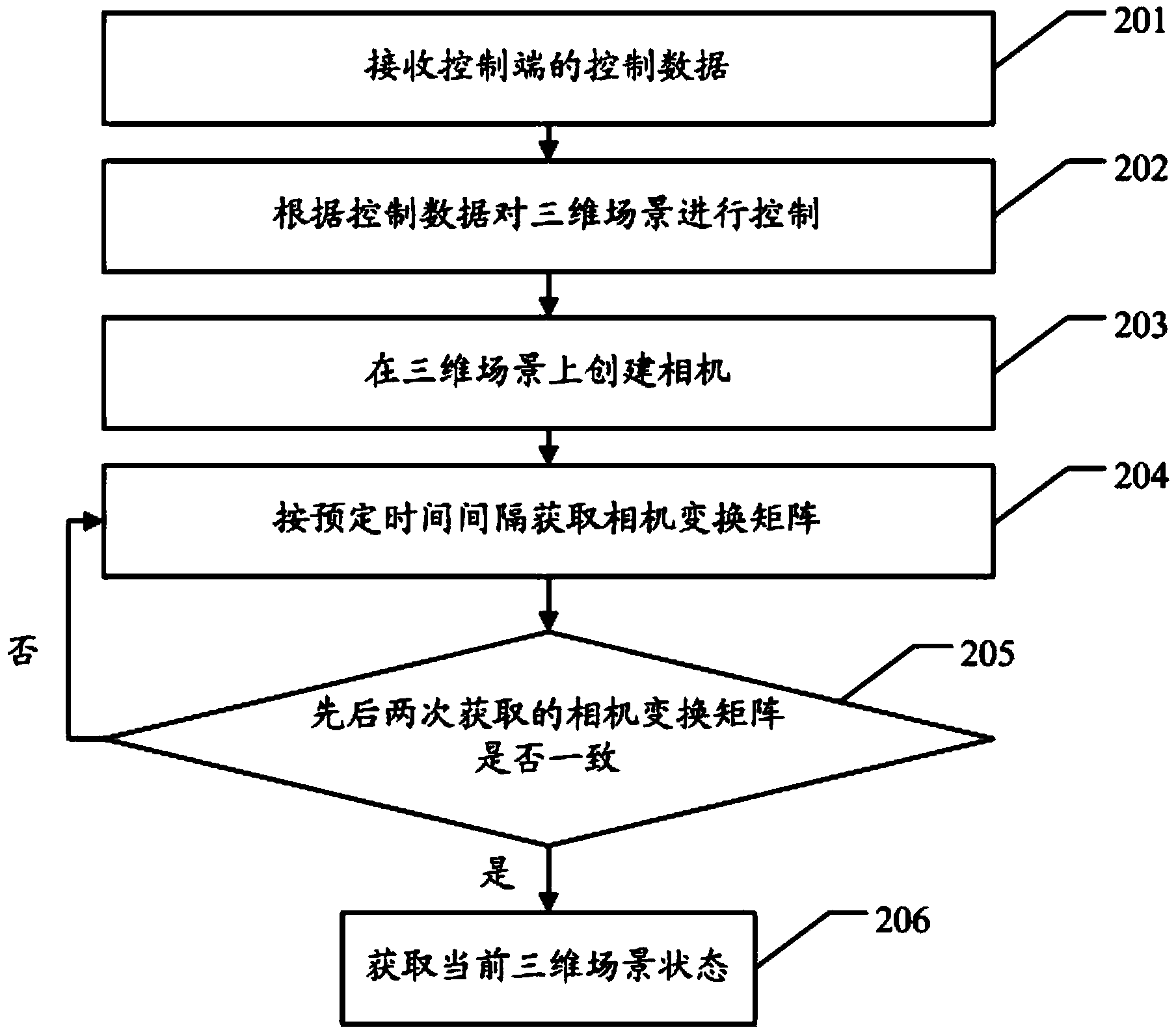

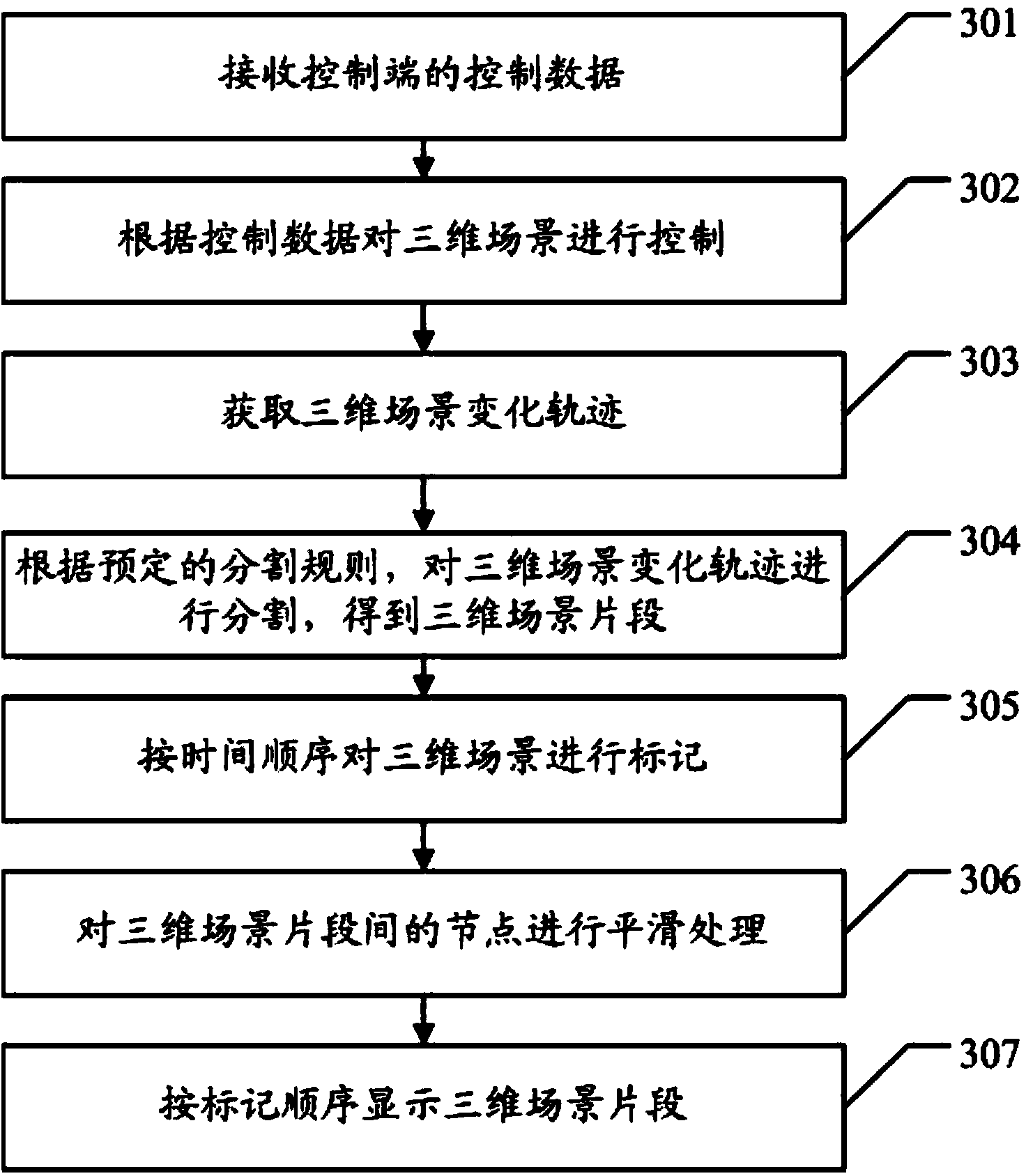

Roaming synchronous display method and device for three-dimensional scene

InactiveCN103473808AReduce data volumeFix screen tearingDigital output to display device3D modellingScreen tearingControl data

The invention discloses a roaming synchronous display method and device for a three-dimensional scene. The roaming synchronous display method and device for the three-dimensional scene can effectively carry out synchronous display on the three-dimensional scene in the roaming process of the three-dimensional scene. The method comprises the steps of carrying out control over the three-dimensional scene according to control data after receiving the control data from a control terminal, detecting the state changing conditions of the three-dimensional scene based on preset time intervals, obtaining the current state of the three-dimensional scene when the three-dimensional scene is detected to be in a changing state, and then displaying the current state changing process of the three-dimensional scene. According to the method, the state changing conditions of the three-dimensional scene are detected in real time, and the current state of the three-dimensional scene is obtained when the three-dimensional scene is detected to be in the changing state; the current state changing process of the three-dimensional scene is then displayed, so that the data size processed by a display unit at each time interval is reduced, the synchronous display is effectively carried out on the changing process of the three-dimensional scene, and the problem of tearing of pictures is solved.

Owner:GUANGDONG VTRON TECH CO LTD

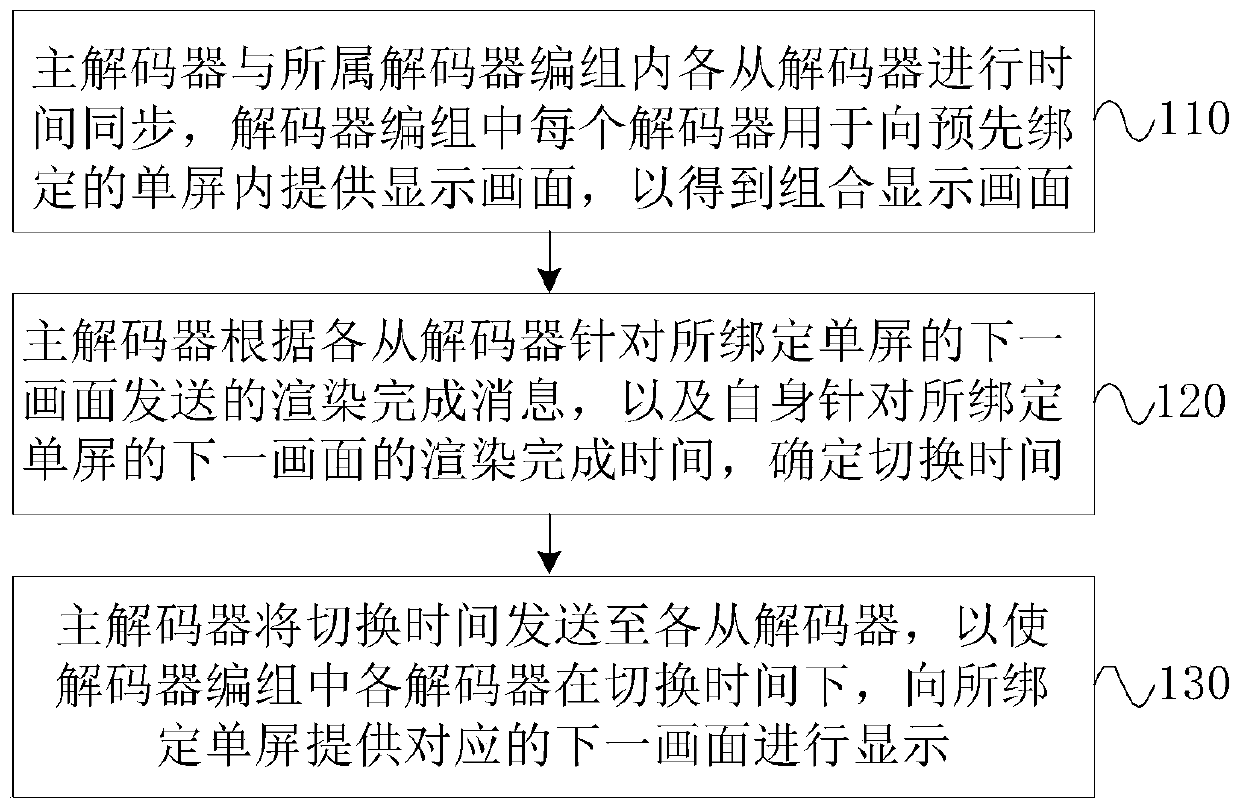

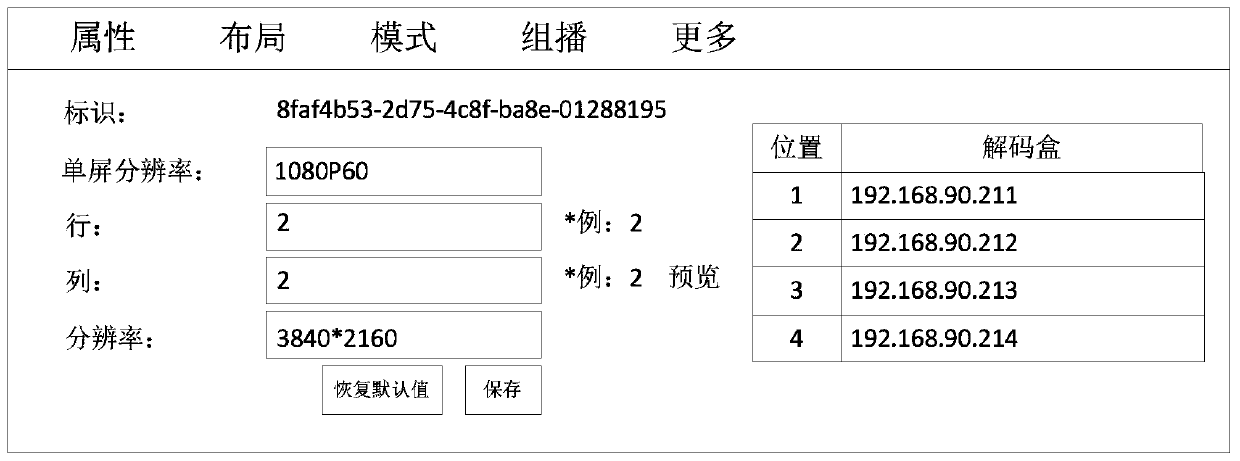

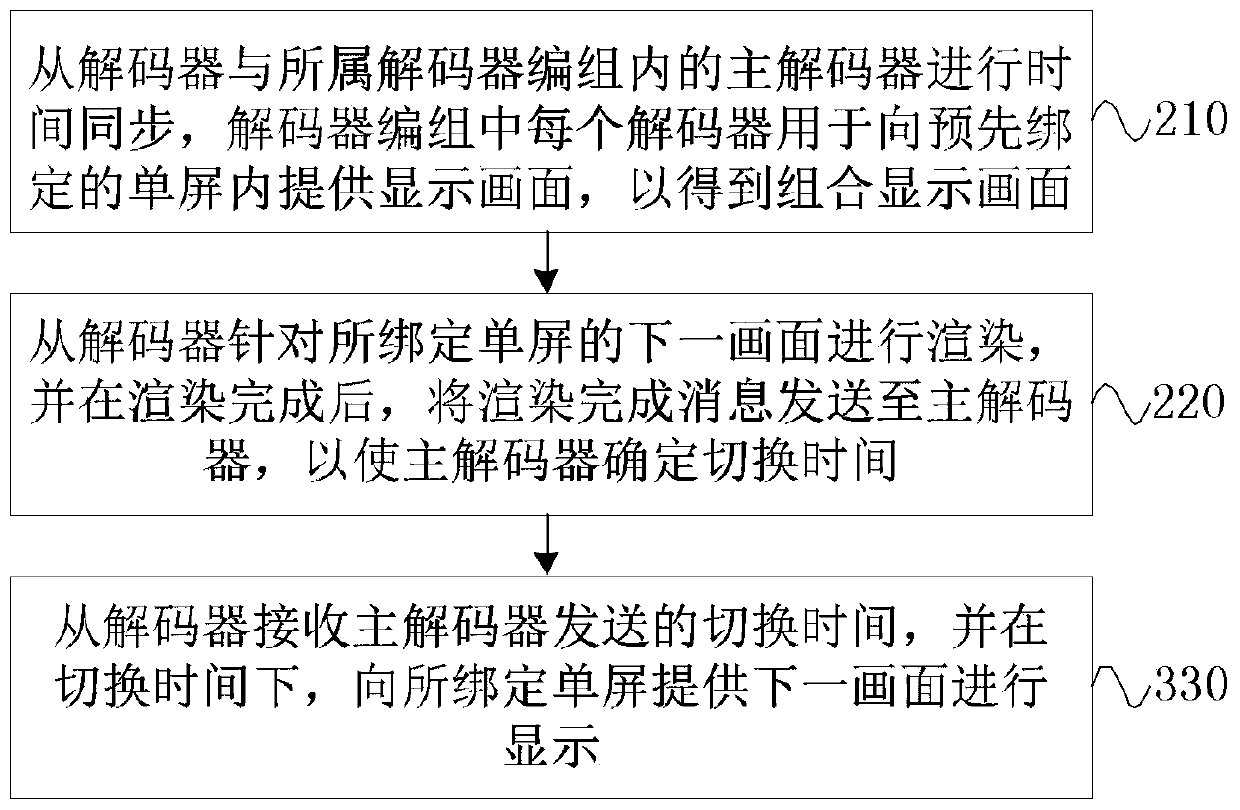

Multi-channel decoder synchronous control method and device, and storage medium

ActiveCN111031194AFix screen tearingScreen display is smoothTelevision system detailsColor television detailsScreen tearingVideo streaming

The embodiment of the invention discloses a multi-channel decoder synchronous control method and device and a storage medium. The method comprises the steps that a master decoder and slave decoders ina decoder group to which the master decoder belongs perform time synchronization; the master decoder determines switching time according to rendering completion messages sent by the slave decoders for a next picture of a bound single screen and rendering completion time of the master decoder for the next picture of the bound single screen; and the master decoder sends the switching time to each slave decoder, so that each decoder in the decoder group provides a corresponding next picture for the bound single screen for display at the switching time. According to the technical scheme of the embodiment of the invention, the time synchronization operation is carried out on the decoders contained in the decoder group, so the problem of picture tearing caused by desynchrony of a plurality of video streams output from the decoders to the television wall is solved, and the television wall formed by a plurality of single screens can carry out smooth picture display.

Owner:KYLAND TECH CO LTD +1

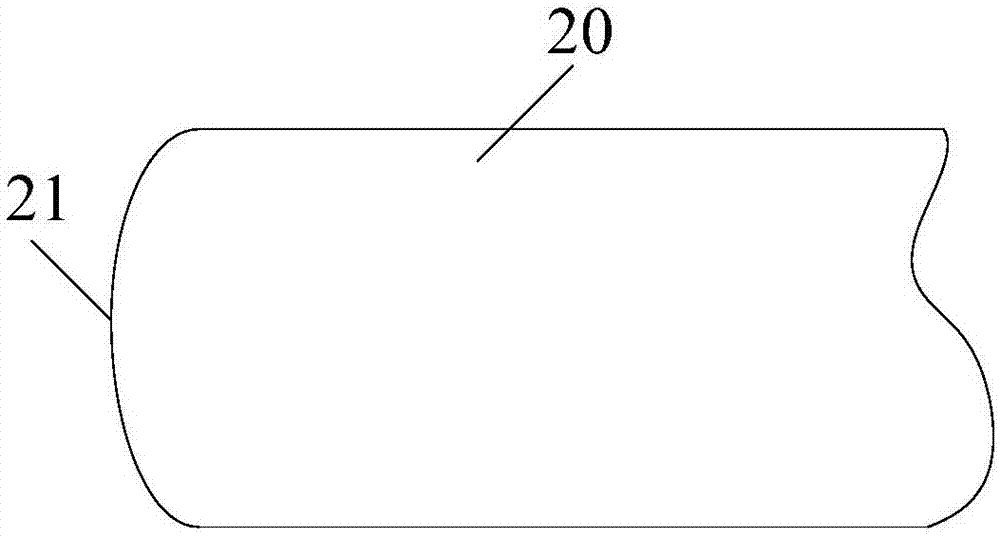

Oil chamber for oil cooler

InactiveCN104457383AAvoid sharp cornersFix the tearHeat exchanger casingsHigh intensityMaximum pressure

The invention provides an oil chamber for an oil cooler. The oil chamber comprises an oil chamber body which comprises an oil chamber upper portion and an oil chamber lower portion, the oil chamber lower portion is circular-arc-shaped and is parallelly provided with assembly grooves axially, the assembly grooves are matched with one ends of heat radiating pipes of the oil cooler, and interval and size of the assembly grooves are set according to those of the heat radiating pipes. The lower portion, needing to bearing maximum pressure, of the oil chamber body is arranged to be circular-arc-shaped and integrally formed with the oil chamber body, so that welding of the heat radiating pipes is enabled to be easier. The oil chamber is simple in structure and convenient to assemble and replace, a joint and the oil chamber body are avoided forming sharp corners, the problem of tearing of positions where the oil chamber is welded with the heat radiating pipes due to the fact that the oil chamber deforms during high-intensity running of the oil cooler is solved, and durability of the oil cooler is improved.

Owner:CHONGQING TOKYO RADIATOR

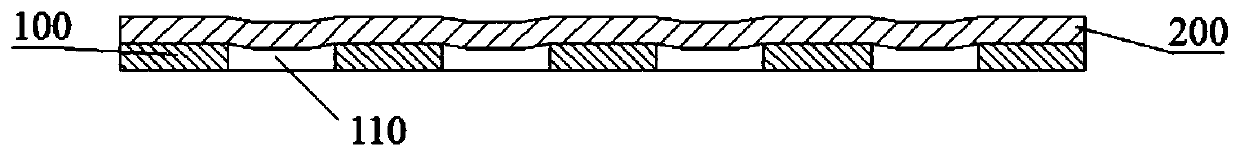

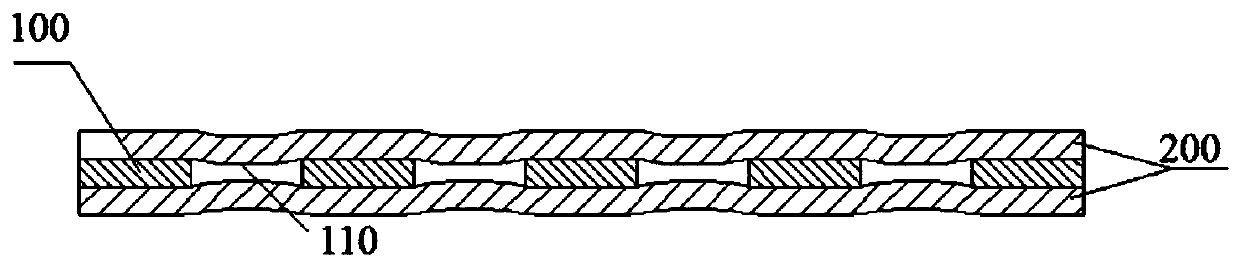

Composite solder and preparation method and application thereof

ActiveCN111468857AHigh strengthImprove shear resistanceWelding/cutting media/materialsSoldering mediaComposite solderComposite material

The invention provides a composite solder and a preparation method and application of the composite solder, and relates to the technical field of welding. The composite solder comprises a stress buffer layer and a solder layer, wherein a through hole is formed in the stress buffer layer, and the solder layer is arranged on at least one surface of the stress buffer layer. The through hole in the stress buffer layer of the composite solder can play a role of slowly releasing stress, so that the composite solder has good anti-shearing performance, bending resistance, stamping resistance and the like, and the preparation of a large-area complex-shape preformed solder is facilitated.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD +1

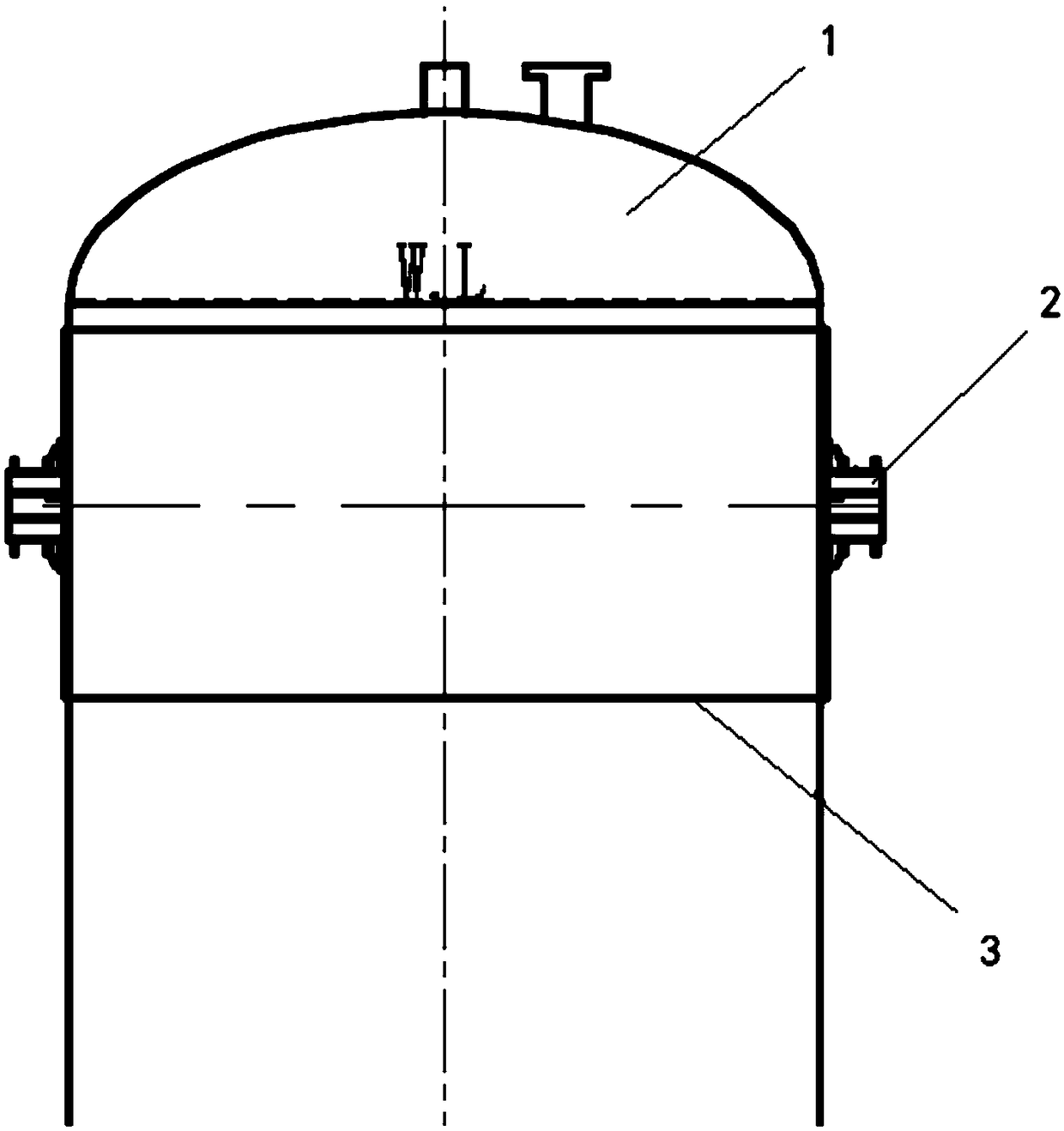

Thin-walled equipment lifting lug reinforcing method

InactiveCN109079377ANo effect on operationOperational impactWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses a thin-walled equipment lifting lug reinforcing method, and aims at reinforcing connection strength between to-be-lifted equipment and lifting lugs and ensuring that cylinder walls of the to-be-lifted equipment do not deform. The method comprises the following steps: (1) determining whether a body diameter and a body wall thickness of to-be-lifted equipment satisfy a lifting lug design requirement or not, or determining whether the body wall thickness of the to-be-lifted equipment satisfies lifting lug design requirement or not through local stress verification, and ifthe determining result is negative, determining the to-be-lifted equipment as thin-walled equipment; (2) adding a stiffening ring cylinder on a cylinder wall, at a position for mounting a lifting lug,of the to-be-lifted equipment; (3) setting circumferential welds at the upper and lower ends, making contact with the cylinder wall of the to-be-lifted equipment, of the stiffening ring cylinder; (4)adding a plug welding hole between the stiffening ring cylinder and the cylinder wall of the to-be-lifted equipment, so as to ensure that the stiffening ring cylinder is tightly combined with the cylinder wall of the to-be-lifted equipment; (5) welding a lifting lug base plate and the lifting lug on the stiffening ring cylinder in sequence, and welding a rib plate between the lifting lug and thestiffening ring cylinder.

Owner:中石化重型起重运输工程有限责任公司 +1

Anti-tearing loading wheel rubber tire

ActiveCN106184443AFix the tearExtended service lifePneumatic tyre reinforcementsEndless track vehiclesSurface layerEngineering

The patent of the invention relates to an anti-tearing loading wheel rubber tire and solves the problem that the existing pure rubber tire structure is torn due to external force damage during use. The anti-tearing loading wheel rubber tire is formed through integrally sulfurating outer-layer rubber, inner-layer rubber, steel wire cord fabric, support rings and a connection piece. The outer-layer rubber is U-shaped and envelops a loading wheel basal body, the inner-layer rubber is positioned in the groove formed in the outer-layer rubber, the support rings and the steel wire cord fabric are arranged in the outer-layer rubber, the support rings are positioned at the feet of the both sides of the outer-layer rubber and are close to the loading wheel basal body, the steel wire cord fabric is sulfurated into the outer-layer rubber along the profile of the outer-layer rubber, the lower part of the steel wire cord fabric is wound on the support rings and then extends into the inner-layer rubber, and the two ends of the steel wire cord fabric are connected together through the connection piece. According to the anti-tearing loading wheel rubber tire, the problems of damage caused by insufficient bonding strength of the multiple layers of rubber, and piercing and tearing of surface-layer rubber in contact with a crawler belt are effectively avoided, the service life of the loading wheel in the whole is effectively prolonged, and the reliability of the loading wheel in the whole is effectively improved.

Owner:INNER MONGOLIA FIRST MACHINERY GRP +1

Double-direction precise hydraulic bar shearing machine and shearing method thereof

ActiveCN105345123ASolve the problem of thermal shear power consumptionSolve wasteShearing machinesStress concentrationBar stock

The invention provides a double-direction precise hydraulic bar shearing machine and a shearing method of the machine. At the beginning of shearing, a moon arc notch is cut in the radial left side of a bar, a gap is cut in the hard layer of the radial surface, stress concentration and slight bar lattice slippage are generated, a shear switch issues an order to an oil cylinder immediately, the motion direction is reversed to the leftward movement, a rear cutter shears off the bar along the gap, and for example, when low-carbon steel is shorn, the radial pressure skewness is small, and burrs are few; and if high-carbon alloy steel is shorn, the center portion cannot be torn off. The double-direction precise hydraulic bar shearing machine comprises a sliding block, a front cutter portion, a rear cutter portion, a shear depth adjusting portion and a spring device. The front cutter portion is used for centering and clamping the bar and is mounted on a front lathe, and the front cutter portion comprises a left wedge, a left cutter table, an oil cylinder, a right wedge, a right cutter table, a screw and blades.

Owner:沈阳恒佳忠祥液压设备有限公司

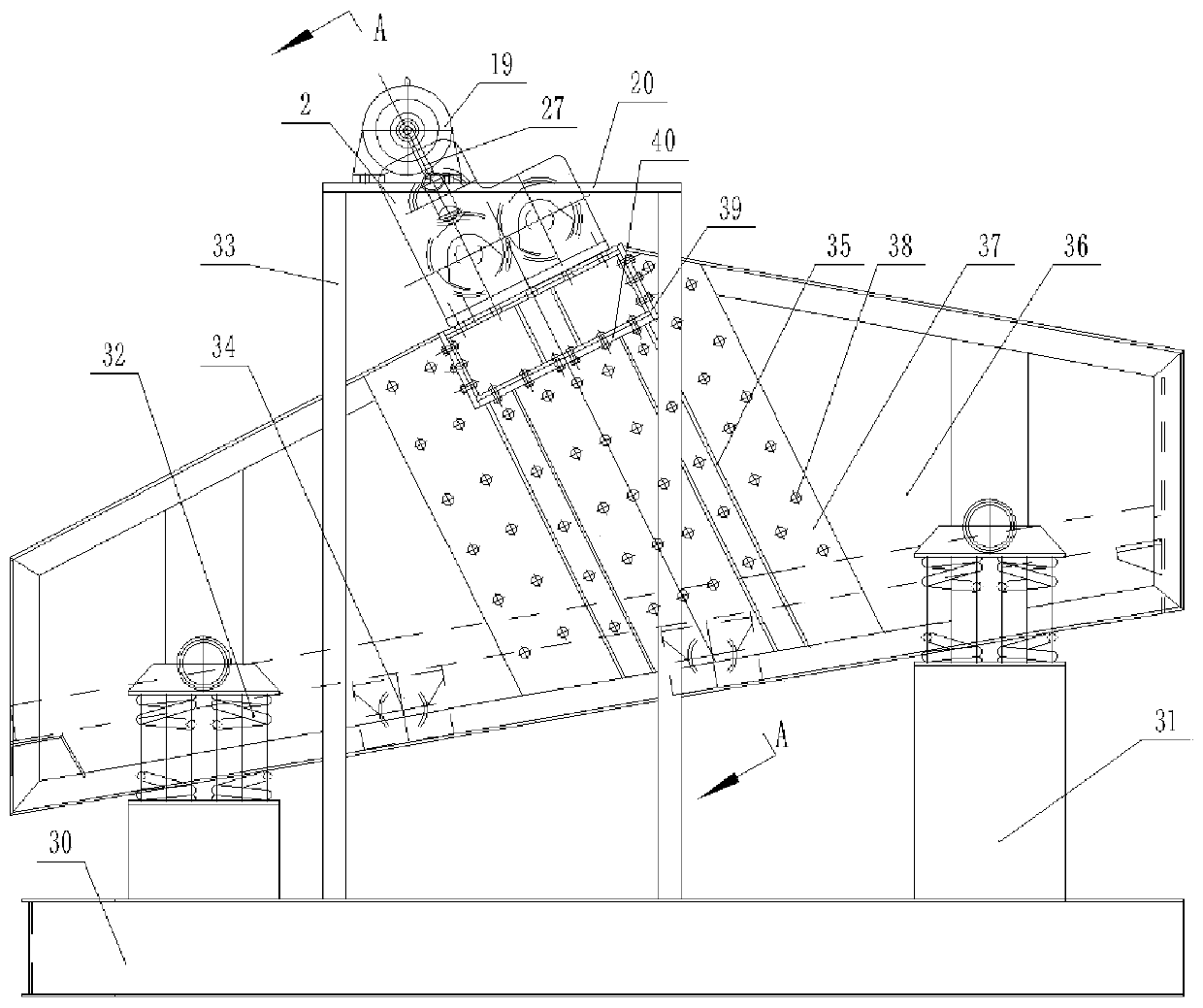

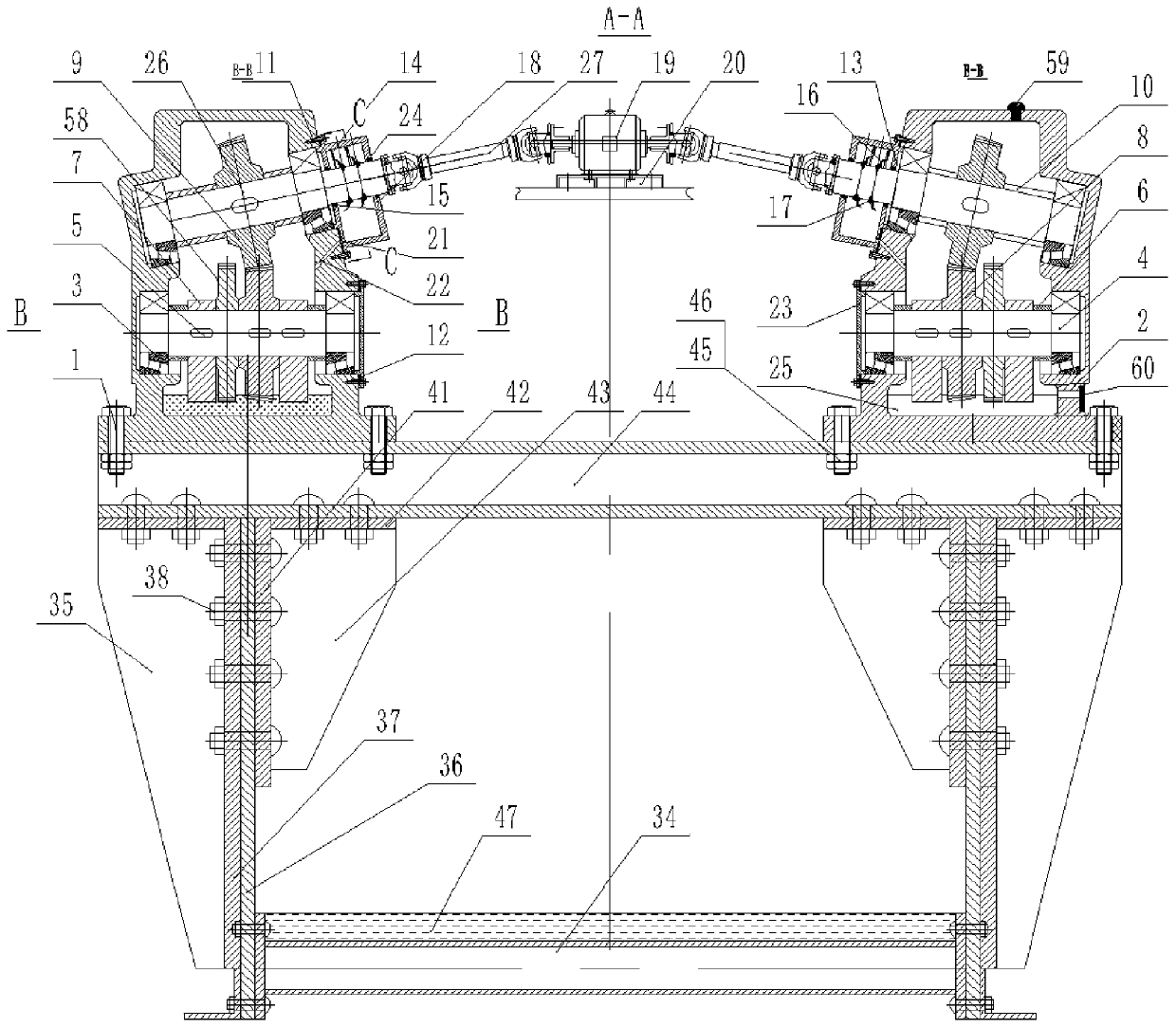

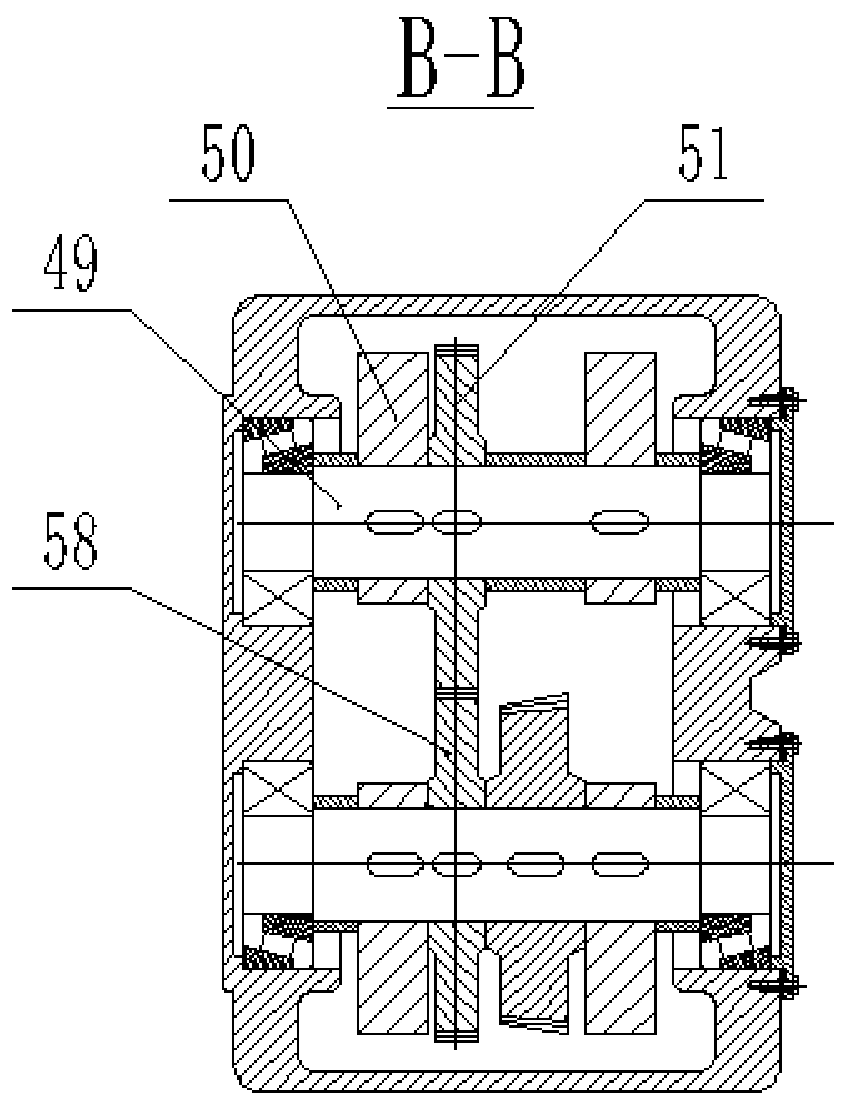

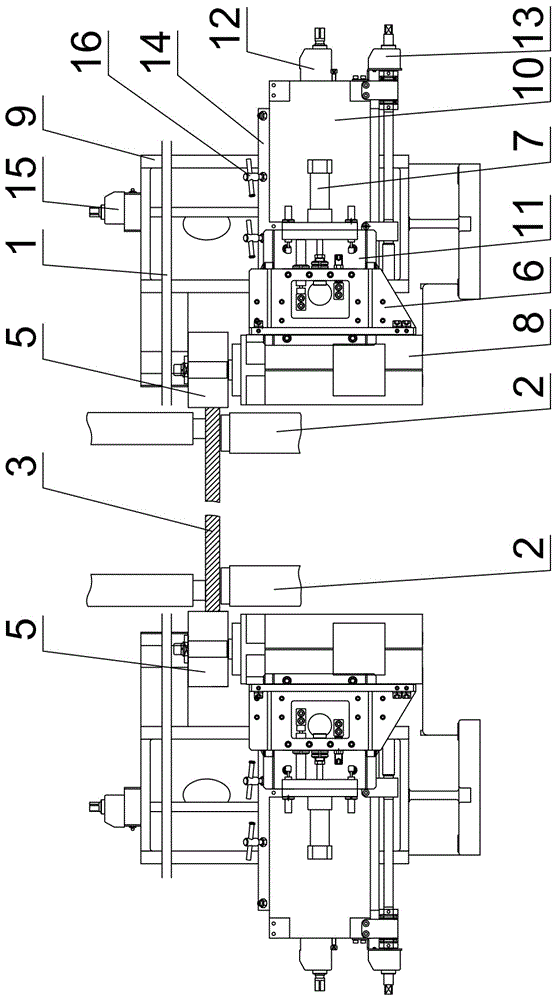

Heavy vibration screening equipment

The invention relates to heavy screening vibration equipment, and belongs to the technical field of material conveying equipment. A vibration excitation motor used in the equipment is a double-output-shaft motor, output shafts at the two ends of the vibration excitation motor are connected with driving shafts installed on vibration exciters on the two sides of a base girder through universal jointcouplings correspondingly, an included angle not smaller than 15 degrees is formed between each driving shaft and the corresponding eccentric shaft, the driving shafts and the eccentric shafts are connected through a pair of bevel gears, the two eccentric shafts are connected through a pair of cylindrical gears, eccentric blocks installed on the two eccentric shafts are the same in structure andsize, and the generated exciting force is superposed in the direction perpendicular to a plane formed by the axes of the two eccentric shafts and counteracted in the parallel direction; and excitationforce generated by each vibration exciter coincides with the center of the corresponding side plate, main rotating components such as gears and bearings are sealed in the vibration exciters, and thethin oil lubrication performance of the vibration exciters is guaranteed. The crack resistance of the side plate is improved, the service life of the vibration exciter is prolonged, and the heavy screening vibration equipment has very remarkable advantages.

Owner:ZHENGZHOU UNIV

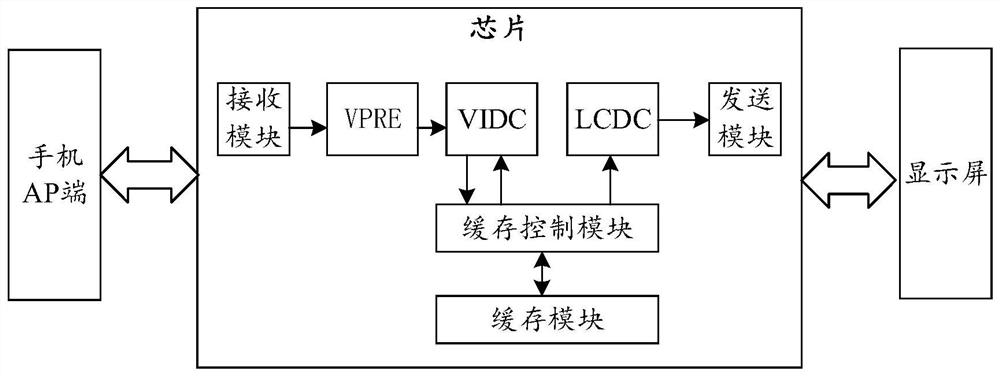

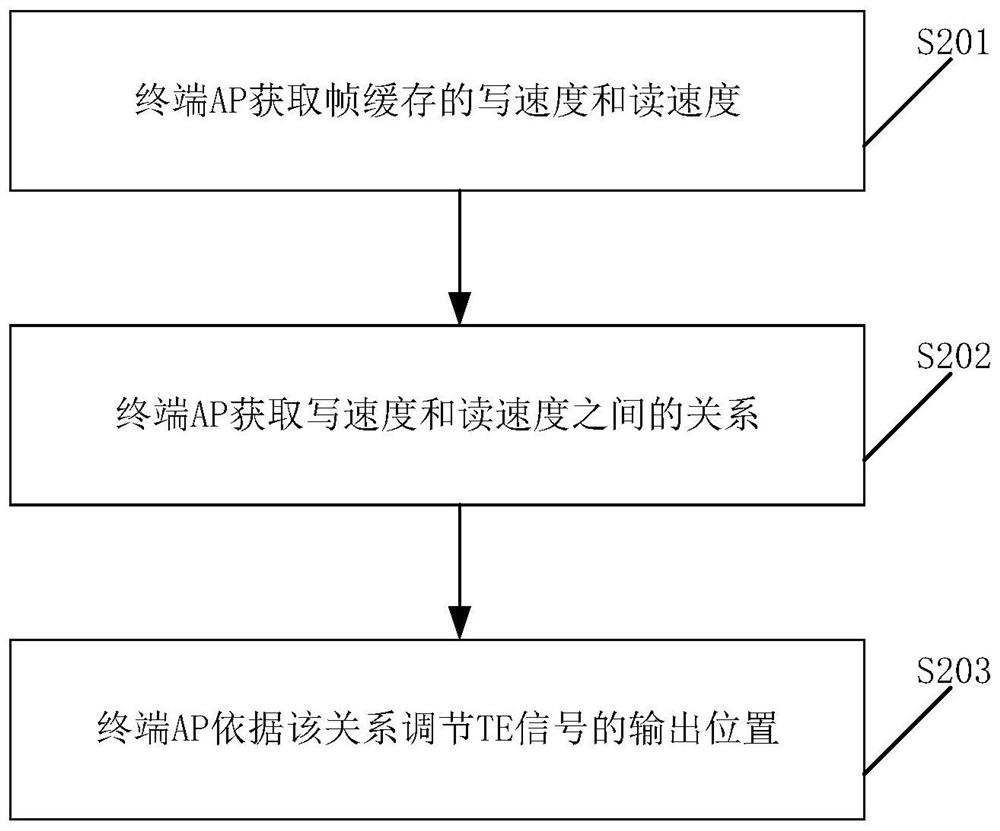

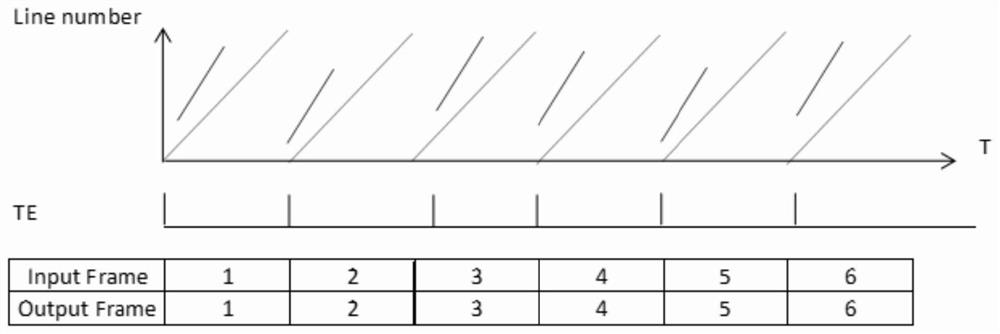

Image frame rate control method and related product

PendingCN114153415AFix the tearTearing does not happenCathode-ray tube indicatorsInput/output processes for data processingImaging qualityControl engineering

The embodiment of the invention provides an image frame rate control method and a related product. The method comprises the following steps that a terminal AP obtains the writing speed and the reading speed of a frame cache; the terminal AP obtains the relation between the writing speed and the reading speed; and the terminal AP adjusts the output position of the TE signal according to the relation. The technical scheme provided by the invention has the advantages of improving the image quality and improving the user experience.

Owner:SHENZHEN XIHUA TECH CO LTD

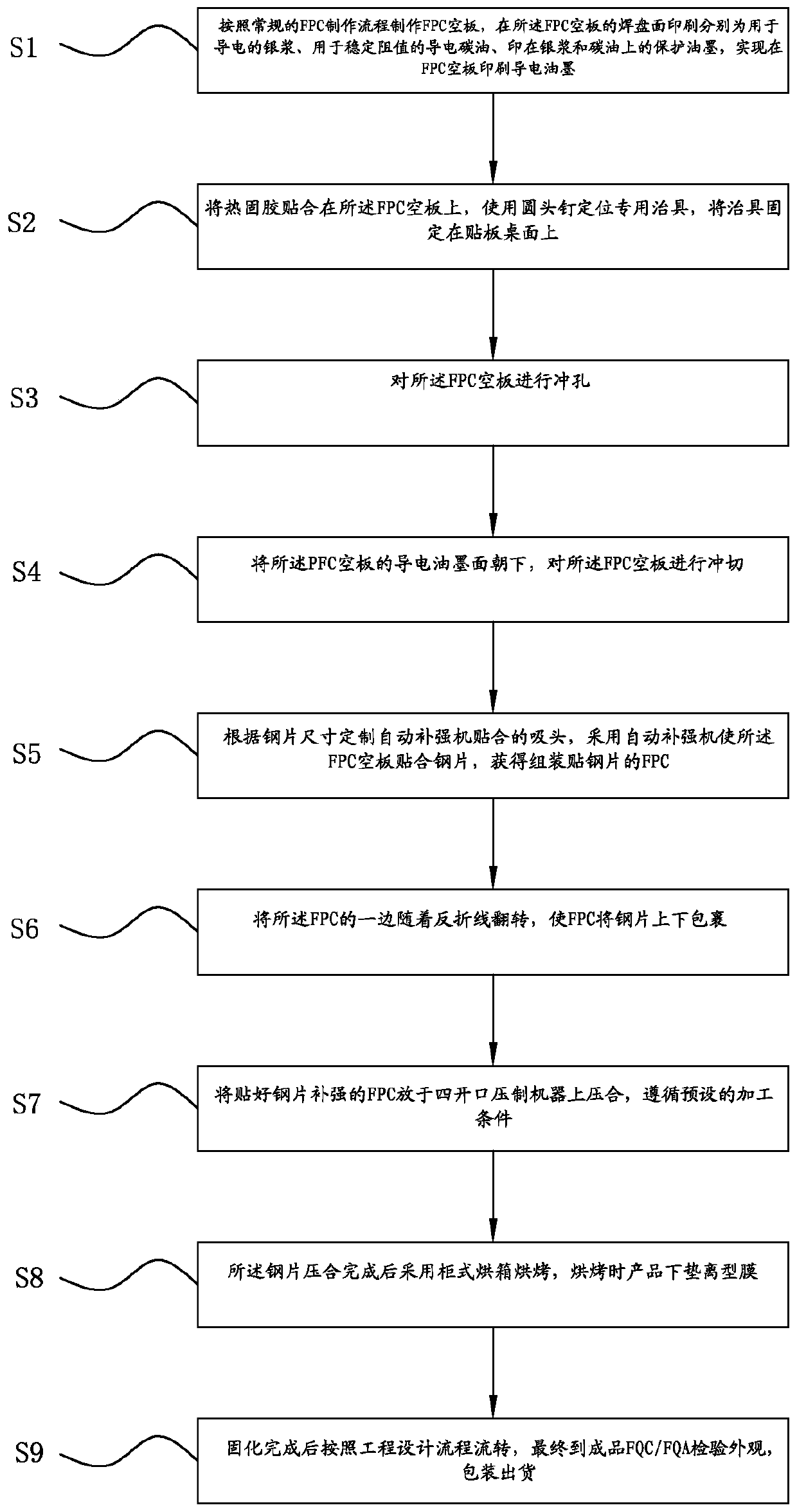

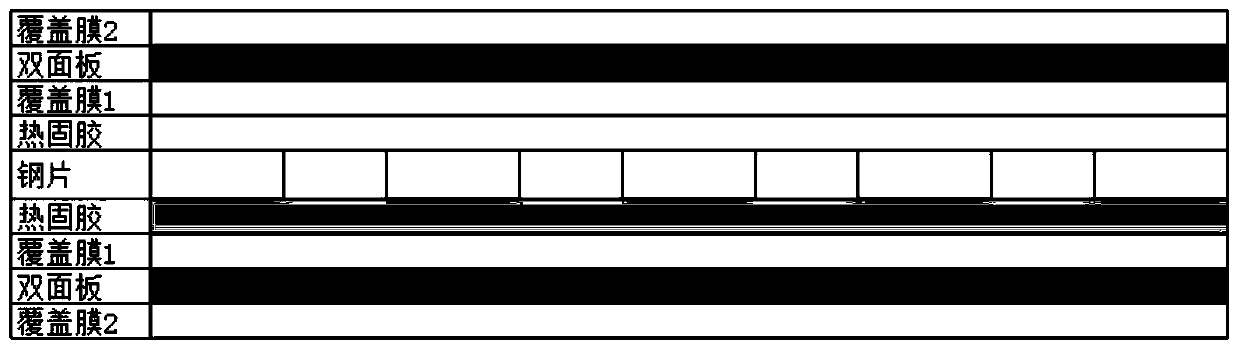

Manufacturing method of novel side key product

ActiveCN111146030AImprove reliabilityPerformance optimization and improvementElectric switchesSilver pastePunching

The invention discloses a manufacturing method for a novel side key product, and the method comprises the following steps: manufacturing an FPC blank board, and printing silver paste, conductive carbon oil and protective ink printed on the silver paste and the carbon oil on a bonding pad surface of the FPC blank board respectively; enabling a thermosetting adhesive to be attached to the FPC blankboard, enabling a special jig to be positioned through round head nails, and enabling the jig to be fixed to a board attaching table top; performing punching; enabling the conductive ink surface of the PFC blank board to face downwards, and punching the FPC blank board; customizing a suction head attached by an automatic reinforcing machine according to the size of the steel sheet, and attaching the FPC blank plate to the steel sheet by adopting the automatic reinforcing machine to obtain an FPC assembled with the attached steel sheet; enabling gone side of the FPC to be turned over along withthe reverse folding line, so that the FPC wraps the steel sheet up and down; putting the FPC pasted with the steel sheet reinforcement on a four-opening pressing machine for pressing, and following apreset processing condition; after the steel sheets are pressed, adopting a cabinet type drying oven for baking, wherein a release film is cushioned under a product during baking; after curing is completed, performing circulation according to the engineering design process, and finally obtaining a finished FQC / FQA; checking the appearance, and performing packaging and shipment.

Owner:SHENZHEN KINWONG ELECTRONICS

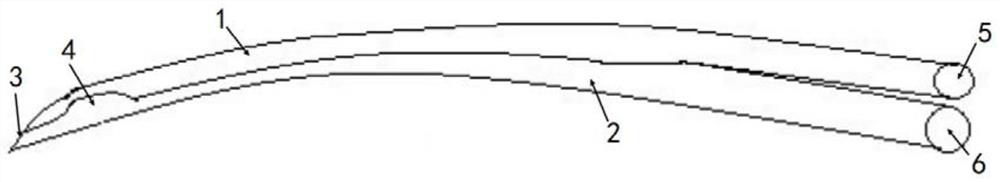

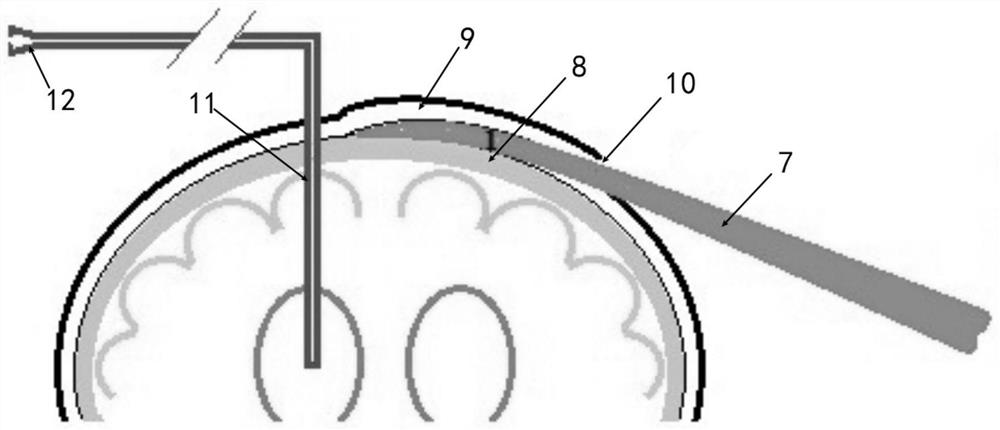

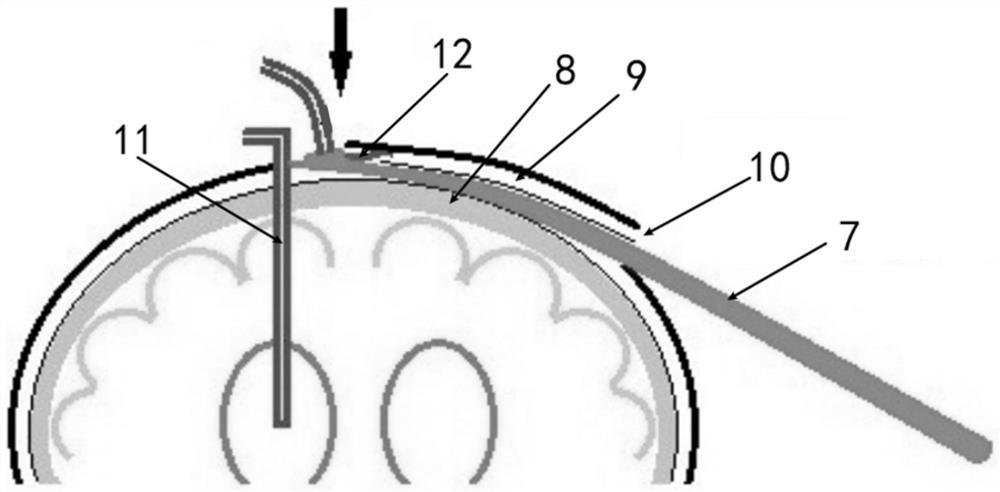

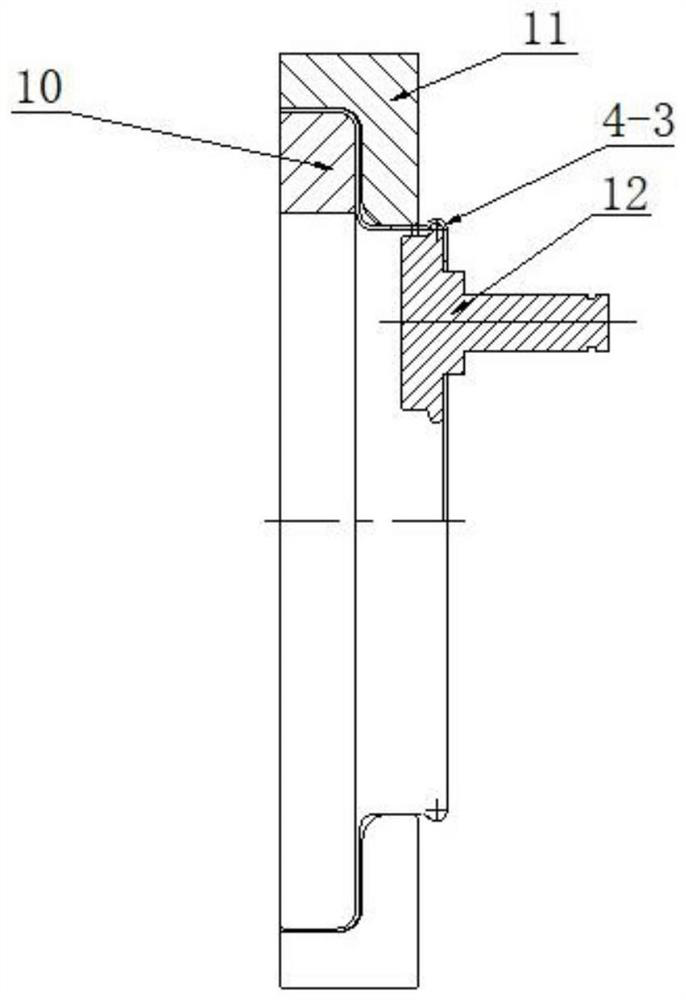

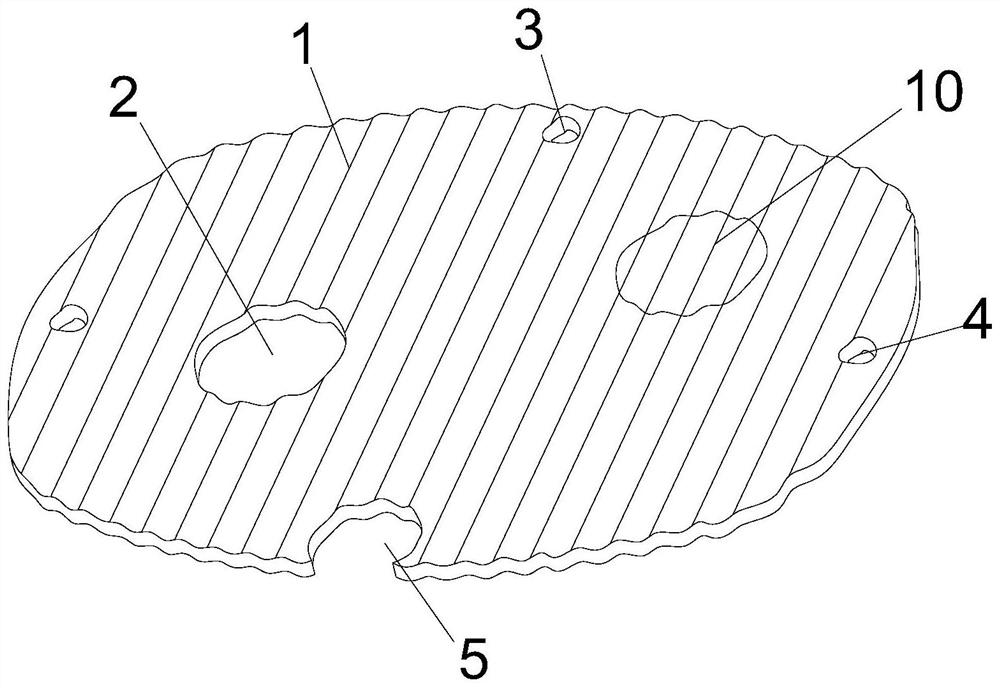

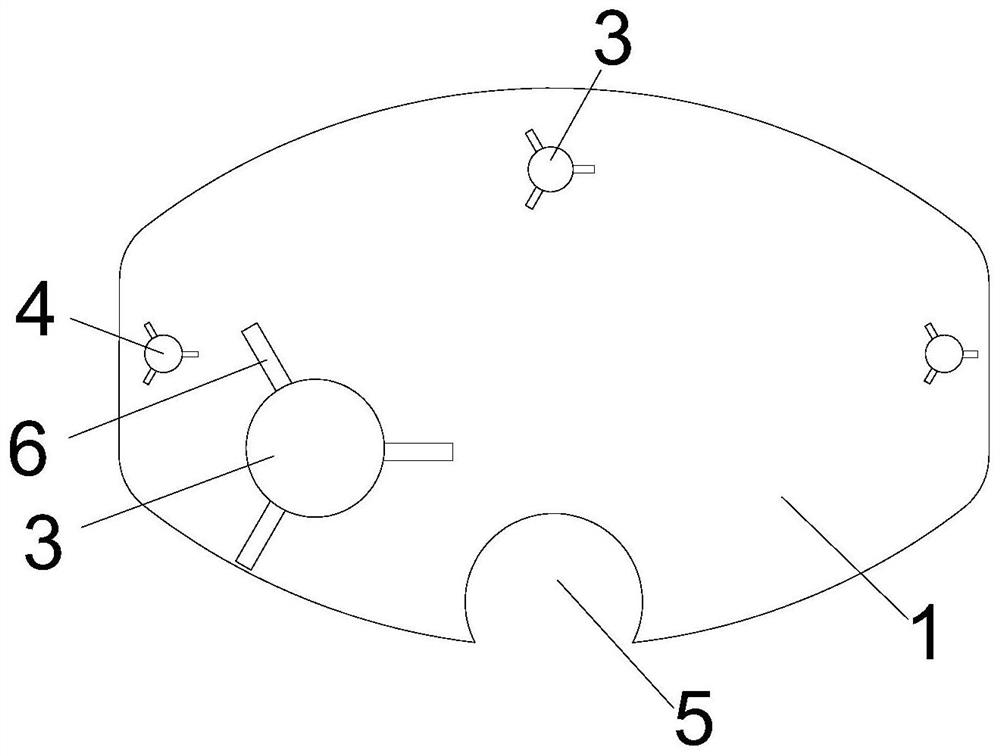

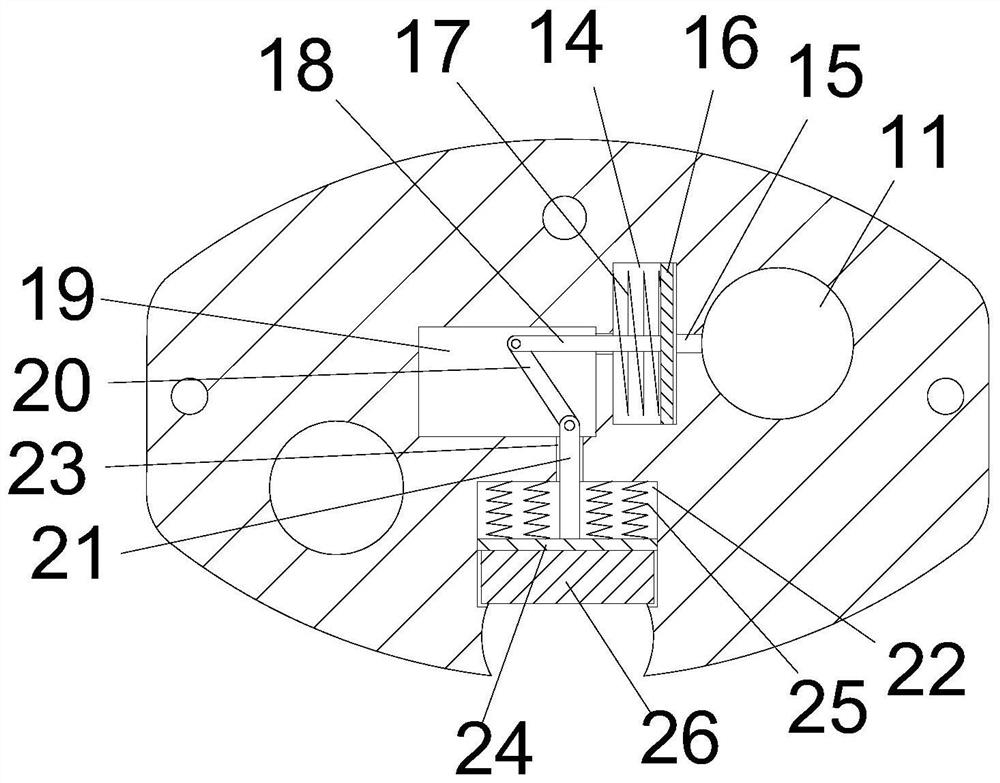

A cranial drainage tube subtly implanted device

ActiveCN111228629BPrevent embeddingReduce resistanceCatheterPhysical medicine and rehabilitationPhysical therapy

The invention discloses a craniocerebral drainage tube submerged implanting device, which comprises an outer cone and a cone core that cooperate with each other, the outer cone is provided with a groove extending from the front end to the middle and rear, the groove and the cone core Cooperate to form a half-wrap structure on the side of the front section of the cone core. The front end of the outer cone and the cone core cooperate together to form a tip. The outer cone is provided with a wing plate on the edge of the groove near the front end. When the cone core withdraws After detaching from the groove, the wing plate is used to cooperate with the enlarged groove with reduced diameter to engage the enlarged end of the drainage tube. When the outer cone is withdrawn, it can effectively and reliably pull the drainage tube back along the subcutaneous tunnel to achieve the purpose of stealth. The tunnel is formed at one time, and the drainage tube sneaking is completed at one time. One end of the semi-wrapped structure formed by the cone core and the outer cone, the size of the incision is similar to the diameter of the submerged tunnel constructed, and the distance and direction of the tunnel can be precisely controlled, avoiding scalp peeling caused by the use of vascular clamps to establish drainage tubes for submersion The problem of not being able to actually create a subcutaneous tunnel.

Owner:济南市传染病医院

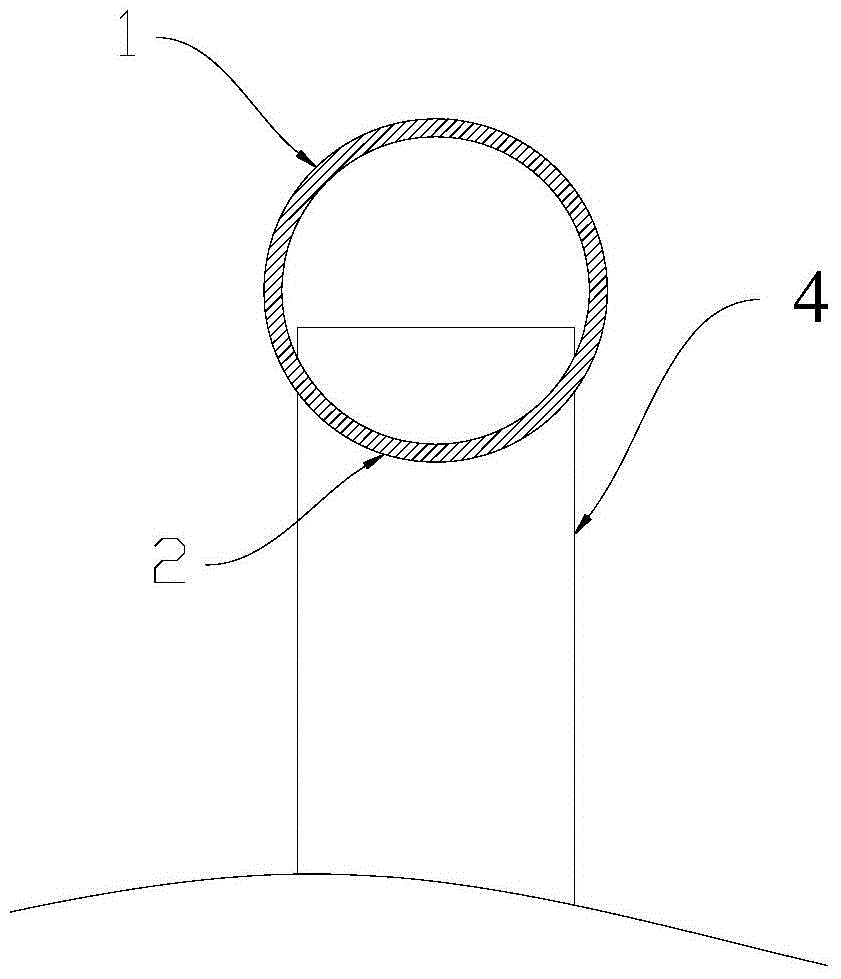

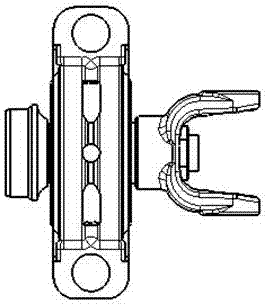

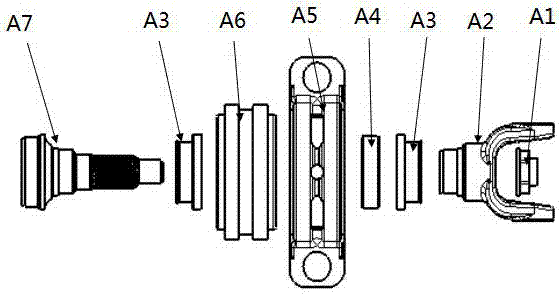

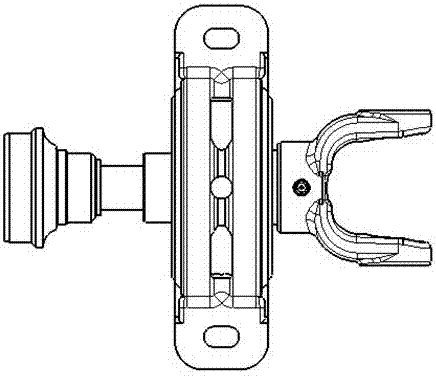

Novel universal joint transmission shaft intermediate support

InactiveCN107461421AFix the tearSolve the pull-off phenomenonClutchesYielding couplingAxial displacementDrive shaft

The invention relates to a novel universal joint transmission shaft intermediate support. The novel universal joint transmission shaft intermediate support comprises a transmission shaft fork, a first sealing ring, a snap spring, a cylindrical roller bearing, an outer framework, an inner framework with a rubber sleeve, a second sealing ring and a spline shaft end. The spline shaft end and a first transmission shaft are welded together. The transmission shaft fork is assembled with a cross shaft and connected with a second transmission shaft. An enough space needs to be reserved for spline fit so that displacement generated by vibration of an engine can be absorbed, the situation that a spline fixedly abuts against the transmission shaft fork and is pulled away from the transmission shaft fork is avoided, and the strength of the spline is taken into account. According to the novel universal joint transmission shaft intermediate support, the transmission shaft fork is fixed, the spline shaft end can slide on the transmission shaft fork in the axial direction, axial displacement caused by vibration of the engine is absorbed, and tearing or pull off phenomenon caused by large rubber sleeve movement amount due to vibration of the engine is avoided. The novel universal joint transmission shaft intermediate support is suitable for the mode that a universal joint transmission shaft is connected with a gearbox through a flange face or a flexible universal joint.

Owner:合肥创智汽车技术开发有限公司

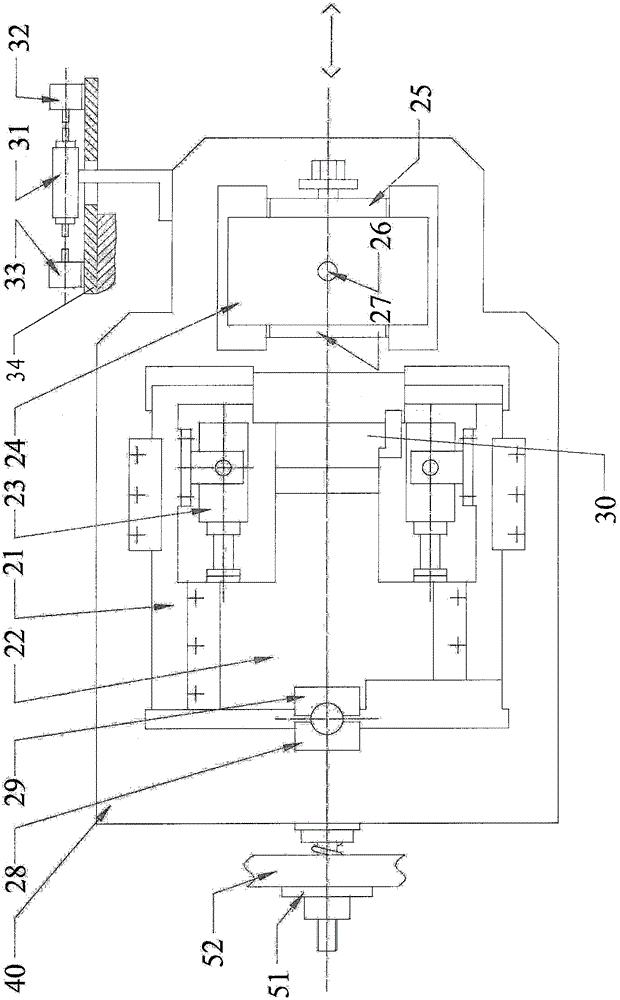

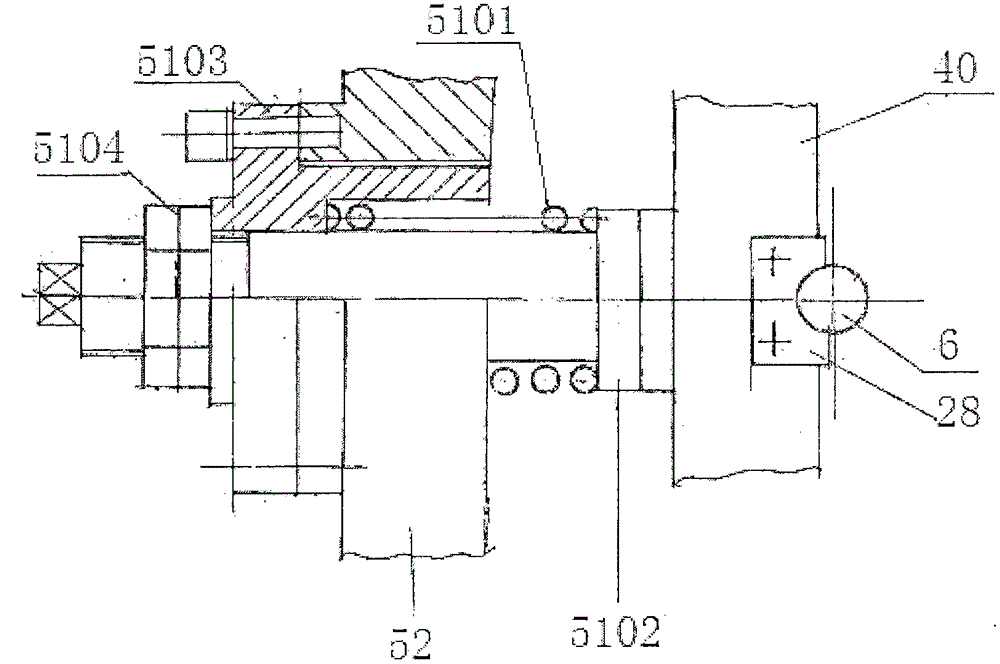

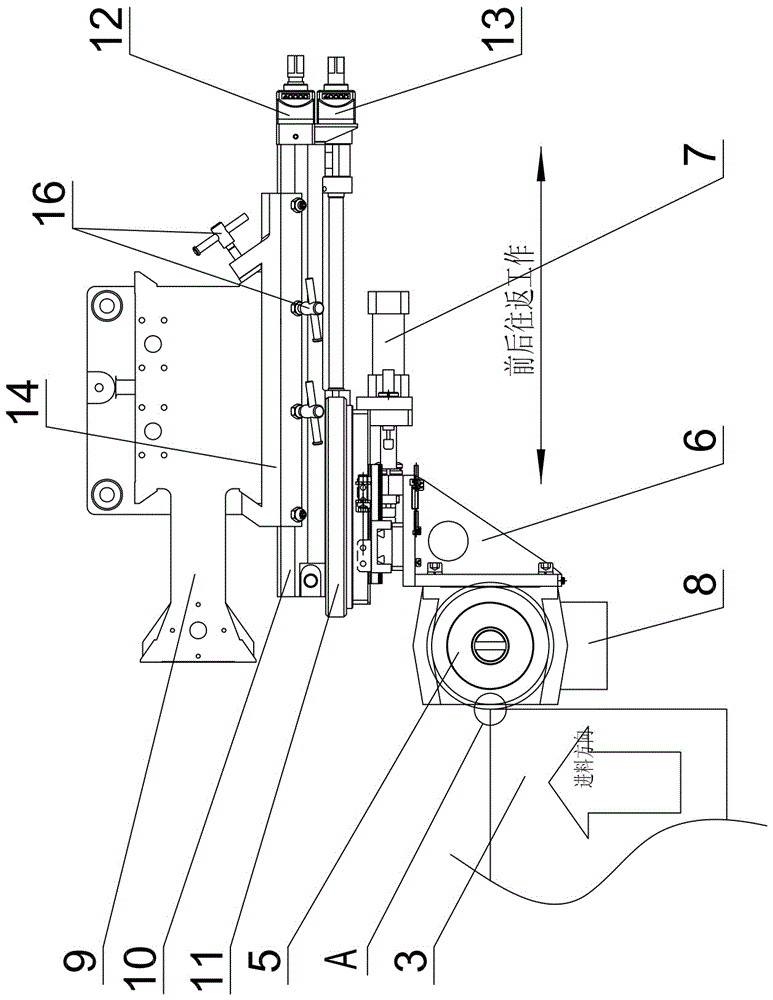

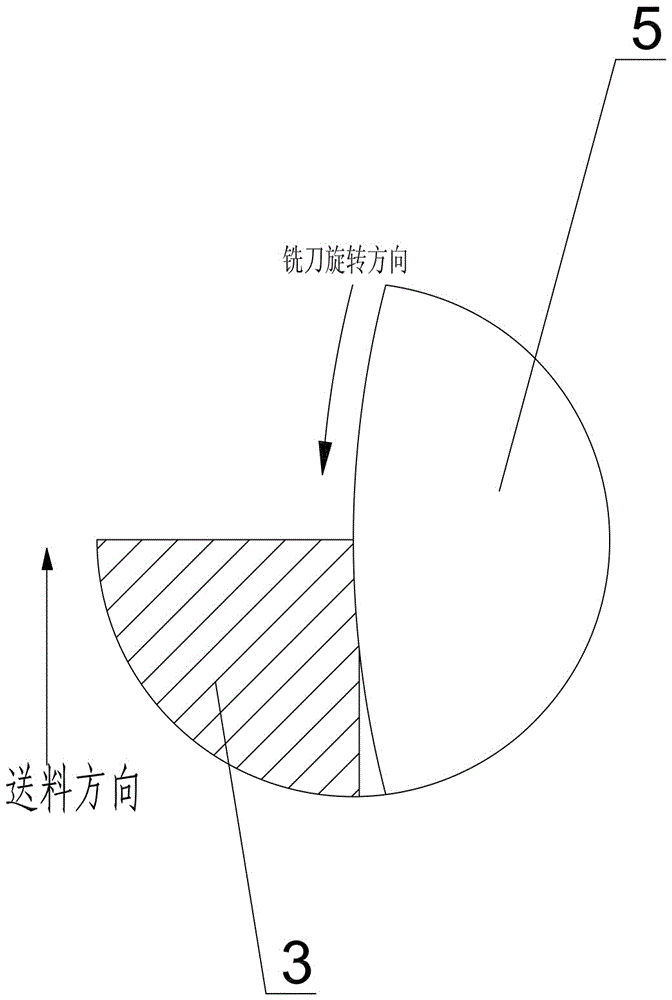

Woodworking double-end milling and skip milling device for ensuring end and corner processing precision of wood materials

ActiveCN105881662AGuaranteed flatnessSolve the collapseProfiling/shaping machinesMilling cutterEngineering

The invention provides a woodworking double-end milling and skip milling device for ensuring the end and corner processing precision of wood materials. The woodworking double-end milling and skip milling device comprises a rack and a material conveying belt, wherein the material conveying belt is mounted at the upper and lower ends of the rack and used for conveying processed wood materials, induction switches and moving type end milling assemblies are arranged on the rack, at least one group of moving type end milling assemblies are symmetrically mounted on the outer side of the material conveying belt, the induction switches are connected with the moving type end milling assemblies and drive the moving type end milling assemblies to move forwards and backwards relative to the rack, and the moving type end milling assemblies are provided with milling cutters rotating oppositely relative to the material conveying direction of the material conveying belt. Through the structural cooperation of the induction switches and the moving type end milling assemblies of the skip milling device, the phenomena of edge breakage, ripping, burring and the like, which possibly occur when the corners of the wood materials are processed are effectively solved, so that automatic operation and high efficiency are realized, the flatness of the processed wood materials can be ensured, and processing quality is ensured.

Owner:REIGNMAC MACHINERY

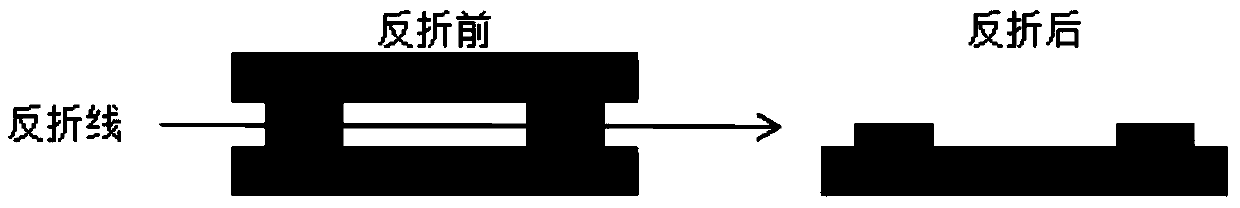

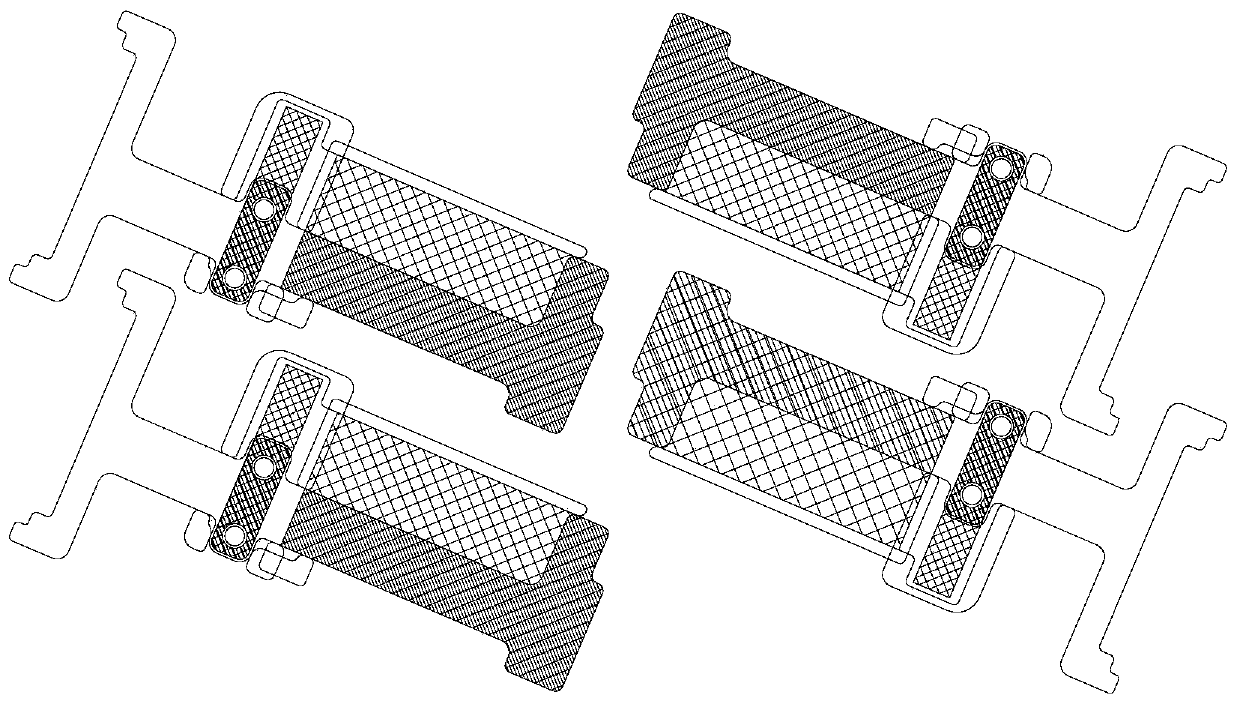

Forming method and mold for flexible circuit board

ActiveCN108124385BAddress bruisesFix the tearCircuit bendability/stretchabilityPrinted circuit aspectsFlexible circuitsStructural engineering

The invention provides a flexible circuit board moulding method. The flexible circuit board moulding method comprises the following steps: providing an FPC substrate, wherein the FPC substrate comprises a plurality of FPC units, each FPC unit comprises an overall outer frame line, each FPC unit comprises a reinforcing zone and a non-reinforcing zone, and the overall outer frame line comprises a connecting outer frame line arranged along an outline of a junction of the reinforcing zone and the non-reinforcing zone, a reinforcing outer frame line arranged around only the reinforcing zone and connected with the connecting outer frame line, and a non-reinforcing outer frame line arranged around only the non-reinforcing zone and connected with the connecting outer frame line; punching the connecting outer frame line; arranging a reinforcing layer on the reinforcing zones of the plurality of FPC units; punching the reinforcing outer frame line and the non-reinforcing outer frame line. The invention further provides a mould for the flexible circuit board moulding method. Through the flexible circuit board moulding method and the mould, a defective FPC caused by easy tearing of the junctions of the reinforcing zones and the non-reinforcing zones of the FPC units can be avoided.

Owner:融物宝国际融资租赁有限公司

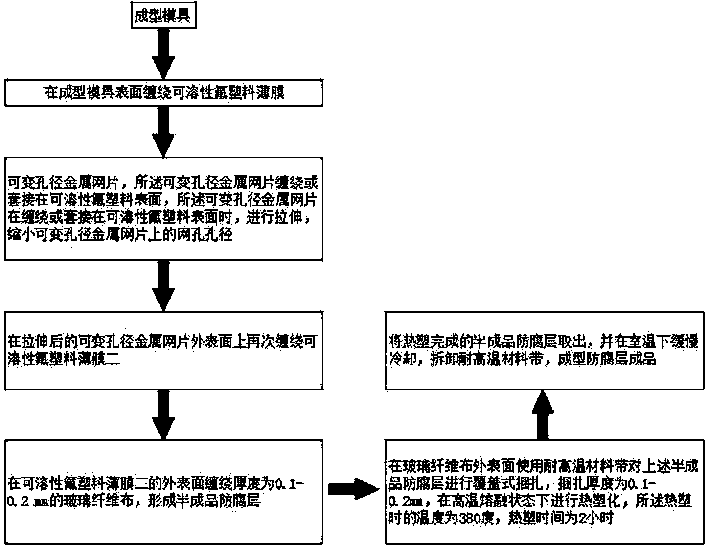

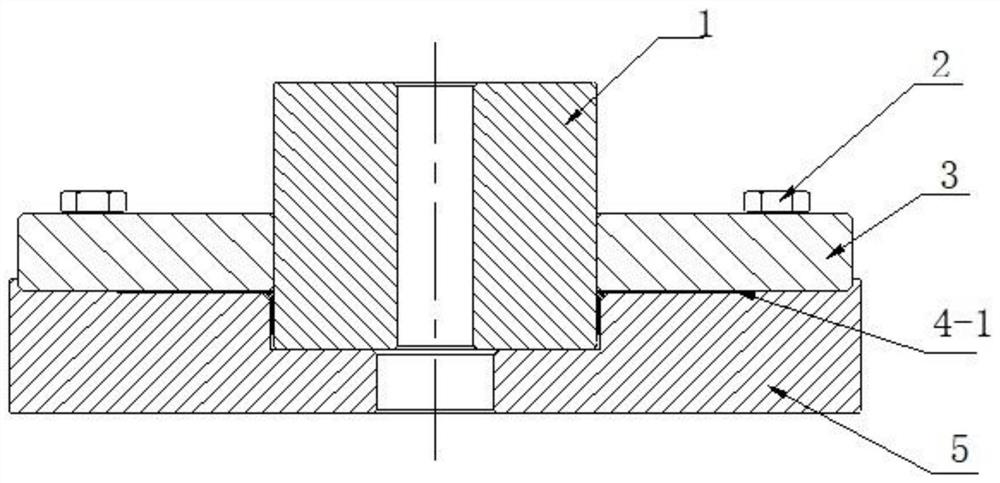

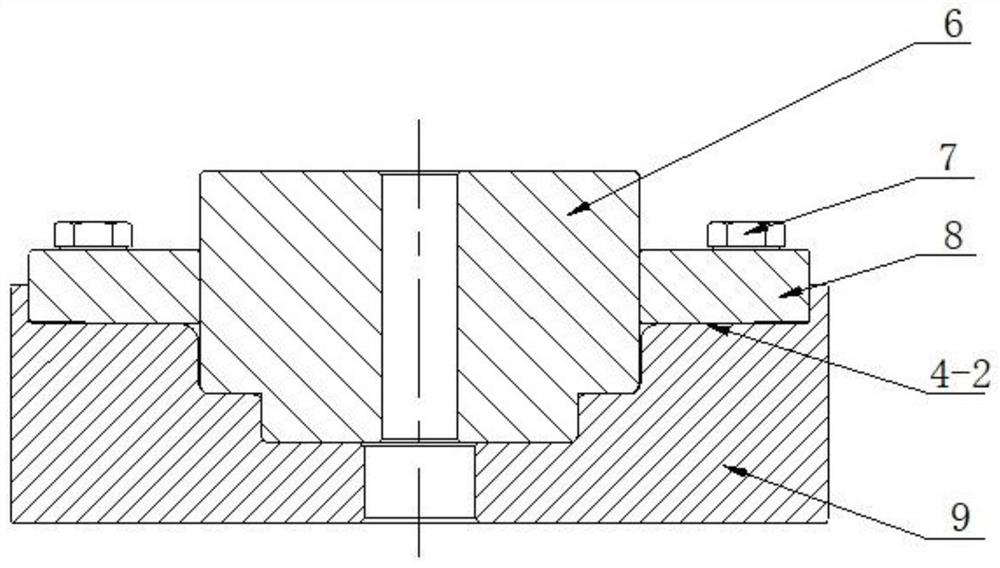

Flue liner fluoroplastic anticorrosive coating manufacturing process

The invention relates to a flue liner fluoroplastic anticorrosive coating manufacturing process, which comprises a forming die and a variable aperture metal mesh. A soluble fluorine plastic thin filmwinds on a surface of the forming die; the variable aperture metal mesh winds or sleeves on a soluble fluorine plastic surface; when winding or sleeving on the soluble fluorine plastic surface, the variable aperture metal mesh is stretched, so that a mesh pore diameter of the variable aperture metal mesh is reduced; a soluble fluorine plastic thin film II re-winds on an outer surface of the stretched variable aperture metal mesh; a glass fiber cloth winds an outer surface of the soluble fluorine plastic thin film II so as to form a semi-finished product anticorrosive coating; on an outer surface of the glass fiber cloth, using a high temperature resistant material tape for bundling the semi-finished product anticorrosive coating in a covering way, melting in high temperature, and heat-plasticizing; and cooling at room temperature, and forming the anticorrosive coating finished product. According to the technical scheme, the pore diameter of the variable aperture metal mesh can be reduced, so that the anticorrosive coating is naturally shrunk during a natural cooling process, and the problem that the anticorrosive coating is fallen off due to expansion under heating and cooling conditions is solved.

Owner:JINAN SHANYUAN ELECTRIC POWER EQUIP

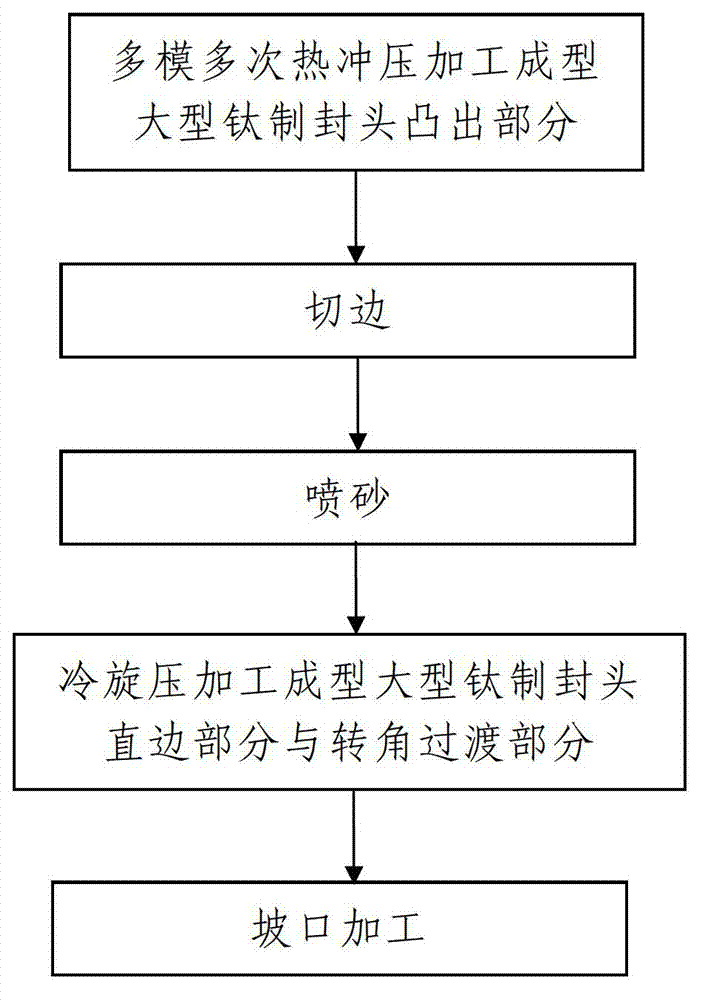

Composite forming method for thin-wall special-shaped part

ActiveCN112872187AEliminate work hardening and stress concentrationEliminate bulgeShaping toolsHot stampingWork hardening

The invention discloses a composite forming method for a thin-wall special-shaped part. The method comprises the following steps that firstly, a plate is selected according to a target thin-wall special-shaped part and is cut to obtain a round plate blank; secondly, the round plate blank is subjected to first-time hot stamping to obtain a first stamping part; thirdly, the first stamping part is subjected to second-time hot stamping to obtain a second stamping part; fourthly, the second stamping part is trimmed through numerical control machining to obtain a semi-finished product; fifthly, the semi-finished product is subjected to first-time rolling flanging to obtain a first rolling part; sixthly, the first rolling part is subjected to second-time rolling flanging to obtain a second rolling part; and seventhly, the second rolling part is subjected to third-time rolling flanging to obtain the thin-wall special-shaped part. According to the method, stamping and rolling are combined, work hardening and stress concentration are reduced or eliminated through multi-die multi-time hot stamping and multi-die multi-time rolling flanging, it is guaranteed that the hot stamping and rolling forming process is completed, meanwhile, the defects such as bumps, wrinkles or snap are reduced or eliminated, the forming precision is improved, the product quality of the thin-wall special-shaped part is improved, and the forming period is shortened.

Owner:西安西材三川智能制造有限公司

A wave-proof plate for liquid tank

ActiveCN112478485BGuarantee the safety of useAvoid excessive movementTank vehiclesLarge containersEngineeringLiquid tank

Owner:南京四达网络科技有限公司

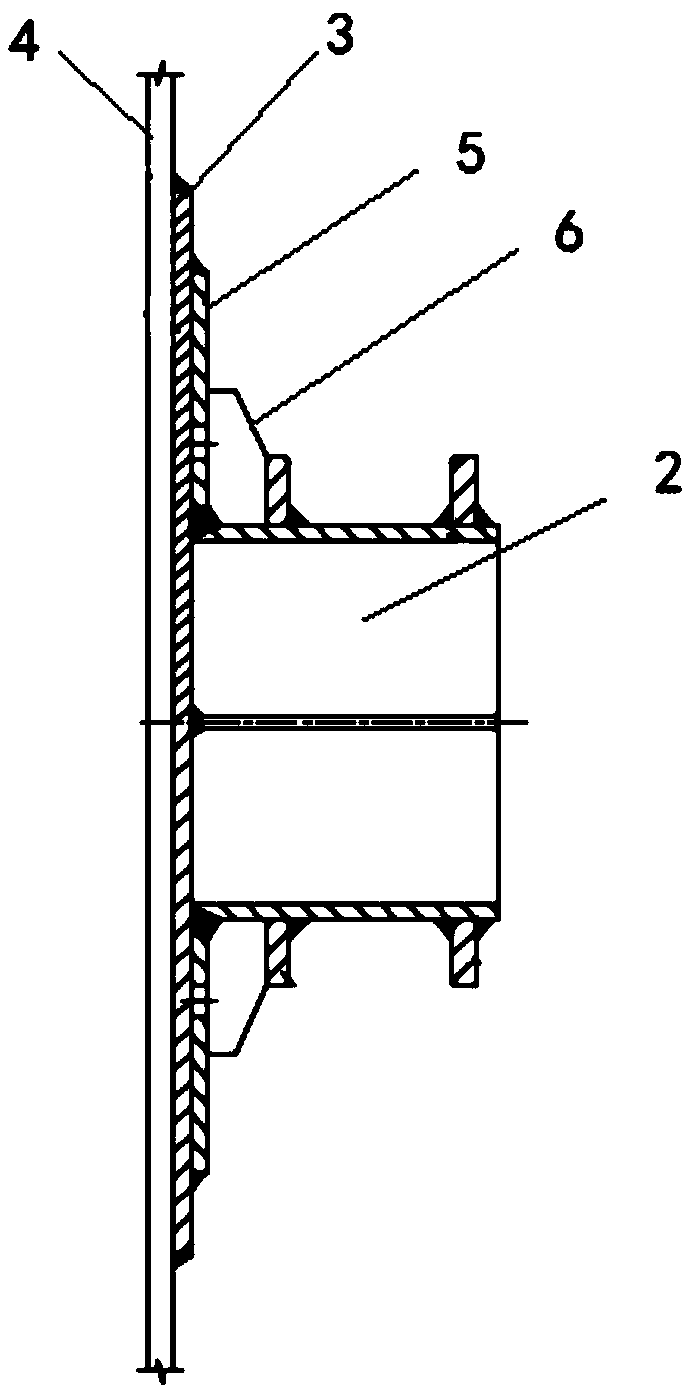

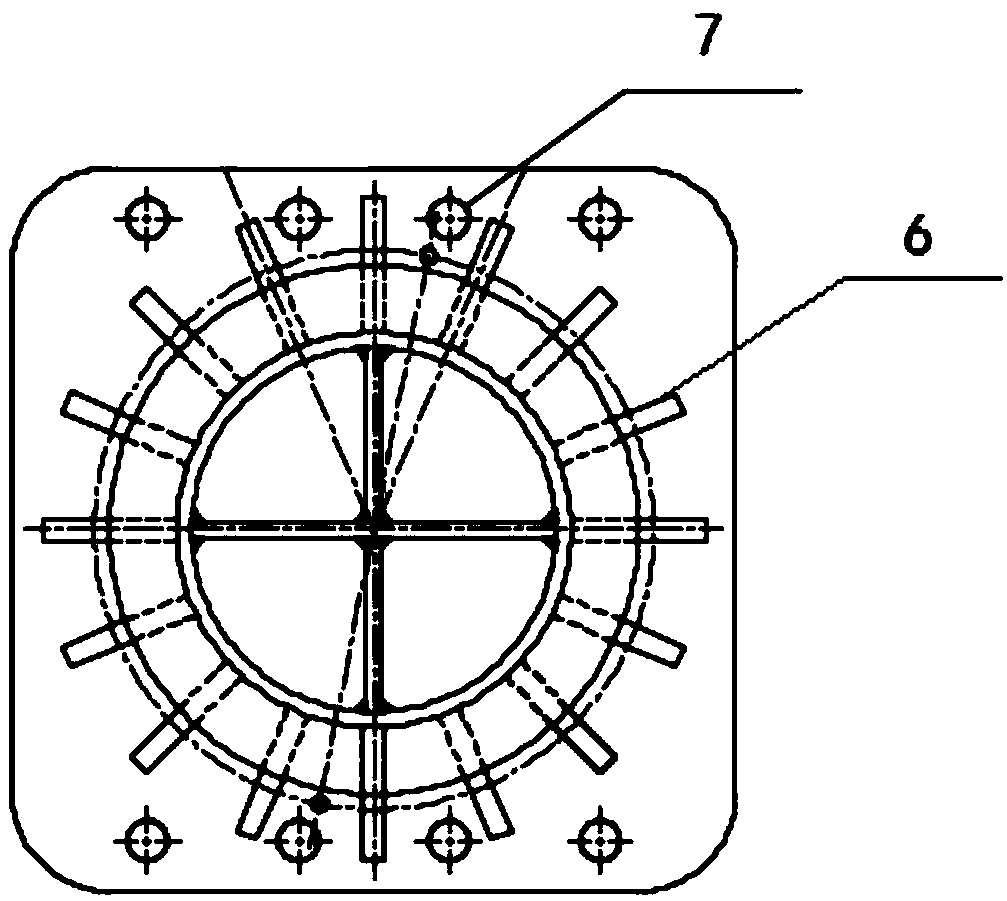

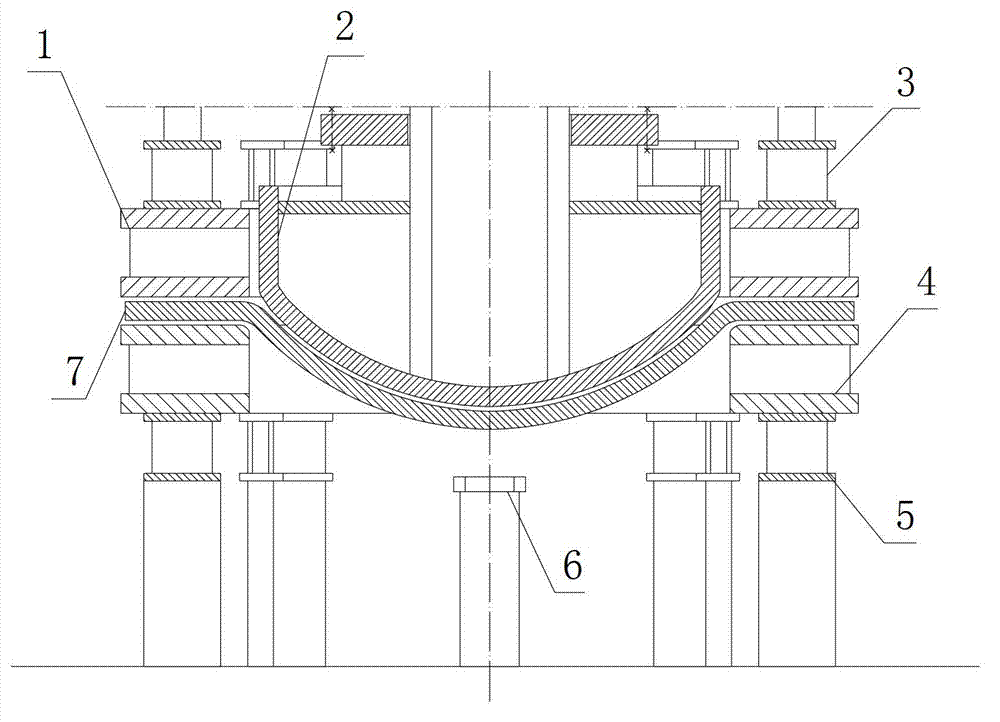

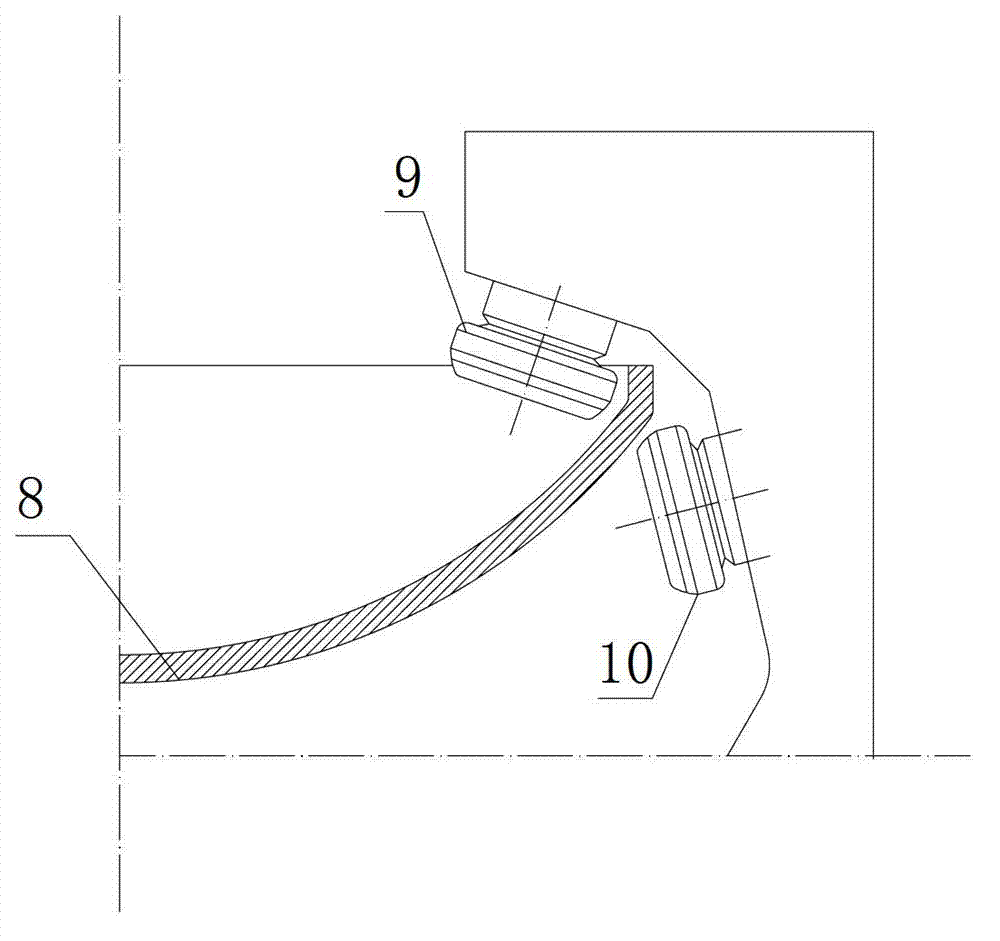

A Composite Forming Process for Large Titanium Heads

ActiveCN103071736BThe process steps are simpleSimple and fast operationShaping toolsHollow articlesHot stampingChemical composition

The invention discloses a composite molding process of a large-size titanium-made end socket. The composite molding process comprises the following steps of: 1, molding a bulge part of the end socket by machining in a multimode and multi-pass hot stamping manner, to be specific, carrying out hot stamping on a machined blank arranged in a stamping die for a plurality of times to obtain a semifinished product of the end socket by adopting a punching machine from front to rear according to a predesigned structure and size of the bulge part of the large-size titanium-made end socket; 2, carrying out side shearing, to be specific, carrying out side shearing on the semifinished product of the end socket; and 3, molding a straight side part and a corner transition part of the end socket by cold spinning , to be specific, carrying out cold spinning on an upper port of the semifinished product of the end socket which is subjected to side shearing in the step 2 to obtain a molded end socket finished-product by adopting spinning equipment according to predesigned structures and sizes of the straight side part and the corner transition part of the large-size titanium-made end socket. The composite molding process disclosed by the invention is simple in steps, reasonable in design, simple and convenient to operate and good in using effect; and both the mechanical property and the chemical components of the molded end socket can meet relative standard requirements.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com