Forming method and mold for flexible circuit board

A molding method and mold technology, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problem of uneven application of force at the joint of FPC reinforced area and non-reinforced area, and easy tearing of the joint between FPC and reinforcement. It can solve problems such as cracking and bad FPC, so as to solve the problems of easy crushing and tearing, avoid FPC tearing and crushing, and improve the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

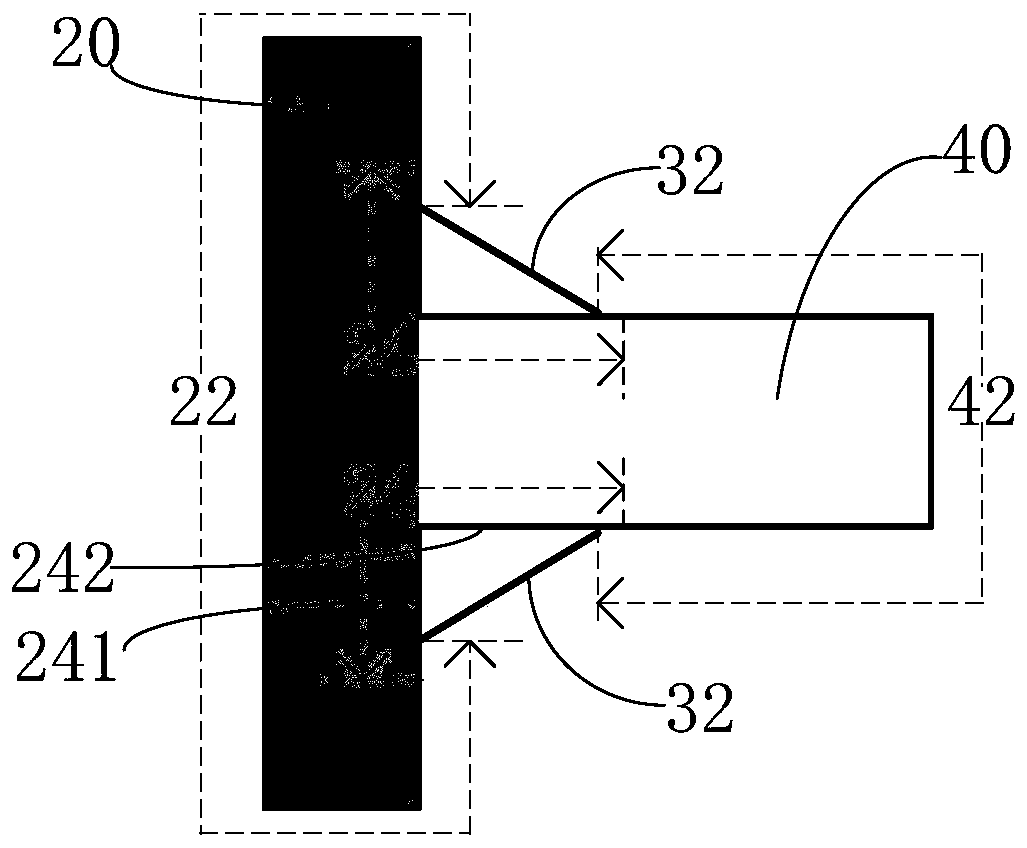

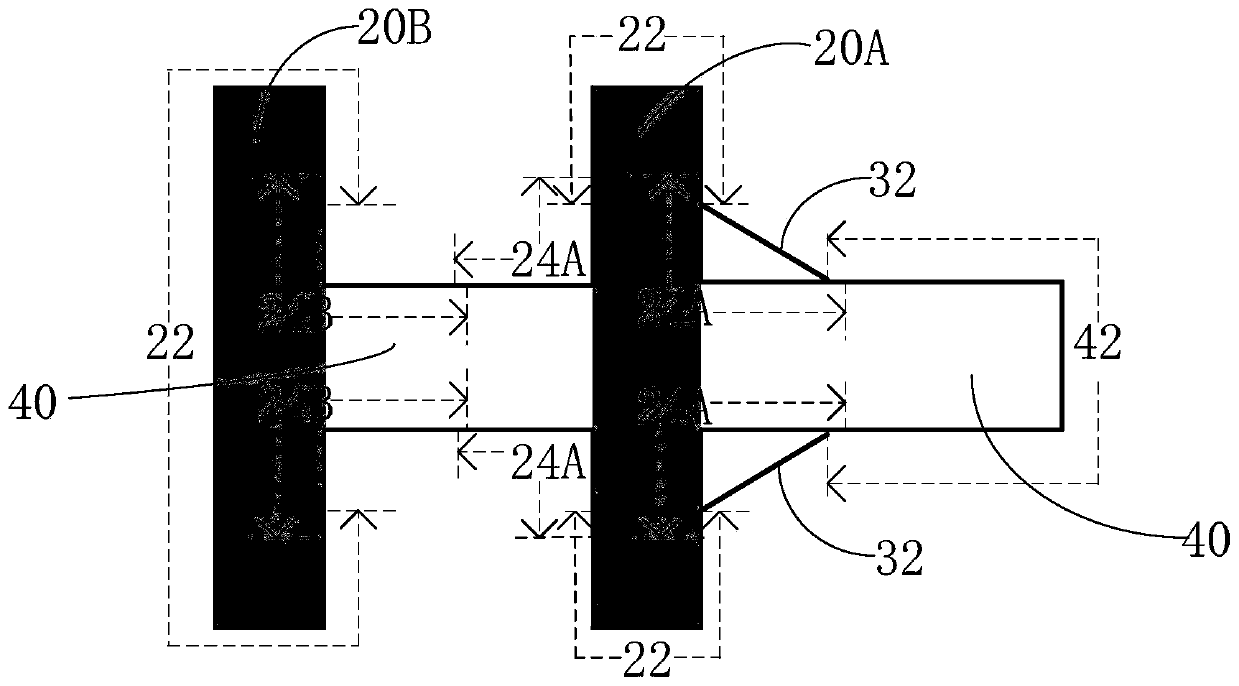

[0058] This embodiment provides a method for punching an FPC substrate, and the FPC substrate includes such as image 3 Multiple FPC units arranged in the arrangement shown. Figure 4A It is a schematic diagram of the appearance structure of the FPC unit product with adhesive tape 50A and adhesive tape 50B in the reinforcement area 20A and reinforcement area 20B respectively before use, Figure 4B It is a schematic diagram of the external structure of the adhesive tape 50A and the adhesive tape 50B when it is used for the FPC unit product.

[0059] The punching method of the FPC substrate specifically includes:

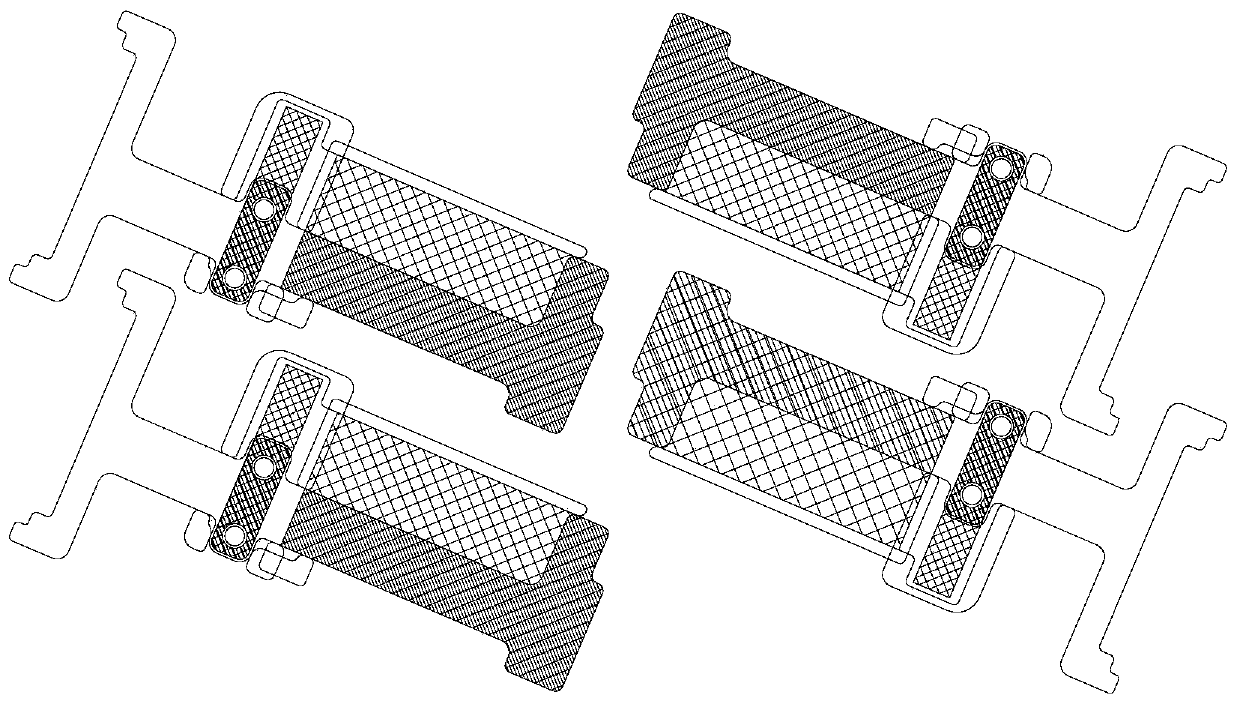

[0060] S101, respectively, using a Figure 5A Dies of the shape shown and as Figure 5B The mold of the shown shape carries out die-cutting to described FPC substrate;

[0061] S201, attaching the FR-4 reinforcement board with adhesive tape 50A and the FR-4 reinforcement board with adhesive tape 50B on the reinforcement area 2A and the reinforcement area 2B respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com