Side-slot-reinforced leading-in optical cable and production process

A fiber optic cable introduction and enhanced technology, which is applied in the field of side groove reinforced fiber optic cable introduction and production technology, can solve the problems of weak protection at the optical fiber, hydrogen loss of the optical fiber, and damage to the optical cable, and achieve overall strength enhancement, wall thickness increase, and wall thickness. Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

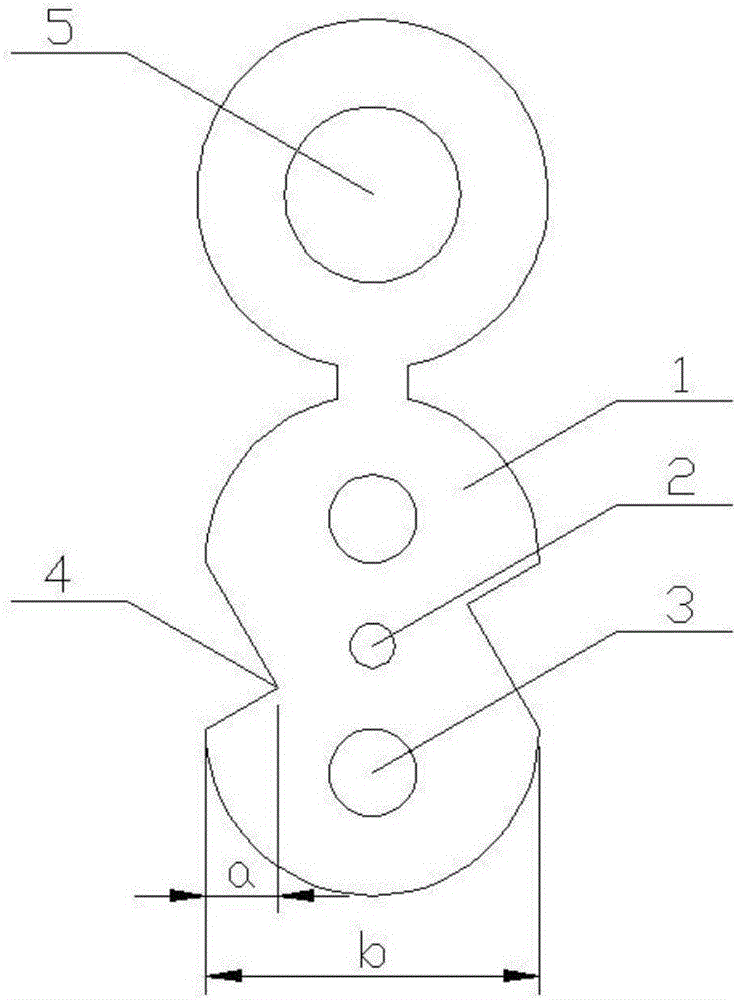

[0027] This implementation is a self-supporting side slot reinforced lead-in cable, including optical fiber 2, playground-type sheath 1, reinforcement 3 and suspension wire 5, the outer side of the optical fiber 2 is wrapped with playground-type sheath 1, and the playground-type sheath 1. A diagonal side groove 4 is arranged on the straight side. The diagonal side groove 4 is a triangular groove. An optical fiber 2 is arranged at the center of the playground-type sheath 1, and symmetrically arranged on both sides of the optical fiber 2. Reinforcement 3 at the round end of the playground sheath 1 . The depth of the oblique side groove 4 is smaller than the thickness between the bottom of the groove and the optical fiber. The depth a of the oblique side groove accounts for 20%-30% of the width b of the playground sheath. The upper end of one side of the circular end of the playground-shaped sheath 1 is provided with a suspension wire 5 , and the outer side of the suspension wir...

example 2

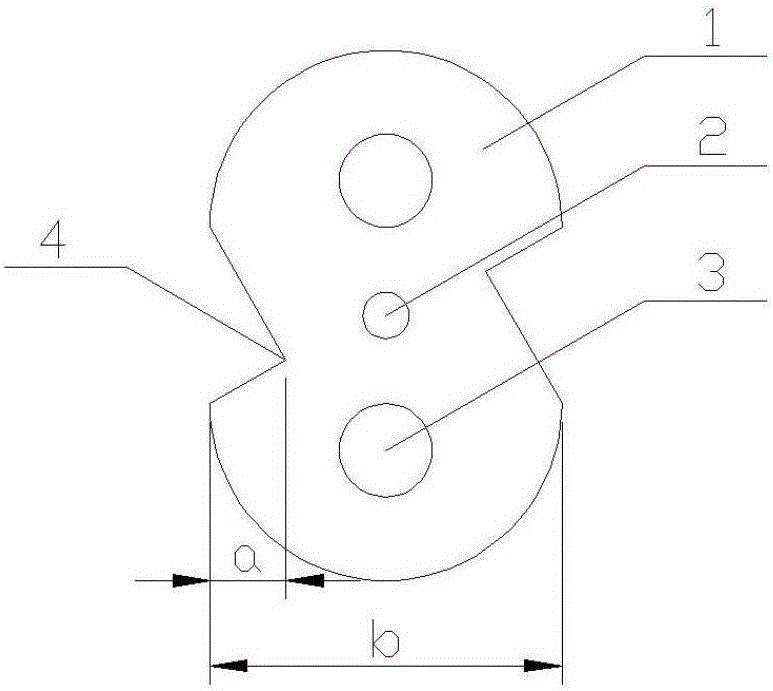

[0035] This implementation is a kind of side groove reinforced lead-in optical cable, including optical fiber 2 and strength member 3, the outer side of the optical fiber 2 is wrapped with a playground-type sheath 1, and a diagonal side groove is arranged on the straight side of the playground-type sheath 1 4. The obliquely opposite side groove 4 is a triangular groove, an optical fiber 2 is arranged at the center of the playground-type sheath 1, and reinforcing members 3 placed at the round ends of the playground-type sheath are symmetrically arranged on both sides of the optical fiber 2 . The depth of the oblique side groove 4 is smaller than the thickness between the bottom of the groove and the optical fiber 2 . The depth a of the oblique side groove accounts for 20%-30% of the width b of the playground sheath.

[0036] A production process for a side slot reinforced drop-in optical cable, which includes the following process steps: Step 1 removes the suspension wire 5 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com