Manufacturing method of novel side key product

A manufacturing method and product technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of special FPC structure, inability to meet product flatness and other problems, and achieve the effect of good performance optimization and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

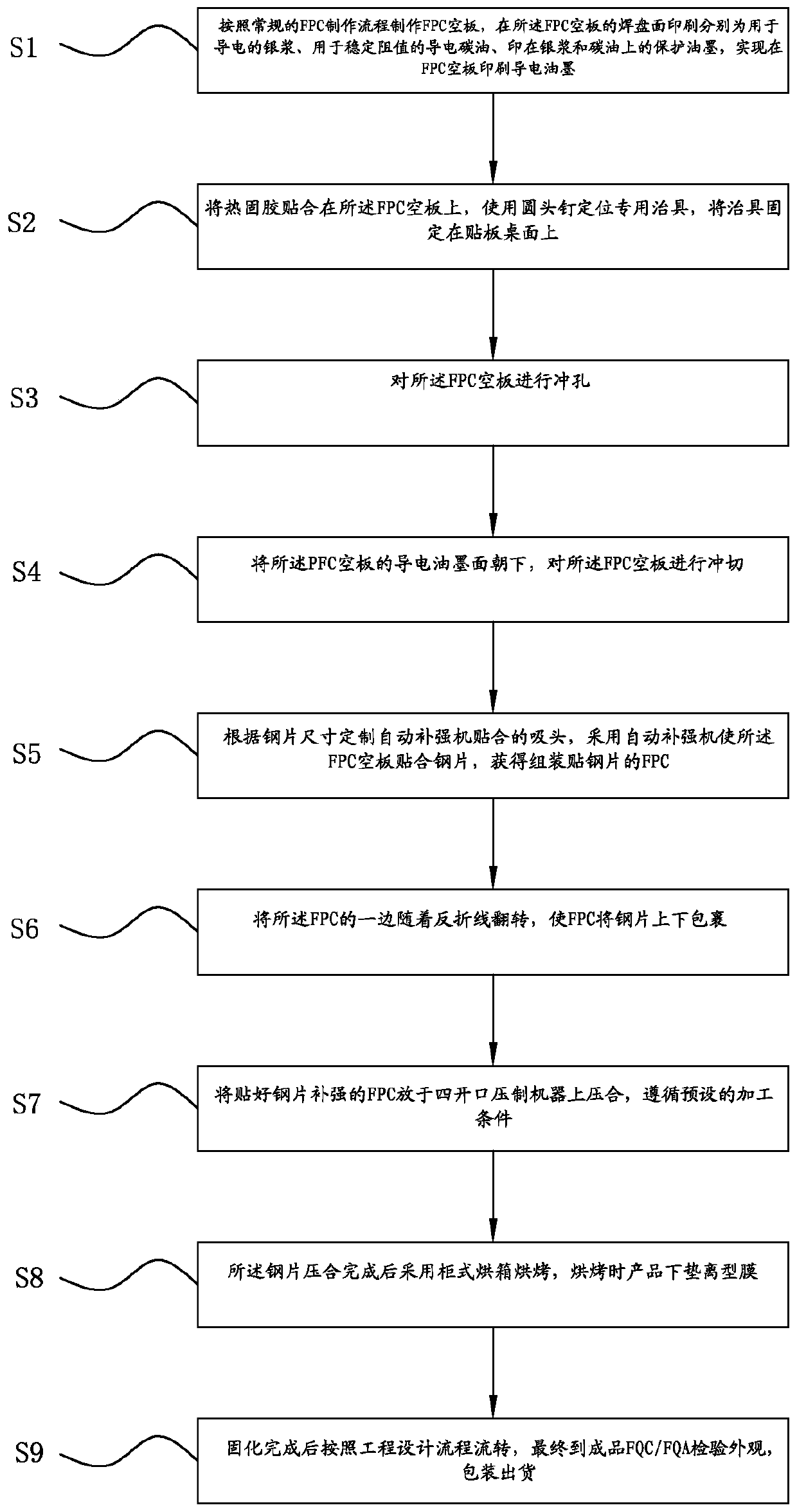

[0064] Such as figure 1 As shown, it is a schematic flow chart of Embodiment 1 of a manufacturing method of a novel side button product of the present invention, comprising the following steps:

[0065] Step S1, making an empty FPC board according to the conventional FPC production process, and printing silver paste for conduction, conductive carbon oil for stable resistance, printing on silver paste and conductive carbon on the pad surface of the FPC empty board The protective ink on the oil can realize the printing of conductive ink on the FPC empty board;

[0066] Step S2, attaching the thermosetting adhesive to the FPC empty board, using a round-head nail positioning special jig, and fixing the jig on the board desktop;

[0067] Step S3, punching the empty FPC board;

[0068] Step S4, with the conductive ink of the PFC empty board facing down, punching the FPC empty board;

[0069] Step S5, customizing the suction head for the automatic reinforcement machine according t...

Embodiment 2

[0076] A method for manufacturing a flexible board of a side button product, mainly including lamination structure design, tool design, flatness control, and a method for manufacturing a side button flexible board.

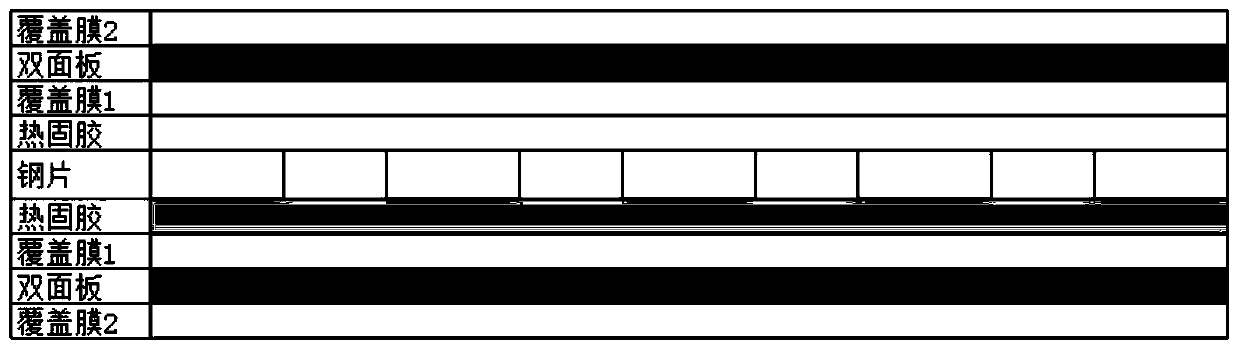

[0077] The laminated structure design includes that the designed flexible board is composed of steel sheet reinforcement, thermosetting glue, cover film 1, double-sided panels, and cover film 2 in sequence.

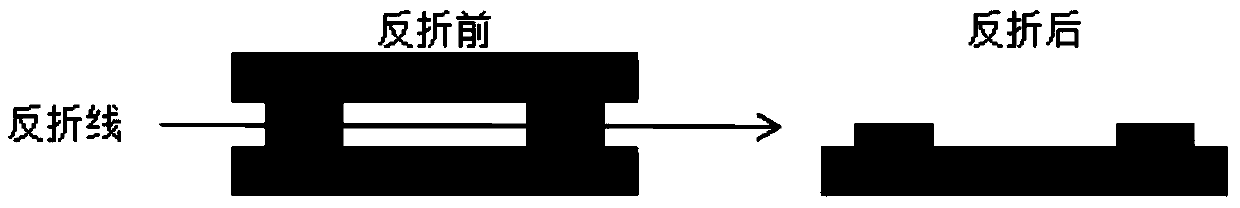

[0078] Specifically, the flexible board (corresponding to the FPC in Embodiment 1, both of which are components used to manufacture side key products) is composed of a reflexed area, a circuit connection area and a finger area.

[0079] As a preferred embodiment, the size of the cover film 1 and the cover film 2 are consistent, both of which are 1 / 2 mil thick in PI and 15 μm thick in glue.

[0080] As a preferred embodiment, the reinforcement of the steel sheet is 0.4-0.6mm thick, and the interval between the steel sheets is 0.5-1.0mm.

[0081] As a preferre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com