Patents

Literature

31results about How to "Performance optimization and improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamically adjusted cache data management and elimination method

PendingCN111159066AAvoid pollutionAvoid replacementMemory architecture accessing/allocationMemory systemsParallel computingEngineering

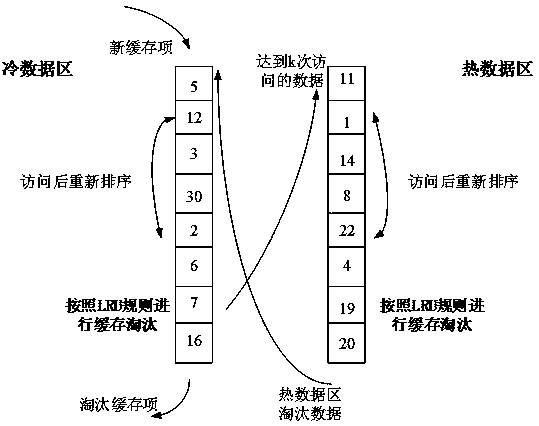

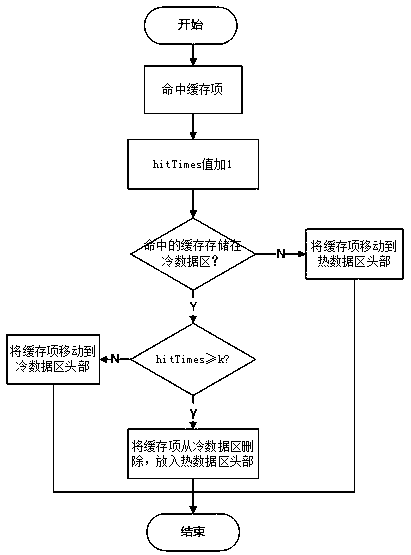

The invention discloses a dynamically adjusted cache data management and elimination method. According to the invention, the position of the cache item in the memory is dynamically adjusted accordingto the access time and hit frequency attribute of the cache item. The memory is divided into a hot data area and a cold data area, the cache items with high hit frequency and short access time are kept at the front part of the hot data area, and the cache items with low hit frequency and long access time are kept at the tail part of the cold data area. When the cache capacity reaches a threshold value and data needs to be eliminated, cache items at the tail part of the cold data area is directly deleted. Accurate elimination of data is realized through dynamic adjustment of the cold and hot data area, the proportion of hotspot data in cache is increased, the cache pollution problem is relieved, and the cache hit rate is increased.

Owner:HANGZHOU DIANZI UNIV

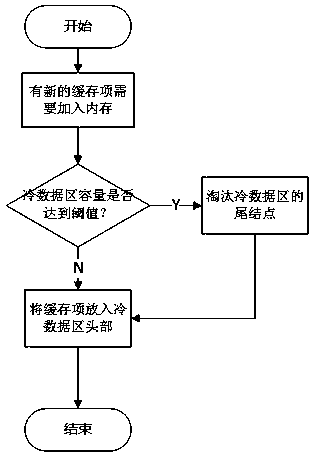

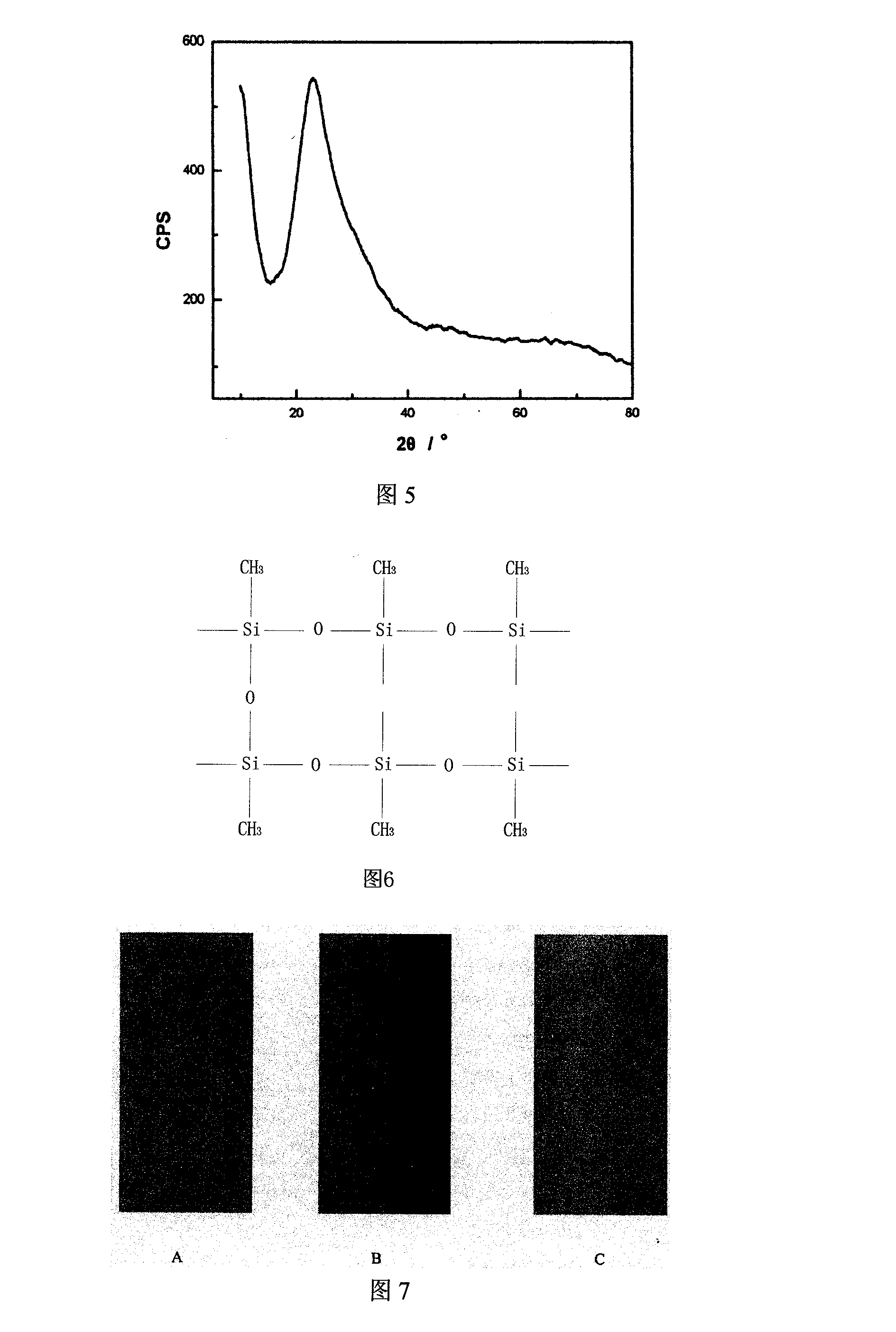

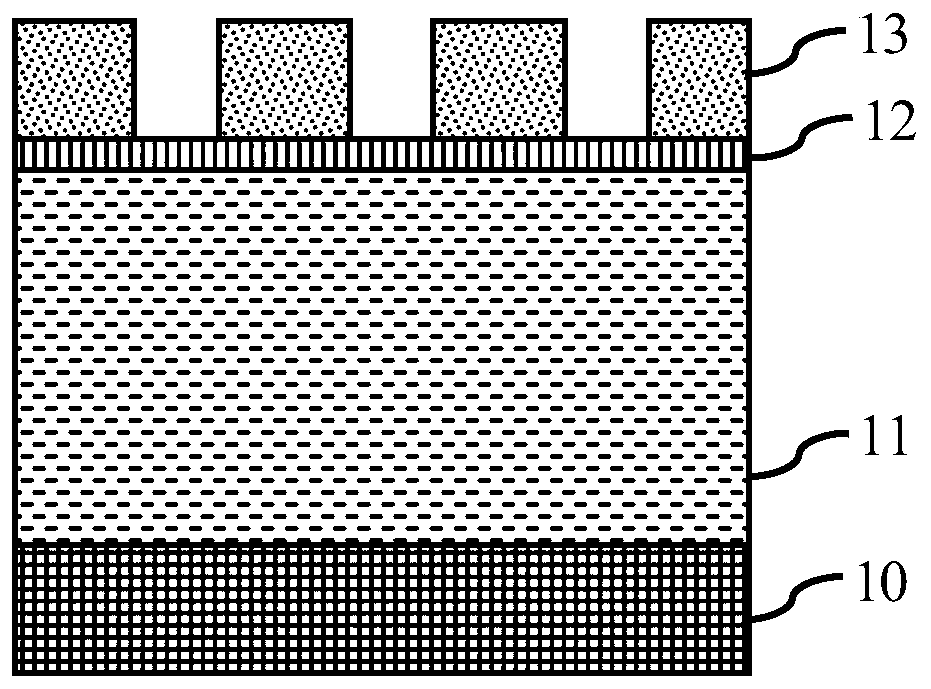

Method for preparing ceramic composite wood

InactiveCN101164744AIncrease profitOvercome the shortcoming of serious volatile lossWood treatment detailsPolymerisation impregnationCeramic compositePositive pressure

The present invention discloses a preparation method of vitrified composite wood material. Said preparation method includes the following steps: (1), preparing MTES-TEOS sol; (2), making the wood material to be treated undergo the process of negative pressure and positive pressure treatment in a treatment tank and impregnating the wood material to be treated with the sol prepared in step 1 in the process of negative pressure treatment; and (3), making the above-mentioned wood material undergo the process of ageing treatment in the room, then making gel treatment in the drying oven so as to obtain the invented vitrified composite wood material.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

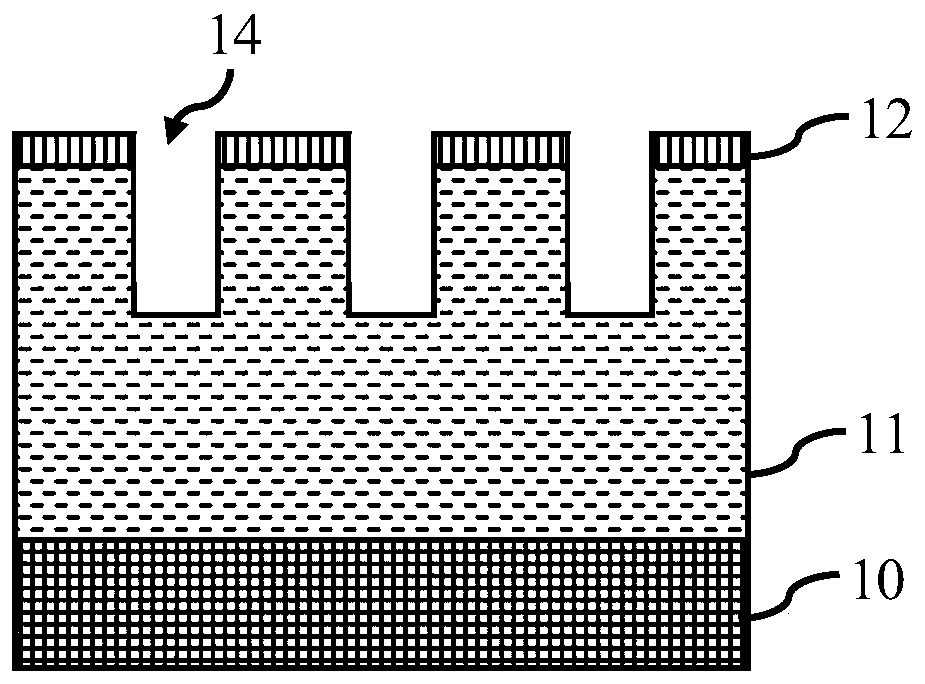

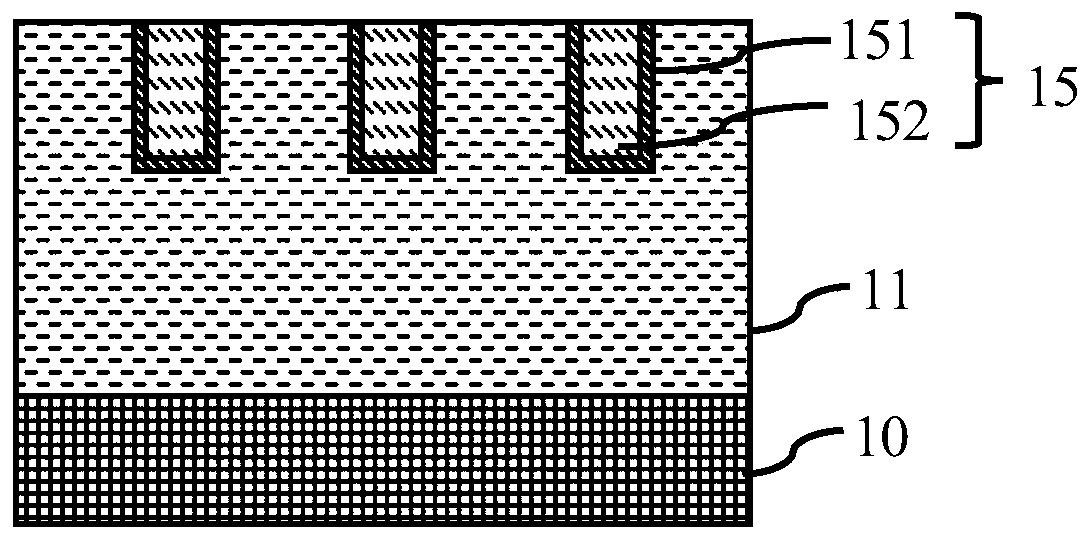

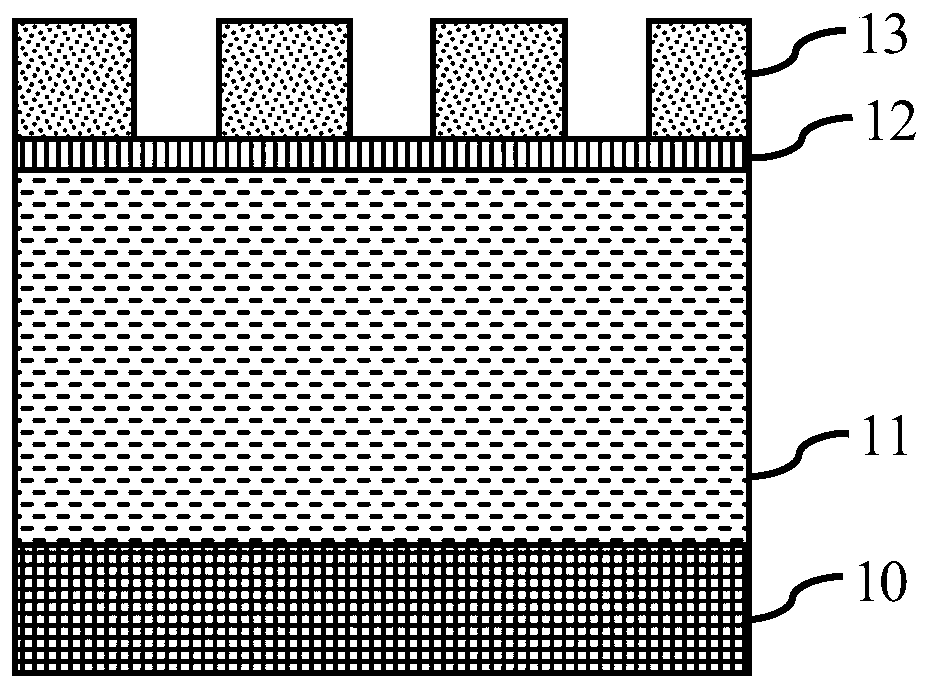

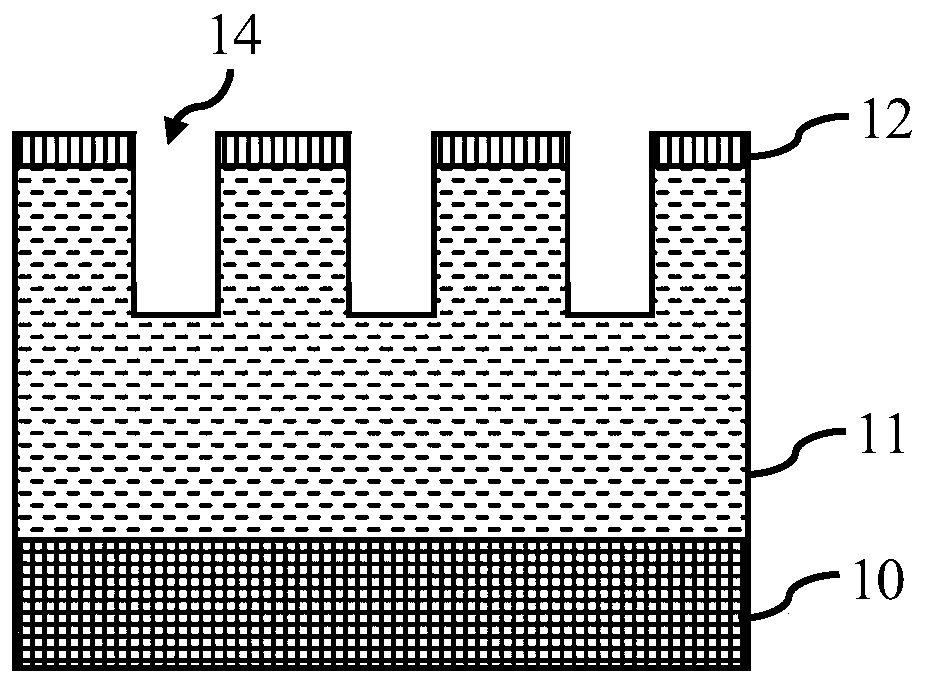

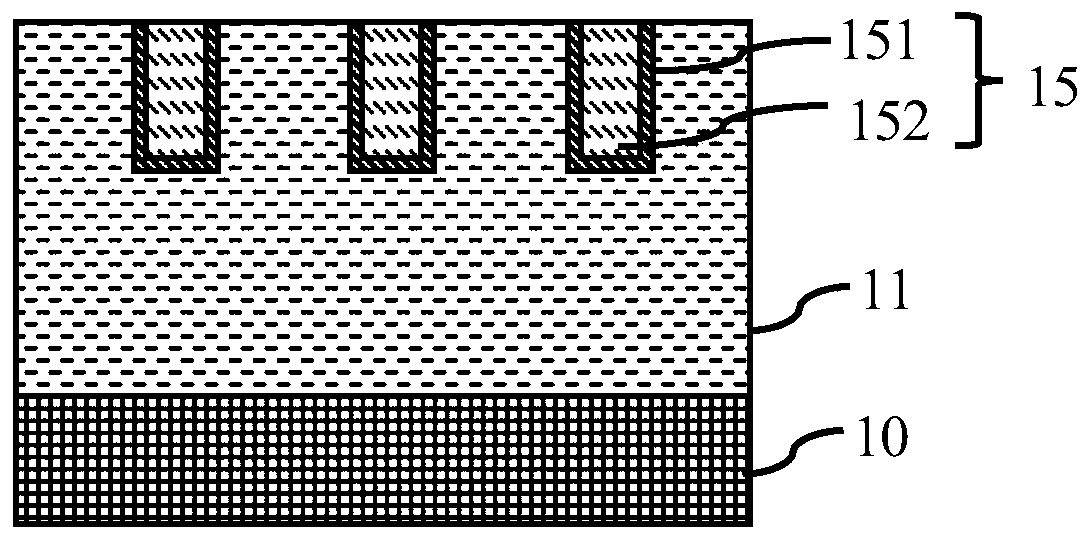

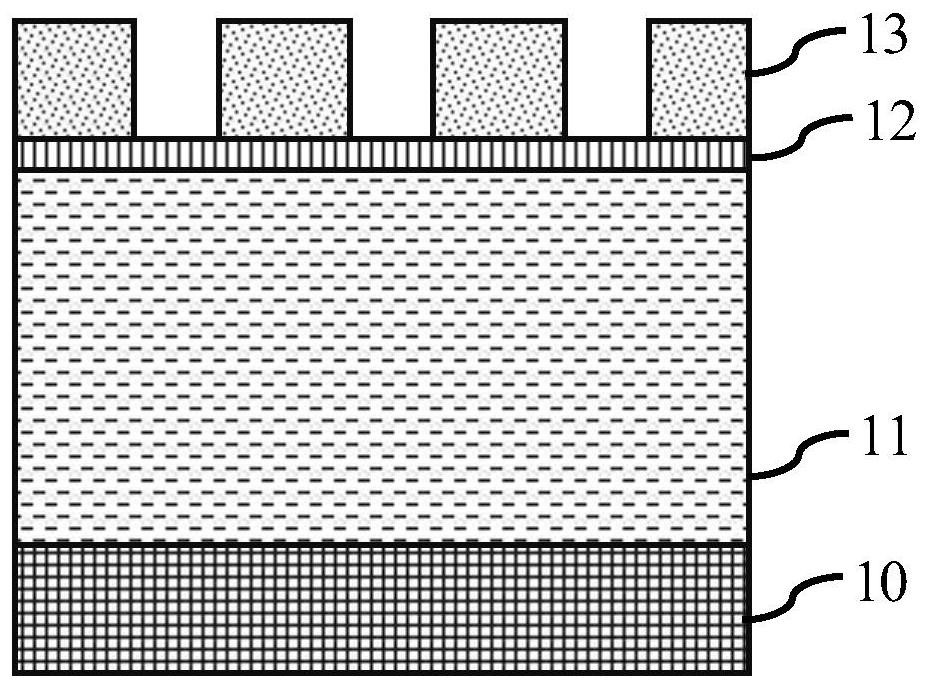

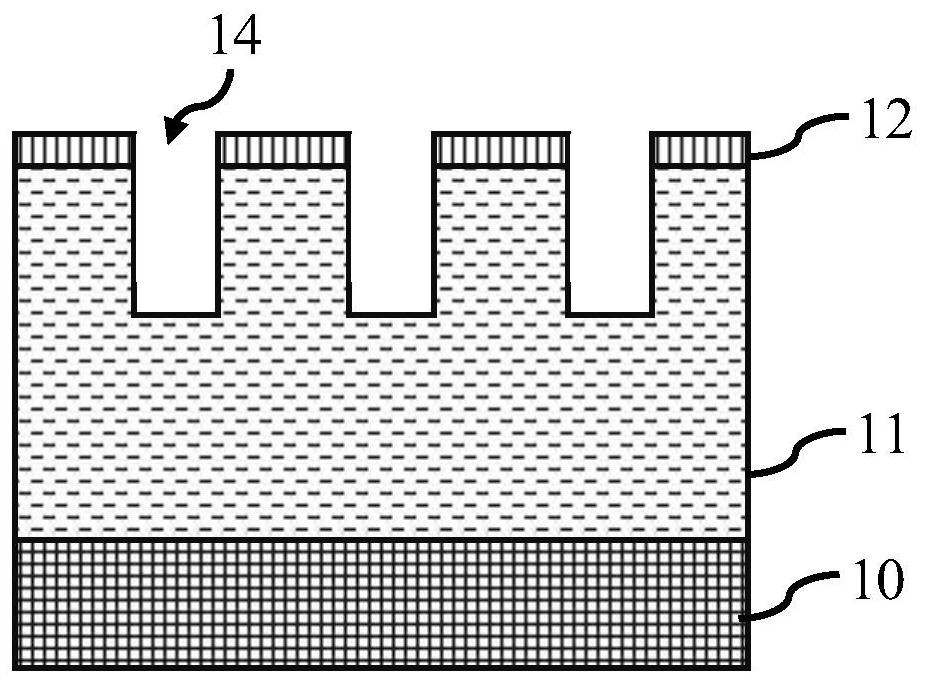

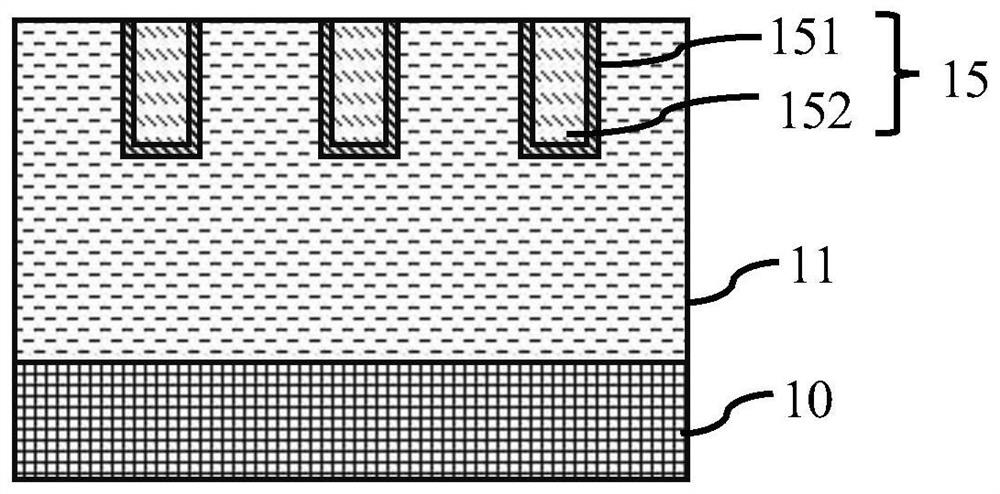

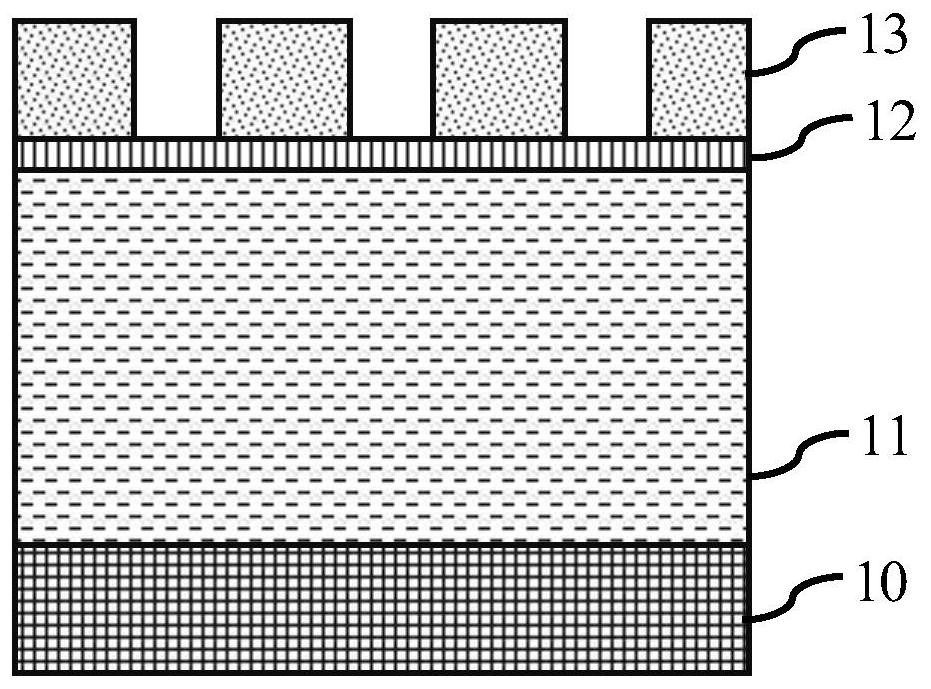

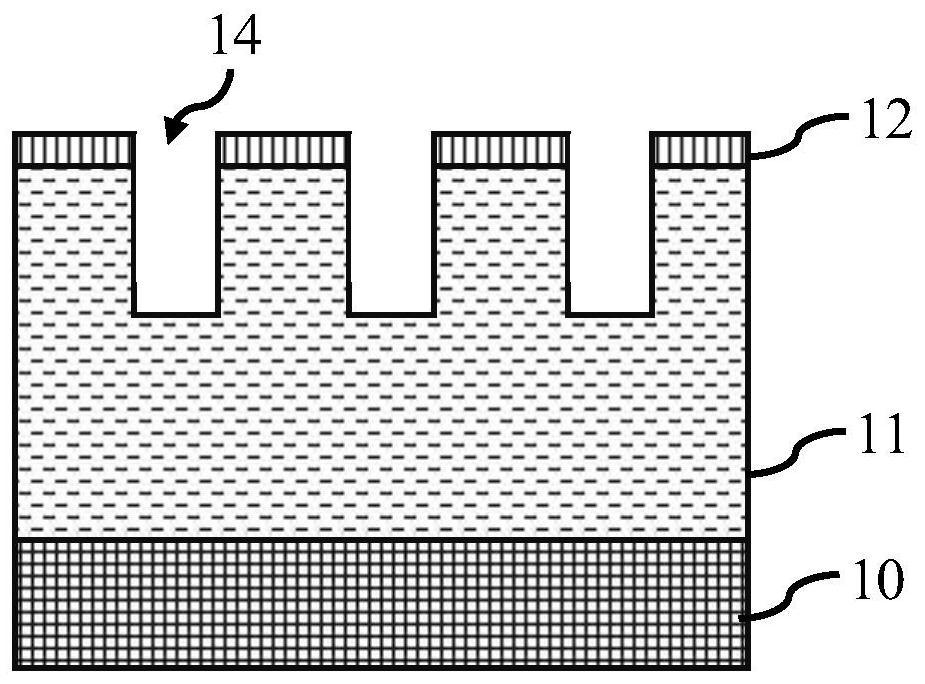

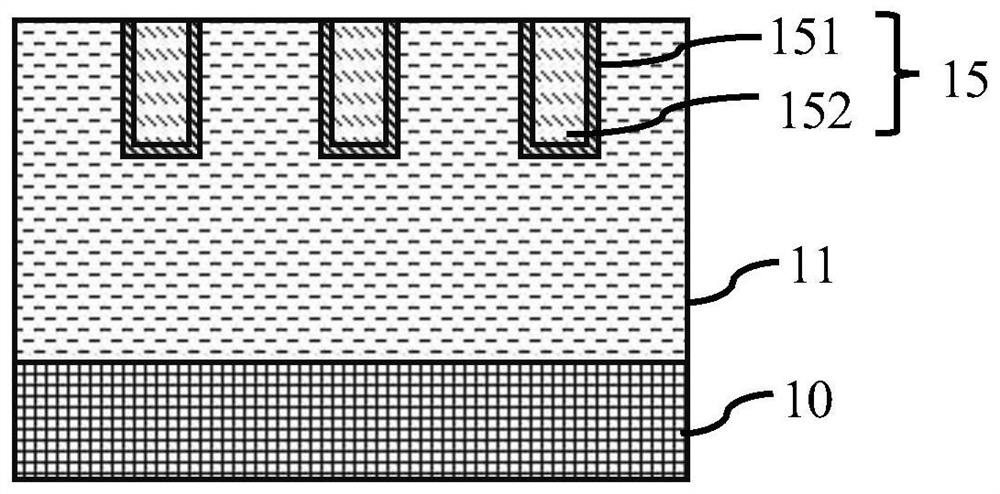

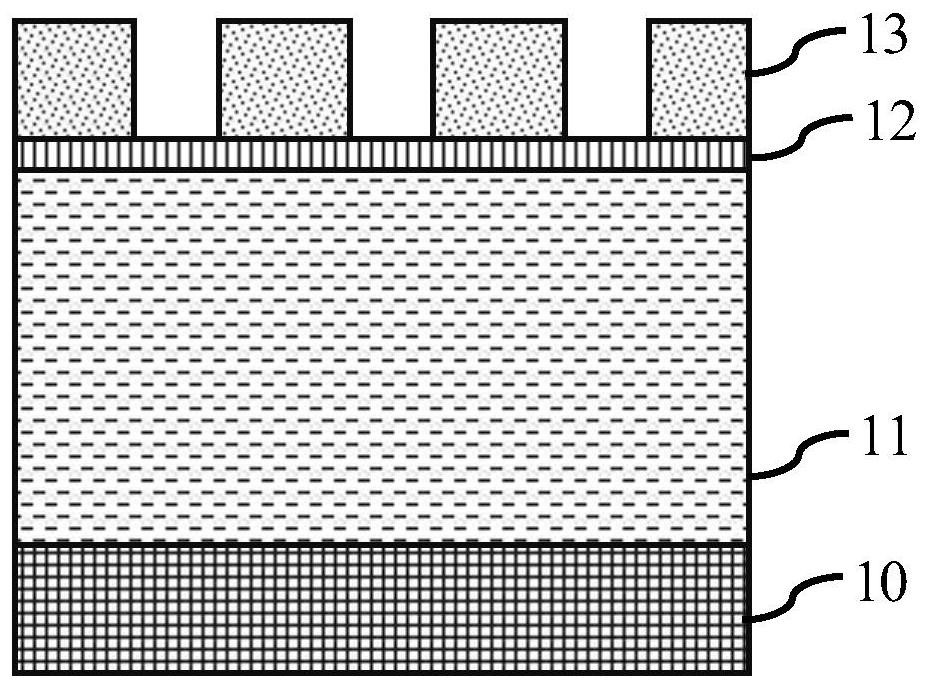

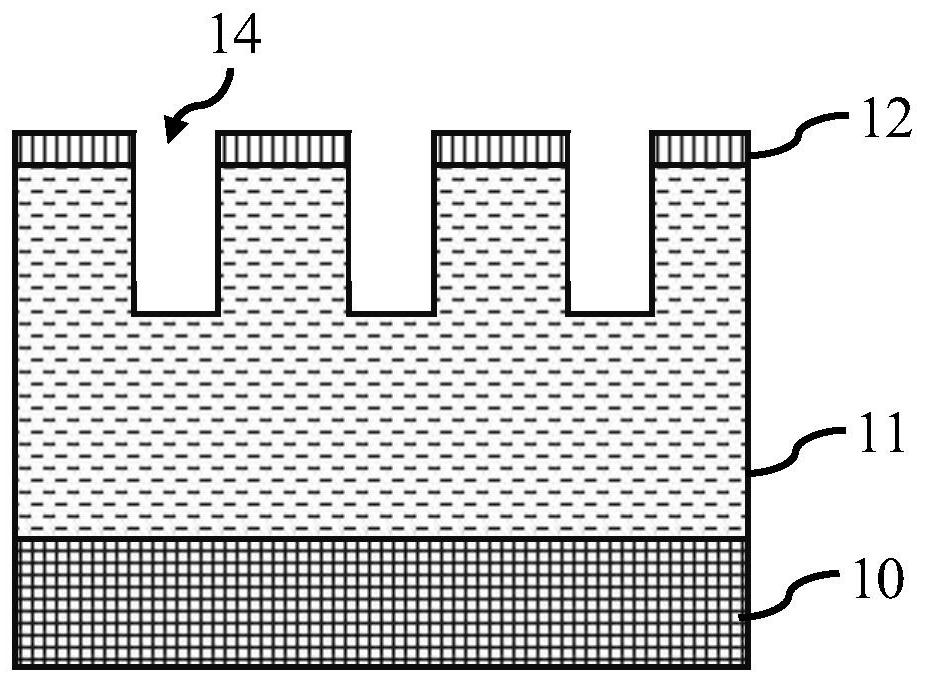

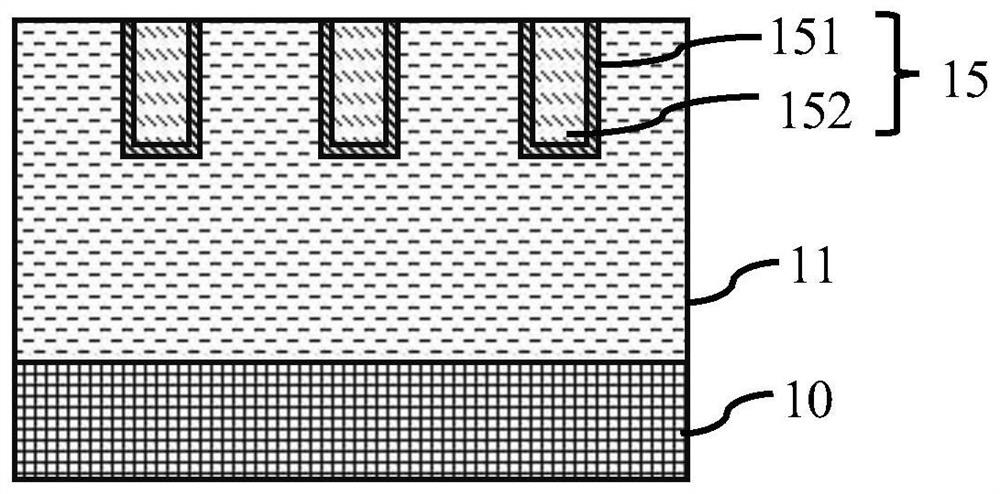

Semiconductor device and manufacturing method thereof

ActiveCN111312654AImprove electrical performanceElectrical performance optimization and improvementSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialElectrical performance

The invention provides a semiconductor device and a manufacturing method thereof, and the manufacturing method of the semiconductor device comprises: forming a trench filling structure in a substrateof a pixel region, and further clamping a high-K dielectric layer between the side wall of a filling material in the trench filling structure and the substrate; forming a plug structure in the substrate of the pad region; covering a buffer dielectric layer on the surface of the substrate in the pixel region and the bonding pad region; etching the buffer dielectric layer to form a first opening which at least exposes part of the substrate at the periphery of the top side wall of the trench filling structure and / or at least part of the top of the trench filling structure; and forming a metal grid layer on the buffer dielectric layer of the pixel region, and filling the first opening so as to be electrically connected with the exposed part of the substrate and / or the trench filling structure.According to the technical scheme of the invention, the metal grid layer is electrically connected with the exposed part of the substrate and / or the trench filling structure, so that the electrical performance of the semiconductor device can be optimized and improved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

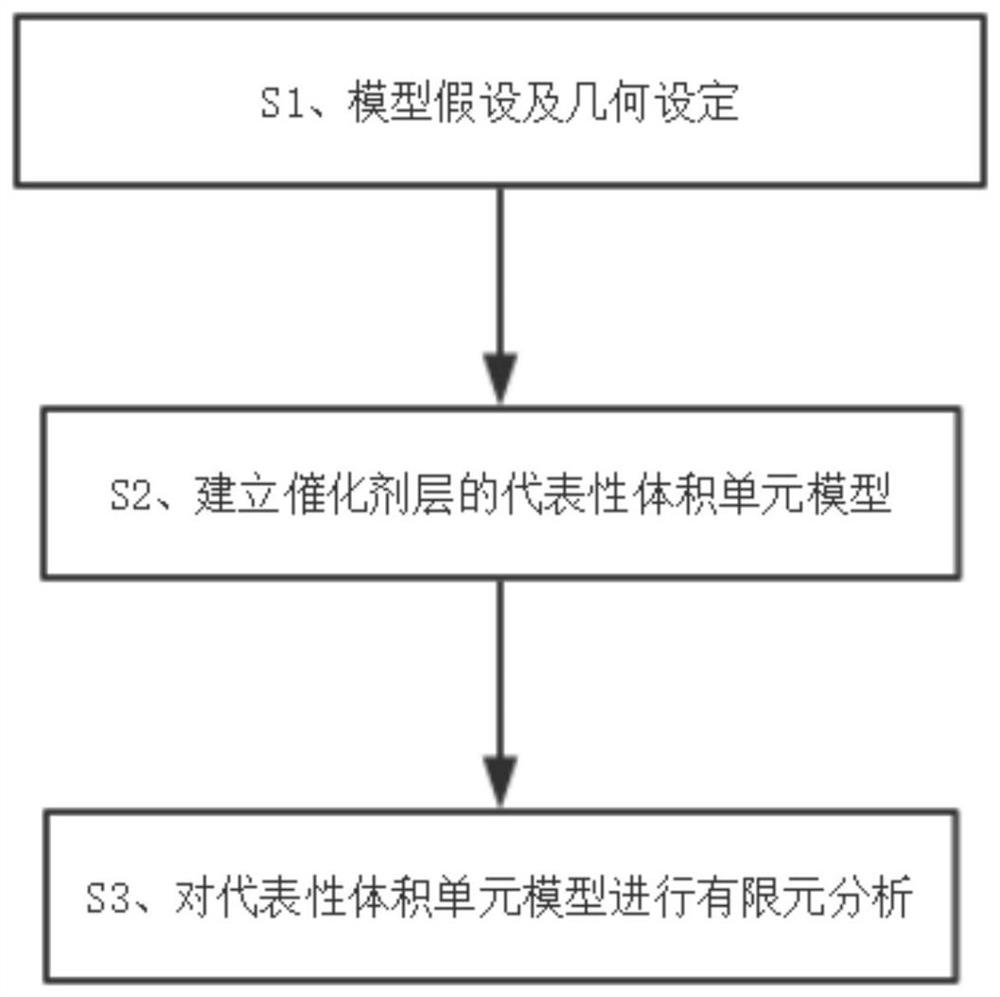

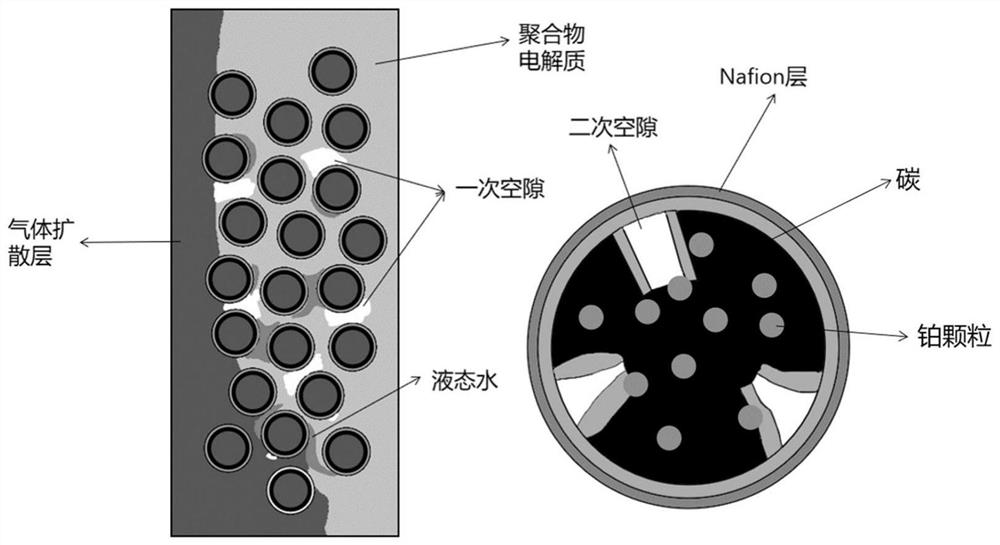

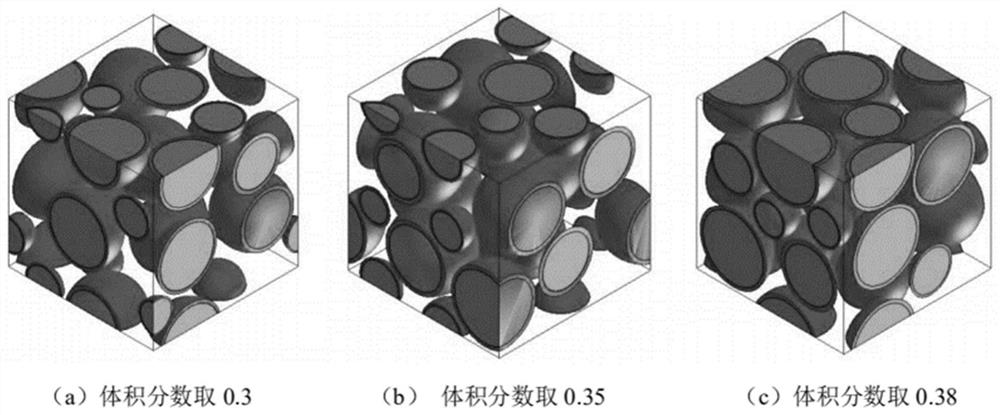

Establishment method and application of catalyst layer microcosmic model

PendingCN112084685AImprove performancePerformance Optimization and ImprovementCell electrodesDesign optimisation/simulationPtru catalystFuel cells

The invention relates to an establishment method and application of a catalyst layer microcosmic model, and the establishment method comprises the following steps: S1, carrying out the model assumption and geometric setting of a catalyst layer, and obtaining a catalyst layer model; S2, establishing a representative volume unit model of the catalyst layer based on the obtained catalyst layer model;and S3, performing finite element analysis on the representative volume unit. Compared with the prior art, the three-dimensional finite element model of a catalyst layer is established on the basis of the actual microstructure and the mechanical property of the catalyst layer, the influence of different microstructures and actual working conditions on the mechanical property of the catalyst layeris further researched, and the performance improvement rule of the catalyst layer is analyzed; model reference is provided for optimizing the microstructure and the mechanical property of the protonexchange membrane fuel cell, and the improvement of the cell performance is facilitated; the invention can also be used for simulation research of the relationship between the microstructures and physical properties of the catalyst layer under different use conditions.

Owner:TONGJI UNIV

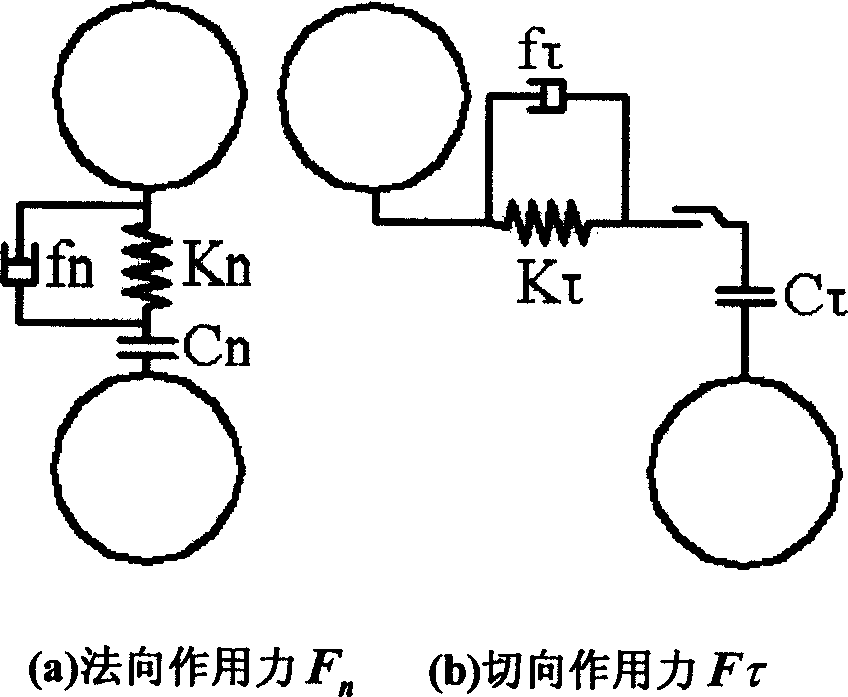

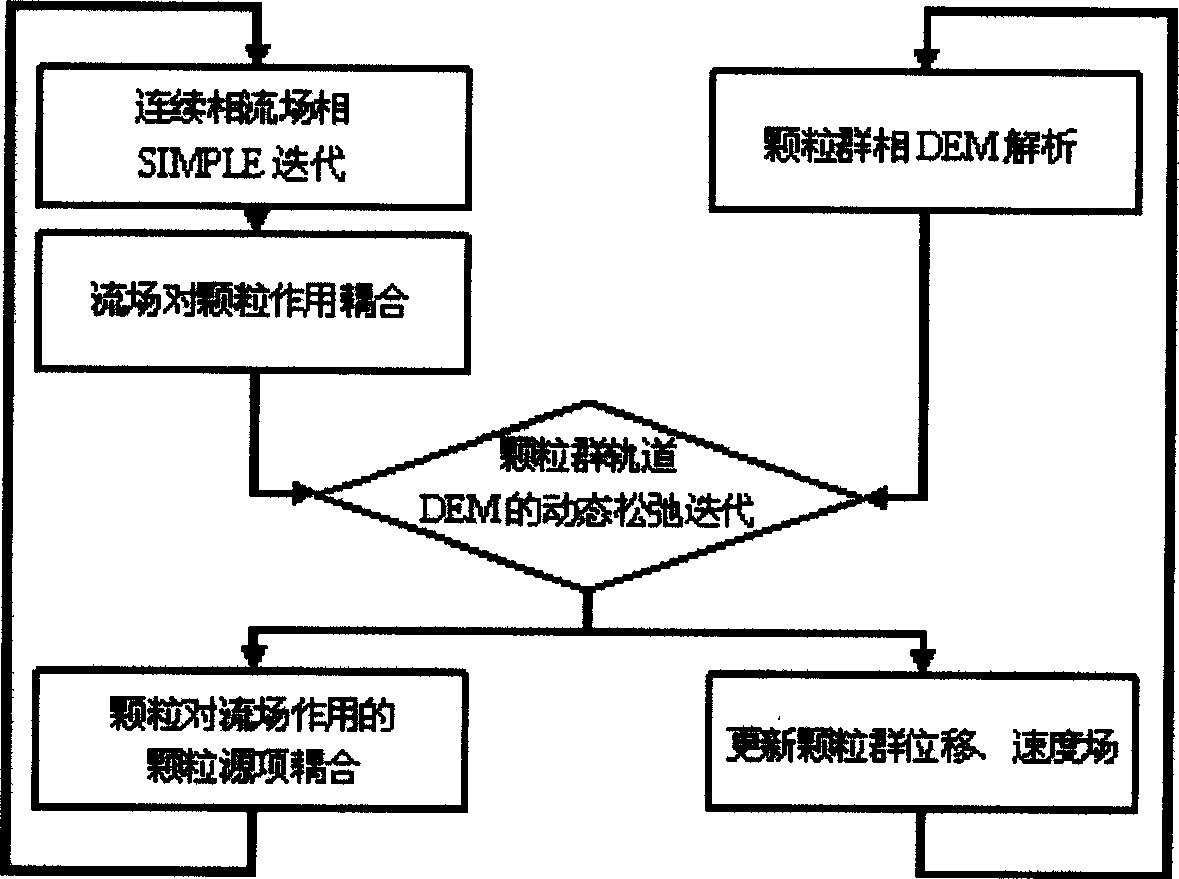

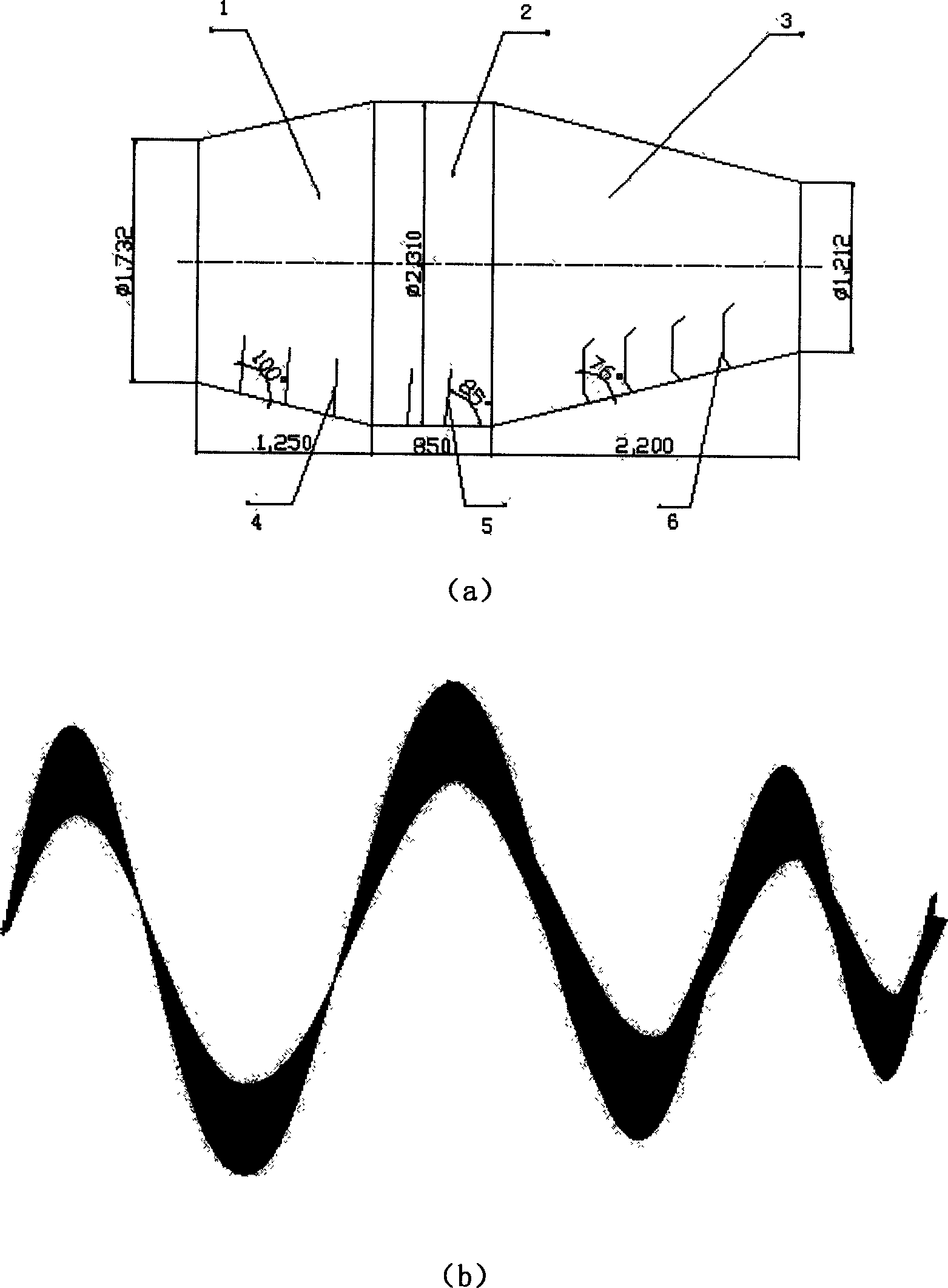

Method for modelling mixed material fluid-solid two-phase flow in mixing cylinder of concrete mixer car

InactiveCN1579726AMeet the design parameter requirementsReduce work intensityCement mixing apparatusData simulationHigh volume manufacturing

The invention discloses a method of constructing module to blend material stream and fix up two phase in the mix canister of beater, which is useful in the construction technology industry. This invention concentrate on the complicated density phrase and several phrase system, with the scatter unit method, and enlarge it to the data simulation of 3-D fluid flows and liquid two phrase flow, build group grain and group track soft module, simulate flow continue phrase by Navier-Stokes equation,at the same time, simulate the effect of grain disperse phrase by disperse unit method, the soft module construction of the collision among the grain is built by diverse unit method, to achieve the data simulate of 3-D two phase of blend material, at last optimize the parameter of blend canister. This invention decrease the work intension of the blend canister design, improve the design efficiency, at the same time optimize and improve the capacity of canister. The blend canister which is designed by this method has good capacity, and has been produced in large number, has got good economy and society effects.

Owner:SHANGHAI JIAO TONG UNIV

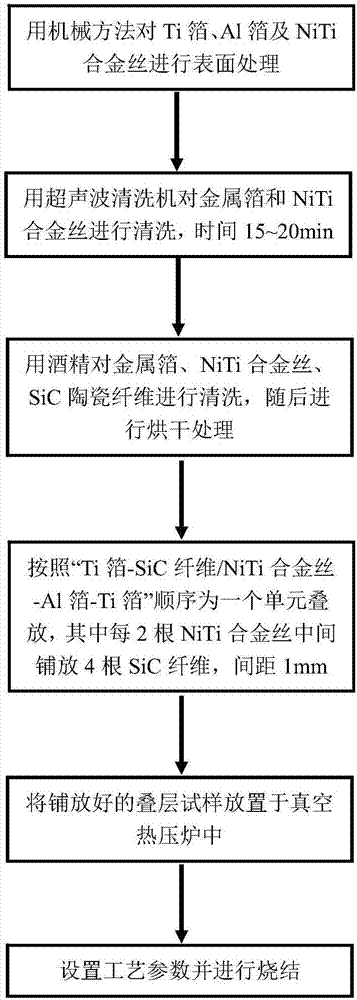

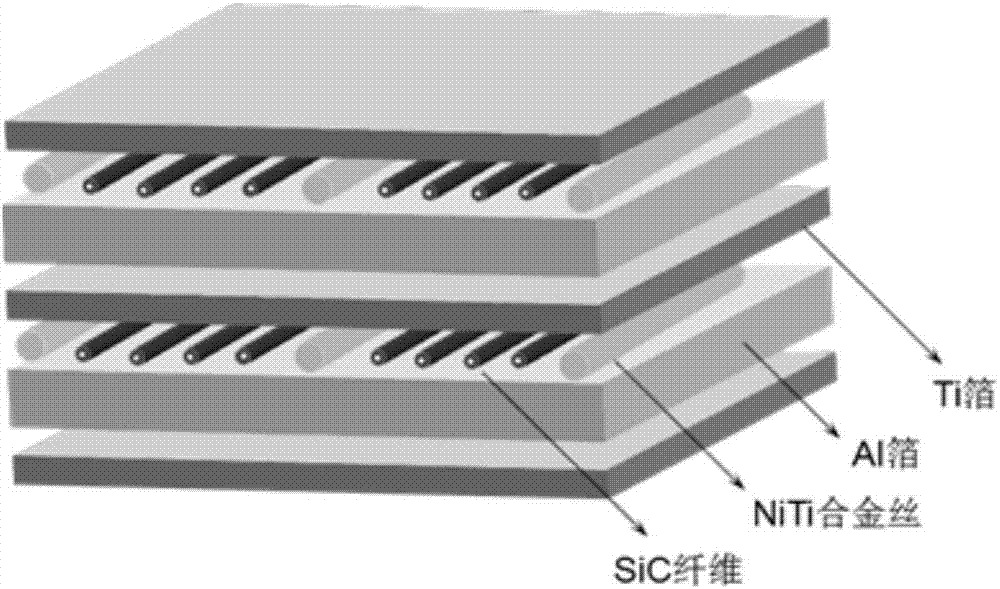

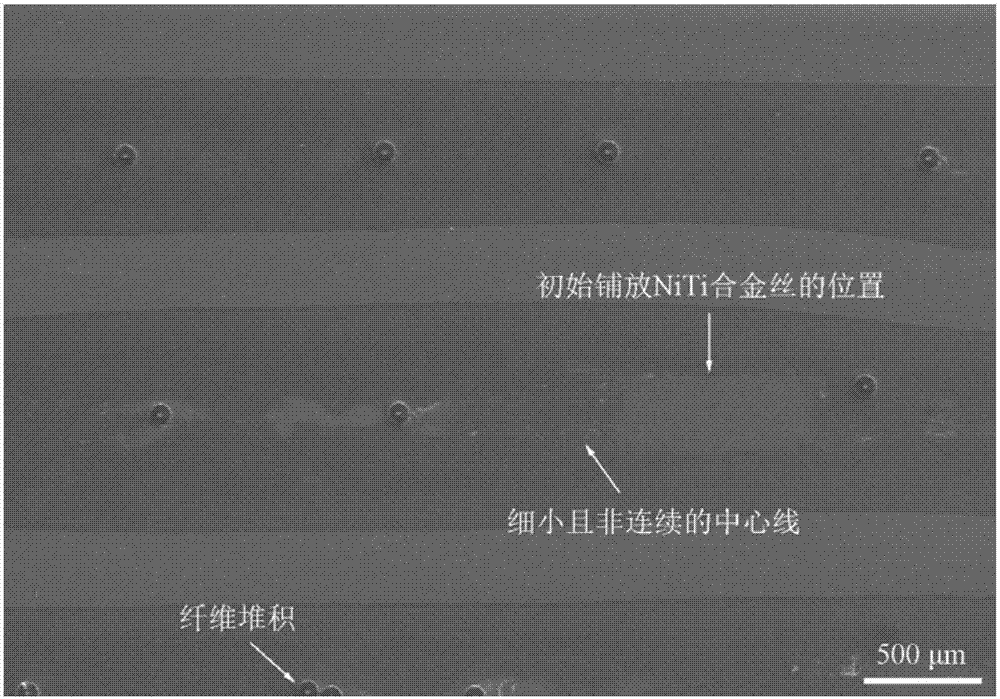

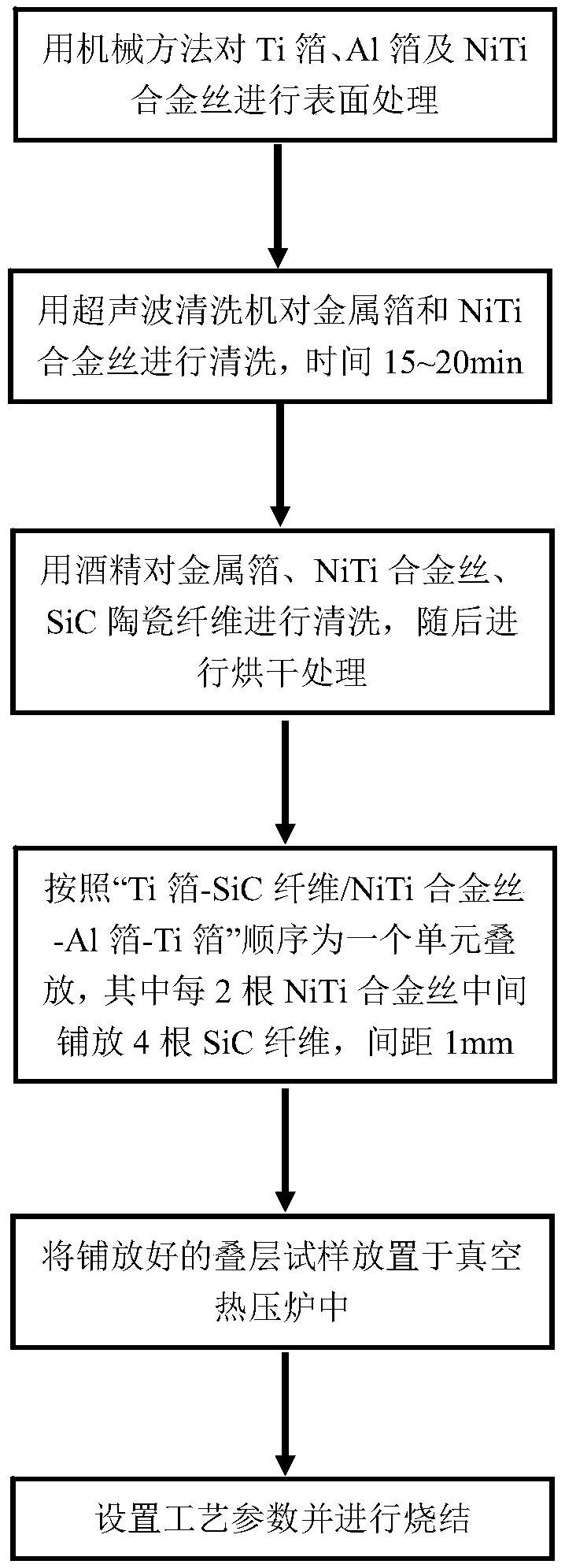

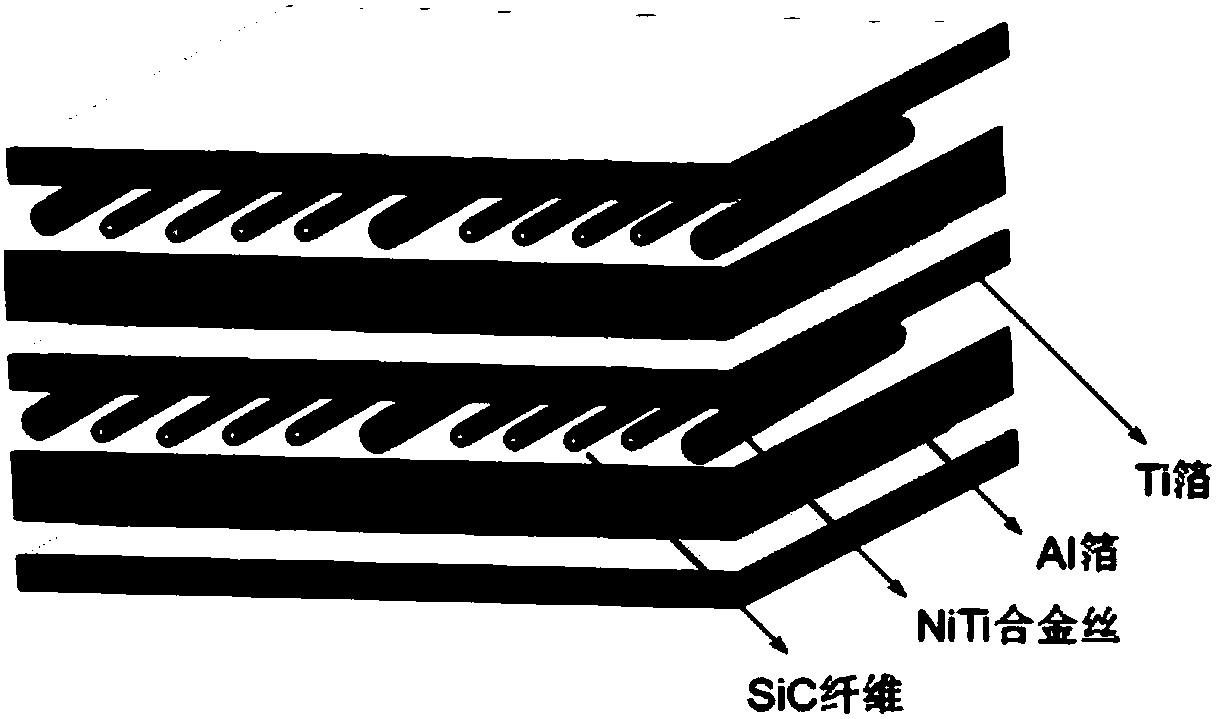

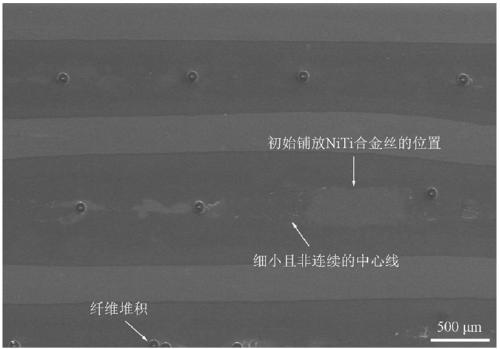

Method for improving titanium-aluminum laminated composite material structure and improving mechanical performance

The invention provides a method for improving a titanium-aluminum laminated composite material structure and improving mechanical performance. Tungsten core SiC ceramic fibers are pre-treated, and NiTi alloy wires, Ti foil and Al foil are subjected to ultrasonic cleaning; the Ti foil, the tungsten core SiC ceramic fibers, the NiTi alloy wires and the Al foil serve as a unit to be stacked according to the sequence of the Ti foil, the tungsten core SiC ceramic fibers, the NiTi alloy wires, the Al foil and the Ti foil, the four SiC fibers are placed between every two NiTi alloy wires, the interval is 1 mm, and the upper surface and the lower surface are both the Ti layers; and sintering is conducted on the unit through a vacuum hot pressing device. According to the method for improving the titanium-aluminum laminated composite material structure and improving the mechanical performance, through the design principle that nickel and titanium elements in the NiTi wires easily react with aluminum elements under the low temperature to form inter-metallic compounds, the SiC fibers and the NiTi alloy wires are simultaneously introduced into inter-metallic compound layers through the vacuum hot pressing sintering method, the SiC fibers serve as reinforcing bodies, introduction of the NiTi alloy wires aims to remove inter-metallic compound layer center lines through the sufficient diffusion reaction mechanism of the NiTi alloy wires and Al, and the SiC fiber / base body interface is improved, so that the mechanical performance of a composite material is improved.

Owner:HARBIN ENG UNIV

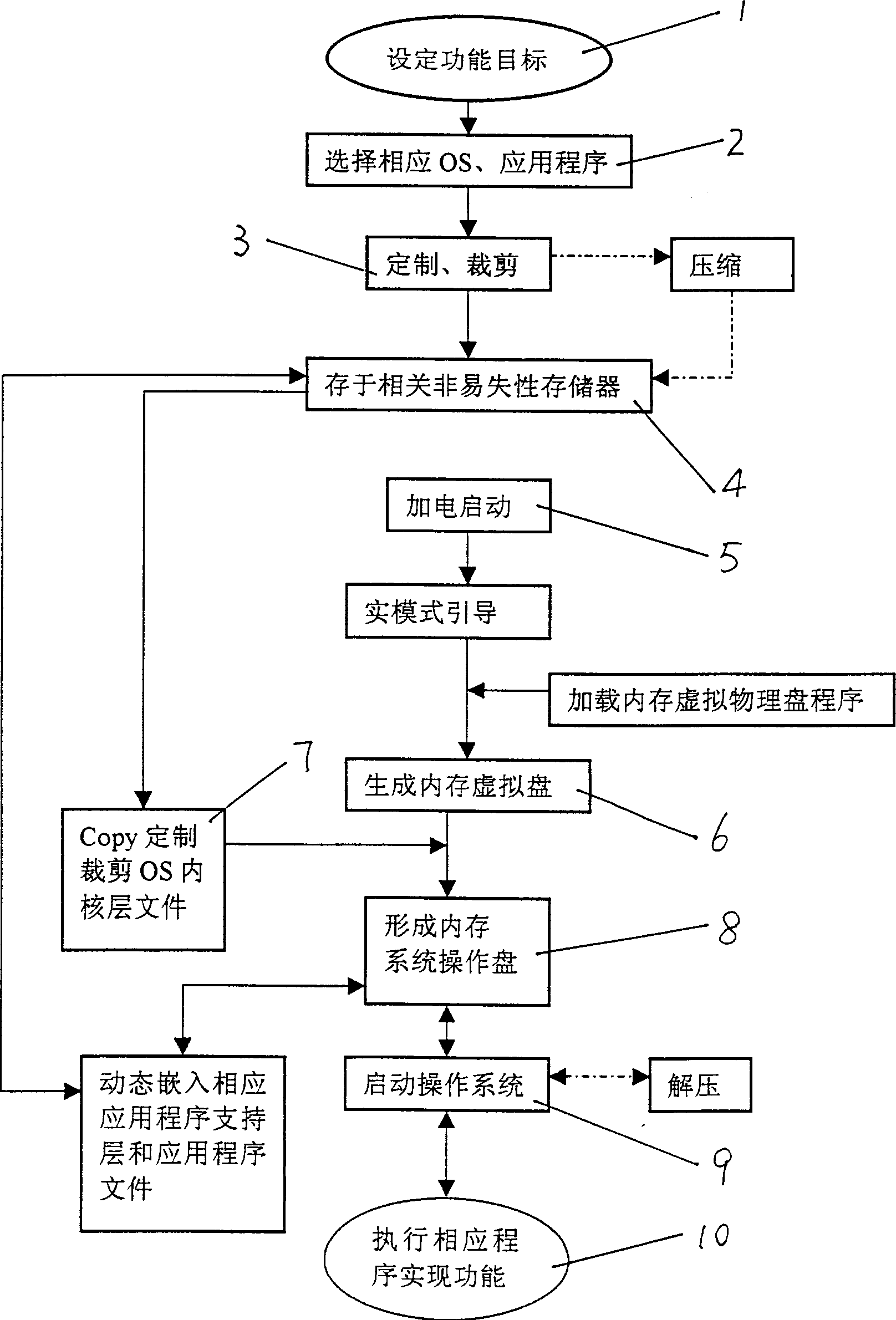

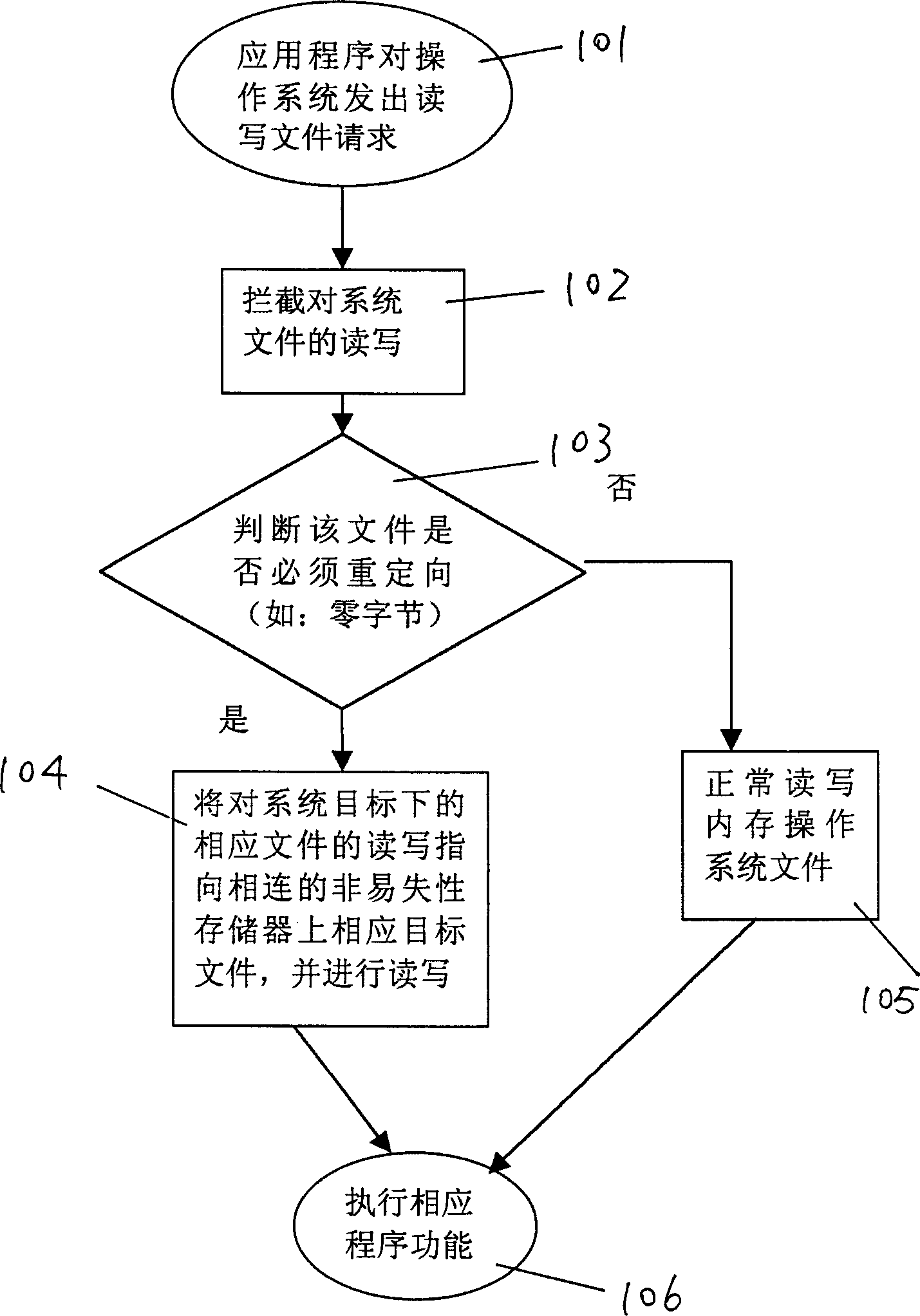

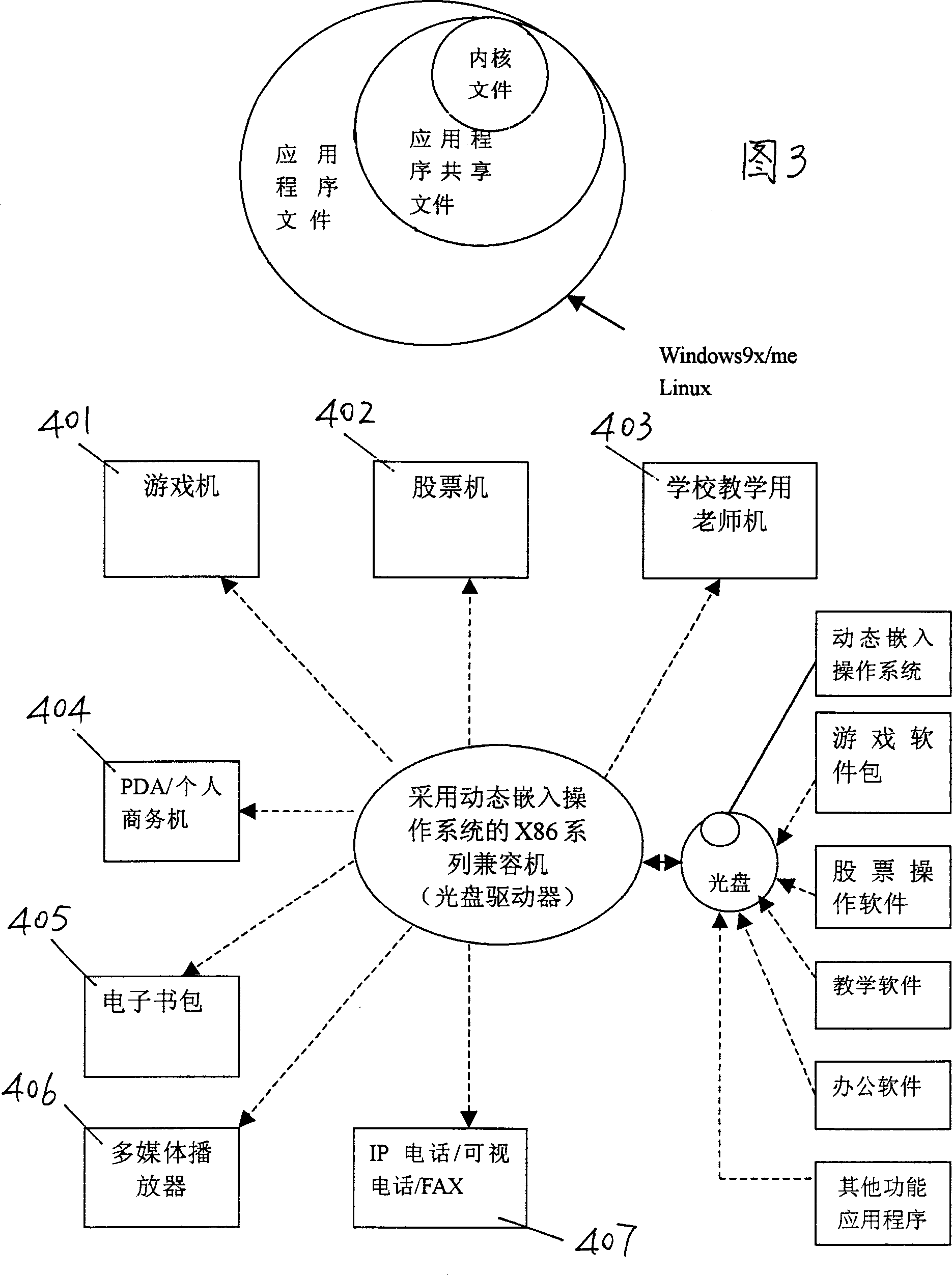

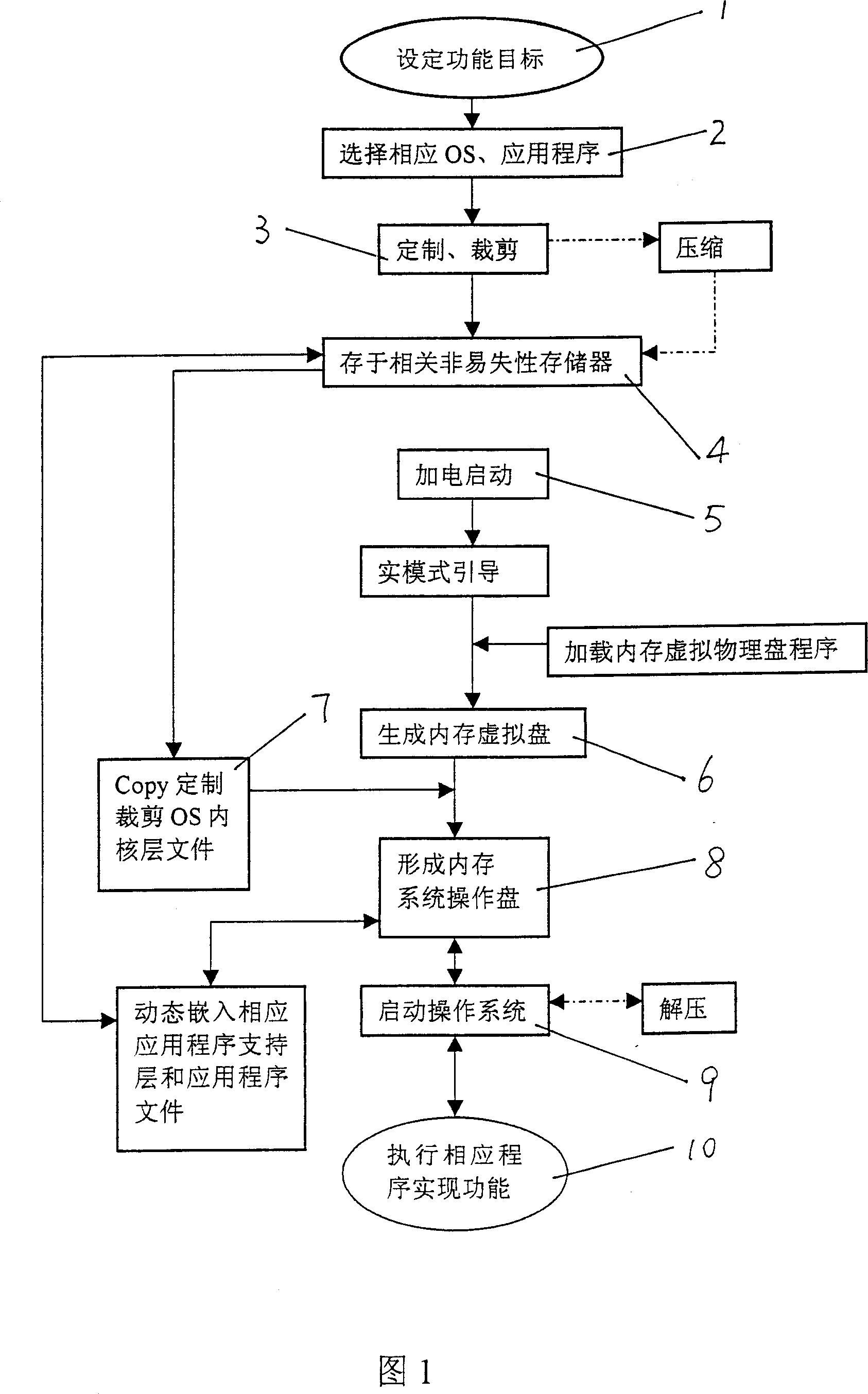

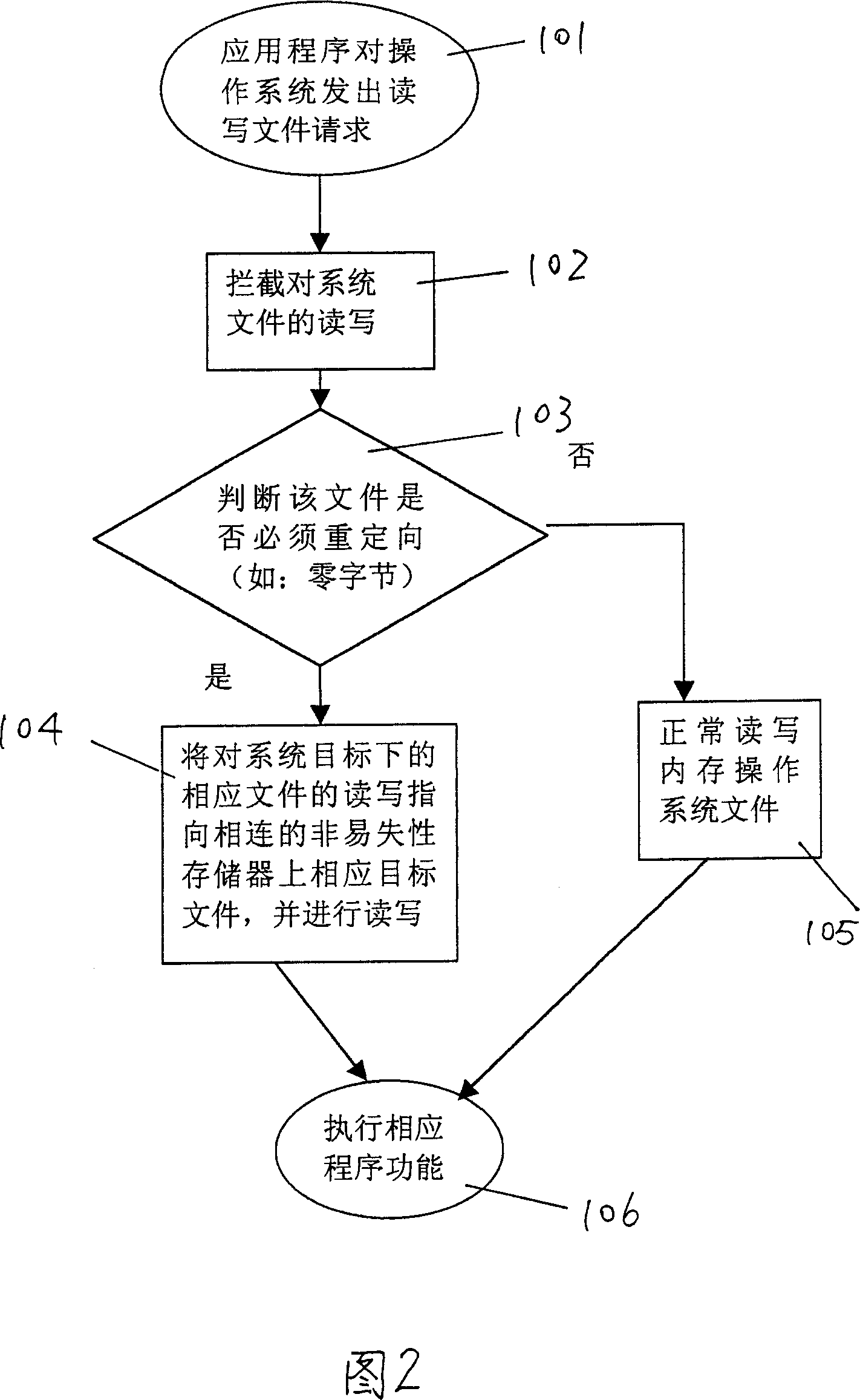

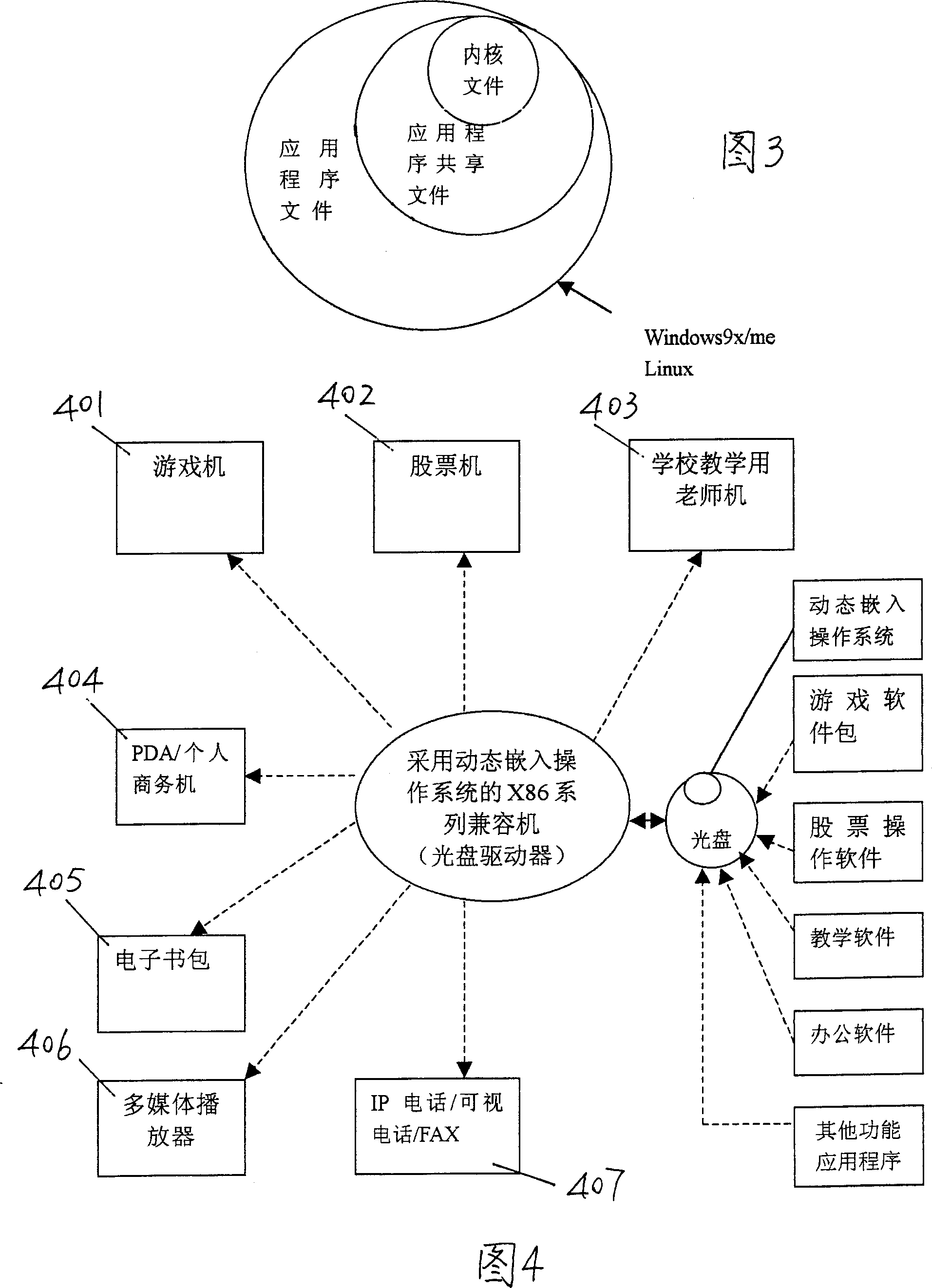

X-86 serial compatible machine and generation method for its operation system

InactiveCN1405684ALow manufacturing costEasy to useMemory adressing/allocation/relocationSpecific program execution arrangementsEmbedded systemApplication software

The characters of the invention are as follows. The operating system files and the application program files stored in the memory are called and stored by using the dynamic embedded mode so as to generate the virtual operation system disc in the memory. The functions of the compatible computer meet the performances of the high end PC, providing the features of low cost, easy of use and maintenance, high efficiency, stability and reliability.

Owner:深圳市索普卡软件开发有限公司

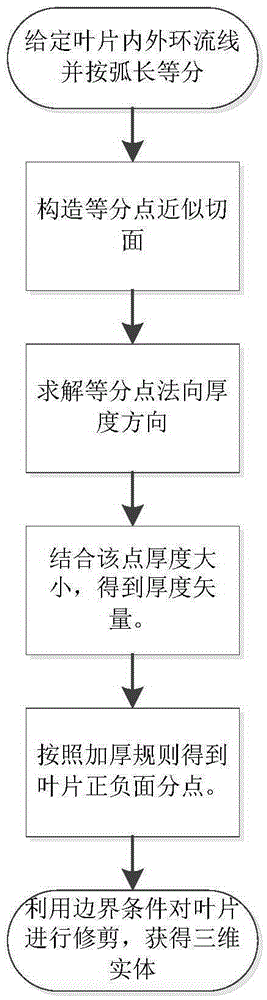

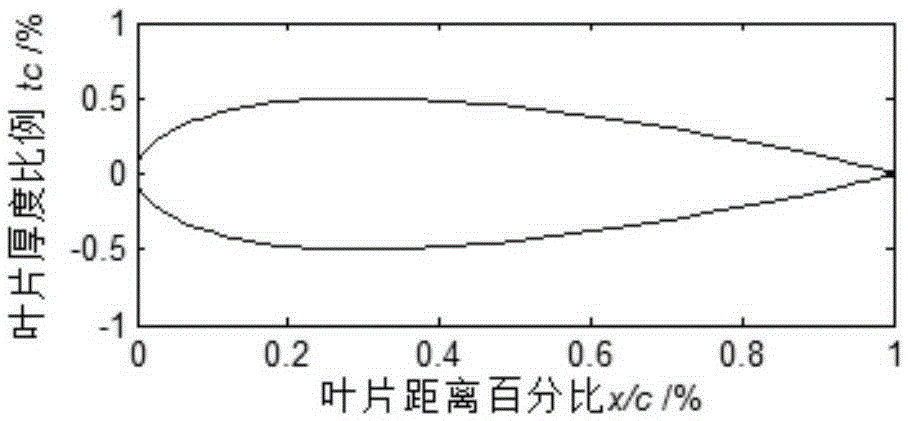

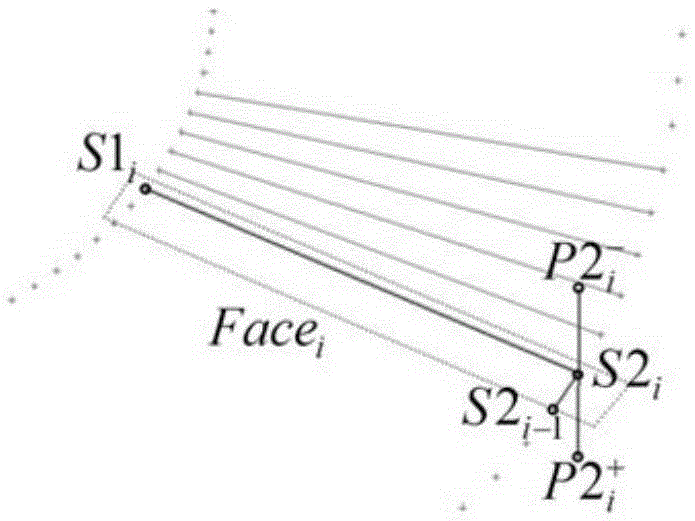

Method for determining thickness of blades of hydraulic torque converter based on water-drop-shaped airfoil function

ActiveCN105240480AImprove continuityPerformance optimization and improvementFluid gearingsInner loopEngineering

The invention discloses a method for determining the thickness of blades of a hydraulic torque converter based on a water-drop-shaped airfoil function. The method comprises the steps that an inner loop line and an outer loop line of a middle flow plane of a certain blade are split into dot matrices; when the normal thickness of a certain dot is calculated, a dot around the dot and a corresponding dot on the corresponding loop line are selected to serve as a group; the normal thickening direction of the dot is calculated through an algorithm; a function value of the corresponding dot of the water-drop-shaped airfoil function is selected to serve as a thickness value of thickening, and a thickness vector is formed; positive pressure surface dots and negative pressure surface dots of the dot are obtained after the dot is thickened, all the dots are subjected to similar operation, and an inner loop pressure surface dot group and an outer loop pressure surface dot group are obtained after thickening; and the blade is formed through the dot groups by means of modeling software, and the thickness of the blade is determined. According to the method, the thickness function which meets the water-drop-shaped airfoil characteristics is converted into the thickness vector and applied to the thickness design of the space blade. The method has the advantages that the thickened blade conforms to the hydrodynamic theory, and meanwhile blade thickness design parameters can be reduced; the blade design accuracy is greatly improved.

Owner:TONGJI UNIV

Semiconductor device and manufacturing method thereof

ActiveCN110783358AImprove electrical performanceElectrical performance optimization and improvementSolid-state devicesDiodeDevice materialEngineering

The invention provides a semiconductor device and a manufacturing method thereof. The manufacturing method of the semiconductor device comprises the steps of forming a groove filling structure in a substrate of a pixel region, and clamping a high-K dielectric layer between a side wall of a filling material in the groove filling structure and a substrate; covering a buffer dielectric layer on a surface of the substrate in the pixel region; etching the buffer dielectric layer to form a first opening which at least exposes parts of the substrate at a periphery of a top side wall of the groove filling structure and / or at least parts of a top of the groove filling structure; filling a first conductive metal layer in the first opening so as to be electrically connected with the exposed parts ofthe substrate and / or the groove filling structure; and forming a metal grid layer on the buffer dielectric layer and electrically connecting the metal grid layer with the first conductive metal layer.In the technical scheme of the invention, the metal grid layer is electrically connected with the exposed parts of the substrate and / or the groove filling structure so that electrical performance ofthe semiconductor device can be optimized and improved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

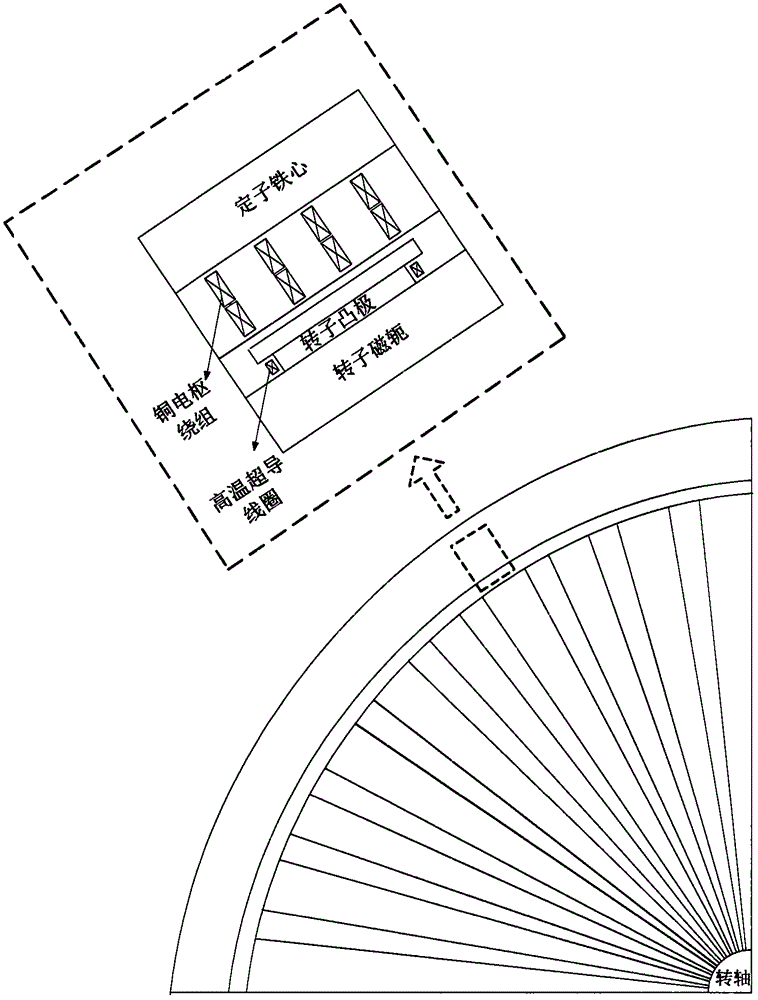

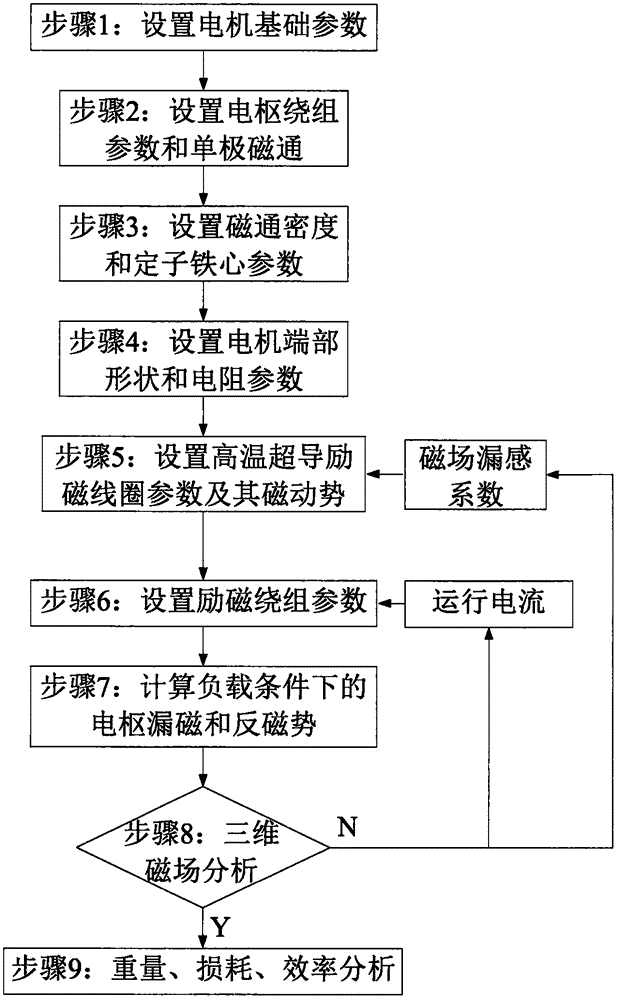

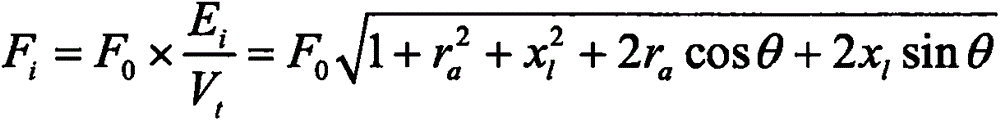

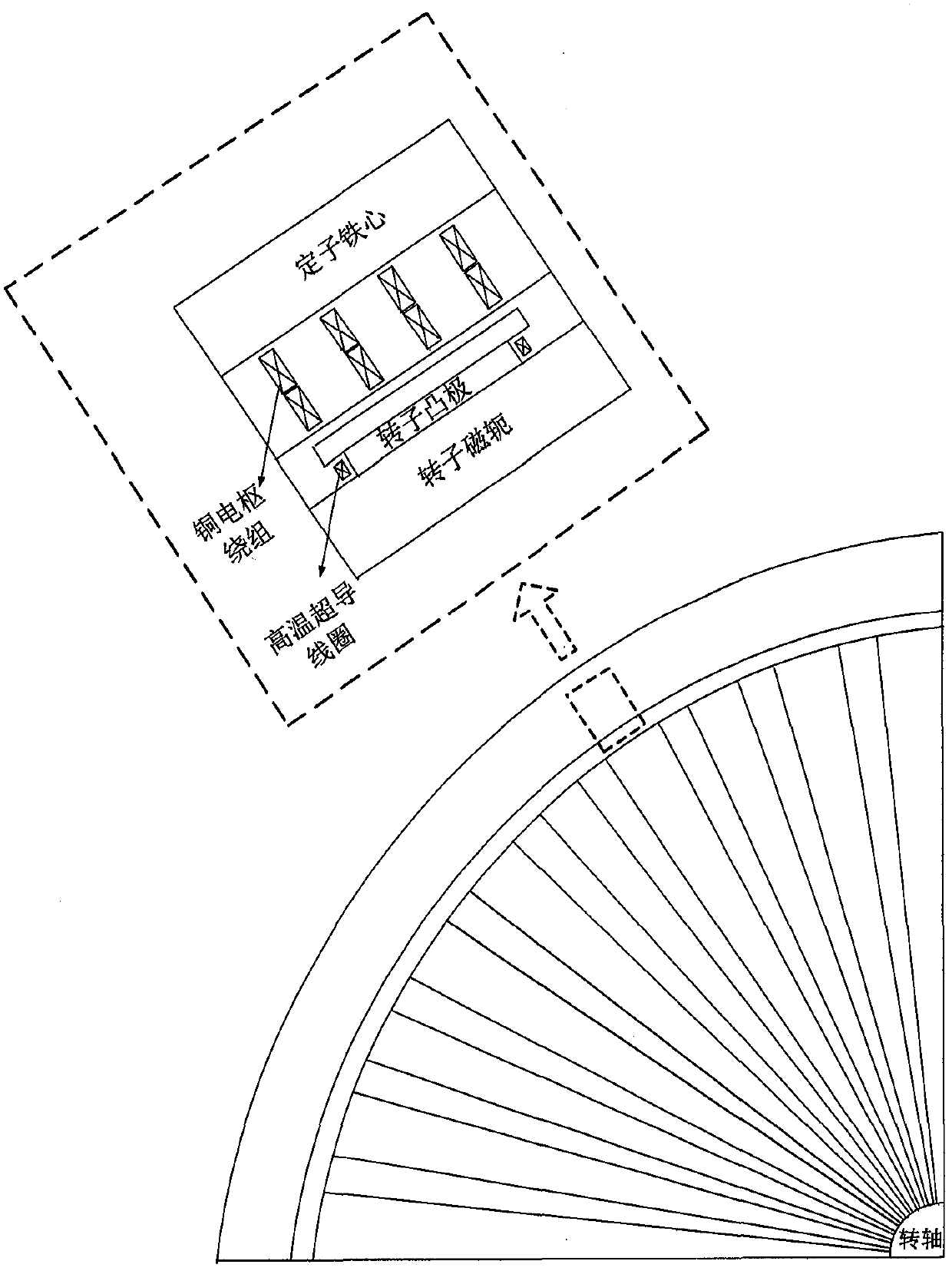

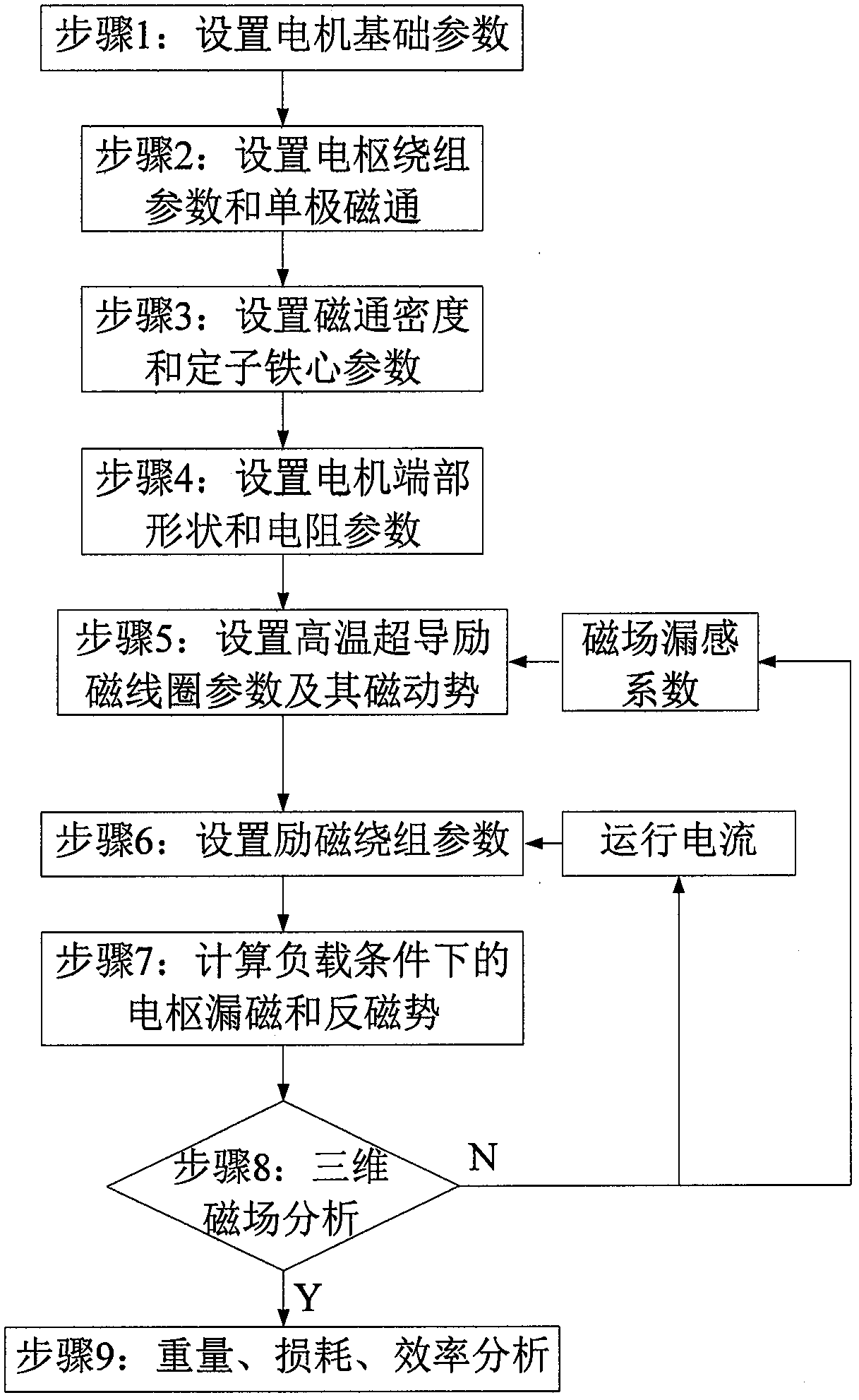

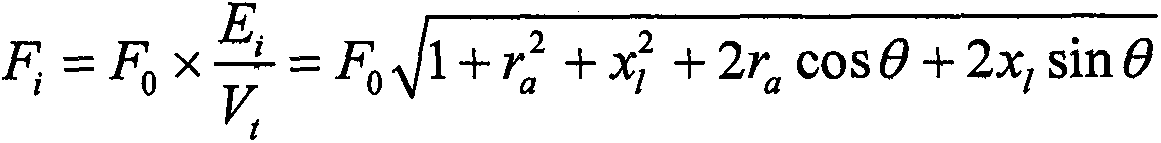

Salient pole type offshore wind turbine parameter optimization method based on high-temperature superconducting magnet exciting coil

InactiveCN106208549AWeight optimizationImprove efficiencyGeometric CADManufacturing dynamo-electric machinesClosed loop feedbackHigh temperature superconducting

The invention discloses a salient pole type offshore wind turbine parameter optimization method based on a high-temperature superconducting magnet exciting coil. A rotor of a motor is a salient pole; the magnet exciting coil adopts a high-temperature superconducting material; and the weight, loss and efficiency analysis of the motor are completed by setting of basic parameters of the motor, armature winding parameters, magnetic flux density, stator iron core parameters, wind turbine armature winding structure, high-temperature superconducting magnet exciting coil parameters, armature magnetic leakage and reverse magnetic potential under a load condition, three-dimensional magnetic field analysis and the like. According to the method, the salient pole type offshore wind turbine parameter optimization method can be carried out automatically according to computational formulas to realize optimization of the weight, the efficiency, the high-temperature superconducting material length and other parameters of the offshore wind turbine; and meanwhile, two closed loop feedback circuits of a magnetic field leakage inductance coefficient and a running current are included in the optimization process, so that the method plays a key role in improvement of the optimization of the motor performance.

Owner:HENAN POLYTECHNIC UNIV

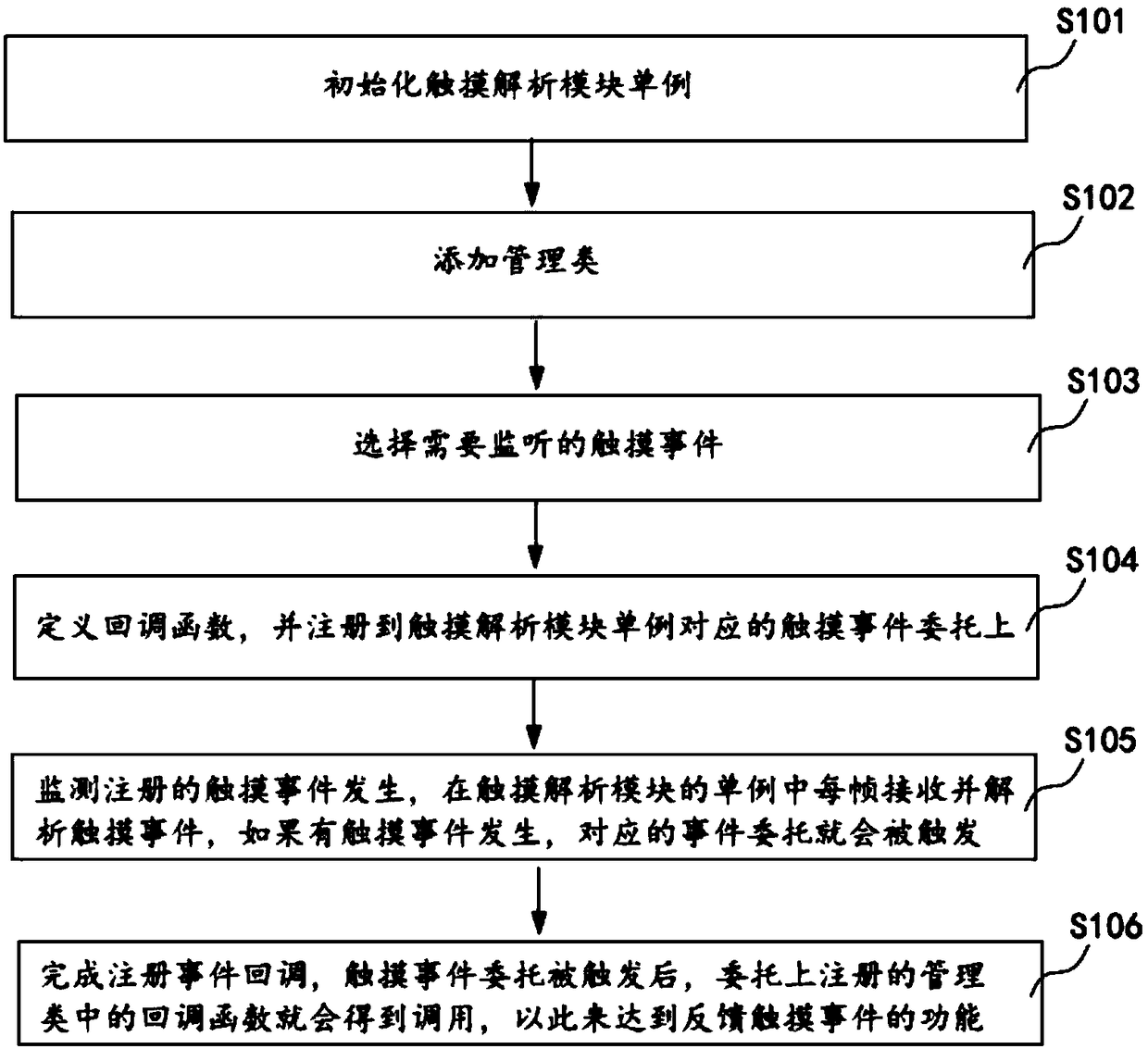

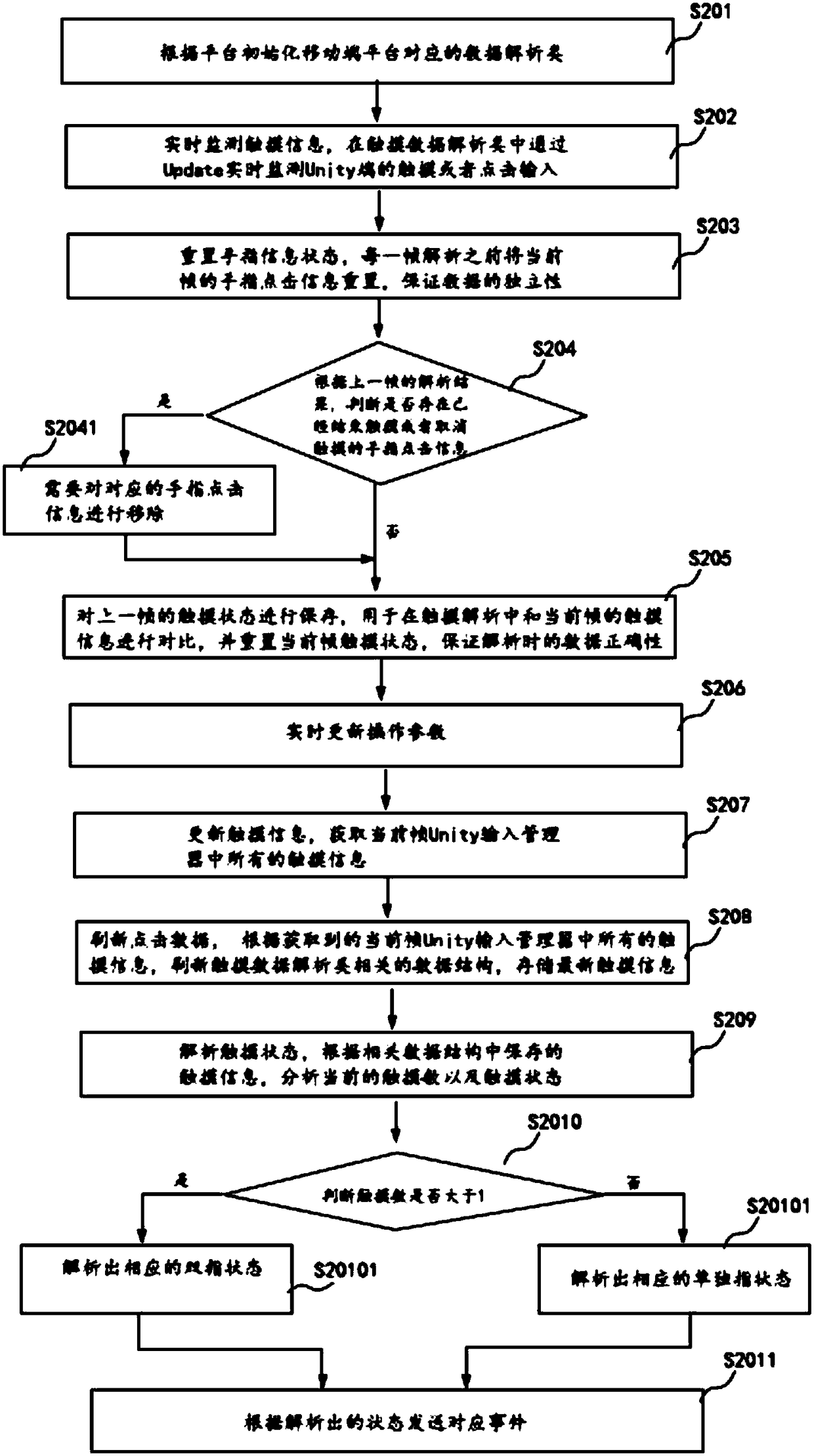

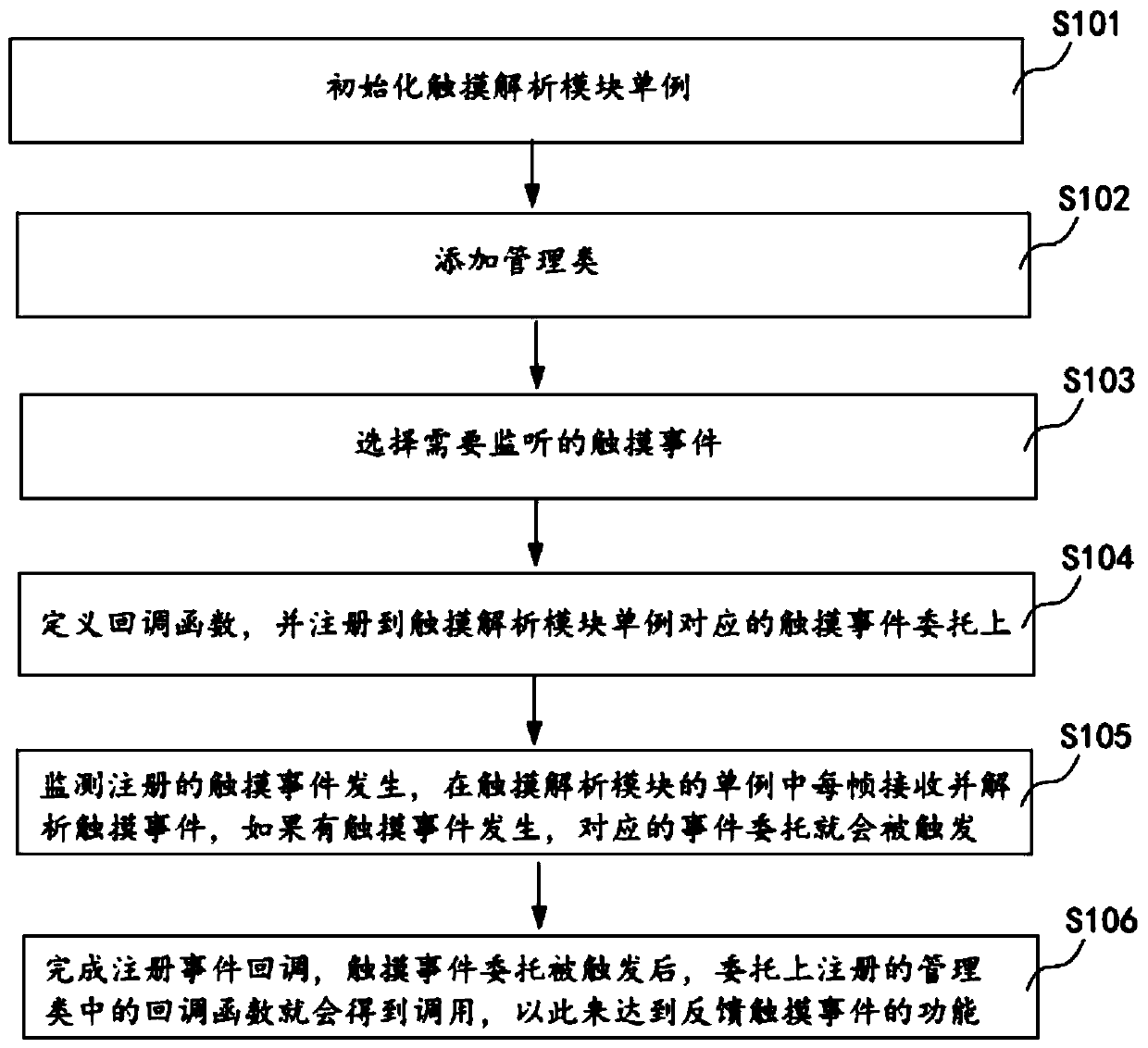

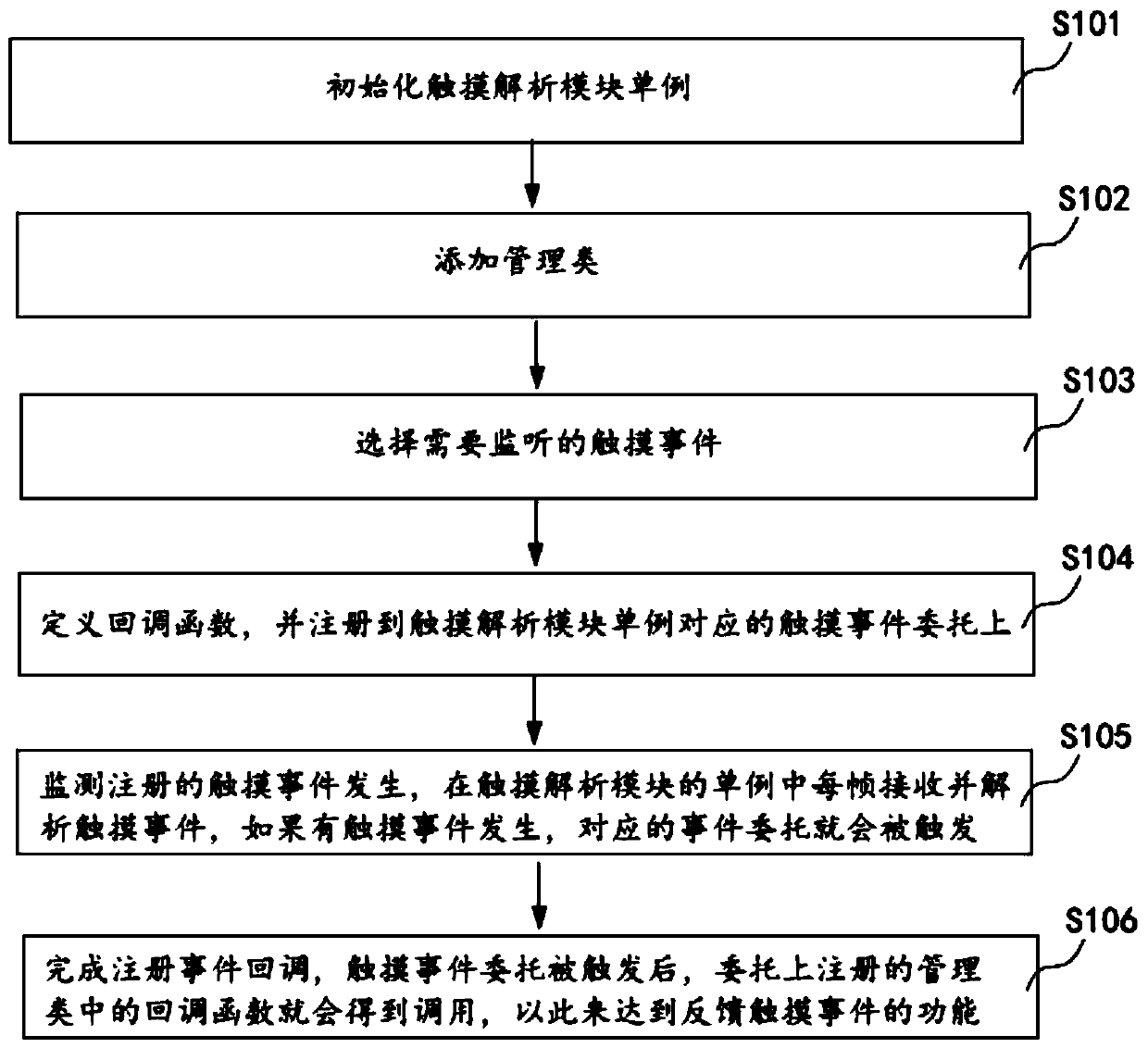

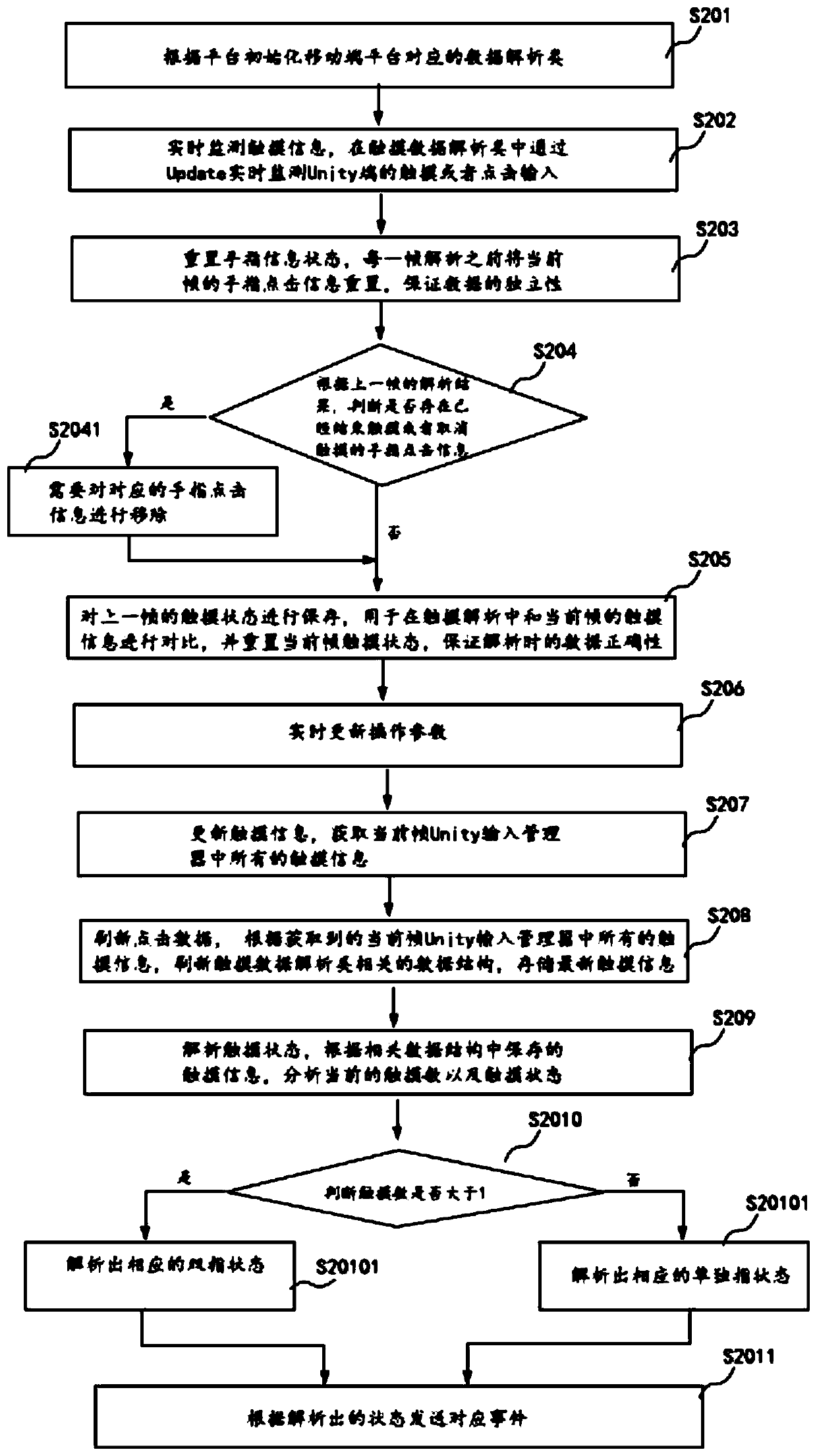

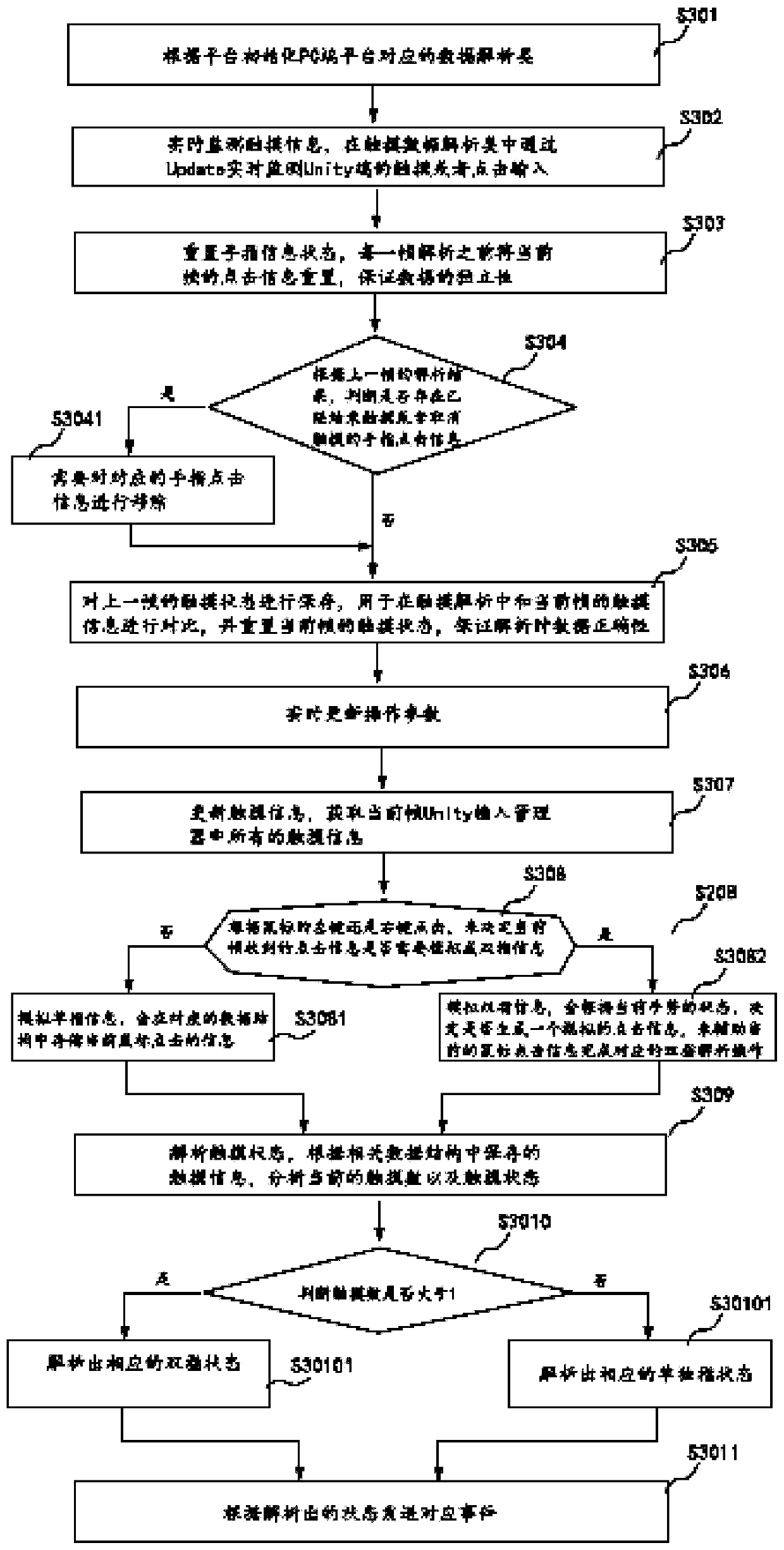

Cross-platform GUI touch event analysis method under the Unity environment

ActiveCN109408055AEasy to installParsing fastExecution for user interfacesCompiler constructionSoftware engineeringMobile end

The invention provides a cross-platform GUI touch event analysis method under the Unity environment, which solves the problem of integrating the event management into the management layer by using a single example class to carry out entrusted event registration management and a touch analysis dispatch mechanism. Multi-platform touch resolution inherits the unified interface, which is manifested asthe same interface to achieve different cross-platform, whether mobile or PC, are unified, and do not occupy more memory. The Unity base class is used as the core of the solution, and the performanceis optimized. There is little overhead except initialization, and there is no other overhead except normal parsing logic in the process. It can be applied to mobile platform and PC platform.

Owner:苏州沁游网络科技有限公司

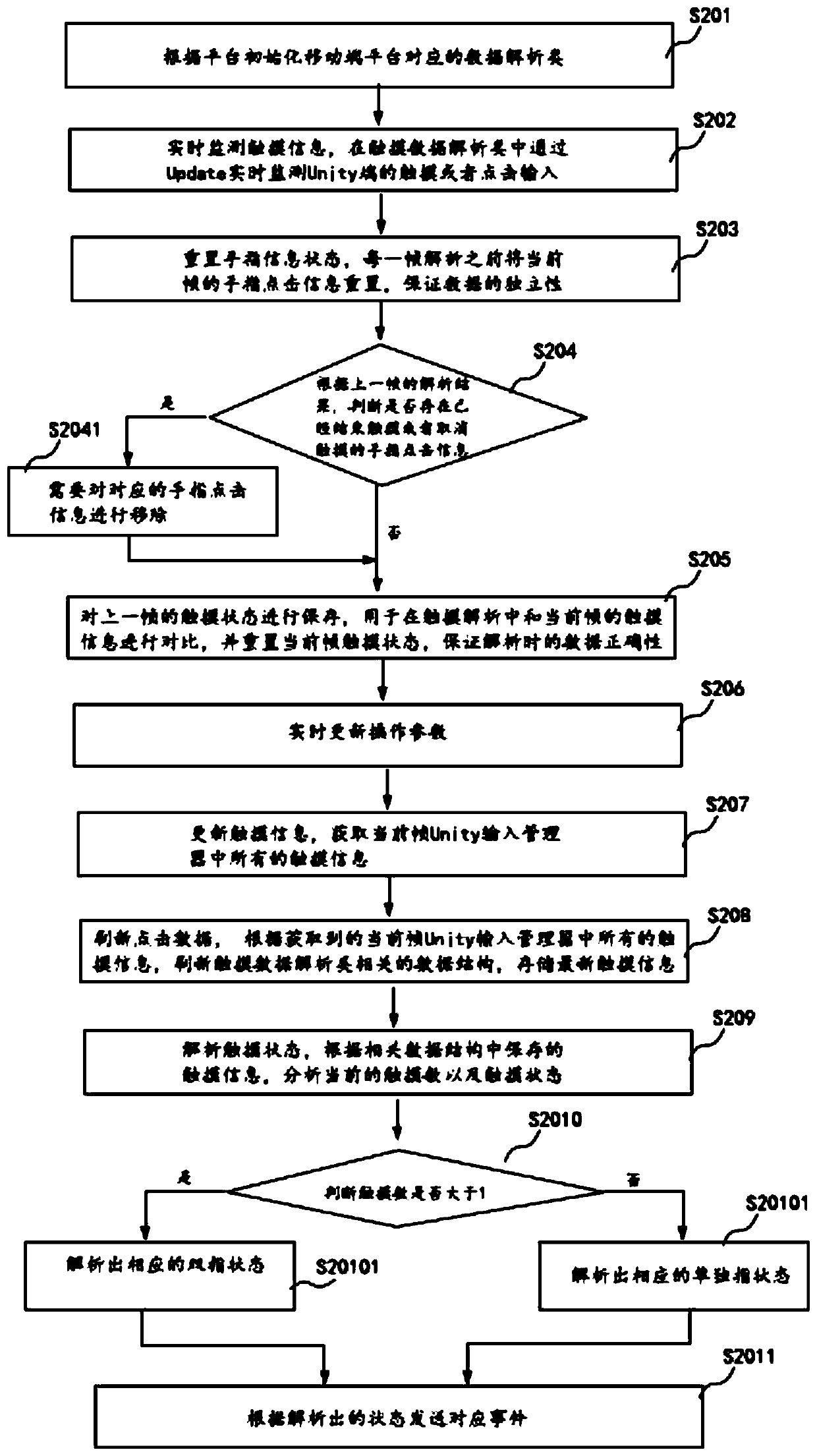

Cross-platform GUI touch event analysis method in Unity environment

ActiveCN110597509AEasy to installParsing fastExecution for user interfacesCompiler constructionSoftware engineeringMobile end

The invention provides a cross-platform GUI touch event analysis method in a Unity environment, which solves the problem of integrating the event management to a management layer by using a single example class to carry out the entrusted event registration management and the touch analysis distribution. The multi-platform touch analysis inherits a unified interface, externally different cross-platforms are realized for the same interface, both a mobile terminal and a PC terminal are unified, and more memories are not occupied. A Unity basic class is used as a scheme implementation core, the performance optimization is better, a little expenditure exists during initialization, and no other extra expenditure exists during the process at ordinary times except for the normal analysis logic. The method can be applied to a mobile terminal platform and a PC terminal platform.

Owner:苏州沁游网络科技有限公司

Method for preparing organic photovoltaic device with super-thick absorption layer and organic photovoltaic device

ActiveCN111697137APerformance Optimization and ImprovementReduce manufacturing costFinal product manufactureSolid-state devicesEngineeringHole transport layer

The invention relates to a method for preparing an organic photovoltaic device with a super-thick absorption layer and the organic photovoltaic device. The method comprises steps that a device is prepared, a first device bottom and a first device top of the device are prepared respectively, and the first device bottom comprises a first substrate, a first electrode located on the first substrate, ahole transport layer located on the first electrode and an ultra-thick absorption layer located on the hole transport layer, the first device top comprises a second substrate, an adhesive layer located on a surface of the second substrate, a second electrode located on the adhesive layer and an electron transport layer located on the second electrode, and the second substrate is provided with a plurality of convex bodies in the length direction, and the top of the first device laminate on the bottom of the first device, and the convex body is made to extend into a super-thick absorption layerto obtain an organic photovoltaic device. The method is advantaged in that performance of the device is optimized and improved, the method is suitable for industrial large-scale production, and production cost can be reduced.

Owner:SUZHOU UNIV

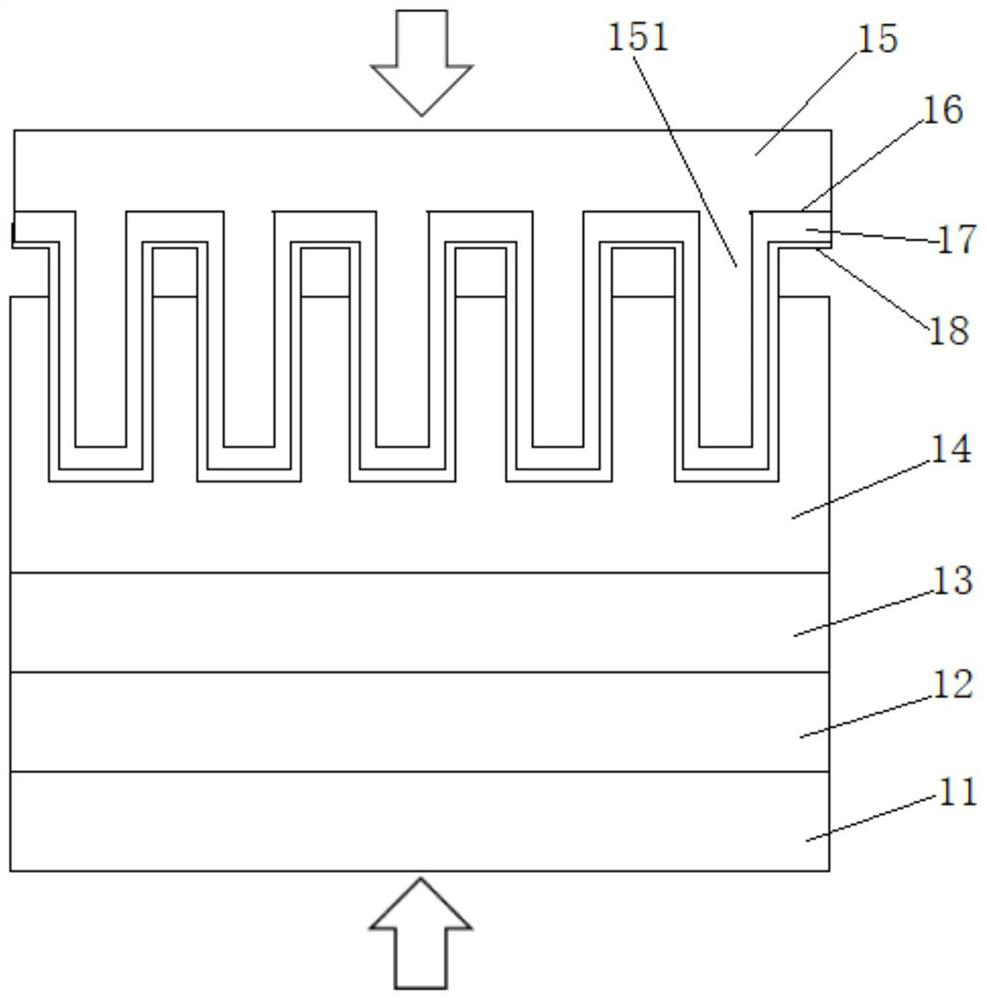

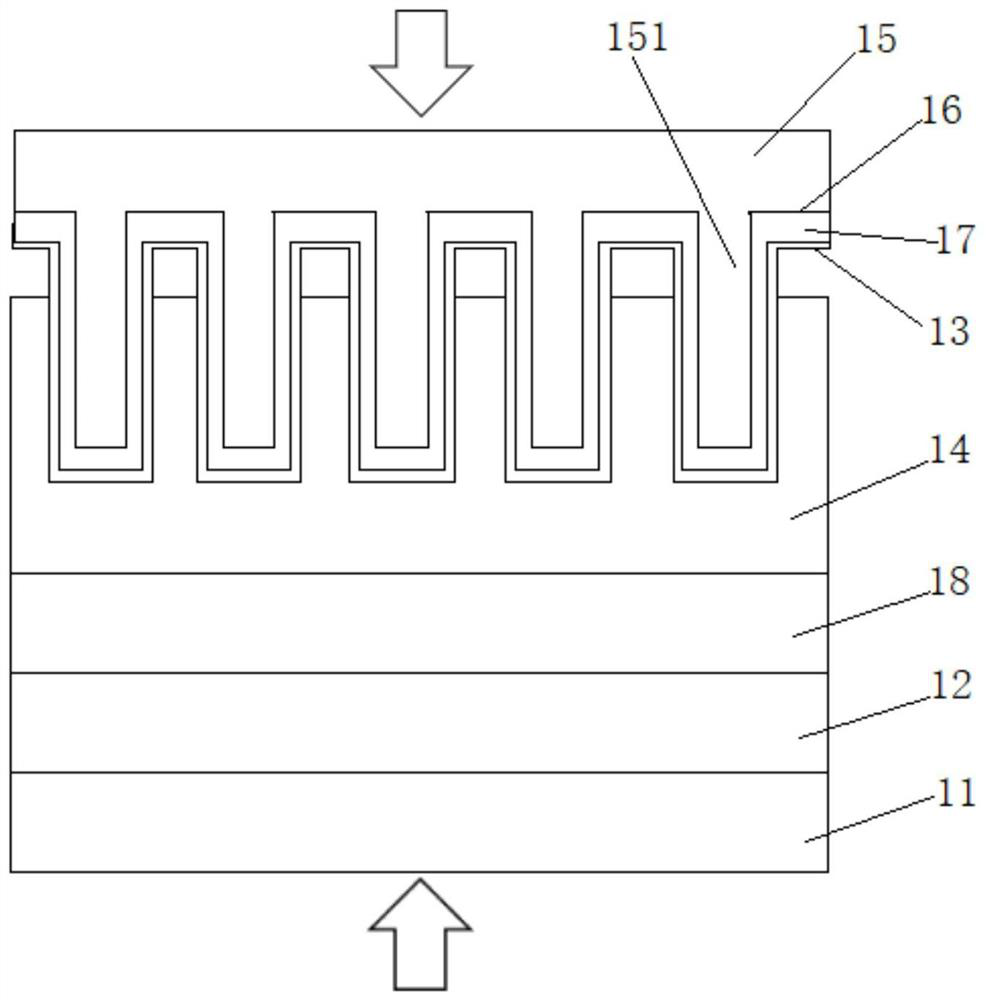

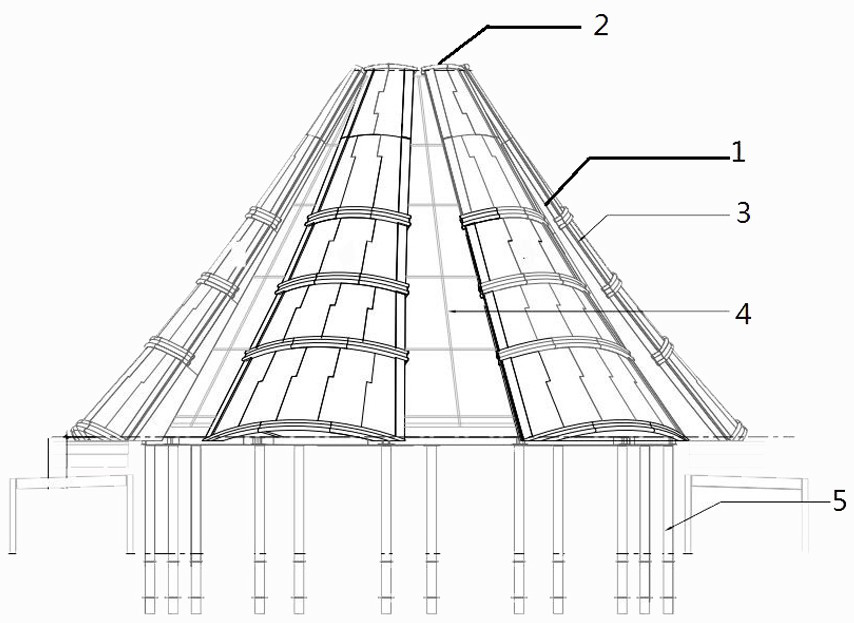

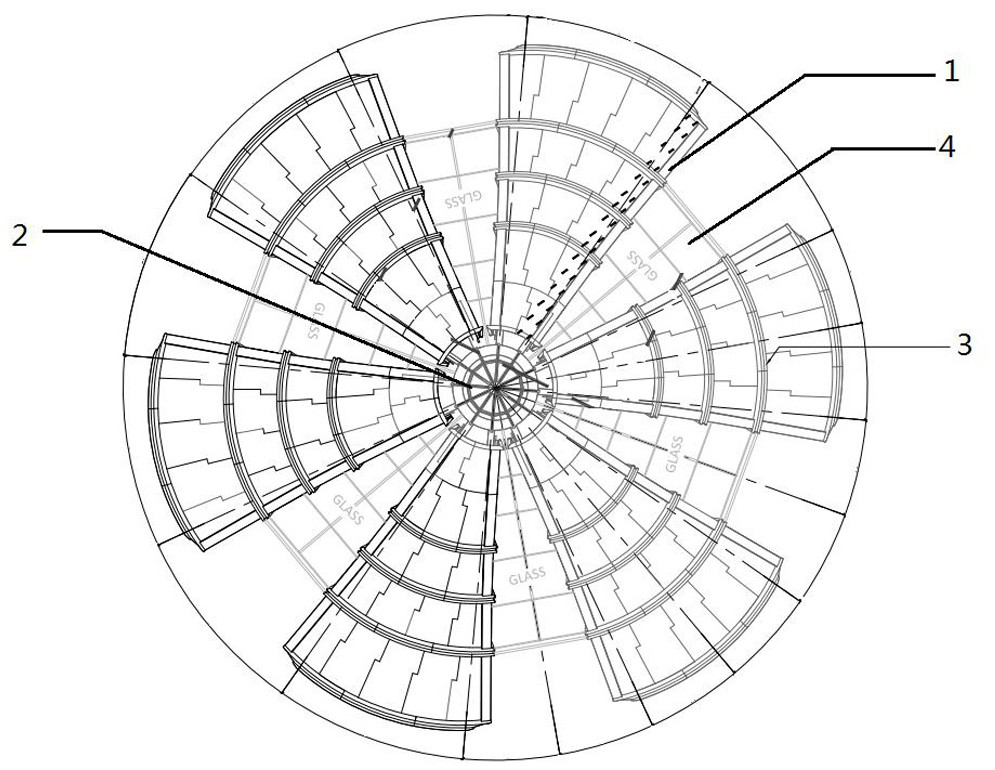

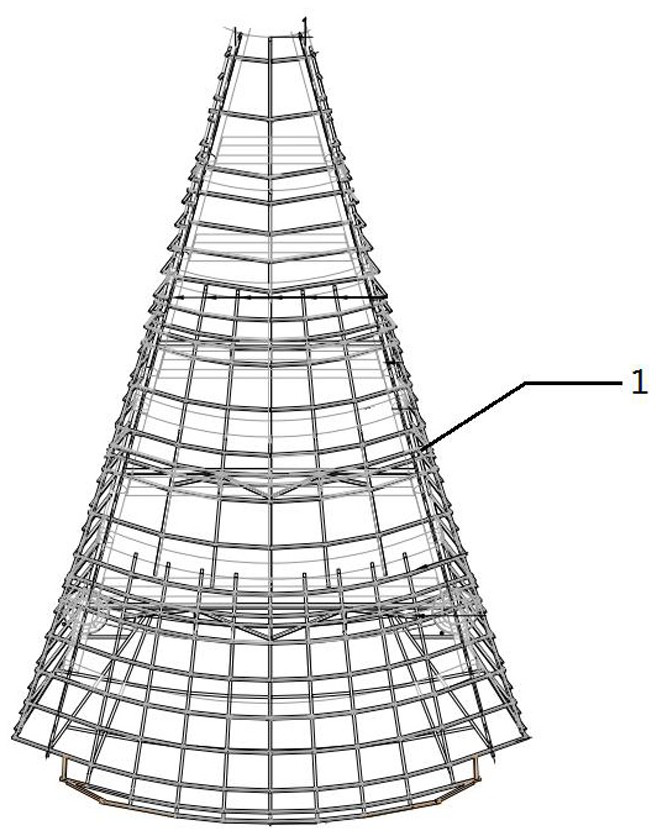

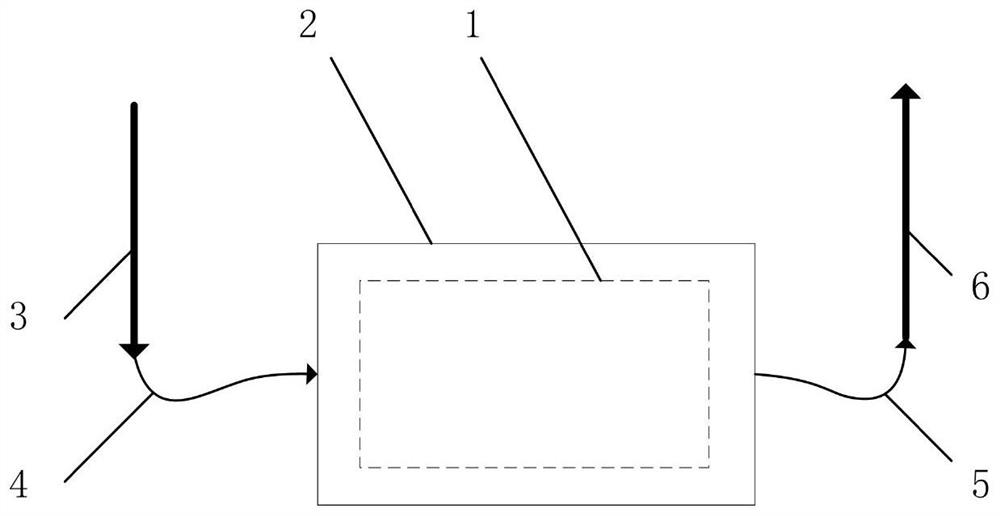

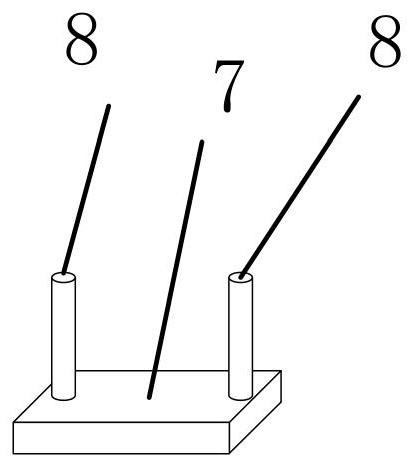

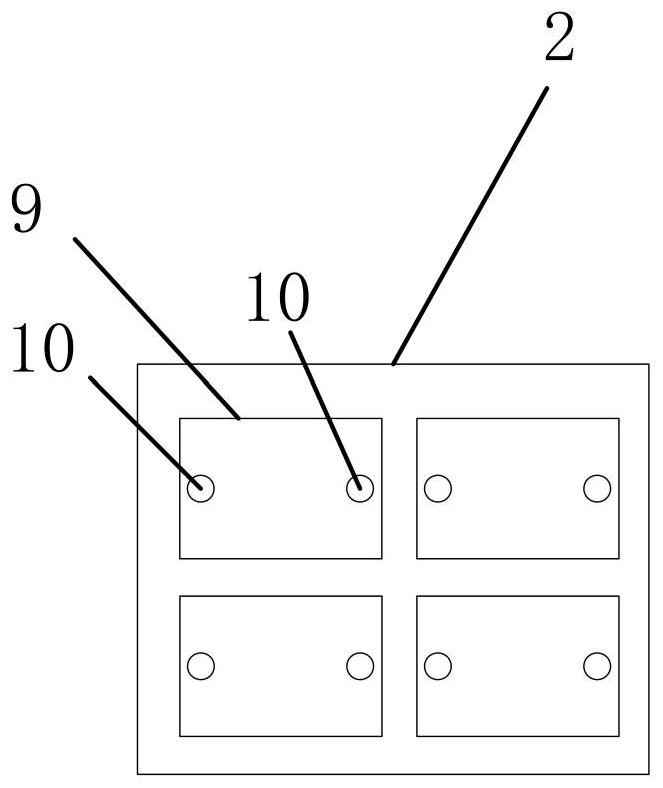

A kind of conical building and construction method thereof

ActiveCN112031152BCreativeConvenient lightingCovering/liningsSky-lights/domesPre stressArchitectural engineering

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

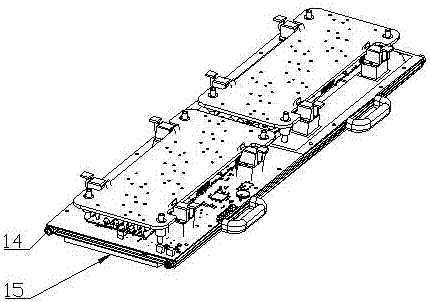

Monocell test fixture with temperature partition setting and test method thereof

PendingCN114878865AConvenient inspectionEasy to findMeasurement instrument housingEnvironmental/reliability testsTemperature controlFuel cells

The invention belongs to the technical field of fuel cell test, discloses a single cell test fixture with temperature partition setting and a test method thereof, and aims to test a single cell according to the actual characteristic of non-uniform actual temperature distribution on the surface of a single cell in a galvanic pile. Temperature zoning conditions are provided for a conventional zoning test board to measure data such as current, resistance, air pressure, humidity and the like of each monitoring zone. The detection subarea and the temperature control subarea can be the same or different. The invention provides deeper technical support for the development of fuel cells.

Owner:大连锐格新能源科技有限公司

Semiconductor device and manufacturing method thereof

ActiveCN111312654BImprove electrical performanceElectrical performance optimization and improvementSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialElectrical performance

The invention provides a semiconductor device and a manufacturing method thereof. The manufacturing method of the semiconductor device includes: forming a trench filling structure in the substrate of the pixel region, and the sidewall of the filling material in the trench filling structure and the substrate A high-K dielectric layer is also sandwiched between them; a plug structure is formed in the substrate of the pad area; the buffer dielectric layer is covered on the substrate surface of the pixel area and the pad area; the buffer dielectric layer is etched to form at least the exposed Part of the substrate at the periphery of the top sidewall of the trench-filling structure and / or a first opening at least part of the top of the trench-filling structure; and, forming a metal grid layer on the buffer medium layer of the pixel region and filling the first opening , so as to be electrically connected to the exposed part of the substrate and / or the trench filling structure. The technical solution of the present invention enables the metal grid layer to be electrically connected to the exposed part of the substrate and / or the trench filling structure, thereby enabling the optimization and improvement of the electrical performance of the semiconductor device.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

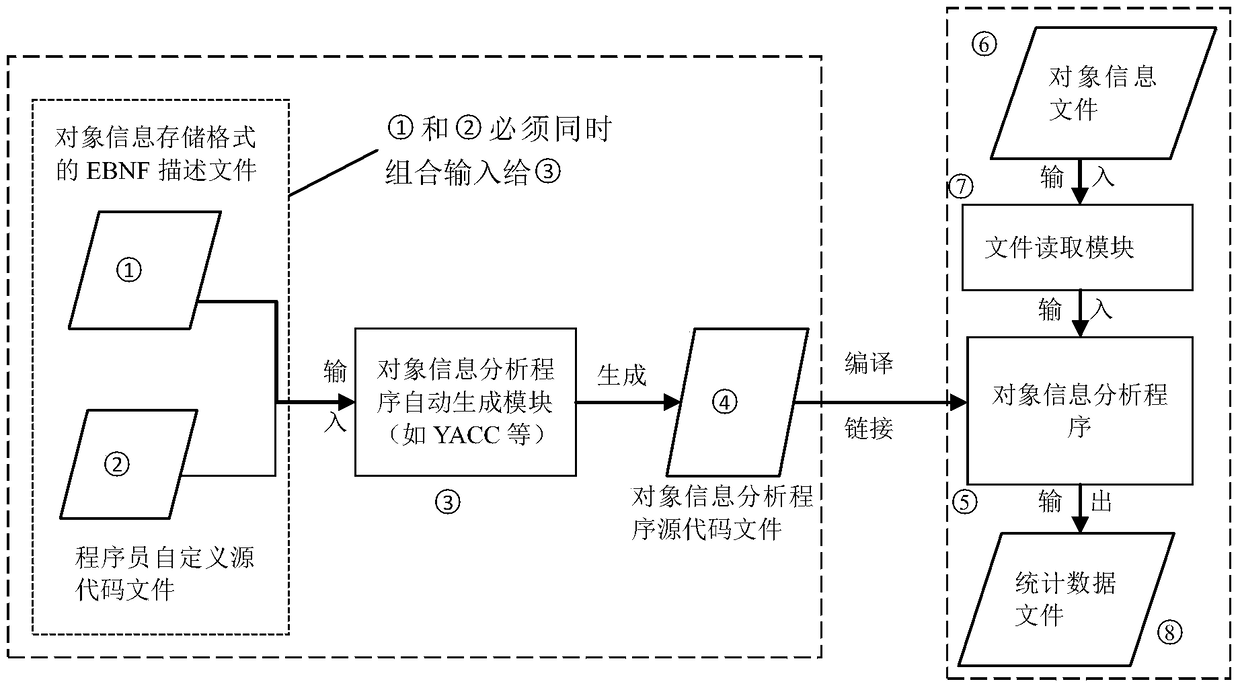

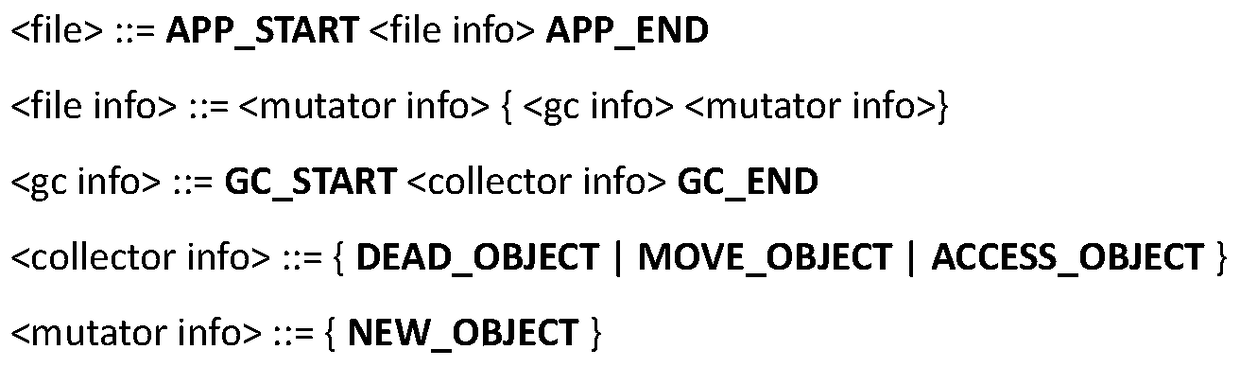

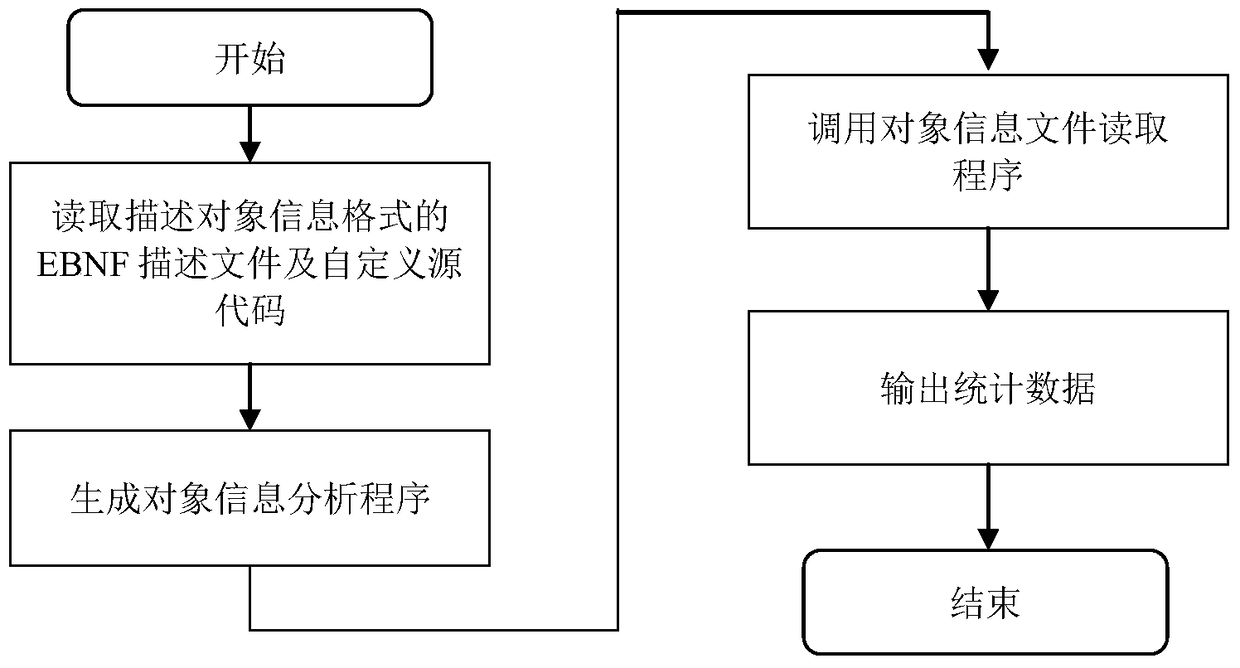

Automatic Generation Method of Java Object Information Analysis Program

ActiveCN105159680BReduce duplication of workEasy to debugTransformation of program codeCreation/generation of source codeSource code fileInformation analysis

The invention provides an automatic generation method for a Java object information analysis program. The method comprises: for binary object information, describing an object information storage format with an EBNF representation method, self-defining a source code file used for analysis by a programmer, analyzing an EBNF description file in the object information storage format and the source code file self-defined by the programmer by utilizing an automatic generation module of an object information analyzer, generating a source code of an object information analysis program, and performing compiling and linking to generate an executable object information analysis program; and reading an object information file, inputting the object information file into the object information analysis program for analysis, and outputting statistic data. The automatic generation method for the object information analysis program can well adapt to the situation of frequent change of an "online" monitoring program and allow the programmer to conveniently customize a required "offline" analysis program, thereby increasing the utilization rate of the object information file and improving the development efficiency of the programmer.

Owner:BEIHANG UNIV

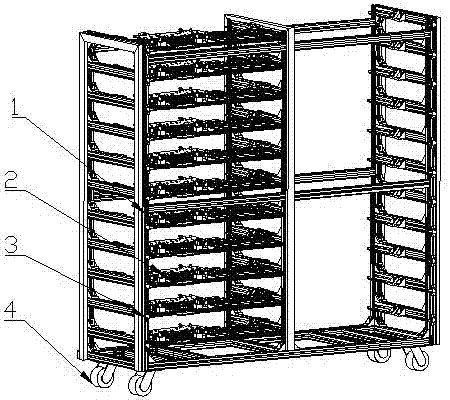

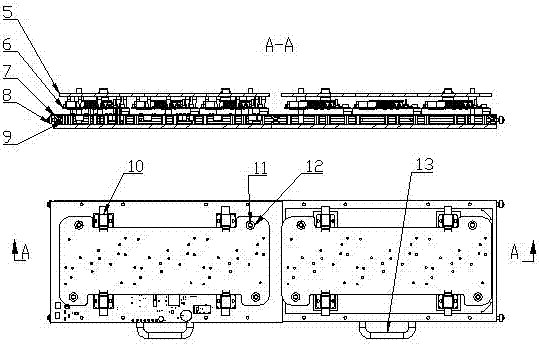

Circuit board ageing vehicle

InactiveCN106940427AImproving Aging Test EfficiencyPerformance Optimization and ImprovementPrinted circuit testingMechanical engineeringEngineering

Owner:焦彬彬

Parameter optimization method of salient pole offshore wind turbine based on high temperature superconducting excitation coil

InactiveCN106208549BWeight optimizationImprove efficiencyGeometric CADManufacturing dynamo-electric machinesClosed loop feedbackHigh temperature superconducting

The invention discloses a salient pole type offshore wind turbine parameter optimization method based on a high-temperature superconducting magnet exciting coil. A rotor of a motor is a salient pole; the magnet exciting coil adopts a high-temperature superconducting material; and the weight, loss and efficiency analysis of the motor are completed by setting of basic parameters of the motor, armature winding parameters, magnetic flux density, stator iron core parameters, wind turbine armature winding structure, high-temperature superconducting magnet exciting coil parameters, armature magnetic leakage and reverse magnetic potential under a load condition, three-dimensional magnetic field analysis and the like. According to the method, the salient pole type offshore wind turbine parameter optimization method can be carried out automatically according to computational formulas to realize optimization of the weight, the efficiency, the high-temperature superconducting material length and other parameters of the offshore wind turbine; and meanwhile, two closed loop feedback circuits of a magnetic field leakage inductance coefficient and a running current are included in the optimization process, so that the method plays a key role in improvement of the optimization of the motor performance.

Owner:HENAN POLYTECHNIC UNIV

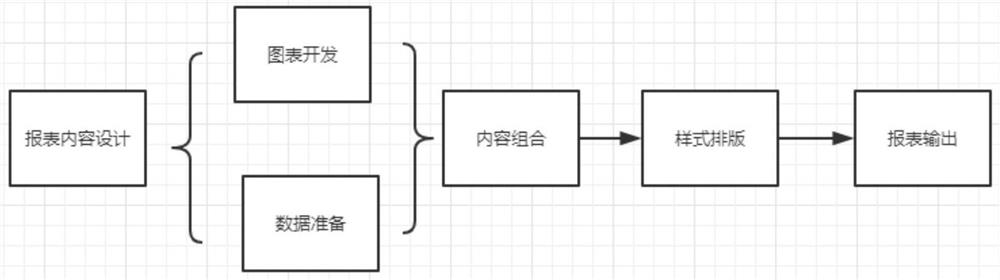

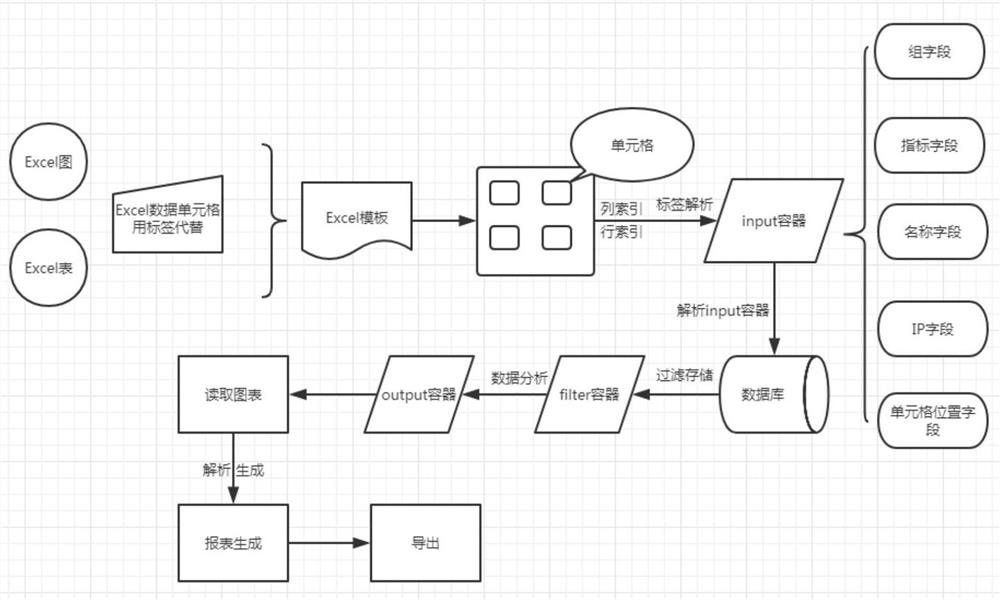

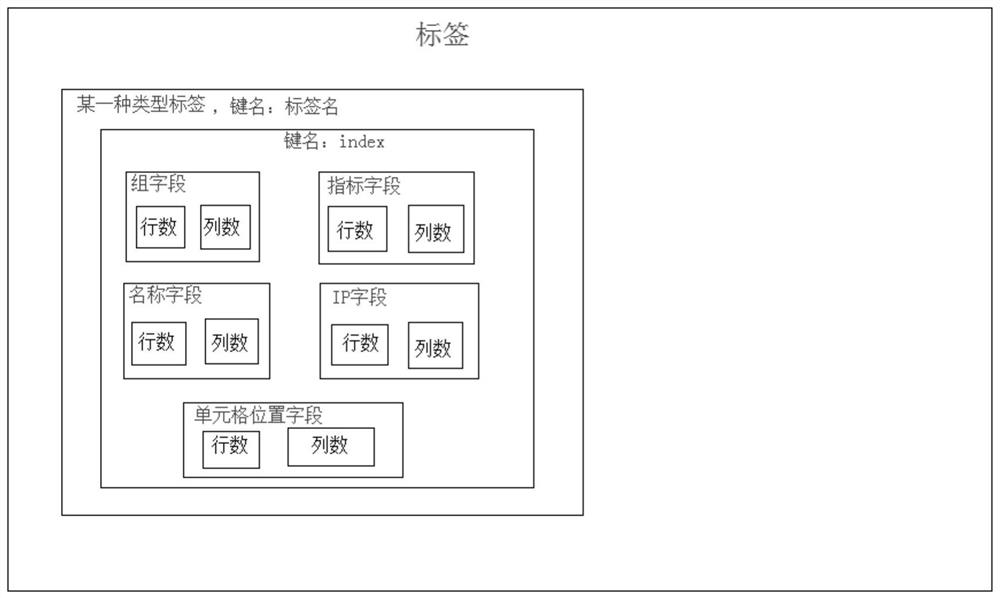

Template report generation method based on multistage container unloading

PendingCN111796803AReduce development pressureMeet the functional experienceText processingSoftware designOriginal dataCooperative interaction

The invention provides a template report generation method based on multistage container unloading. The template report generation method comprises the following steps of: 1) replacing cells of actualdata in a report template with labels; 2) reading the template and storing positions and content of the cells of the labels into an input container; 3) reading a field of the input container, performing original data extraction after analyzing the field, filtering the extracted original data, and storing the filtered original data in a filter container; 4) performing analysis and classification processing on the data to obtain data required by the report and corresponding cell information, and storing the data and the cell information into an output container; and 5) reading the template, andperforming result replacement on the data cells of the labels in the template according to the data of the output container to generate a report with complete content. According to the template report generation method disclosed by the invention, the output of a report focuses on the analysis of the data in a label form, and the development pressure of a report chart is reduced; through a container cooperative interaction mode, the performance optimization is greatly improved; and the idea of the template is adopted to meet the functional experience of different users.

Owner:宝牧科技(天津)有限公司

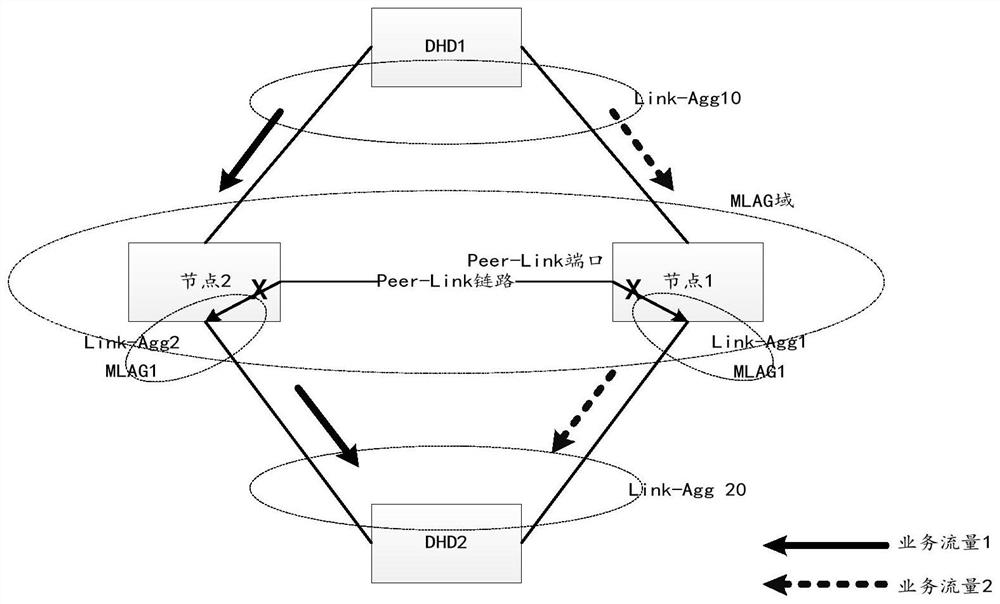

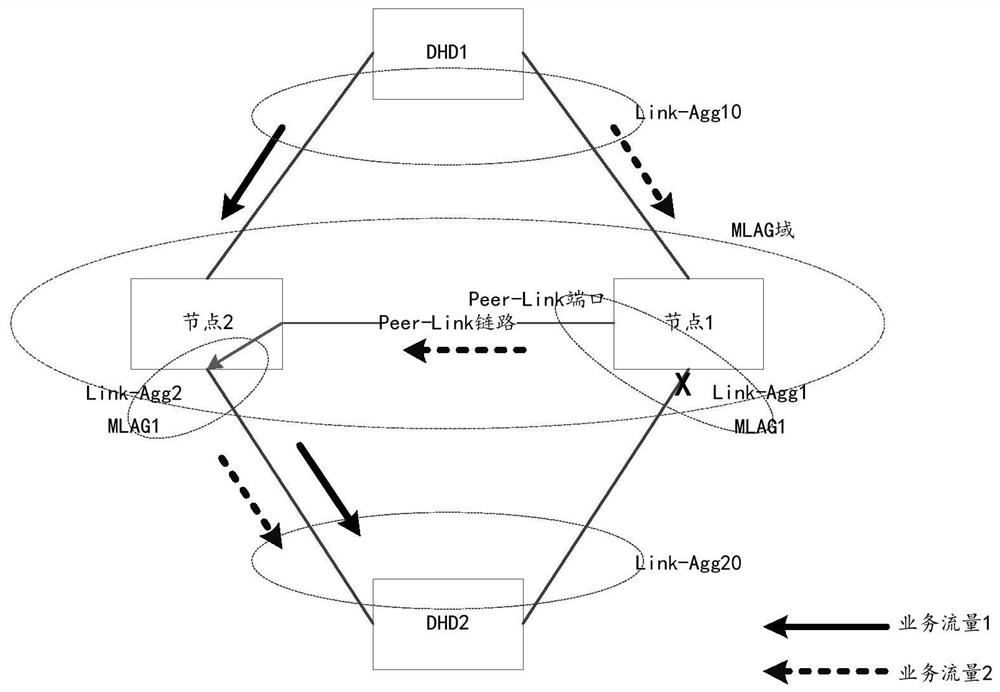

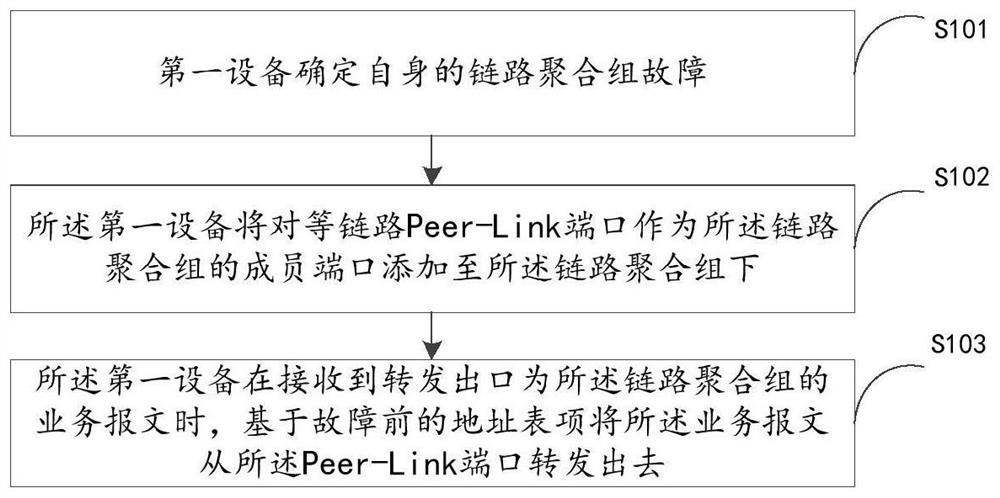

A message forwarding method, device, dual -living system and communication equipment

ActiveCN110730125BPerformance optimization and improvementTransmissionTelecommunicationsLink aggregation

The present application relates to a message forwarding method and device, a dual-active system and communication equipment, and belongs to the technical field of communication. The method includes: the first device determines that its own link aggregation group is faulty; the first device adds the Peer-Link port as a member port to the link aggregation group; When sending packets, the service packets are forwarded from the Peer-Link port based on the address entry before the failure. When the link aggregation group of the first device fails, the Peer-Link port is added to the link aggregation group as a member port, so that the address entry originally added to the link aggregation group of the first device is not changed. In this way, all the service traffic that needs to be forwarded through the link aggregation group is forwarded to the second device through the Peer-Link port for processing, so that the performance of service traffic fault recovery is optimized.

Owner:MAIPU COMM TECH CO LTD

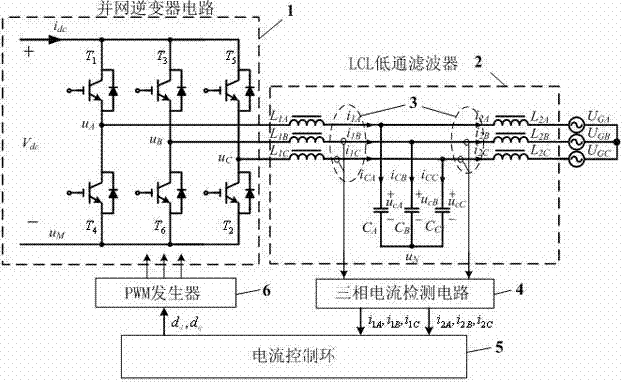

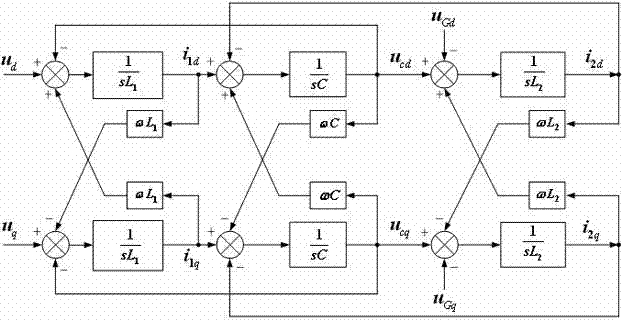

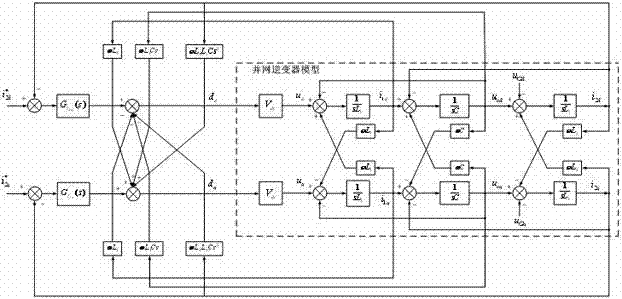

Rotational coordinate transformation based current decoupling control method for three-phase grid-connected inverter

ActiveCN102142694BStable outputGood output current waveformAc-dc conversionSingle network parallel feeding arrangementsPower inverterGrid connected inverter

The invention discloses a rotational coordinate transformation based current decoupling control method for a three-phase grid-connected inverter. With regard to a grid-connected inverter with an LCL (Inductor Capacitor Inductor) filter, an inversion three-phase output current signal and a grid-side three-phase current signal are transformed into two groups of orthogonal current signals in a synchronous rotation coordinate system through adopting coordinate transformation, the two groups of orthogonal current signals are subjected to the calculation of weighted average to be used as an inverter current controlled feedback signal and an inverter current controlled decoupling signal under a rotational coordinate system, the feedback signal is compared with a control given signal to obtain an error signal, and the obtained error signal is subjected to proportional-integral regulation and then is subjected to a combined operation with the decoupling signal to obtain a pulse duty-ratio signal for controlling a three-phase inverter switch to operate under the rotational coordinate system, so that output current waveform and amplitude control of the grid-connected inverter can be realized. Through adopting the method disclosed by the invention, the signal coupling problem existing in three-phase current control of the LCL filter three-phase grid-connected inverter can be effectively solved, the capacity of independently controlling each phase of output current is enhanced, and the favorable output current waveform of a grid-connected system can be achieved.

Owner:ZHEJIANG UNIV

Semiconductor device and manufacturing method thereof

ActiveCN110783358BImprove electrical performanceElectrical performance optimization and improvementSolid-state devicesDiodeDevice materialElectrical connection

The invention provides a semiconductor device and a manufacturing method thereof. The manufacturing method of the semiconductor device includes: forming a trench filling structure in the substrate of the pixel region, and the sidewall of the filling material in the trench filling structure and the substrate A high-K dielectric layer is interposed therebetween; the buffer dielectric layer is covered on the substrate surface of the pixel region; the buffer dielectric layer is etched to form at least part of the substrate and / or the periphery of the top sidewall of the trench filling structure exposed A first opening at least part of the top of the trench filling structure; filling the first conductive metal layer in the first opening to electrically connect with the exposed part of the substrate and / or the trench filling structure; forming a metal grid layer on the on the buffer medium layer and electrically connected with the first conductive metal layer. The technical solution of the present invention enables the metal grid layer to be electrically connected to the exposed part of the substrate and / or the trench filling structure, thereby enabling the optimization and improvement of the electrical performance of the semiconductor device.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Semiconductor device and method of manufacturing the same

ActiveCN111029352BImprove electrical performanceElectrical performance optimization and improvementSolid-state devicesDiodeDevice materialElectrical performance

The present invention provides a semiconductor device and a method for manufacturing the same. The method for manufacturing the semiconductor device includes: forming a trench filling structure in a substrate of a pixel region, and filling material in the trench filling structure with sidewalls and the substrate A high-K dielectric layer is also sandwiched therebetween; the buffer dielectric layer is covered on the substrate surface of the pixel region, and the buffer dielectric layer buries the trench filling structure; the buffer dielectric layer is etched to form at least the trench filling Part of the substrate and / or the trench at the periphery of the top sidewall of the structure fills at least part of the first opening at the top of the structure; and, forming a metal grid layer on the buffer dielectric layer and filling the first opening so as to be compatible with the exposed part The substrate and / or the trench filling structure are electrically connected. The technical solution of the present invention enables the metal grid layer to be electrically connected to the exposed part of the substrate and / or the trench filling structure, thereby enabling optimization and improvement of the electrical performance of the semiconductor device.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

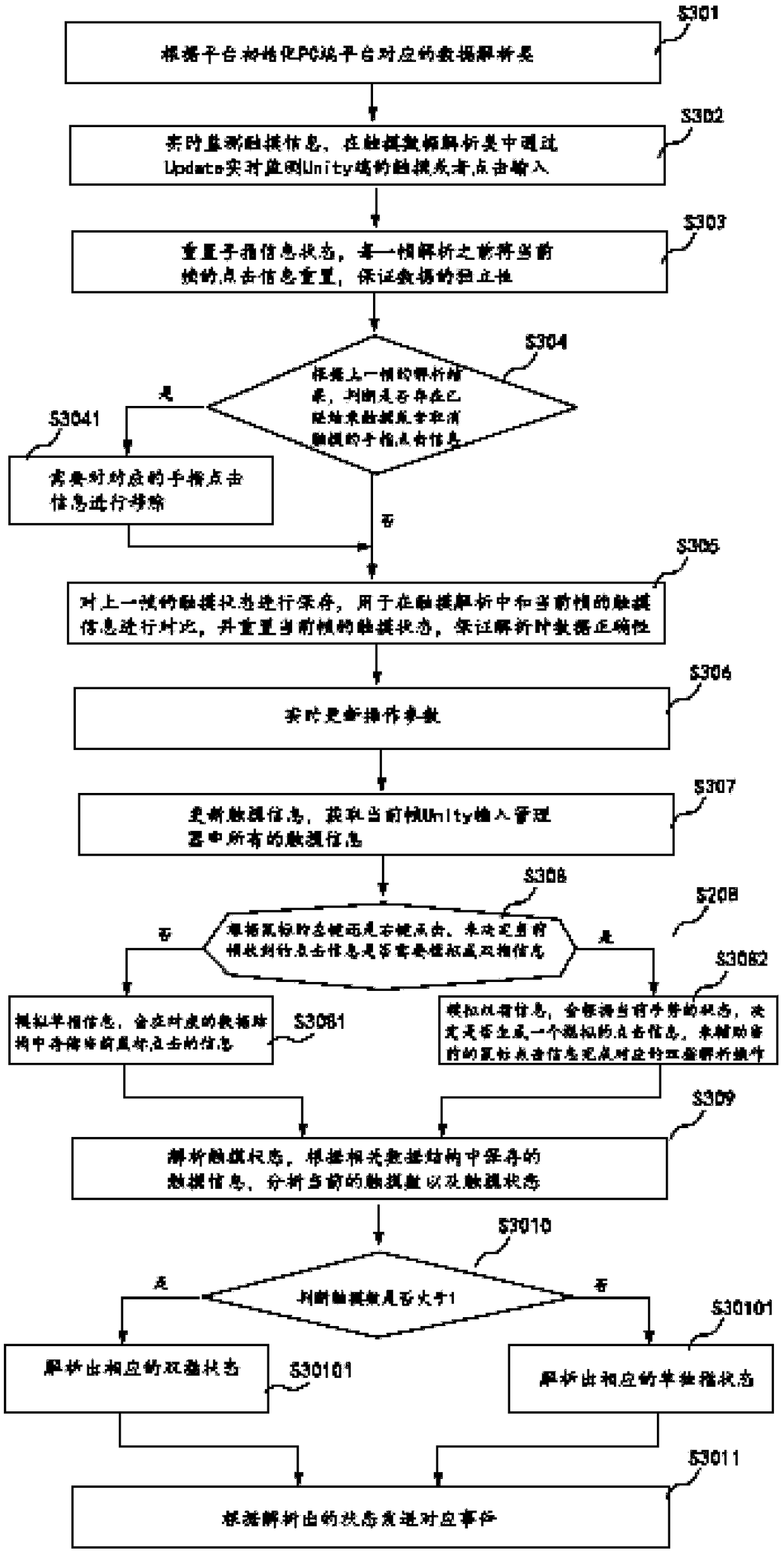

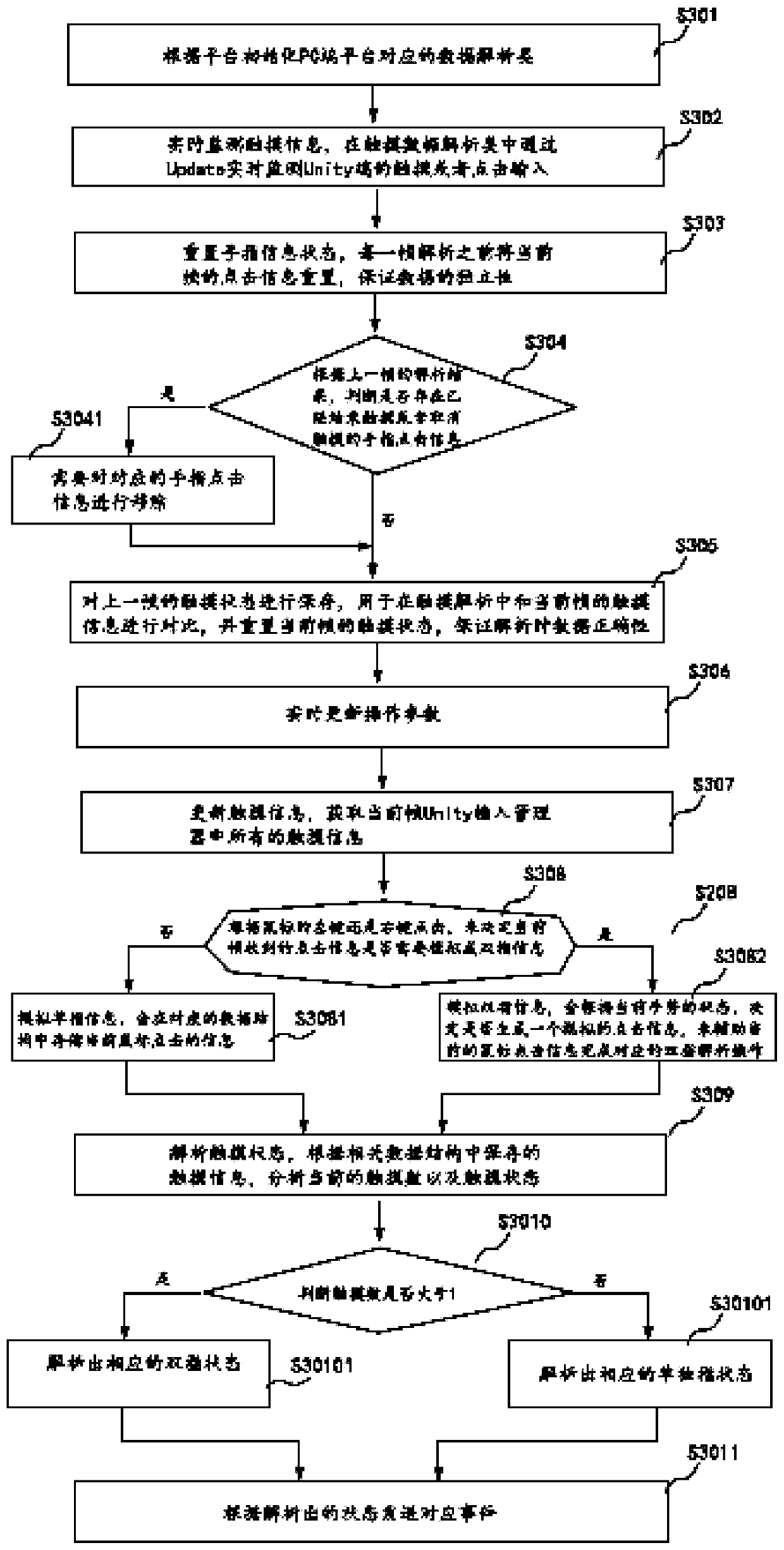

Cross-platform GUI touch event analysis method in Unity environment

ActiveCN110597499AEasy to installParsing fastExecution for user interfacesCompiler constructionMulti platformSoftware engineering

The invention provides a cross-platform GUI touch event analysis method in a Unity environment, which solves the problem of integrating the event management to a management layer by using a single example class to carry out the entrusted event registration management and the touch analysis distribution. The multi-platform touch analysis inherits a unified interface, different cross-platforms are realized for the same interface, both a mobile terminal and a PC terminal are unified, and more memories are not occupied. A Unity basic class is used as a scheme implementation core, the performance optimization is better, a little expenditure exists during initialization, and no other extra expenditure exists during the process at ordinary times except for the normal analysis logic. The method can be applied to a mobile terminal platform and a PC terminal platform.

Owner:苏州沁游网络科技有限公司

X-86 serial compatible machine and generation method for its operation system

InactiveCN100367238CReduce manufacturing costAppliances are easy to useMemory adressing/allocation/relocationSpecific program execution arrangementsOperational systemComputer compatibility

The characters of the invention are as follows. The operating system files and the application program files stored in the memory are called and stored by using the dynamic embedded mode so as to generate the virtual operation system disc in the memory. The functions of the compatible computer meet the performances of the high end PC, providing the features of low cost, easy of use and maintenance, high efficiency, stability and reliability.

Owner:深圳市索普卡软件开发有限公司

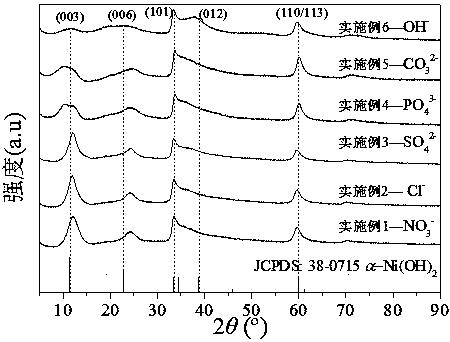

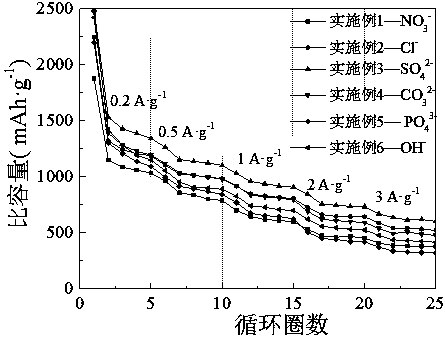

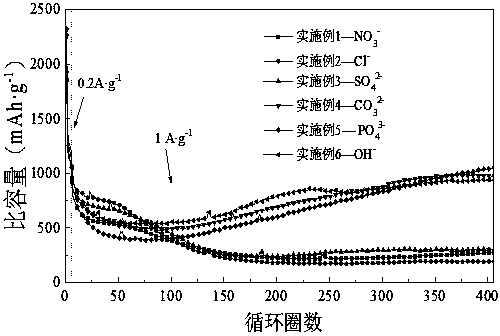

Method for optimizing lithium storage performance of alpha-Ni(OH)2 material

ActiveCN111268748AImprove lithium storage performanceImprove performanceNegative electrodesSecondary cellsPhysical chemistryHomogeneous precipitation

The invention discloses a method for optimizing the lithium storage performance of an alpha-Ni(OH)2 material. Nickel nitrate hexahydrate is used as a nickel source, urea is used as a precipitant, anda homogeneous precipitation method is adopted to prepare an alpha-Ni(OH)2 material containing NO3 <-> between layers. The alpha-Ni(OH)2 material containing NO3 <-> between layers is respectively addedinto various sodium compound solutions for anion exchange, thereby finally obtaining the alpha-Ni(OH)2 material containing different anions between layers, that is, achieving the optimization of thelithium storage performance of the alpha-Ni(OH)2 material. The method disclosed by the invention has the advantages and meanings that the types of intercalated anions of the alpha-Ni(OH)2 material areregulated and controlled through a very simple method, so that the lithium storage performance of alpha-Ni(OH)2 is optimized; on one hand, the influence rule of different intercalation anions on thelithium storage performance of alpha-Ni(OH)2 is found out, and on the other hand, the method provides a new thought for performance optimization and improvement of the alpha-Ni(OH)2 material as the lithium ion battery negative electrode material.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

A method for improving the microstructure and mechanical properties of titanium-aluminum layered composites

The invention provides a method for improving a titanium-aluminum laminated composite material structure and improving mechanical performance. Tungsten core SiC ceramic fibers are pre-treated, and NiTi alloy wires, Ti foil and Al foil are subjected to ultrasonic cleaning; the Ti foil, the tungsten core SiC ceramic fibers, the NiTi alloy wires and the Al foil serve as a unit to be stacked according to the sequence of the Ti foil, the tungsten core SiC ceramic fibers, the NiTi alloy wires, the Al foil and the Ti foil, the four SiC fibers are placed between every two NiTi alloy wires, the interval is 1 mm, and the upper surface and the lower surface are both the Ti layers; and sintering is conducted on the unit through a vacuum hot pressing device. According to the method for improving the titanium-aluminum laminated composite material structure and improving the mechanical performance, through the design principle that nickel and titanium elements in the NiTi wires easily react with aluminum elements under the low temperature to form inter-metallic compounds, the SiC fibers and the NiTi alloy wires are simultaneously introduced into inter-metallic compound layers through the vacuum hot pressing sintering method, the SiC fibers serve as reinforcing bodies, introduction of the NiTi alloy wires aims to remove inter-metallic compound layer center lines through the sufficient diffusion reaction mechanism of the NiTi alloy wires and Al, and the SiC fiber / base body interface is improved, so that the mechanical performance of a composite material is improved.

Owner:HARBIN ENG UNIV

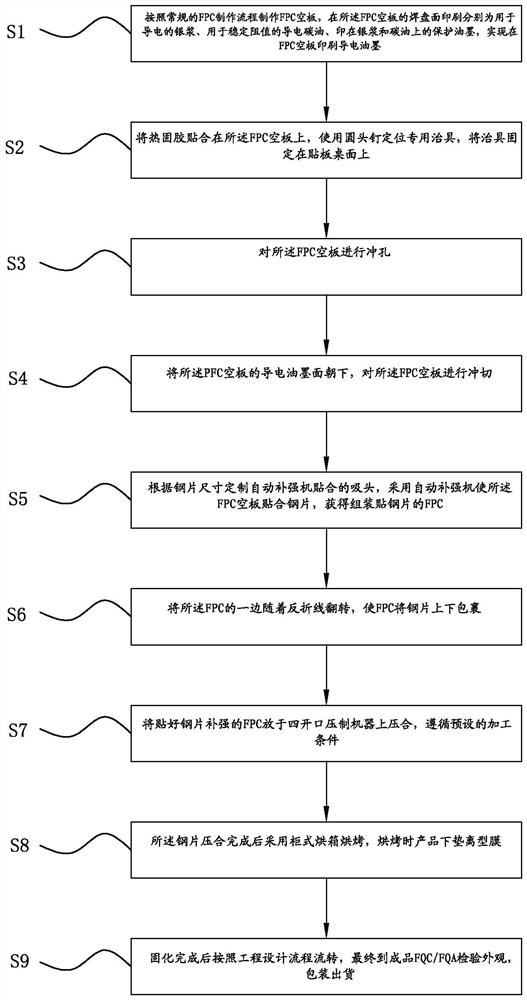

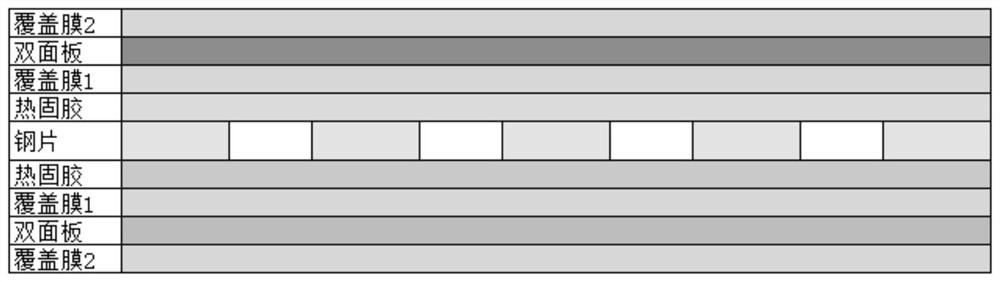

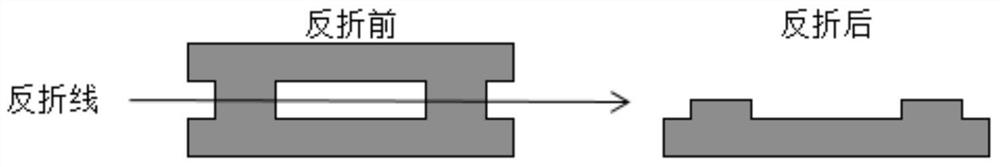

A kind of manufacturing method of side key product

ActiveCN111146030BImprove reliabilityPerformance optimization and improvementElectric switchesSilver pasteEngineering

The invention discloses a method for making a novel side key product, comprising: making an FPC empty board, and printing silver paste, conductive carbon oil, and protective ink printed on the silver paste and carbon oil on the pad surface of the FPC empty board; Attach the thermosetting adhesive to the FPC empty board, use a round-head nail to position the special jig, and fix the jig on the desktop of the board; punch holes; place the conductive ink of the PFC empty board facing down, and The FPC empty board is punched; according to the size of the steel sheet, the suction head for the automatic reinforcement machine is customized, and the automatic reinforcement machine is used to make the FPC empty board fit the steel sheet, so as to obtain the FPC assembled and pasted with the steel sheet; One side of the above-mentioned FPC is turned over with the anti-folding line, so that the FPC wraps the steel sheet up and down; the FPC with the steel sheet reinforced is placed on the four-opening pressing machine for pressing, and the preset processing conditions are followed; after the steel sheet is pressed It is baked in a cabinet oven, and the product is covered with a release film during baking; after curing, it will be circulated according to the engineering design process, and finally the appearance of the finished product will be inspected by FQC / FQA, and the product will be packaged and shipped.

Owner:SHENZHEN KINWONG ELECTRONICS

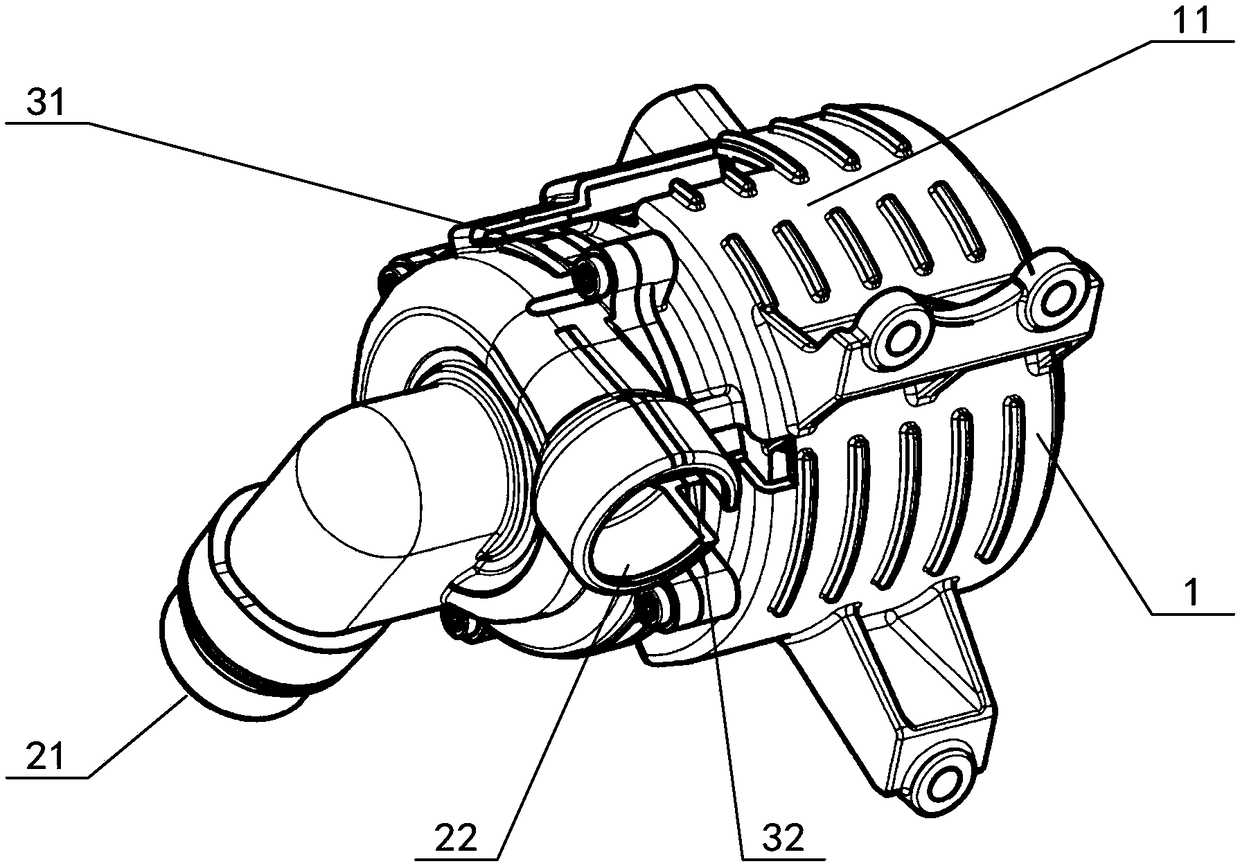

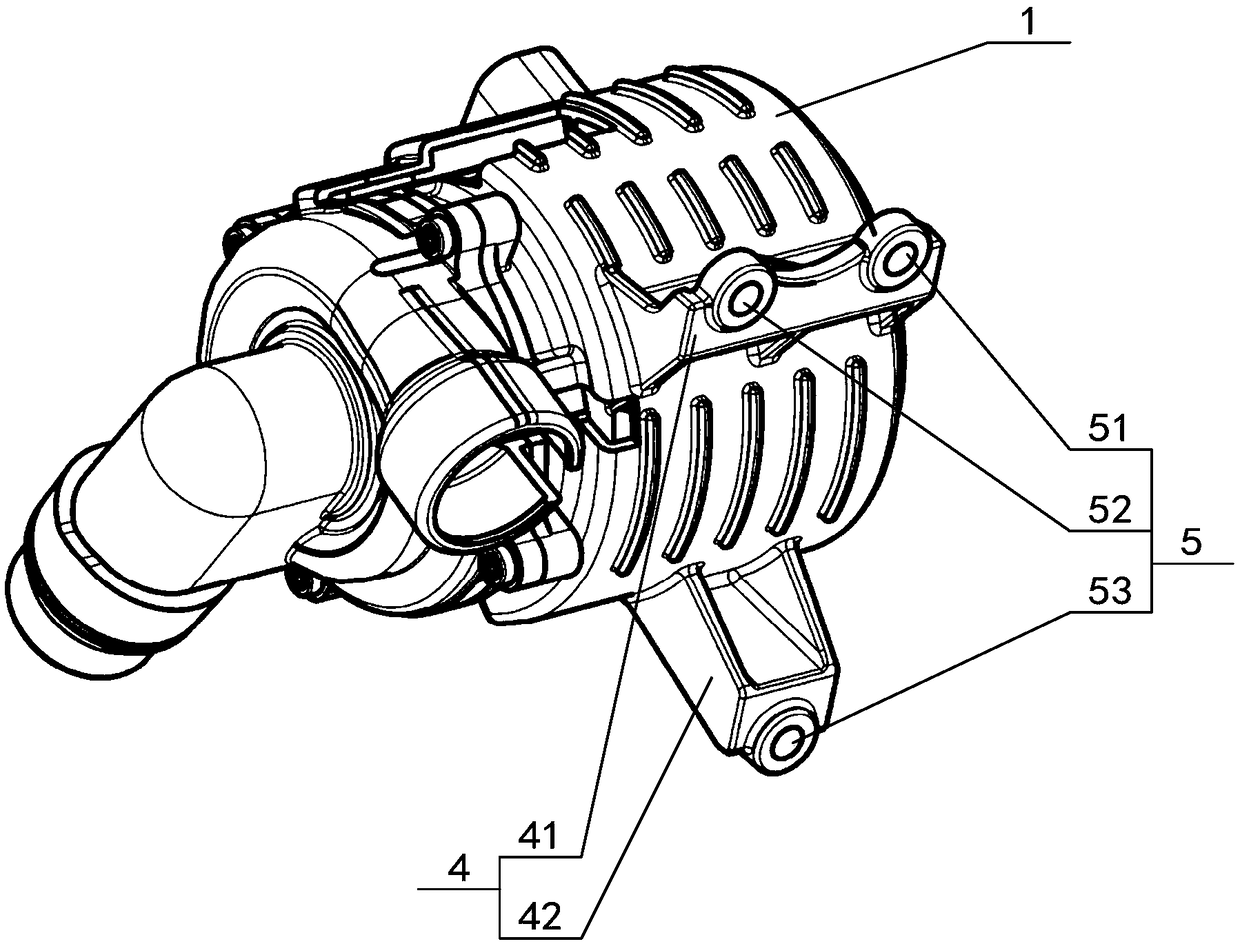

Electronic water pump and automobile applying same

InactiveCN109404340AReliable controlEasy to controlPump componentsPumpsManufacturing technologyEngineering

The invention discloses an electronic water pump and an automobile applying the same, and relates to the technical field of automobile manufacturing. The technical problem that an existing electronicwater pump is poor in heat dissipation effect is solved. The electronic water pump comprises a water pump shell, the water pump shell is provided with a channel structure, and the channel structure and cooling channels integrated on motor unit shells form parallel cooling liquid flowing channels. In the using process, the electronic water pump conducts forced cooling through the cooling liquid flowing channels, and meanwhile the electronic water pump achieves heat dissipation by adopting air flowing.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com