Inverse texture plane blade for planning

A texture and planing technology, which is applied in the direction of manufacturing flat surface processing machines, wood processing appliances, manufacturing tools, etc., to reduce labor intensity, improve flatness and smoothness, and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

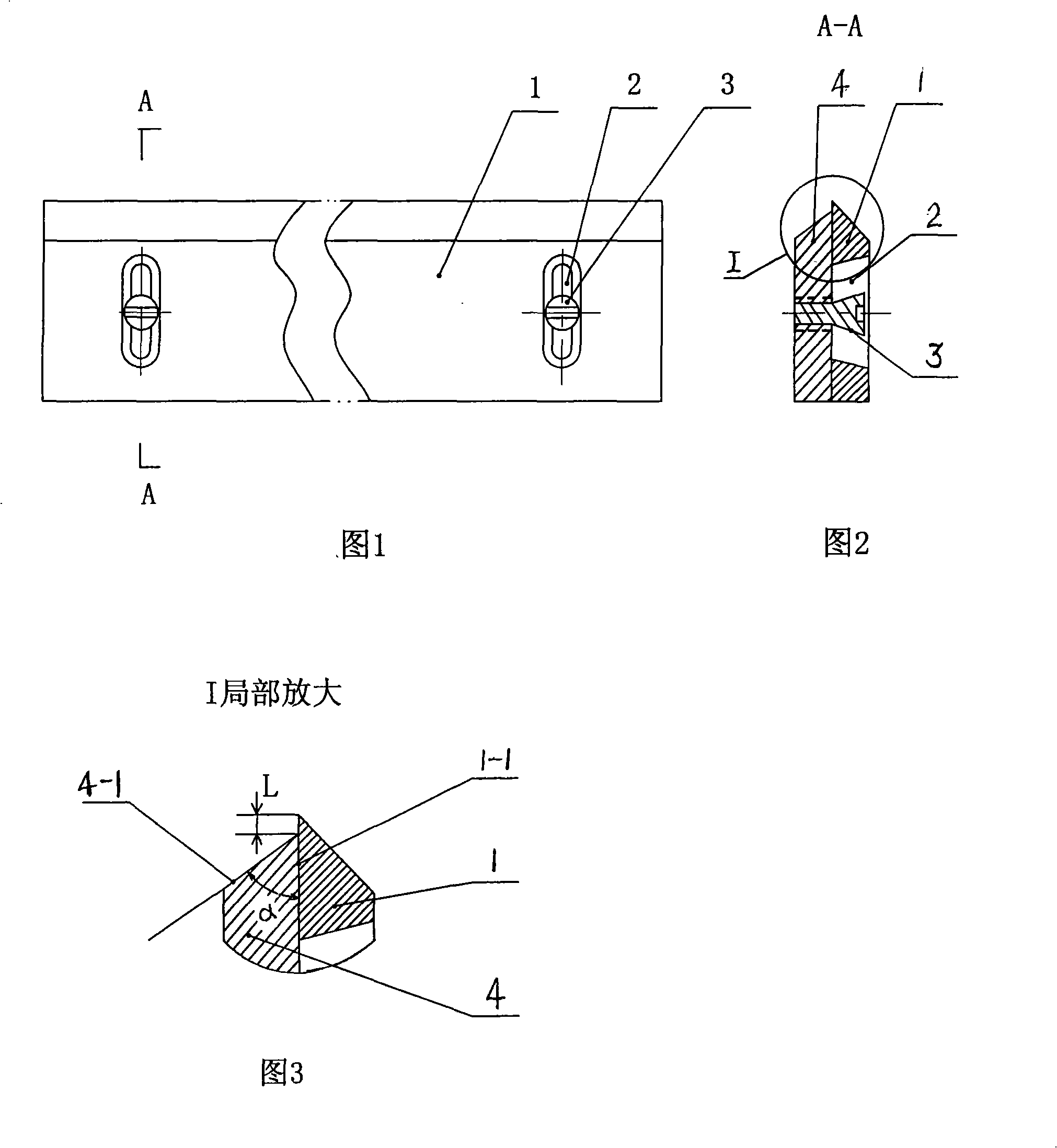

[0010] The specific structure and working principle of the present invention will be further described in the following embodiments in conjunction with the accompanying drawings.

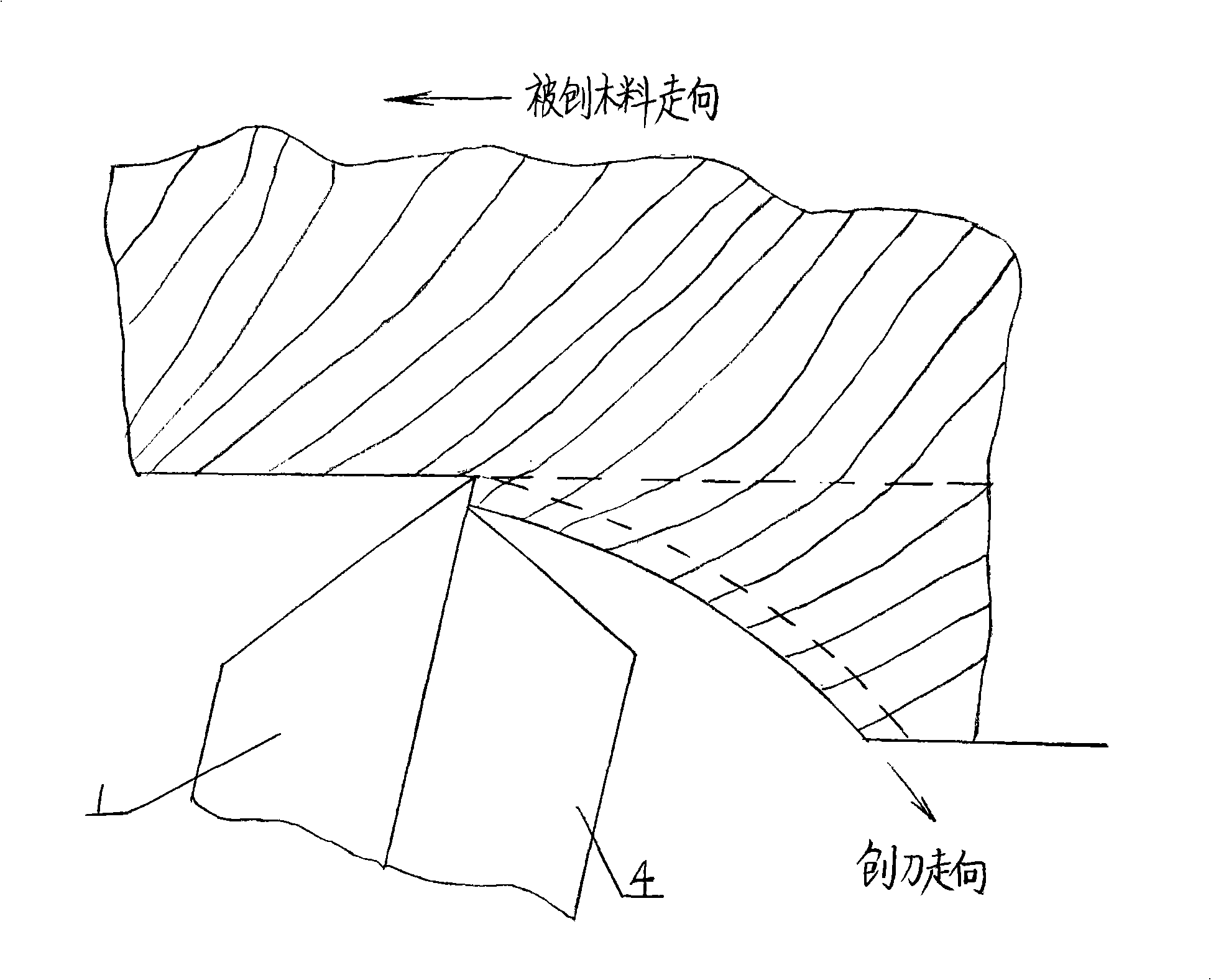

[0011] As shown in the drawings, the reverse texture planer of the present invention has a main blade 1, and a support body 4 is arranged in front of the main blade 1, and the top surface 4-1 of the support body is inclined to the front side of the main blade. 1-1, the tip of the support body is slightly lower than the cutting edge of the main blade.

[0012] The distance between the tip of the support body and the cutting edge of the main blade is L shown in FIG. 3 .

[0013] Obviously, the cross-sectional shape of the support should enable the planer of the present invention to be mounted on the cutter shaft of the planer. The most suitable cross-sectional shape of the support body is a flat sheet as shown in the drawings, that is, the support body is a support sheet. There are many other cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com