Flue liner fluoroplastic anticorrosive coating manufacturing process

A technology of flue lining and manufacturing process, which is applied in the field of tail flue anti-corrosion, which can solve the problems of corrosion, wear and scaling, affect the anti-corrosion effect and life, and easy to fall off, so as to reduce shedding and tearing problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

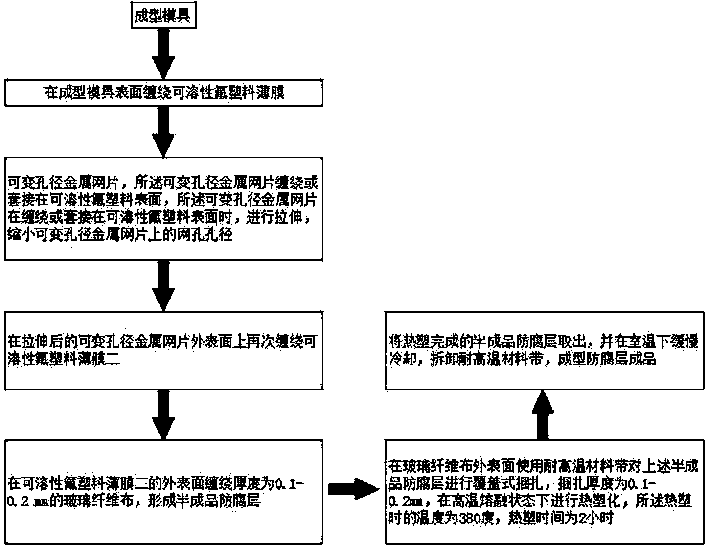

[0020] Such as figure 1 As shown, a flue liner fluoroplastic anti-corrosion layer manufacturing process, including:

[0021] Forming mold;

[0022] Wrap a soluble fluoroplastic film on the surface of the forming mold;

[0023] Variable aperture metal mesh, the variable aperture metal mesh is wound or sleeved on the surface of the soluble fluoroplastic, when the variable aperture metal mesh is wound or sleeved on the surface of the soluble fluoroplastic, it stretches and shrinks The mesh aperture on the variable aperture metal mesh;

[0024] Wrap the soluble fluoroplastic film 2 again on the outer surface of the stretched variable-aperture metal mesh;

[0025] Wrap glass fiber cloth with a thickness of 0.1-0.2 mm on the outer surface of the soluble fluoroplastic film 2 to form a semi-finished anti-corrosion layer;

[0026] On the outer surface of the glass fiber cloth, use a high-temperature-resistant material tape to cover the above-mentioned semi-finished anti-corrosion l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com