Composite forming method for thin-wall special-shaped part

A technology for composite forming and special-shaped parts, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult realization and complicated rolling forming process, reduce pressure, solve scratches or tears, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment includes the following steps:

[0051] Step 1. According to the target product, that is, a titanium thin-walled special-shaped part with a nominal diameter DN of 200mm and a wall thickness of 0.5mm, select the TA2 whole plate and perform water cutting to obtain a circular slab;

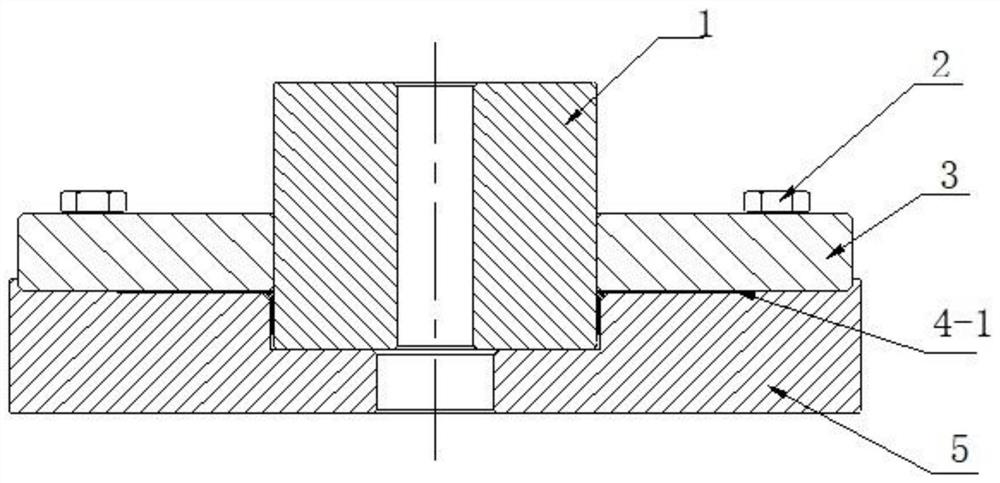

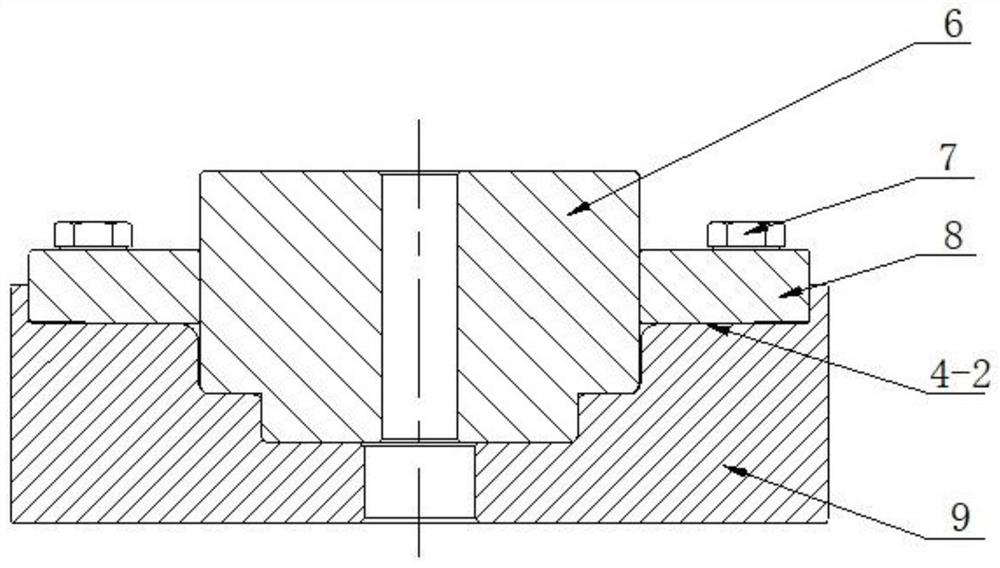

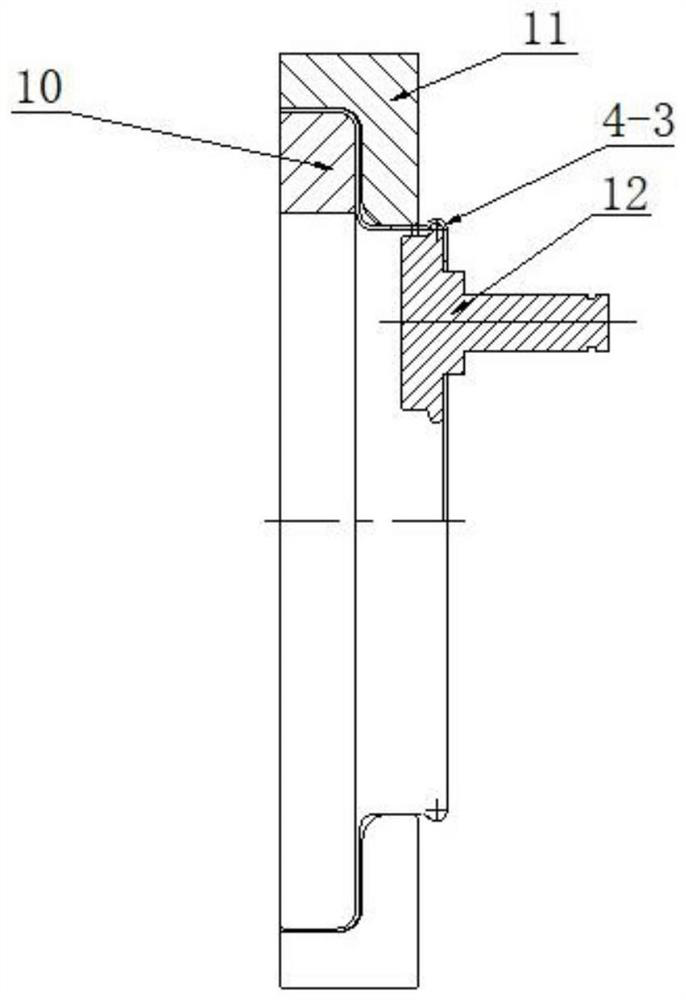

[0052] Step 2. Clean the oil stains and sundries on the surface of the circular slab obtained in Step 1, and coat it with a high-temperature-resistant and anti-oxidation coating with a thickness of 0.2 mm to 1.0 mm, and heat it in a heating furnace at a temperature of 200 ° C. 0.5h, then quickly lift and align, place on the first lower die 5 of the stamping die and assemble the first pressing plate 3, use the first locking member 2 to connect the first pressing plate 3, the circular slab and the first lower die The mold 5 is locked, and then the first upper mold 1 is put into the circular slab in the first press plate 3, and the punching machine is opened to drive the first uppe...

Embodiment 2

[0063] This embodiment includes the following steps:

[0064] Step 1. According to the target product, that is, a titanium thin-walled special-shaped part with a nominal diameter DN of 300mm and a wall thickness of 3mm, select a titanium whole plate and perform water cutting to obtain a circular slab;

[0065] Step 2. Clean the oil stains and sundries on the surface of the round slab obtained in Step 1, and coat it with a high-temperature resistant and anti-oxidation coating with a thickness of 0.2 mm to 1.0 mm, and heat it in a heating furnace at a temperature of 600 ° C. 1h, then quickly lift and align, place on the first lower die 5 of the stamping die and assemble the first pressing plate 3, use the first locking member 2 to connect the first pressing plate 3, the circular slab and the first lower die 5 lock, then put the first upper die 1 into the circular slab in the first press plate 3, start the punching machine to drive the first upper die 1 to perform the first hot s...

Embodiment 3

[0076] This embodiment includes the following steps:

[0077] Step 1. According to the target product, that is, a stainless steel thin-walled special-shaped part with a nominal diameter DN of 100mm and a wall thickness of 0.5mm, select the whole stainless steel plate and cut it to obtain a circular slab;

[0078] Step 2. Clean the oil stains and sundries on the surface of the round slab obtained in Step 1, place it in a heating furnace and heat it for 1 hour at a temperature of 200°C, then quickly lift and align it, and place it in the stamping die. On the first lower mold 5 and assemble the first pressure plate 3, use the first locking member 2 to lock the first pressure plate 3, the circular slab and the first lower mold 5, and then put the first upper mold 1 into the first At the circular slab in the pressing plate 3, start the stamping machine to drive the first upper die 1 to perform the first hot stamping on the circular slab, and form the first concave platform on the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com