Micro-foamed plastic automobile door panel with Persian column

A micro-foaming, automotive technology, used in doors, vehicle parts, transportation and packaging, etc., can solve problems such as affecting product appearance and performance, and prone to swelling and bulging on the surface of automobile door panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

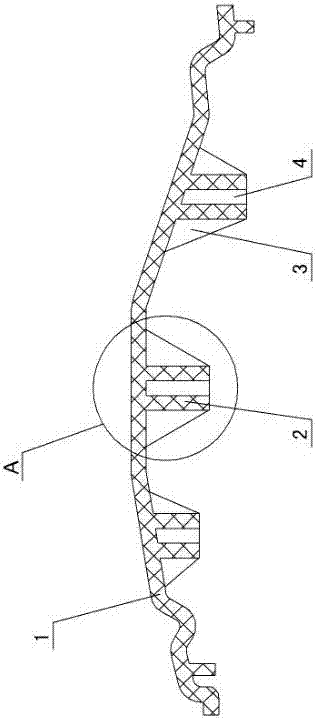

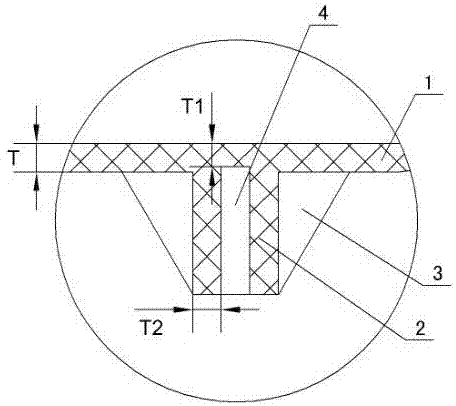

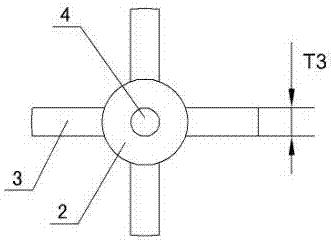

[0009] The invention relates to a micro-foamed plastic automobile door panel with Persian columns, such as figure 1 — image 3 As shown, it is characterized in that: comprise micro-foamed plastics injection-molded automobile door panel body 1, fixed post 2 is formed under the automobile door panel body, the outer wall of fixed post is shaped on reinforcement piece 3, is shaped on fixing hole 4 in the fixed post, so The thickness T of the automobile door panel body 1 is 2.5-3 mm, the thickness T1=(0.75-0.9) T from the bottom of the fixing hole 4 in the fixing column 2 to the upper end surface of the automobile door panel body 1, and the wall thickness T2 of the fixing column =(0.75—0.9)T, the thickness T3 of the reinforcing sheet 3=0.8 T2. The main feature is to adjust the wall thickness T1=(0.75—0.9)T between the bottom of the fixing hole 4 in the mold cavity of the injection mold and the upper surface of the car door body 1, and the wall thickness T2=(0.75—0.9)T of the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com