A kind of preparation method of expanded polytetrafluoroethylene composite film

A technology of polytetrafluoroethylene and composite film, which is applied in the field of plastic processing, can solve problems such as bulging and composite film cooling too fast, and achieve the effect of improving product quality, reducing cooling speed, and eliminating bulging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

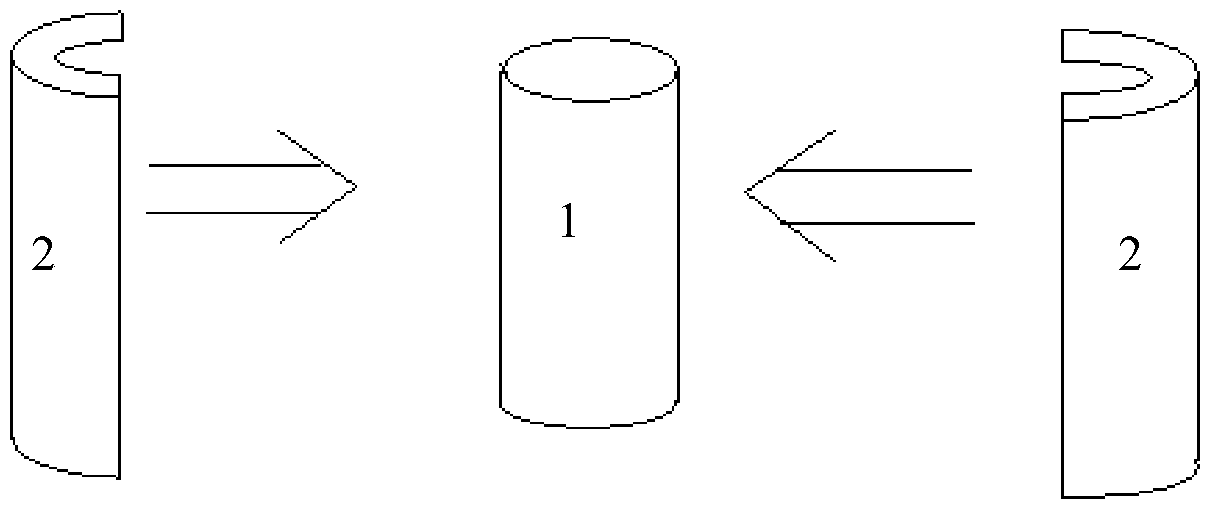

[0029] Laminated rolls and guards for heat treatment see figure 1 , the coating roller 1 is cylindrical, the coating roller 1 and the protective cover are made of stainless steel, the protective cover is composed of two semi-cylinders 2 of the protective cover, and the two semi-cylinders pass through screws and screw holes before heat treatment Butt together to form a cylindrical protective cover, which is set outside the film-coated roller. The diameter of the protective cover is 20mm larger than that of the film-coated roller, and the thickness of the protective cover is 2mm.

[0030] The preparation process of expanded polytetrafluoroethylene composite membrane is as follows:

[0031] 1) Dispersed polytetrafluoroethylene resin is prepared into a calendered film by a paste molding method, and an expanded polytetrafluoroethylene film is obtained through biaxial stretching, and the thickness of the film is 0.05mm.

[0032] 2) Roll the prepared film onto the film-coating roll...

Embodiment 2

[0043] The film-coated roller and protective cover that are used for heat treatment are as embodiment 1.

[0044] The preparation process of expanded polytetrafluoroethylene composite membrane is as follows:

[0045] 1) Dispersed polytetrafluoroethylene resin is prepared into a calendered film by a paste molding method, and an expanded polytetrafluoroethylene film is obtained through vertical and horizontal biaxial stretching, and the thickness of the film is 0.02mm.

[0046] 2) Roll the prepared film onto the film-coating roller through the film-coating unit. The film-rolling speed is 4 laps / minute, the pressure is 0.40MPa, and the thickness of the film is 1.4mm. Unload, and add a protective cover to the roller covered with film.

[0047] 3) Carry out heat treatment on the film-coated roller equipped with a protective cover in a salt bath furnace, the heat treatment temperature is 365°C, the treatment time is 2 hours, and the heat treatment is naturally cooled at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com