Heavy vibration screening equipment

A vibrating equipment and vibrating screening technology, which is applied in the direction of vibrating fluid, filter screen, solid separation, etc., to achieve the effect of increasing area, reducing vibration force and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

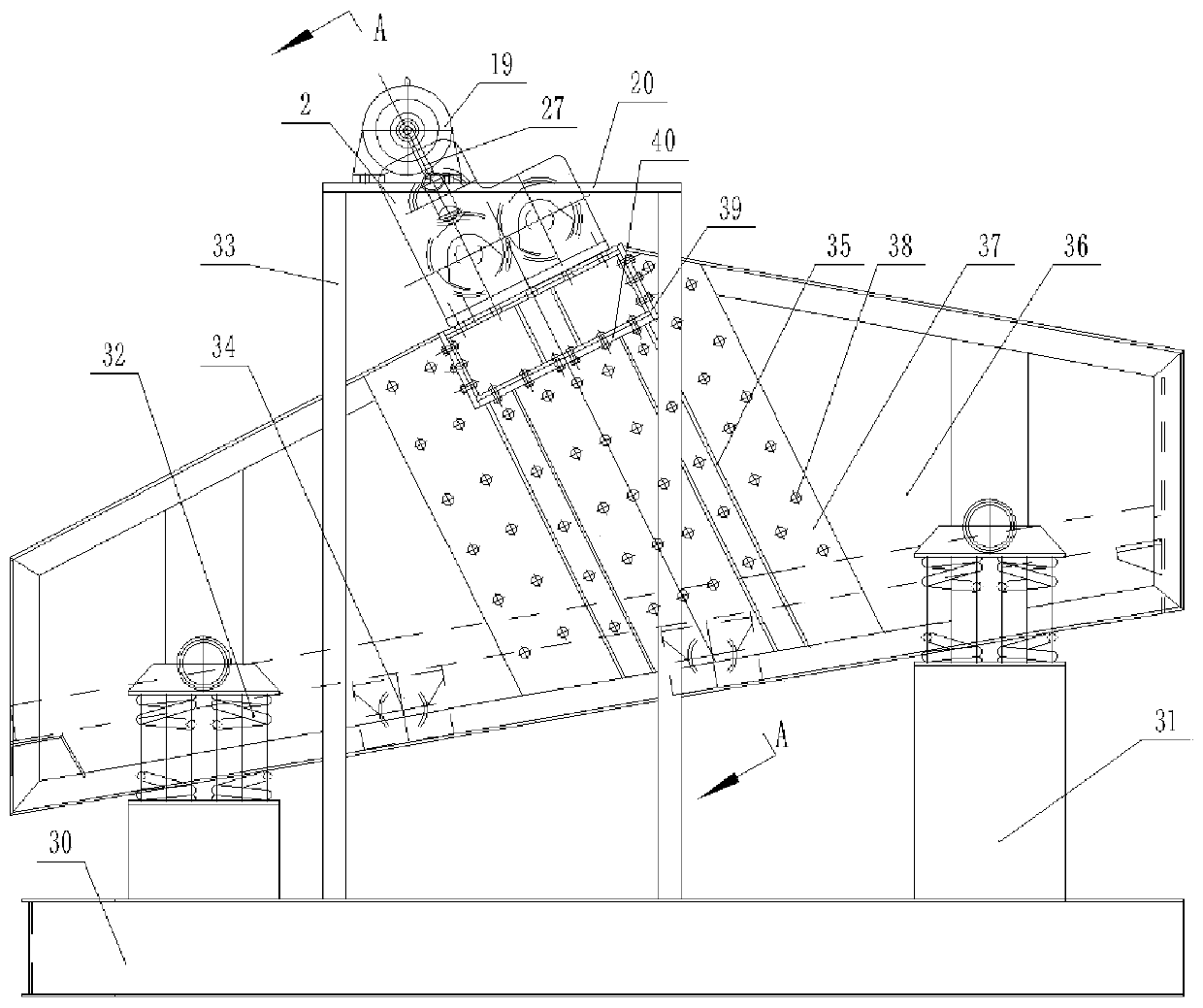

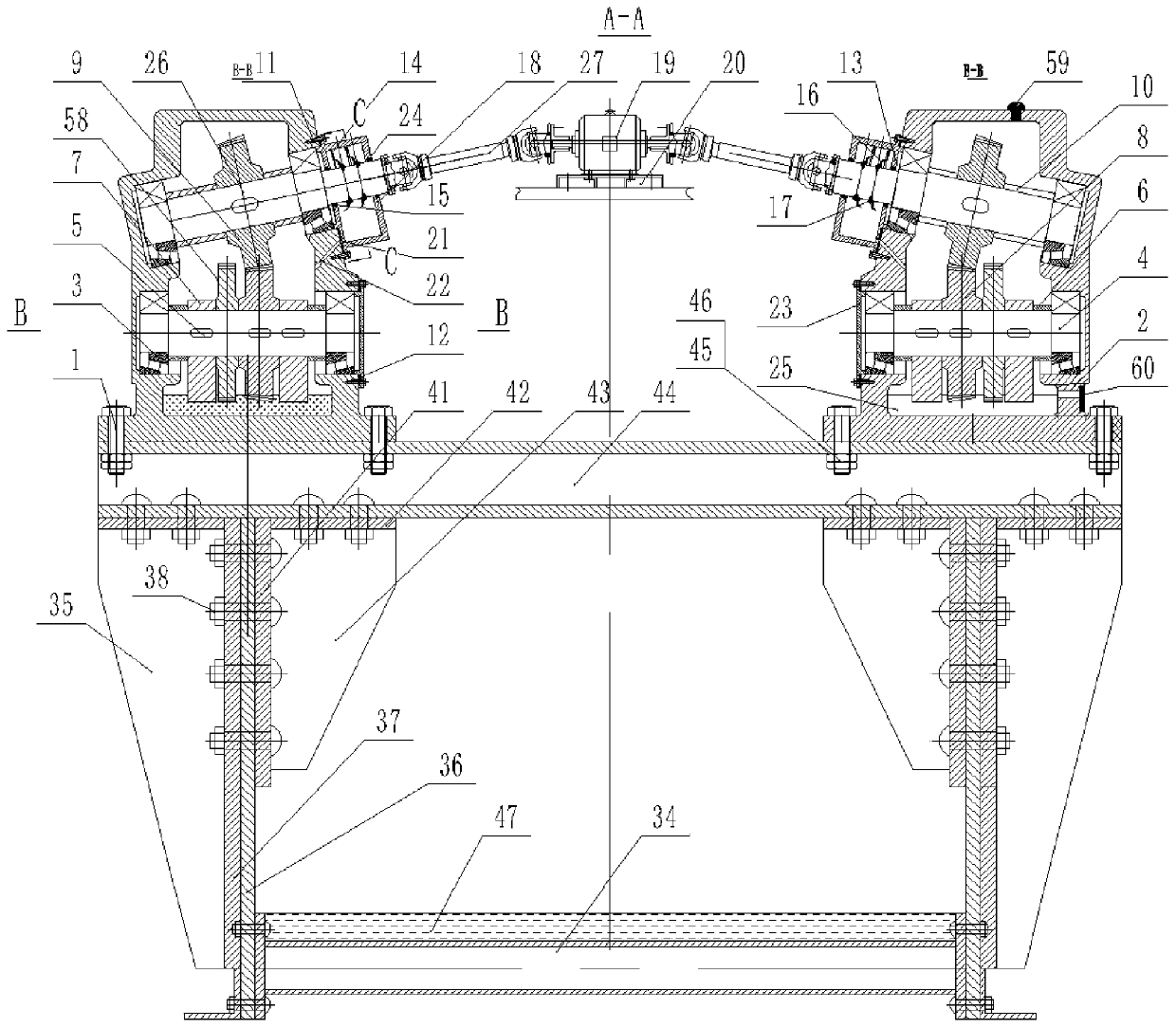

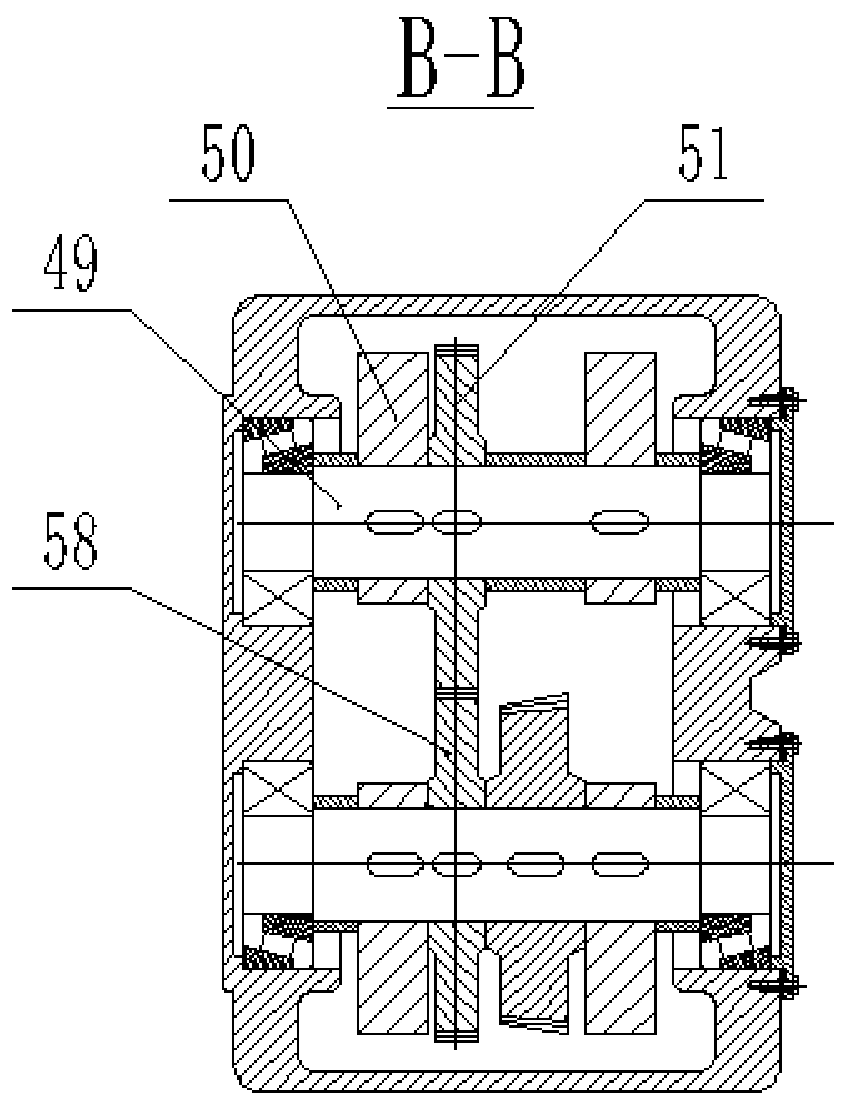

[0029] figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The structure diagrams of two embodiments of the present invention are shown. In these five figures, the meanings of the serial numbers of each part are as follows: 1. Mounting hole; 2. Vibrator shell; 3. Centripetal thrust bearing; 4. Eccentric Shaft Ⅰ; 5. Metal connection key; 6. Shaft ring; 7. Eccentric block Ⅰ; 8. Driven bevel gear; 9. Driving bevel gear; 10. Locating ring; 11. Compression bolt; 12. Sealing felt Pad; 13. Tightening end cover; 14. Oil baffle; 15. O-shaped rubber sealing ring; 16. Oil throwing ring; 17. Fixing bolt; 18. Oil return chamber; 19. Vibration motor; 20. Motor installation Frame; 21, oil return hole; 22, oil return passage; 23, closed end cover; 24, sealing felt ring; 25, lubricating thin oil; 26, drive shaft; 27, coupling, 30, base; 31, spring Support; 32, spring; 33, motor bracket; 34, connecting beam; 35, outer rib; 36, side plate; 37, outer reinforcing plate; 38, rivet; 39, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com