Anti-tearing loading wheel rubber tire

A road wheel and anti-tearing technology, which is applied to tire parts, reinforcement layers of pneumatic tires, vehicle components, etc., can solve problems such as tearing, and achieve the effect of improving service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

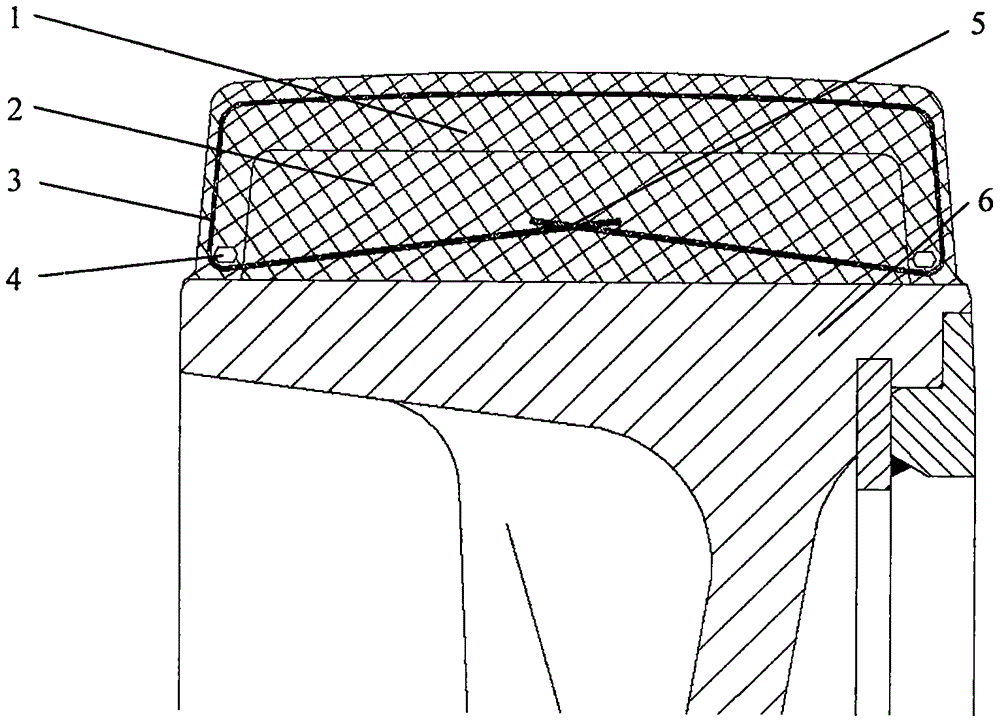

[0012] Such as figure 1 As shown, the present invention includes outer layer rubber 1, inner layer rubber 2, steel cord 3, support ring 4, and connector 5, and the above components are manufactured by integral vulcanization.

[0013] The outer layer of rubber 1 is ∩-shaped and coated on the outside of the road wheel base 6 , and the outer layer of rubber 1 has a built-in steel cord 3 to enhance the tear resistance of the outer layer of rubber 1 .

[0014] After the steel cord 3 is vulcanized inside the outer layer rubber 1, it is wound around the support ring 4, and the outer layer rubber 1 protrudes from the position of the support ring 4. The steel cords 3 protruding from both sides are fixed together in the inner layer rubber 2 through the connecting piece 5, and a certain expansion and contraction margin is maintained during fixing.

[0015] The inner rubber 2 is vulcanized in the groove formed by the outer rubber 1, and the steel cord 3 is guaranteed to have a certain te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com