Automatic tobacco shred feeding system

A wire feeding system and a technology for shredded tobacco, which are applied to tobacco, cigarette manufacturing, solid materials, etc., can solve the problems of wind shredding and moisture instability of shredded tobacco, reduce the impact of tobacco raw materials, facilitate flexible production, and solve shredding problems. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

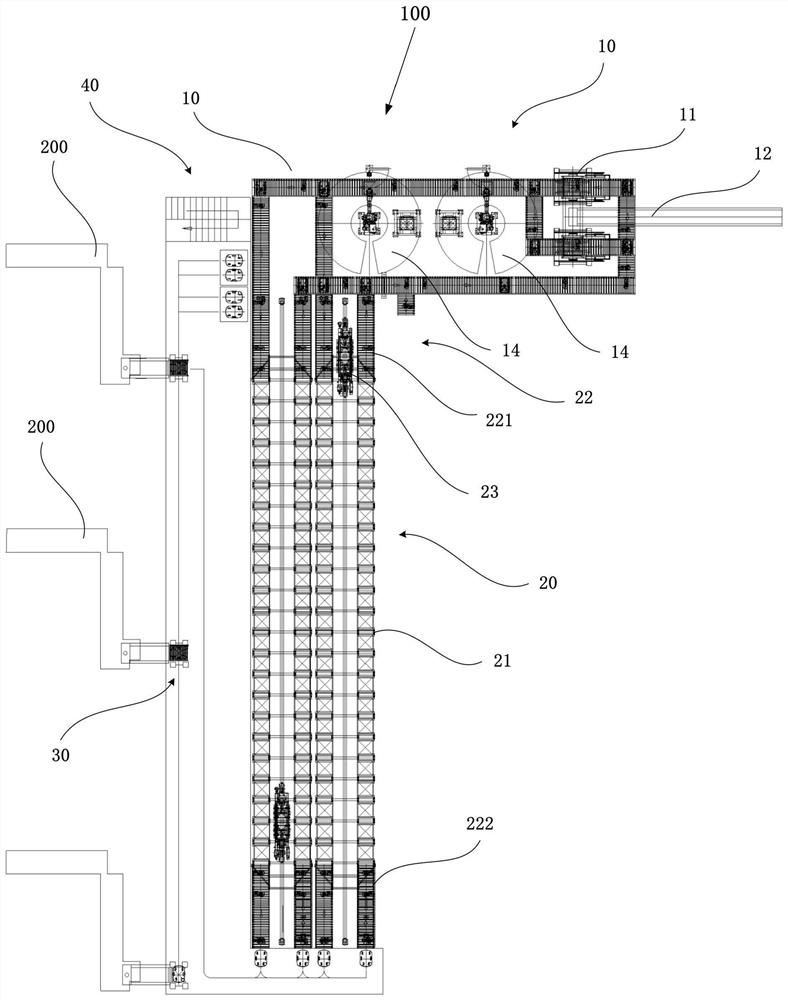

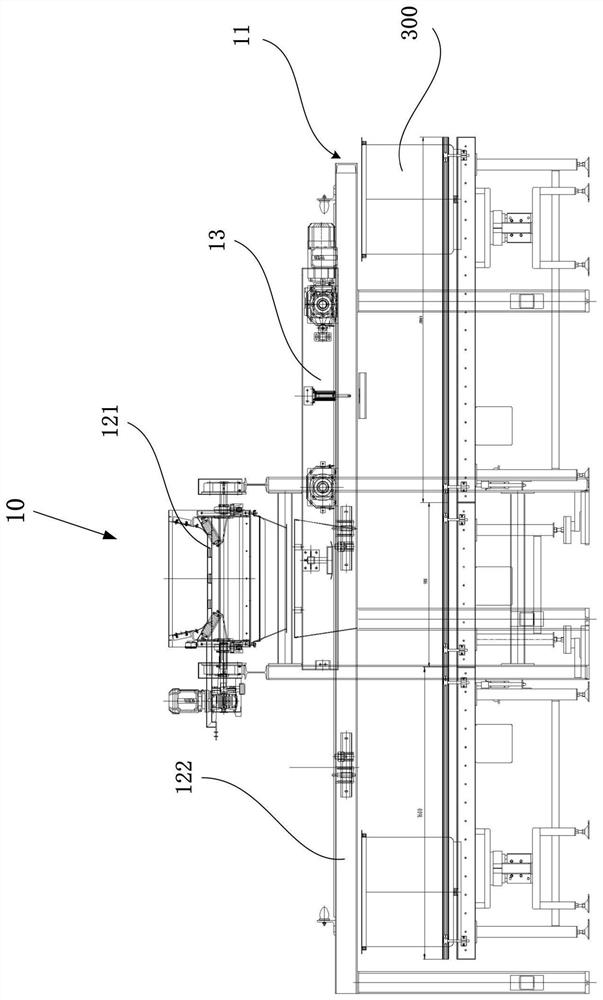

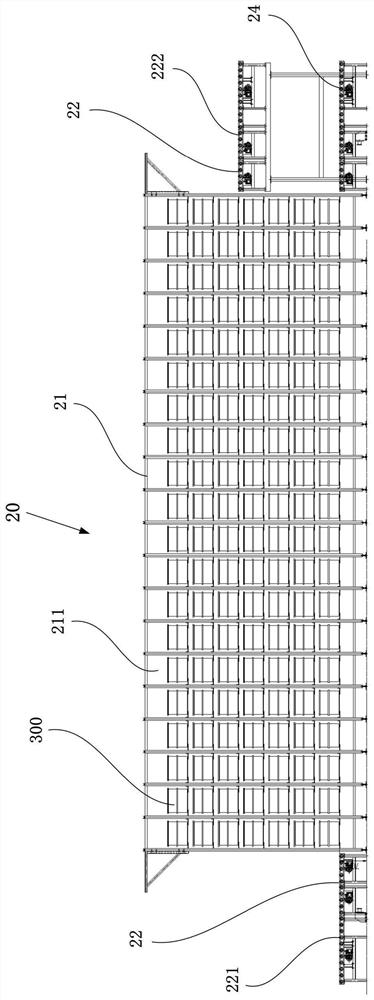

[0028] as attached Figures 1 to 4As shown, this embodiment discloses a tobacco automatic wire feeding system 100, which is used to realize the transfer and feeding of shredded tobacco between the shredded machine not shown in the figure and the cigarette rolling machine 200, that is, to produce the shredded tobacco by the shredded machine. The shredded tobacco is boxed and stored, and then the cigarette box is taken out from the storage area according to actual needs and the shredded tobacco in it is fed into the cigarette rolling machine, so as to realize wire feeding.

[0029] Such as figure 1 As shown, the automatic tobacco wire feeding system 100 includes: a packing unit 10 , a storage unit 20 , a wire feeding unit 30 and a transfer unit 40 .

[0030] The box packing unit 10 is connected to the silk machine, and is used for automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com