Spray pyrolysis device with microwave heating and method for preparing ternary precursor thereof

A technology of spray pyrolysis and microwave heating, which is applied in chemical instruments and methods, electrical components, chemical/physical/physicochemical processes of energy application, etc. It can solve the problem of ternary oxide powder without cost-effective advantages. Physical and chemical indicators, large amount of additives and other problems, to achieve the effect of accelerating thermal decomposition rate, avoiding poor appearance, and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

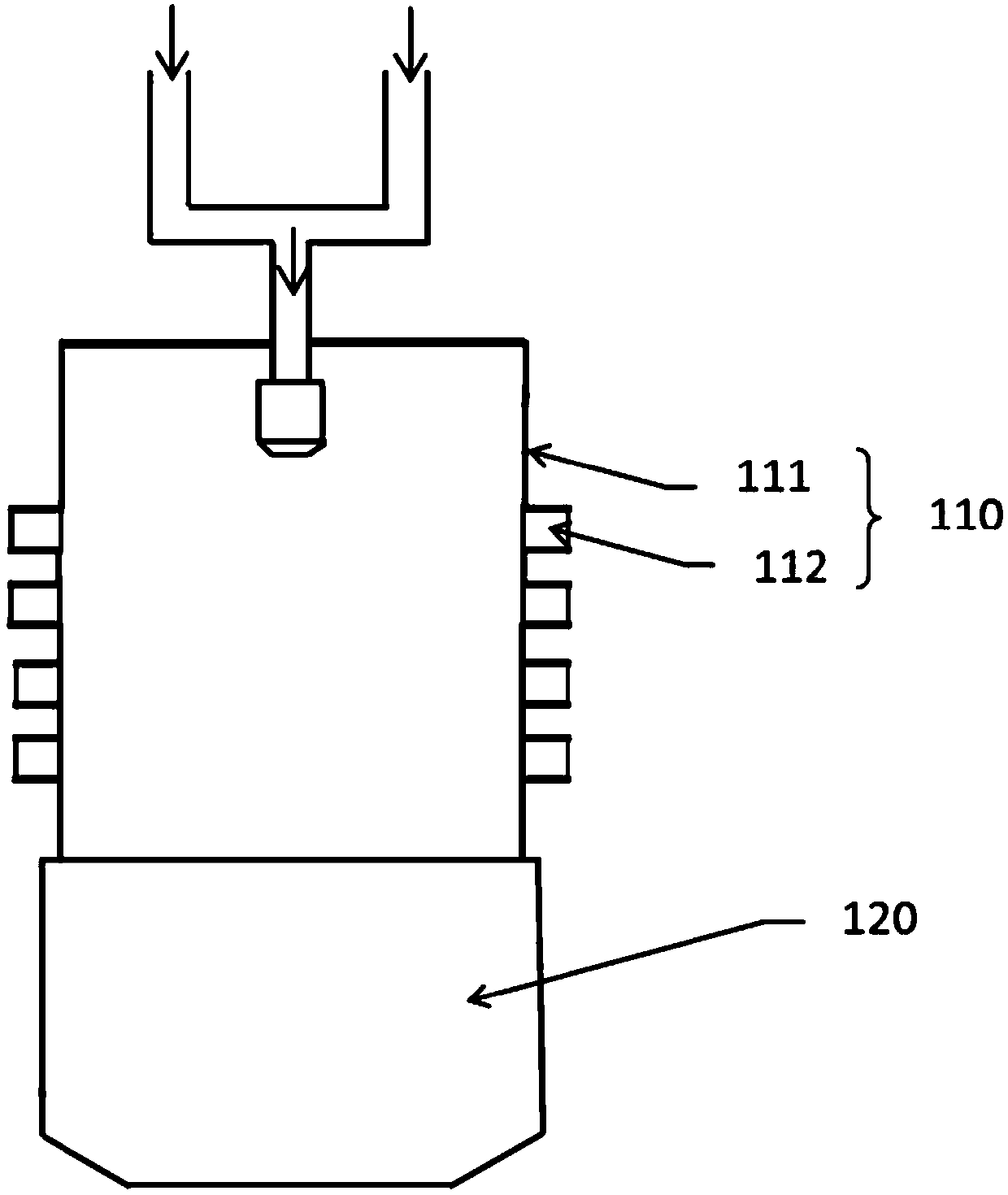

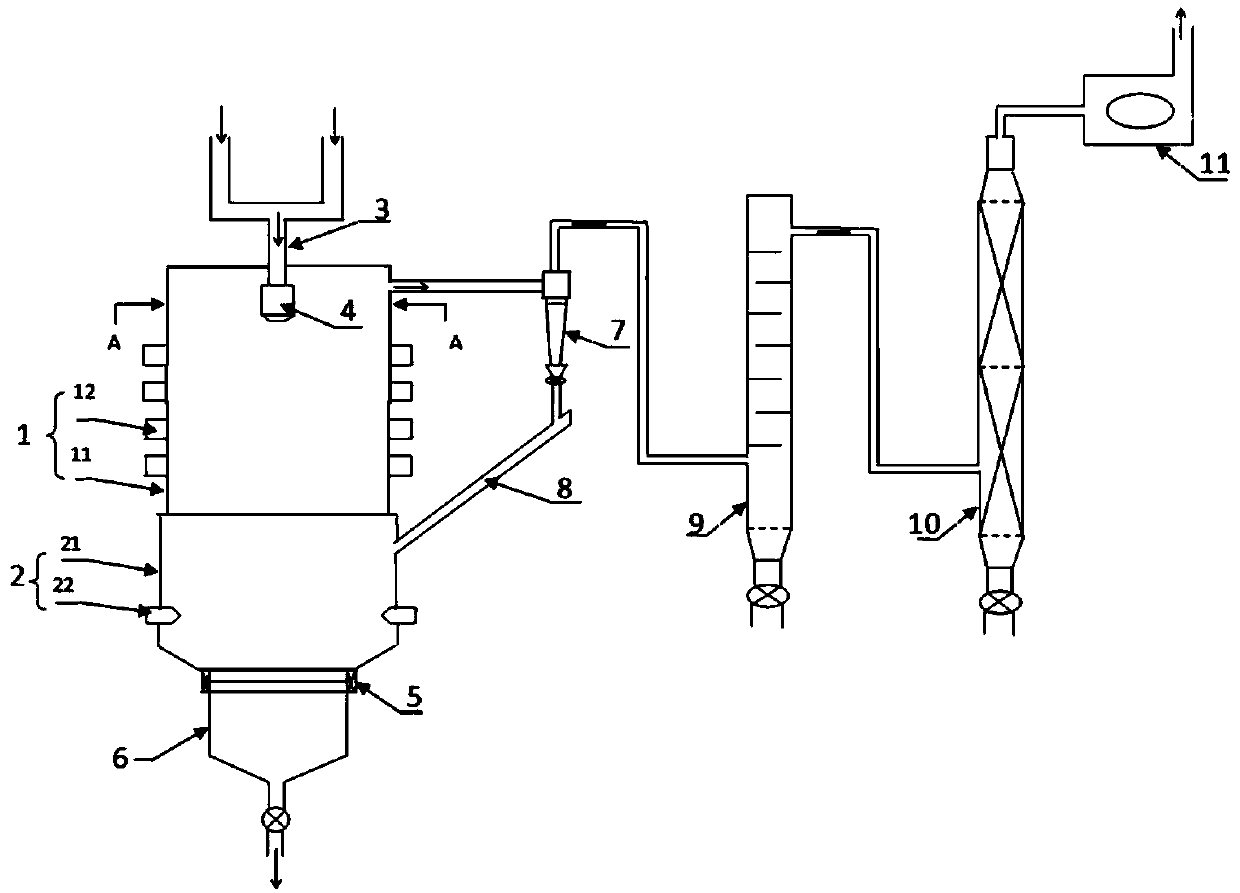

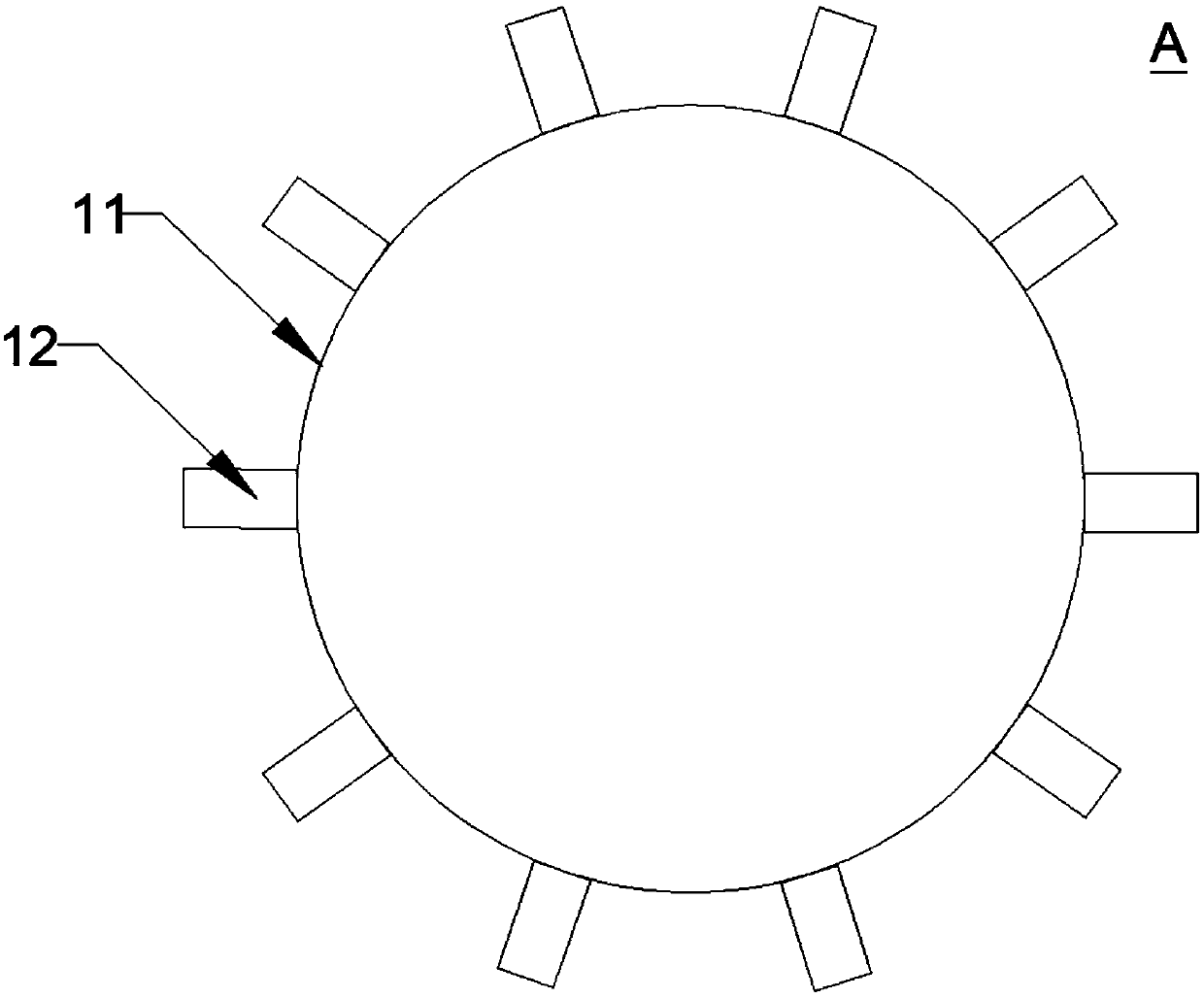

[0126] This embodiment provides a spray pyrolysis device with microwave heating, the tower height of the spray pyrolysis device is 18.6m, the inner diameter is 5.5m, and the vertical distance between the bottom end of the two-fluid nozzle and the initial position of the evaporation zone is 30cm , the ratio of the cavity height in the microwave heating zone to the cavity height in the sintering zone is 1:2, and the number of microwave generator components set in each zone of the microwave heating unit is: 5 groups in the evaporation zone, 3 groups in the drying zone and 2 groups in the thermal decomposition zone, Each group of microwave heaters is arranged with 10 microwave heaters every 1m along the circumference of the spray pyrolysis tower cavity.

[0127] This example also provides a method for preparing a ternary precursor, which is carried out in the spray pyrolysis device with microwave heating provided in this example, and prepared by secondary high-temperature calcinati...

Embodiment 2

[0142] This example provides a method for preparing the ternary 811 precursor, which is carried out in the spray pyrolysis device provided in Example 1, and the prepared ternary 811 precursor is used for secondary high-temperature calcination to prepare ternary 811 Positive electrode material, described method comprises the following steps:

[0143] (1) Configuration of ternary 811 precursor mixed solution

[0144] Accurately weigh a certain mass of LiCl and NiCl according to the molar ratio Li:(Ni+Co+Mn)=1:1, Ni:Co:Mn=0.8:0.1:0.1 2 ·6H 2 O, CoCl 2 ·6H 2 O and MnCl 2 4H 2 O, add deionized water to dissolve and configure a mixed solution with a total metal ion concentration of 0.5M.

[0145] (2) Preparation of ternary 811 precursor

[0146] Start the smoke exhaust fan, the PLC control automatically adjusts the frequency of the smoke exhaust fan, so that the pressure in the furnace reaches the set value -150Pa, then sprays deionized water into the spray pyrolysis device t...

Embodiment 3

[0152] This example provides a method for preparing a Zr-doped ternary precursor. The method is carried out in the spray pyrolysis device provided in Example 1, and the prepared Zr-doped ternary precursor is used for secondary The ternary 811 cathode material doped with Zr is prepared by high-temperature calcination, and the method comprises the following steps:

[0153] (1) Configuration of Zr-doped ternary 811 precursor mixed solution

[0154] Accurately weigh a certain amount of LiCl and NiCl according to the molar ratio Li:(Ni+Co+Mn+Zr)=1.03:1, Ni:Co:Mn:Zr=0.8:0.1:0.095:0.005 2 ·6H 2 O, CoCl 2 ·6H 2 O, MnCl 2 4H 2 O and ZrOCl 2 ·8H 2 O, add deionized water to dissolve and configure a mixed solution with a total metal ion concentration of 1.0M.

[0155] (2) Preparation of Zr-doped ternary 811 precursor

[0156] The difference from Example 1 is that the control operation parameters are as follows: liquid inlet pressure 1.8bar, liquid inlet speed 0.6m 3 / h, the carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com