A railway funnel driver brake device

A brake device and hand brake technology, which is applied to the railway brake system, railway car body parts, railway vehicle brake operating mechanism, etc., can solve problems such as difficult manufacturing, broken pedals, and complicated bracket structure , to achieve the effect of simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

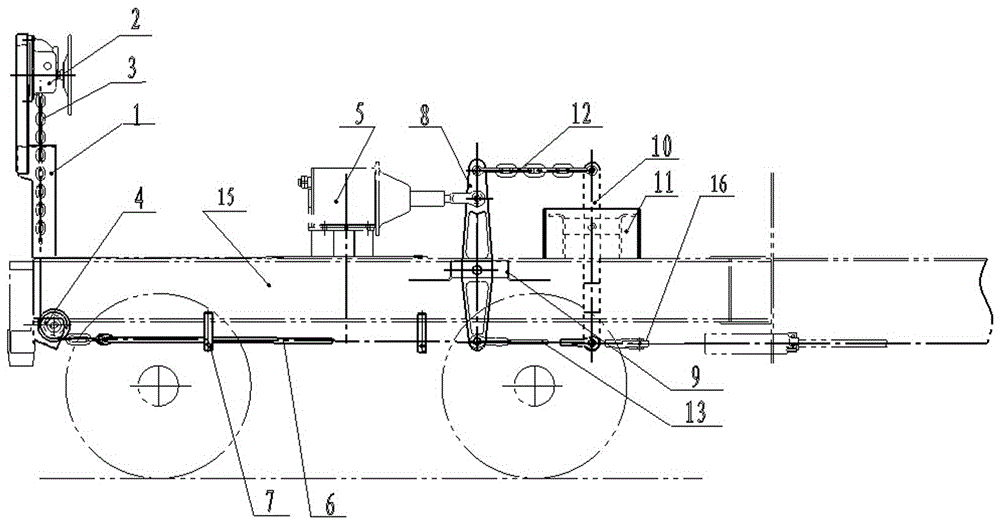

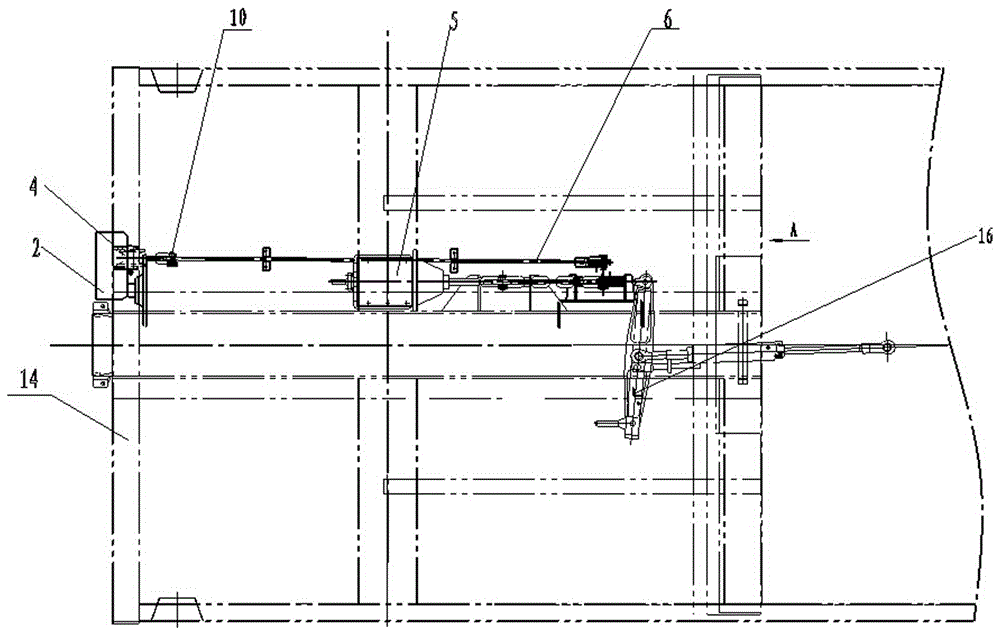

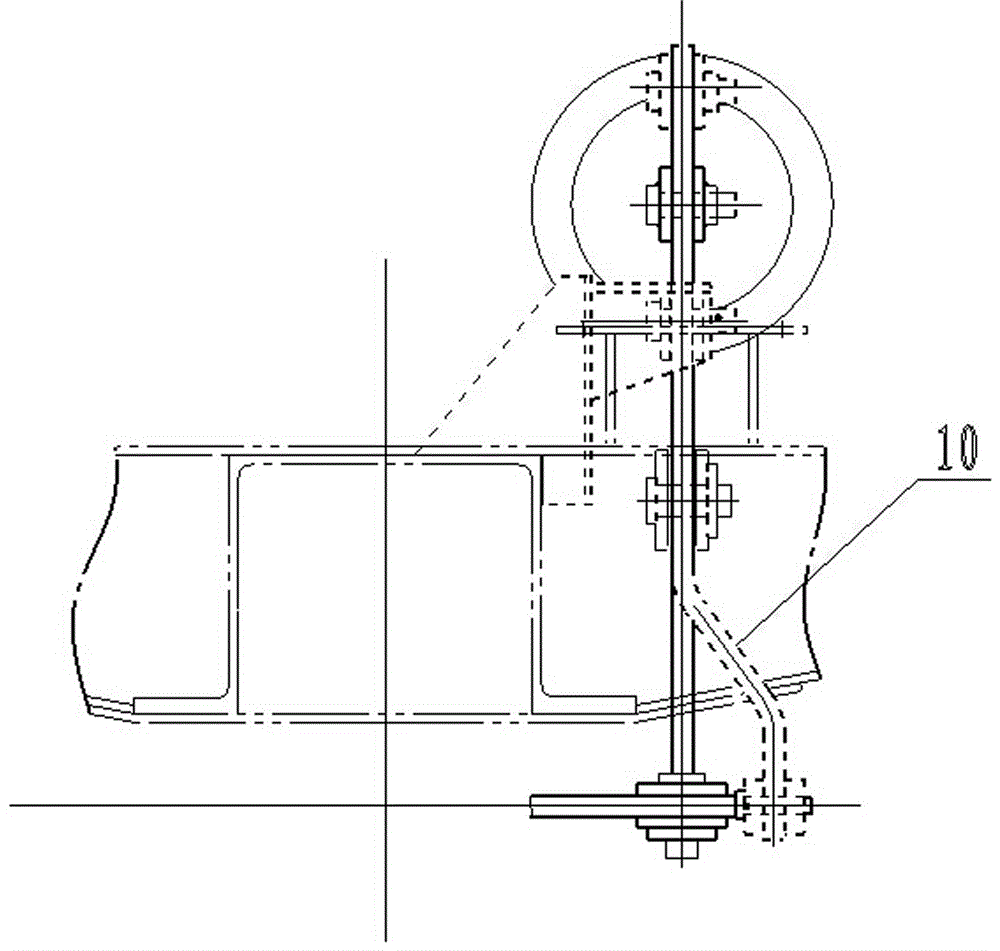

[0053] A railway hopper driver braking device, such as figure 1 , 2 , 3, including hand brake bracket 1, hand brake 2, hand brake chain 3, fixed pulley and support 4, brake cylinder and push rod 5, and hand brake lever 6 And hand brake pull rod guide frame 7, vertical lever 8 and vertical lever fulcrum seat 9, conversion lever 10 and conversion lever fulcrum seat 11, horizontal transmission chain composition 12 and conversion pull rod composition 13,

[0054] The handbrake bracket is fixed vertically on the end beam with sufficient strength and rigidity. The fixed pulley and support are installed on the inside or outside of the end beam 14. The moving pull rod is hung under the bottom frame through the brake rod guide frame, the vertical lever is vertically hinged on the bottom frame through the fulcrum seat of the vertical lever, the fulcrum seat of the conversion lever is fixed on the bottom plate or the traction beam, and the conversion lever is vertically installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com