Microencapsulated chitosan-oligosaccharide, and preparing method and applications thereof

A technology for encapsulating chitosan oligosaccharide and chitosan oligosaccharide, which is applied in the directions of bacteria, applications, and dairy products used in food preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: the preparation of microencapsulated chitosan oligosaccharide

[0066] (1) Use deionized water to prepare a 8w / v% solution of whey protein isolate at room temperature, then stir with an electric mixer for 60 minutes to fully dissolve the whey protein isolate, adjust the pH to 8.0, and store at 4°C overnight Fully hydrate the whey protein isolate; finally, heat in a water bath at 80°C for 30 minutes, and cool to room temperature to obtain a whey protein isolate solution;

[0067] (2) Weigh sodium alginate according to the mass ratio of whey protein isolate to sodium alginate of 4:1, and slowly add sodium alginate into deionized water at a temperature of 50°C during the stirring process to fully dissolve After obtaining the sodium alginate solution with a mass fraction of 30%;

[0068] (3) Slowly add sodium alginate solution to the whey protein isolate solution, stir until completely dissolved, and obtain wall material solution;

[0069] (4) Add chitosan o...

Embodiment 2

[0072] Embodiment 2: the preparation of microencapsulated chitosan oligosaccharide

[0073] (1) Sodium caseinate was prepared into a 5w / v% solution with deionized water at room temperature, then stirred with an electric mixer for 120 minutes to fully dissolve the whey protein isolate, then adjusted the pH to 7.0, and stored at 4°C overnight Fully hydrate the whey protein isolate; finally, heat in a water bath at 95°C for 15 minutes, and cool to room temperature to obtain a sodium caseinate solution;

[0074] (2) Weigh maltodextrin according to the mass ratio of sodium caseinate to maltodextrin of 2:1, and slowly add maltodextrin into deionized water at a temperature of 60°C during the stirring process to fully dissolve After obtaining a mass fraction of 30% maltodextrin solution;

[0075] (3) Slowly add the maltodextrin solution to the sodium caseinate solution, stir until completely dissolved, and obtain the wall material solution;

[0076] (4) Add chitosan oligosaccharides...

Embodiment 3

[0080] Embodiment 3: the preparation of modulating milk

[0081] Select the qualified fresh milk of microorganism and physicochemical index, add 0.10% microencapsulated chitosan oligosaccharide with a wall-core ratio of 2:1, 0.3% commercially available stabilizer and 0.2% aspartame, and then heat Homogenization is carried out under the conditions of 58°C, primary homogenization pressure of 18MPa, and secondary homogenization pressure of 3MPa; finally, sterilized by ultra-high temperature sterilization at 135°C / 5s, and aseptically filled after cooling, to obtain Modified milk.

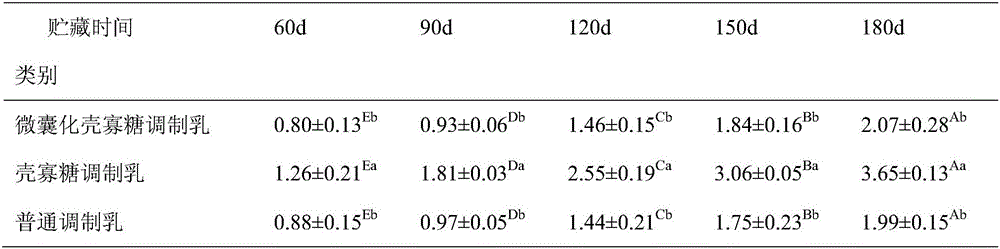

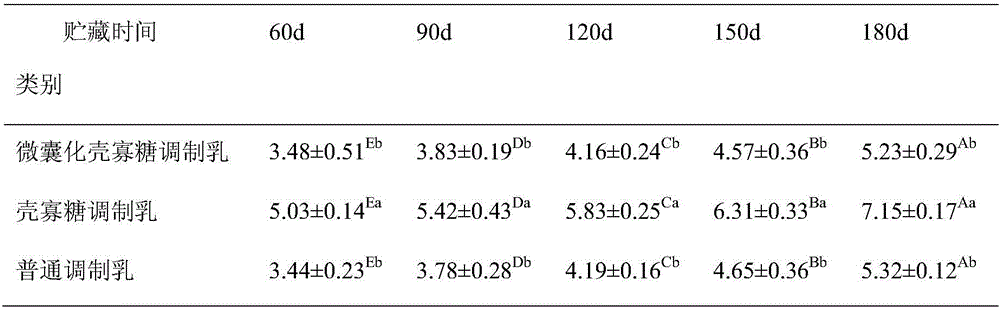

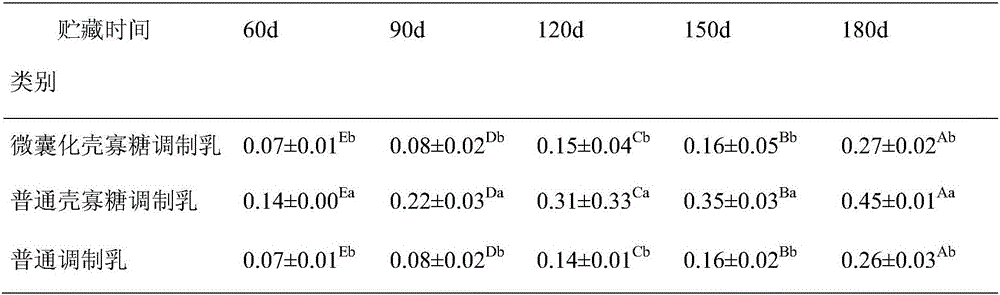

[0082] A 180-day storage experiment was carried out on the obtained modified milk, and the storage stability of the microencapsulated chitosan oligosaccharide modified milk was studied with the fat floating rate, protein precipitation rate and stability index as indicators. The milk and common modulation milk were used as a control, and the measurement results are shown in Tables 1, 2, and 3. It can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com