Swirling aggregation air flotation degreasing column

A technology of swirling air flotation and coalescence air flotation, which is applied in the direction of grease/oily substance/suspended matter removal device, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., which can solve the low efficiency of oil removal and suspended matter removal , can not maintain the best gas-liquid ratio, uneven release of bubbles and other problems, to achieve the effect of shortening the floating and sinking time, shortening the residence time, and strengthening the effect of coarse graining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

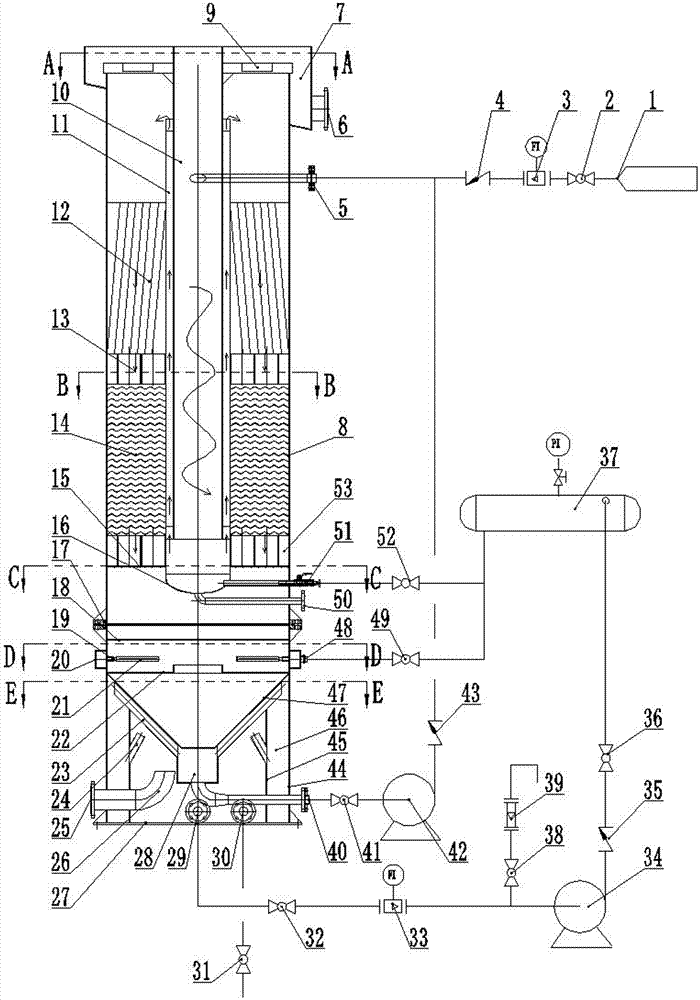

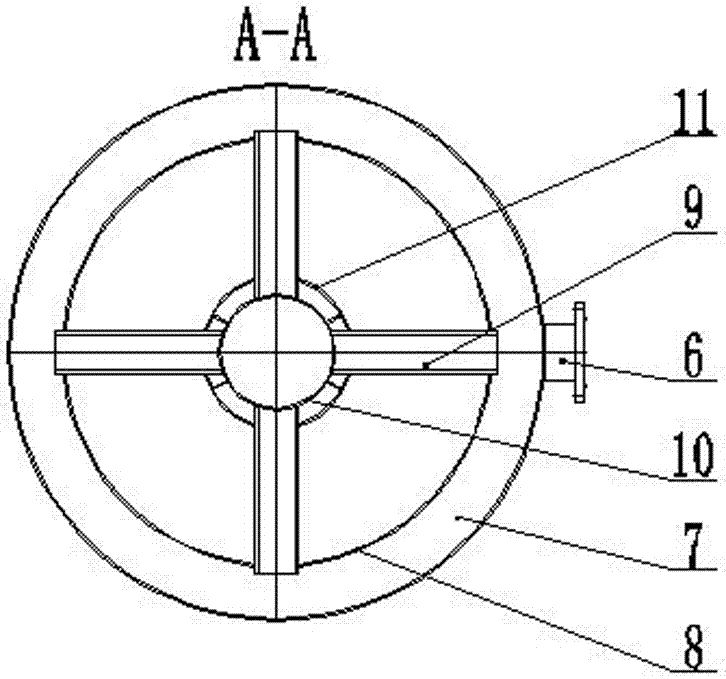

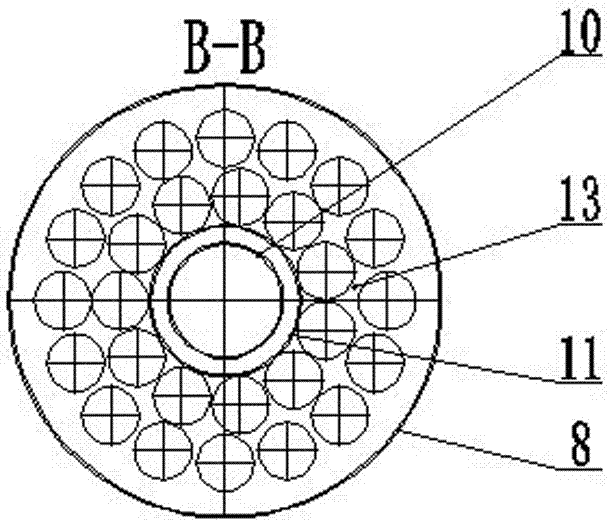

[0031] Such as Figure 1 to Figure 6 A swirl coalescing air flotation degreasing column shown includes a lower air flotation column 44, an upper air flotation column 8, and a swirl dissolved air tank 37, and the upper air flotation column 8 is connected with the lower air flotation column 44 An O-ring 17 is arranged between them, and a bottom plate 27 is arranged at the bottom of the lower air flotation column 44 .

[0032] The upper air flotation column 44 is provided with a swirl air flotation column outer cylinder 11, the swirl air flotation column outer cylinder 11 is connected with the swirl dissolved air tank 37, and the bottom of the swirl air flotation column outer cylinder 11 is provided with Lower head 16, the bottom of the lower head 16 of the swirl air flotation column outer cylinder 11 is provided with a central swirl air flotation column blowdown pipe 50 extending to the outside of the upper air flotation column 8, the swirl air flotation column outer cylinder 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com