Shield tunnel segment lining-anchor rod structure system

A shield tunnel segment and anchor rod technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of low longitudinal deformation resistance, low longitudinal rigidity, easy floating, and tunnel deformation, so as to reduce the unfavorable soil The effect of properties, enhancing the longitudinal deformation resistance, reducing the effect of sinking or floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

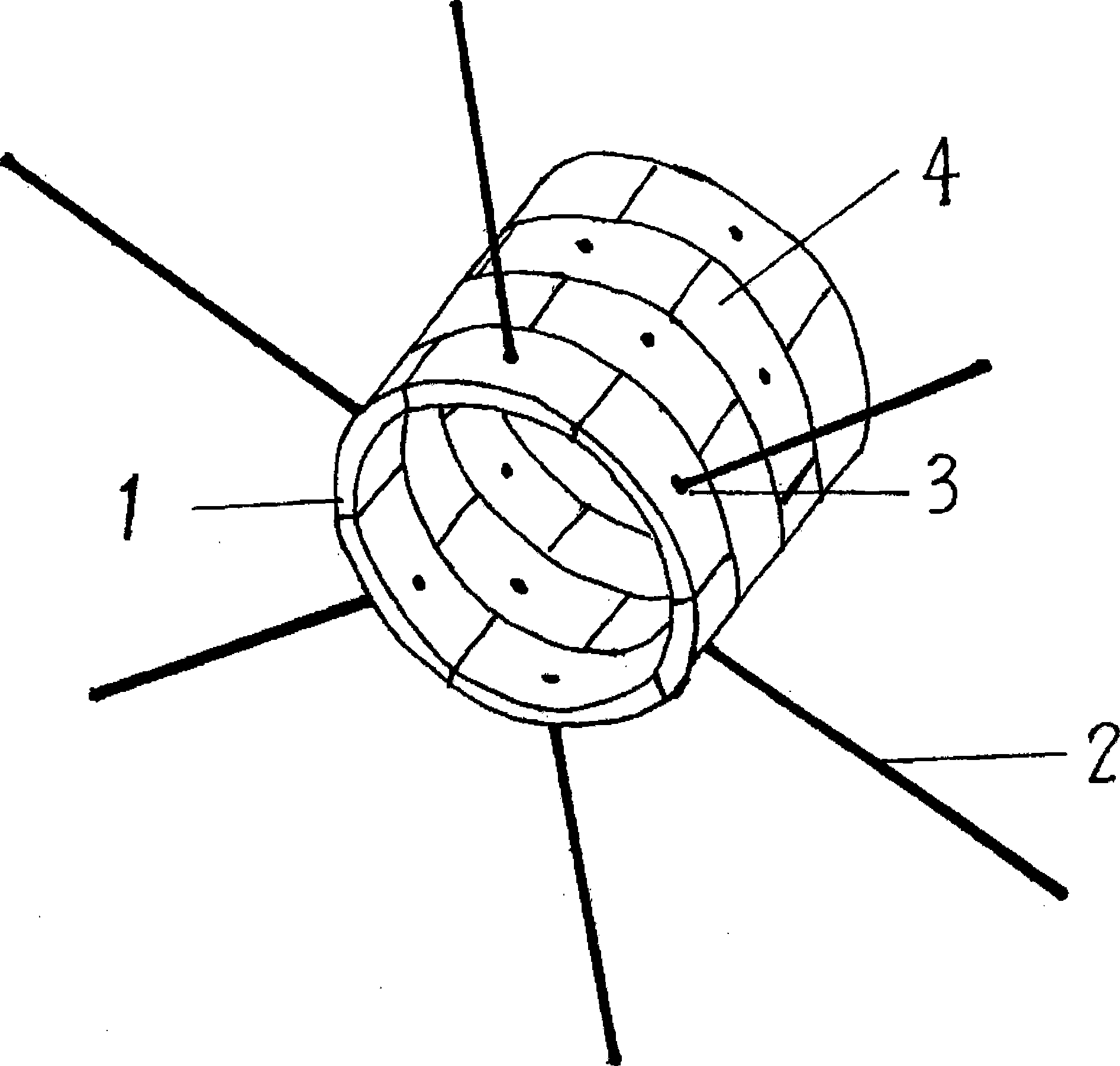

[0025] see figure 1 , the shield tunnel segment lining-anchor structure system, including the segment lining 4 and the anchor rod 2 built by the segment 1, the reserved anchor hole 3 is left on the segment 1, and the anchor rod 2 passes through the anchor hole 3 Drive into the soil, and screw the bolts at the end of the anchor rod 2 with nuts at the inner side of the anchor hole 3 to establish an effective connection between the segment 1 and the anchor rod 2 .

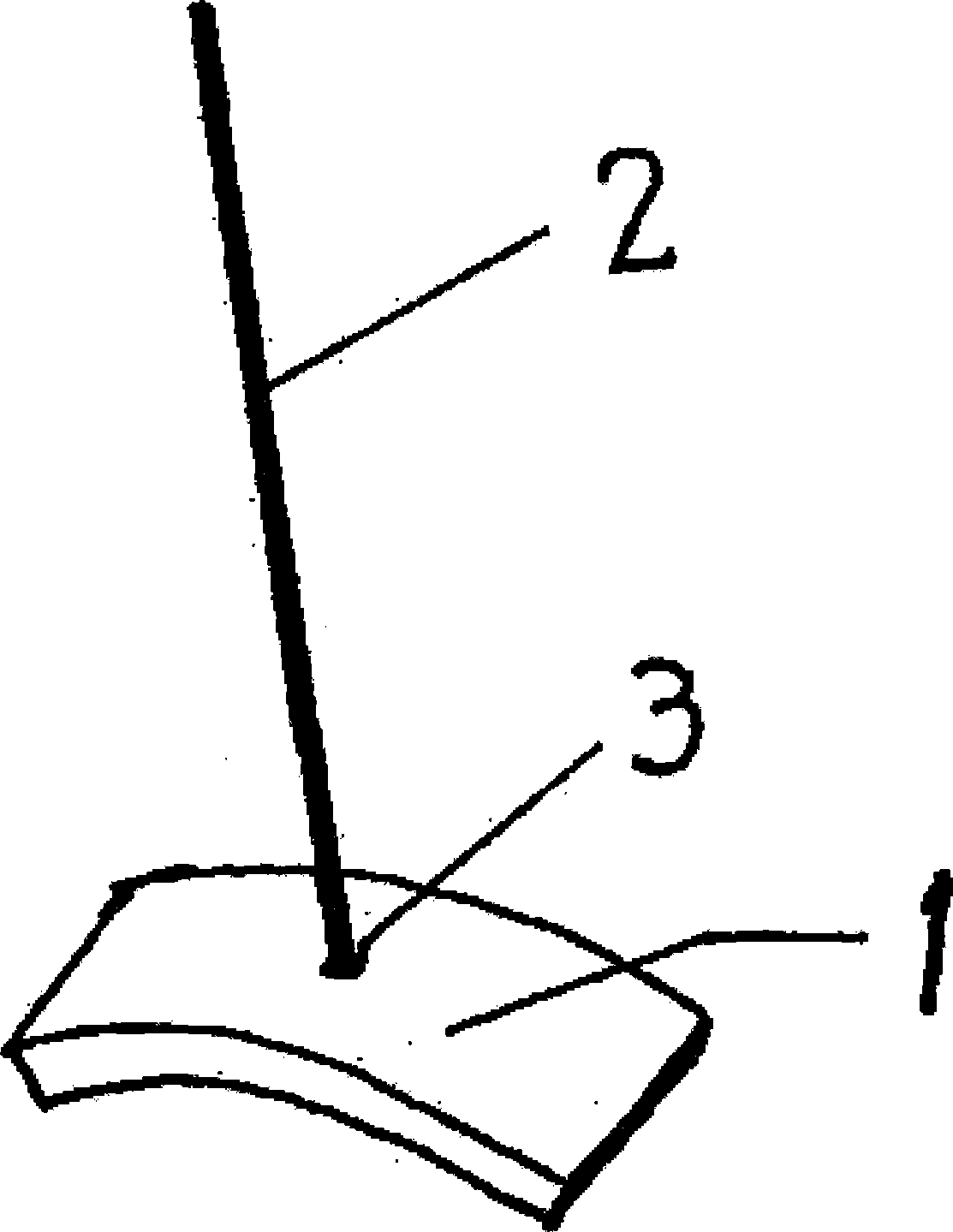

[0026] see figure 2 , a typical combination of this embodiment is: only one anchor rod 2 passes through one anchor hole 3 on a piece of segment 1 .

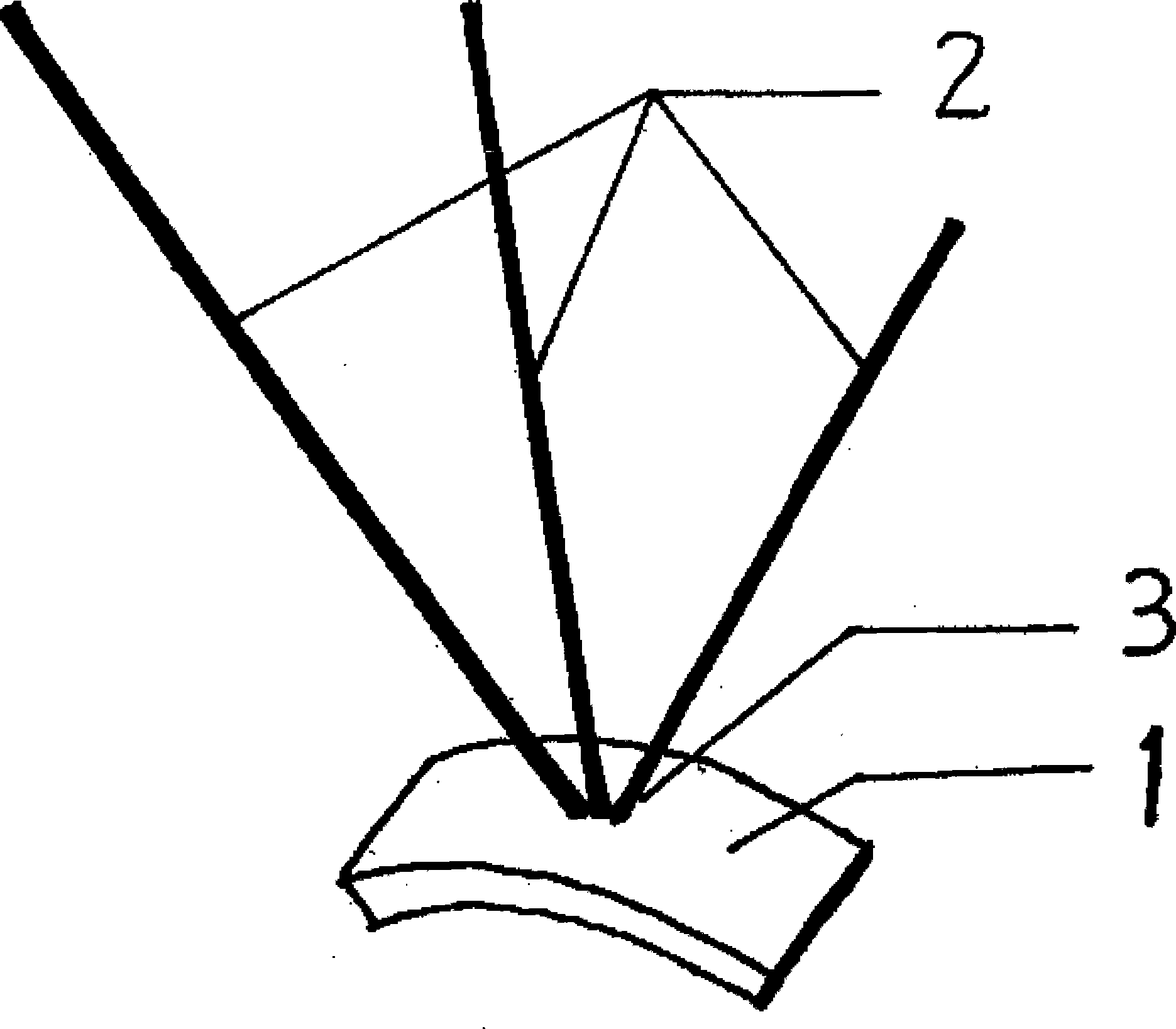

[0027] see image 3 , Another typical combination of this embodiment is: three anchor rods 2 pass through one anchor hole 3 on a segment 1 .

[0028] see Figure 4 , the third typical combination of this embodiment is: an anchor rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com